Structure–property relationship in high

advertisement

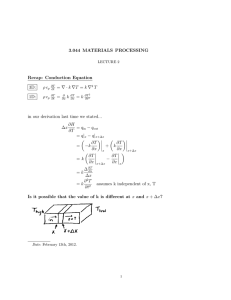

Materials Science and Engineering B106 (2004) 132–140 Structure–property relationship in high-tension ceramic insulator fired at high temperature Rashed Adnan Islam a , Y.C. Chan a,∗ , Md. Fakhrul Islam b b a Department of Electronic Engineering, City University of Hong Kong, 83 Tat Chee Avenue, Kowloon Tong, Hong Kong Department of Materials and Metallurgical Engineering, Bangladesh University of Engineering and Technology, Dhaka 1000, Bangladesh Received 7 March 2003; accepted 2 September 2003 Abstract Ceramic insulators are widely used in microelectronic devices. In this paper, the mechanical and electrical properties of porcelain ceramic insulator fired at 1350 ◦ C have been investigated along with microstructural characterization using scanning electron microscopy (SEM) in order to understand the structure–property relationship of ceramic insulator. The bending and the dielectric strength were measured on various samples fired at 1350 ◦ C. The bending strength (757.3 kg/cm2 ) and the dielectric strength (28.36 kV/mm) was found short of the desired value. The microstructural features developed clearly describe why the dielectric strength and the bending strength are not up to the mark. EDAX analysis, X-ray fluorescence (XRF) and X-ray diffractometry (XRD) techniques were also done to support the results. XRD pattern shows 70% mullite and 20% quartz peak intensity and the XRF results shows 22.64% Al2 O3 that indicates low mullite formation and hence it is confirmed that it is mullite, the crystalline phase, which contribute together with quartz particle to the dielectric and mechanical strength. SEM image shows large number of microcracks that also hinder the high electrical and mechanical properties of porcelain ceramic insulator. © 2003 Published by Elsevier B.V. Keywords: Bending strength; Dielectric strength; Mullite; Glassy phase; Microcracks 1. Introduction Insulators are materials, which prevent or regulate current flow in electrical circuits by being inserted as a barrier between conductors. The properties required being an insulator is high resistivity, high dielectric strength, a low loss factor, good mechanical properties, dissipation of heat and protection of conductors from severe environment, like humidity and corrosiveness. Ceramics are widely used as insulating materials. The advantage of ceramic insulators which frequently indicate their use, are superior electrical properties, absence of creep or deformation under stress at room temperature and greater resistance to environmental changes. One of the great advantages of ceramics as insulators is the fact that they are not sensitive to the minor changes in composition, fabrication, techniques, and firing temperature. Ceramic insulators are widely used in the microelectronic devices as well as in power transmission lines. For the electrical insulation application the properties ∗ Corresponding author. Tel.: +852-2788-7130; fax: +852-2788-7579. E-mail address: eeycchan@cityu.edu.hk (Y.C. Chan). 0921-5107/$ – see front matter © 2003 Published by Elsevier B.V. doi:10.1016/j.mseb.2003.09.005 most concerned are the dielectric and mechanical strength. Dielectric strength (represented by kilovolt per millimeter) measures the ability to withstand large field strength without electrical breakdown. For high-tension electrical insulation the dielectric strength has to be above 30 kV/mm [1]. The microstructure of porcelain electrical insulator body shows mullite needle in both glassy phase and unresolved clay matrix (cannot be specified by an optical microscope and need SEM equipped with EDAX to resolve) with some undissolved quartz particle. The thermal behavior of silica and alumina shows that the mullite (3Al2 O3 2SiO2 ) phase starts to form at 1100 ◦ C and above this temperature mullite crystals continue to grow and the needles appear [2]. It has some specific properties like high creep resistance, low thermal expansion and good thermal and chemical stability which makes it desirable for high tension structural insulating material [3]. Slow firing and slow cooling favour the formation of mullite crystals and the size of the mullite crystals increase with firing [4]. The glassy phase and the quartz particles are other two important features of the microstructure. But where dielectric performance such as high dielectric strength is required glassy phase and mobile ion R.A. Islam et al. / Materials Science and Engineering