- PebblePad

advertisement

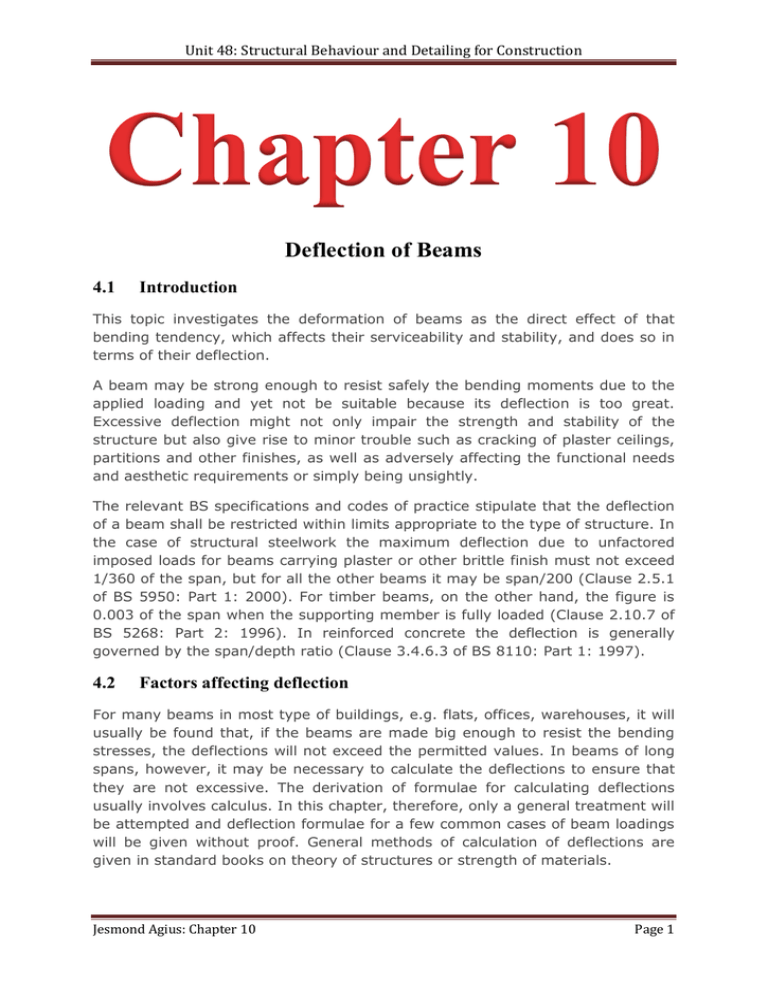

Unit 48: Structural Behaviour and Detailing for Construction Deflection of Beams 4.1 Introduction This topic investigates the deformation of beams as the direct effect of that bending tendency, which affects their serviceability and stability, and does so in terms of their deflection. A beam may be strong enough to resist safely the bending moments due to the applied loading and yet not be suitable because its deflection is too great. Excessive deflection might not only impair the strength and stability of the structure but also give rise to minor trouble such as cracking of plaster ceilings, partitions and other finishes, as well as adversely affecting the functional needs and aesthetic requirements or simply being unsightly. The relevant BS specifications and codes of practice stipulate that the deflection of a beam shall be restricted within limits appropriate to the type of structure. In the case of structural steelwork the maximum deflection due to unfactored imposed loads for beams carrying plaster or other brittle finish must not exceed 1/360 of the span, but for all the other beams it may be span/200 (Clause 2.5.1 of BS 5950: Part 1: 2000). For timber beams, on the other hand, the figure is 0.003 of the span when the supporting member is fully loaded (Clause 2.10.7 of BS 5268: Part 2: 1996). In reinforced concrete the deflection is generally governed by the span/depth ratio (Clause 3.4.6.3 of BS 8110: Part 1: 1997). 4.2 Factors affecting deflection For many beams in most type of buildings, e.g. flats, offices, warehouses, it will usually be found that, if the beams are made big enough to resist the bending stresses, the deflections will not exceed the permitted values. In beams of long spans, however, it may be necessary to calculate the deflections to ensure that they are not excessive. The derivation of formulae for calculating deflections usually involves calculus. In this chapter, therefore, only a general treatment will be attempted and deflection formulae for a few common cases of beam loadings will be given without proof. General methods of calculation of deflections are given in standard books on theory of structures or strength of materials. Jesmond Agius: Chapter 10 Page 1 Unit 48: Structural Behaviour and Detailing for Construction 4.2.1 Load AB (figure 1) represents a beam of span L metres supported simply at its ends and carrying a point load of W kN at mid-span. Let us assume that the deflection due to the load is 5mm. It is obvious that, if the load is increased, the deflection will increase. It can be proved that the deflection is directly proportional to the load, i.e. a load of 2W will cause a deflection of 10mm, 3W will produce a deflection of 15mm and so on. W must therefore be a term in any formula for calculating deflection. W ½l ½l A B 5mm l Figure 1: Deflection of a beam under loading 4.2.2 Span In figure 2 (a) and (b) the loads W are equal and the weights of the beams, which are assumed to be equal in cross-section, are ignored for the purposes of this discussion. The span of beam (b) is twice that of beam (a). It is obvious that the deflection of beam (b) will be greater than that of beam (a), but the interesting fact (which can be demonstrated experimentally or proved by mathematics) is that instead of the deflection of (b) being twice that of (a), it is 8 times (e.g. 40mm in this example). If the span of beam (b) where 3L, its deflection would be 27 times that of beam (a). In other words, the deflection of a beam is proportional to the cube of the span, therefore L3 is a term in the deflection formula. W W 5mm 40mm l 2l (a) (b) Figure 2: Effect of span upon deflection: the span of (b) is twice that of (a) Jesmond Agius: Chapter 10 Page 2 Unit 48: Structural Behaviour and Detailing for Construction 4.2.3 Size and Shape of Beam Figure 3 (a) and (b) represents two beams (their weights being ignored) of equal spans and loading but the moment of