B106 (2004) 132–140 133 Table 1 Composition of different raw materials used in the insulator body SiO2 TiO2 Al2 O3 Fe2 O3 MgO CaO Na2 O K2 O Composition China clay (plastic) China clay (body) Ball clay (white) Bejoypur clay (local) Ball clay (black) Feldspar Quartz 50.18 0.014 33.34 1.88 1.05 0.94 0.81 2.58 11 51.86 0.50 34.72 0.57 0.07 0.07 0.041 0.18 8 54.43 1.84 30.97 1.37 0.34 0.17 0.17 0.81 8 72.09 1.02 18.69 1.01 0.14 0.10 0.11 0.61 32 61.27 1.41 24.85 0.17 0.26 0.65 0.25 0.44 – 74.98 0.08 14.37 0.83 0.08 0.68 3.54 4.91 21 98.17 – – 0.5 – – 0.34 0.45 20 content must be minimized [5]. At higher temperatures an increasing amount of liquid is formed which at equilibrium would be associated with mullite as a solid phase. The general equilibrium conditions do not change at temperatures above about 1200 ◦ C so that long firing times at this temperature give results that are very similar to shorter times at higher temperatures [6]. The initial mix is composed of relatively large quartz and feldspar grains in a fine-grained clay matrix [7]. Fine mullite needles appear at about 1000 ◦ C but cannot be resolved with an optical microscope until temperatures of at least 1250 ◦ C are reached. With further increases of temperature mullite crystals continue to grow [8]. The solution rim of high-silica glass around each quartz grain increases in amount at higher temperatures. By 1350 ◦ C grains smaller than 20 m are completely dissolved [9]. The objective of this research is to find out the structure–property relationship in high-tension ceramic insulators. It is aimed to determine the phases, which are detrimental to high dielectric and mechanical strength. 2. Experimental The processing of insulating body was done in the Bangladesh Insulator and Sanitary ware Factory (BISF) Ltd. The composition of the insulating body is shown in Table 1. The flow sheet for the insulating body preparation is shown in Fig. 1. Two types of samples were prepared, one for dielectric testing and another for mechanical testing. The samples are shown in Fig. 2. The dielectric strength was measured using high voltage dielectric tester (Model No. DTS—100 D) manufactured by High Voltage Inc., having a maximum output voltage of 100 kV. The thickness of the specimen was kept below 3 mm to avoid the maximum probability of pores and cracks in the measuring regions. The breakdown voltage of a spark gap between two metal spheres was used as a measure of voltages up to the highest encountered in high voltage testing. The test was followed by the ASTM standard no D3755 [10]. The bending strength was measured by three-point bending. The load in Newton at which the insulating body breaks was converted to kg/cm2 . The result of both bending and the dielectric strength is reported on Tables 2 and 3. The samples Fig. 1. Flow chart of the insulator body processing. 134 R.A. Islam et al. / Materials Science and Engineering B106 (2004) 132–140 Table 3 Dielectric strength of insulating materials fired at 1350 ◦ C Specimen no. Applied voltage (kV) Specimen thickness (mm) Dielectric strength (kV/mm) Average (kV/mm) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 85 70 75 70 75 82 71 70 65 82 73 70 75 76 2.46 2.54 2.39 2.74 2.86 2.97 2.41 2.65 2.49 2.82 2.28 2.6 2.94 2.61 34.55 27.55 31.38 25.54 26.22 27.45 29.46 26.41 26.1 28.92 32.01 26.92 25.51 29.11 28.36 acterized by a set of line positions 2θ and a set of relative line intensities, I. The specimens for SEM were prepared according to the optical ceramography and were coated by Agar SEM carbon coater. The SEM was done by the Philips XL30 FEG (Field Emission Gun) Scanning Electron Microscope. Semi quantitative analysis was performed by EDAX on four spots shown in Fig. 4. X-ray fluorescence (XRF) was done on the grounded samples of the fired body. Fig. 2. Test specimen for (a) dielectric strength test and (b) bending strength test. are then prepared for X-ray diffractometry (XRD) and scanning electron microscopy (SEM) and EDAX analysis. For XRD the fired bodies are ground to −300 mesh and then examined according to the Hanwalt method. X-ray patterns were recorded in a JEOL JDX-8P X-ray diffractometer. All the diffraction patterns were recorded under identical conditions using a beam current of 20 mA at 30 kV. Scanning speed used in all cases was 1◦ /min. The powder was charTable 2 Bending strength data of different samples fired at 1350 ◦ C Sample no. Firing temperature (◦ C) Load Diameter reading (cm) (N) Bending strength (kg/cm2 ) Mean bending strength (kg/cm2 ) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 1350 310 275 285 292 311 324 325 311 285 302 307 335 321 341 745 693 689 704 770 793 807 768 701 741 749 844 776 822 757.3 1.026 1.01 1.024 1.025 1.016 1.02 1.015 1.017 1.018 1.019 1.021 1.01 1.024 1.025 3. Results and discussion The target of our research was to attain the dielectric strength of 30 kV/mm. The results of dielectric strength measured on various samples are shown in Table 3. Although some samples attain 30 kV/mm, the average (28.36 kV/mm) does not meet the target goal. Again the bending strength was expected to be very high but it reaches the average figure of 757.3 kg/cm2 reported in Table 2. The SEM analysis (from Figs. 3–6) shows very small size cracks, quartz, mullite needle and unresolved clay matrix (cannot be detected by the optical microscope and needs EDAX analysis to detect it). EDAX spectrum is shown from Figs. 7–10. The compositions of elements in different spots in atomic percentage are given in Table 4. The XRD pattern is shown in Fig. 11 and the analysis is also shown in Table 5. The XRF result is shown in the Table 6. SEM micrographs show quartz, mullite needles, glassy rim and unresolved clay matrix. At the boundary of quartz Table 4 Atomic percentage of the elements found from EDAX analysis Elements Spot 1 Spot 2 Spot 3 Spot 4 Si Al O K 54.66 18.82 26.50 Negligible 48.70 21.61 27.08 2.59 61.96 8.98 22.09 4.03 75.15 3.13 21.71 – R.A. Islam et al. / Materials Science and Engineering B106 (2004) 132–140 135 Fig. 3. SEM image of porcelain ceramic insulator showing quartz grains, glass rim and clay matrix. small rim of glassy phase is observed which is due to the partial melting of quartz. The particles observed are in the size of 1–5 m or even 10-m quartz particles can be seen. Undissolved quartz particle is not coherent with the unresolved clay matrix. SEM images of the porcelain show mullite needles and EDAX analysis on that needles support the exact chemical composition of the mullite. Images indicate mullite’s preferential orientation on the surface of clay or kaolinite matrix. Probably the mullite in the clay matrix is the seed for the crystallisation of the mullite needles. The mullite needles observed in the clay matrix are generally termed as primary mullite. The morphology of the mullite needle is like acicular crystal. The mullite needles seem to be interlocked, which actually act as the strength increaser. When mullite crystal forms from the clay matrix it increases the volume by 10%. The increase in volume heals up any cavity or porosity or any cracks formed due to shrinkage and other thermal expansion. The SEM image clearly describes this nature. Where there is a low mullite content or no mullite the cracks become more prominent. Fig. 4. SEM image of porcelain ceramic insulator showing a quartz grain and a glassy rim surrounded by micro cracks and mullite needles in a clay matrix. Points 1–4 indicates the EDAX spots. 136 R.A. Islam et al. / Materials Science and Engineering B106 (2004) 132–140 Fig. 5. SEM image of porcelain ceramic insulator showing acicular shapes of mullite needles and some interconnected cracks in clay matrix. Table 5 XRD analysis of grounded samples fired at 1350 ◦ C Diffraction angle (2θ) d-Spacing I/I0 Diffraction planes, h k l Phases present 10.3 11.8 13.6 14.8 17.5 18.2 22.2 26.3 29 3.95 3.45 3.001 2.75 2.33 2.24 1.84 1.56 1.42 30 70 20 20 20 20 15 15 10 200 210 112 220 102 040 311 211 250 Mullite Mullite Clay Mullite Quartz Clay Mullite Quartz Mullite The matrix surrounding the quartz particle and beneath the mullite needles is supposed to be the unresolved clay matrix. The glass rim around the quartz particle shown (in Fig. 4) is due to the partial dissolution of quartz. The reason behind this is above 1200 ◦ C, the quartz particle starts to fuse and a rim of glass was formed surrounding the quartz particle. Each region was inspected by the EDAX analysis. The point 1, which was taken in the needle region, is shown in Fig. 8 shows aluminium content almost three times of the silicon content. The mullite has a stoichiometric formula of Al6 Si2 O13 , where the ratio of aluminium-to-silicon is 3. From this point of view it is clearly understood that the needle shape areas are mullite. Another EDAX result, which is chosen in the large particle (point 4), shows only silicon and oxygen. These regions are quartz particle. The regions surrounding the quartz particle (shown in point 3) show almost all silicon and oxygen with small amount of Na, K and Al. This is the glassy phase. The matrix shows considerable amount of aluminium and silicon (shown in point 2). These are the regions of unresolved clay matrix. The XRF results show a large amount (70%) of SiO2 and a very small amount (22.64%) of Al2 O3 (Table 6). The XRD pattern shows the mullite, clay and quartz peaks. But the intensity of the mullite is the largest among all. The result of the XRD pattern confirms the phases present in the ceramic insulator. The fired body also shows 70% silica and 22.64% alumina in sample fired at BISF at 1350 ◦ C according to the XRF result. Weight ratio corresponding to the stoichiometric formula of mullite shows that there has to be 2.55 times alumina than silica. So from the results it can be estimated that there is a very low mullite formed in the fired body. The bending strength and the dielectric strength of ceramic insulator at 1350 ◦ C is found 757 kg/cm2 and 28.36 kV/mm respectively, which is not good for ceramic insulator in service life. There are various reasons behind these low strengths. Actually the strength both bending and the dielectric, in the ceramic insulator is given by the mullite phase and the quartz particle. The undissolved quartz strengthens the rigid skeleton of the ceramic body as well as disconnects the conductivity. The interlocking system of Table 6 XRF results of various raw materials and the fired body Samples SiO2 TiO2 Al2 O3 Fe2 O3 MnO MgO CaO Na2 O K2 O P2 O5 Total LOI BISF burned body 70.03 0.81 22.64 1.38 0.02 0.32 0.54 1.17 2.77 0.04 100 0.05 R.A. Islam et al. / Materials Science and Engineering B106 (2004) 132–140 137 Fig. 6. SEM image of porcelain ceramic insulator showing wide regions of mullite crystals in a matrix of clay. the mullite needles is another reason for strengthening the ceramic insulator. The phase, which reduces the bending and dielectric strength of ceramic insulator, is the presence of glassy phase. The glassy phase will have a harmful effect if the amount is quite high. When there is a low amount of glassy phase content it is quite advantageous to the ceramic insulator as it only fills up the pores. But when the amount gets higher it only just increases the volume and decreases the density and that’s why decreases the bending and dielectric strength. Increase in glassy phase increases the liquid viscosity and helps to maintain the shape during firing. On the other hand mullite, which is a crystalline phase, have a vital role on mechanical and electrical strength. As the matrix of the ceramic sample is either clay matrix or the glassy phase the needle shape mullite maintain the stress level in a higher order as just in a composite matrix. But here in our sample the SEM micrograph (shown in Figs. 3 and 6) and the XRF results signifies the lower amount of mullite formation and that’s why there is a significant effect on bending and dielectric strength. Again with increasing the temperature the partial dissolution of quartz phase occurs which starts at 1200 ◦ C. Increased glassy phase and decreasing the quartz content tends to decrease the bending and dielectric strength of the porcelain ceramic insulator. At 1350 ◦ C, there will be a considerable amount of glassy phase. When there is a large amount of glassy phase present in the structure the mobile ions such as Na+ , K+ , Al3+ and Li+ finds an easy path to move and hence increases the Fig. 7. EDAX analysis of glassy phase showing high amount of silica and other oxides (spot 3 in Fig. 4). 138 R.A. Islam et al. / Materials Science and Engineering B106 (2004) 132–140 Fig. 8. EDAX analysis of mullite needles showing stoichiometric amount of alumina and silica (spot 1 in Fig. 4). Fig. 9. EDAX analysis of clay matrix showing the proportionate amount of silica and alumina (spot 2 in Fig. 4). Fig. 10. EDAX analysis of quartz showing almost all the silica (spot 4 in Fig. 4). R.A. Islam et al. / Materials Science and Engineering B106 (2004) 132–140 139 Fig. 11. XRD Pattern of powdered fired body showing the intensities of mullite, quartz and clay. conductivity. On the other hand, the strength can be greatly increased by undissolved quartz. If there is a large amount of undissolved quartz then it creates an obstacle in the way of conductive path that is glassy phase in which mobile ion can easily move. If it were possible to retain the undissolved quartz with higher amount of mullite then the strength would be greatly increased. Another reason for low dielectric and bending strength is the presence of microcracks in the ceramic insulator. The cracks are observed