inertia of beam (b) is twice that of beam (a). Obviously, the greater the size of the beam, the smaller the deflection (other conditions being equal). It can be proved that the deflection is inversely proportional to the moment of inertia, e.g. the deflection of beam (b) will be one-half that of beam (a). Moment of inertia I is therefore a term in the denominator of the deflection formula. (It may be noted that, since the moment of inertia of a rectangular cross section beam is bd3/12, doubling the breadth of a rectangular beam decreases the deflection by one-half, whereas doubling the depth of a beam decreases the deflection to 1/8 of the previous value.) W W l (a) l (b) Figure 3: Effect of size and shape upon deflection: (a) moment of inertia of beam = 1 unit; (b) moment of inertia of beam = 2 units 4.2.4 ‘Stiffness’ of Material The stiffer the material of a beam, i.e. the greater its resistance to bending, the smaller will be the deflection, other conditions such as span, load, etc., remaining constant. The measure of the ‘stiffness’ of a material is its modulus of elasticity E and deflection is inversely proportional to the value of E. 4.3 Derivation of Deflection Formulae A formula for calculating deflection must therefore contain the load W, the cube of the span L3, the moment of inertia I, and the modulus of elasticity E. For standard cases of loading, the deflection formula can be expressed in the form , where c is a numerical coefficient depending on the disposition of the load and also on the manner in which the beam is supported, that is, whether the ends of the beam are simply supported or fixed, etc. For figure 4 the values of c are respectively 1/48 and 5/384. W and L3 are in the numerator of the formula because an increase in their values means an increase of deflection, whereas E and I are in the denominator because an increase in their values means a decrease of deflection. Jesmond Agius: Chapter 10 Page 3 Unit 48: Structural Behaviour and Detailing for Construction Referring to figure 4 it should be obvious (neglecting the weights of the beams) that although the beams are equally loaded, the deflection of beam (b) will be less than that of beam (a). In fact, the maximum deflection of beam (a) is and the maximum deflection of beam (b) is 100kN 3m W = 100kN UDL l = 6m (b) l = 6m (a) Figure 4: Deflection Formulae Table 1 gives the values of c for some common types of loading, etc. Table 1: Values of coefficient c for deflection formula Condition of loading Value of c (max at A) W ½l ½l A B A 𝑙 W/2 A Jesmond Agius: Chapter 10 𝑙 A W/2 𝑙 B Page 4 Unit 48: Structural Behaviour and Detailing for Construction 𝑙 W/2 𝑙 W/2 𝑙 A A UDL =W l W 𝑙 𝑙 A Fixed Beam A UDL =W l Fixed Beam W l Cantilever A A UDL =W l Cantilever When the load system is complicated, e.g. several point loads of different magnitudes, or various combinations of point loads and uniformly distributed loads, the deflections must be calculated from first principles. Jesmond Agius: Chapter 10 Page 5 Unit 48: Structural Behaviour and Detailing for Construction In certain simple cases it is possible to derive deflection formulae mathematically without using the calculus, and the following example is given for the more mathematically minded student. Practical Example 1 Work out the value of the coefficient of the deflection formula for the following scenario and verify your answers with table 1. W ½l ½l A A B Answer See lecturer explanation during the lesson. Try to work out the coefficient of the deflection formula of the other diagrams found in table 1. Practical Example 2 A 406 × 178 UB54 simply supported at the ends of a span of 5m carries a uniformly distributed load of 60 kN/m. Calculate the maximum deflection. (E = 205 000 N/mm2) Answer The formula for the maximum deflection is (from table 1) Where W = 60 × 5 = 300 kN = 0.3 × 106 N l = 5000 mm E = 205 000 N/mm2 I = 18720 cm4 = 187 200 000 mm4 = 187.2 × 106 mm4 (Taken from table of universal beams) Therefore Jesmond Agius: Chapter 10 Page 6 Unit 48: Structural Behaviour and Detailing for Construction Practical Example 3 Calculate the safe inclusive uniformly distributed load for a 457 × 152 UB52 simply supported at its ends if the span is 6m and if the span is 12m. The maximum permissible bending stress is 165N/mm2 and the maximum permissible deflection is 1/360 of the span. E is 205 000 N/mm2. Answer Part 1 Z = 950 cm3 = 950 000 mm3 (Taken from table of universal beams) From last year notes we have deducted that the elastic modulus can be expressed as So Also, Maximum bending moment can be calculated by using the equation . This has to be equal to . Therefore Implies So Maximum Deflection for simply supported uniformly distributed loads is equal to Where W = 209 000 N l = 6000 mm E = 205 000 N/mm2 I = 21370 cm4 = 213 700 000 mm4 = 213.7 × 106 mm4 (Taken from table of universal beams) Therefore Maximum permissible deflection = Therefore safe load = 209.0 kN Jesmond Agius: Chapter 10 Page 7 Unit 48: Structural Behaviour and Detailing for Construction Answer Part 2 For a 12m span Z = 950 cm3 = 950 000 mm3 (Taken from table of universal beams) From last year notes we have deducted that the elastic modulus can be expressed as So Also, Maximum bending moment can be calculated by using the equation . This has to be equal to . Therefore Implies So Maximum Deflection for simply supported uniformly distributed loads is equal to Where W = 104 500 N l = 12000 mm E = 205 000 N/mm2 I = 21370 cm4 = 213 700 000 mm4 = 213.7 × 106 mm4 (Taken from table of universal beams) Therefore Maximum permissible deflection = This means that, although the beam is quite satisfactory from the strength point of view, the deflection is too great, therefore the load must be reduced. Now Jesmond Agius: Chapter 10 Page 8 Unit 48: Structural Behaviour and Detailing for Construction Therefore Giving W = 64.2 kN and this is the maximum permitted load for the beam. (Instead of being obtained from the deflection formula, W can also be obtained from ) Practical Example 4 Calculate the safe inclusive uniformly distributed load for a 200 mm × 75 mm timber joist, simply supported at its ends, if the span is 4m and if the span is 8m. The maximum permissible bending stress is 6N/mm2 and the maximum permissible deflection is 0.003 of the span. E is 9500 N/mm2. Answer Part 1 The cross section of a timber joist is usually a rectangle. Thus (See lesson 9) From lesson 9 we have deducted that the elastic modulus can be expressed as So Also, Maximum bending moment can be calculated by using the equation (this is the equation for maximum bending moment of uniformly distributed loads. This has to be equal to . Therefore Implies So Maximum Deflection for simply supported uniformly distributed loads is equal to Where W = 6 000 N l = 4000 mm E = 9500 N/mm2 Jesmond Agius: Chapter 10 Page 9 Unit 48: Structural Behaviour and Detailing for Construction (See lesson 9 for second moment of area of rectangular cross section shapes) Therefore Maximum permissible deflection = Therefore safe UDL for the 4 m span = 6.0 kN Answer Part 2 The cross section of the second timber joist is same. Thus and Also, Maximum bending moment can be calculated by using the equation (this is the equation for maximum bending moment of uniformly distributed loads. This has to be equal to . Therefore Implies So Maximum Deflection for simply supported uniformly distributed loads is equal to Where W = 3 000 N l = 8000 mm E = 9500 N/mm2 (as before) Therefore Jesmond Agius: Chapter 10 Page 10 Unit 48: Structural Behaviour and Detailing for Construction Maximum permissible deflection = This means that, although the timber joist is quite satisfactory from the strength point of view, the deflection is too great, therefore the load must be reduced. Now Therefore Implies Giving W = 1.7 kN and this is the maximum permitted load for the timber joist. (Instead of being obtained from the deflection formula, W can also be obtained from Jesmond Agius: Chapter 10 ) Page 11