mainly near the quartz particle and those regions where the crystalline phase or mullite phase is less or absent. The cracks are peripheral around the quartz grain. At the crack tip some expansion cracks are also to be observed. Cracks can occur for various reasons. Cooling through the quartz inversion temperature of 573 ◦ C results in a quartz particle volume decrease of 2% which can produce sufficient strain to cause cracking of the glassy matrix and even in a rare case quartz itself which is observed in Fig. 4. Transgranular crack is observed in the middle of the quartz particle, which is due the differential thermal contraction in the quartz inversion point. The cracking severity largely depends on cooling rate. Slow cooling rate through the transformation zone will produce small strain. The nature of cracks in porcelain body is dependent on the expansion coefficient of the matrix and the particle. Circumferential cracking results due to the particles contracting more than the matrix. This is true for quartz particle in the feldspathic glass of the porcelain body matrix. The stress generation and associated cracking due to the presence of quartz particles tend to be severe because of rapid displacive phase transformation of quartz during cooling. The evidence of having these types of cracks is clearly observed in Figs. 4 and 5. The residual cracks results if the matrix contracts more than the particle resulting in emanating from the parti- cles. In Fig. 4, the large quartz particle exhibits continuous peripheral fracture at or near the grain boundaries and interconnected matrix fracture. An effect that can lead to artefacts in microstructural evolution is the release of induced stresses during specimen preparation like grinding and polishing of samples might lead to some observed cracks on the surface because of stress release. Crack size can be seen in the SEM images, which is shown in Fig. 5. The crack width is very small seems to be 0.1 micron or less which is not visible in the optical microscope. When such a crack retains in the structure, air or any type of gas stays in those cracks, which have a higher conductivity than any other phases of the structure. Again the crack tips always act as stress concentrators, which, lead to further cracks or failure and that, reduces the bending strength. So this type of micro cracks surely deteriorates the dielectric and mechanical properties of ceramic insulator. 4. Conclusion From the above discussion, it is clearly understood that mullite and the quartz are the two phases, which contributes to the mechanical and electrical properties of the ceramic insulator. In the reverse, if the glassy phase content gets higher it no longer contributes to the properties of the ceramic insulator instead it reduces the mechanical property (bending strength) and dielectric property (dielectric strength). The mullite formation is less due to the presence of small amounts of Al2 O3 (22.64%) and a large amount of SiO2 (70.03%). Again the presence of high amount of SiO2 will lead to the presence of high amount of glassy phase that is the most detrimental for developing high dielectric strength. Because if the glassy phase increases it gives a 140 R.A. Islam et al. / Materials Science and Engineering B106 (2004) 132–140 free path to the mobile ions like Na+ , K+ , Al3+ etc. to move and hence increases the conductivity. EDAX analysis of glass rim shows considerable amount of Na and K ion. Another important microstructural features that reduce the bending and the dielectric strength is microcracks. SEM images clearly show micro sized cracks, which are 0.1 m in width in general. The presence of those micro sized cracks surely reduces the mechanical and electrical properties that are clearly reflected in the bending strength and dielectric strength data, which are 757 kg/cm2 and 28 kV/mm respectively. XRD pattern describes the presence of mullite, clay matrix and quartz particle. The presence of low percentage of mullite can be understood by the intensity of the mullite peak, which is almost 70%. The formation of low mullite, presence of micro cracks and the dissolution of quartz particle is the main cause of lacking the dielectric and mechanical properties of the ceramic insulator. So it can be concluded that the best mechanical and dielectric properties can be achieved by higher mullite and quartz content with lower amount of glassy phase and the absence of microcracks. Acknowledgements The authors would like to acknowledge the collaboration of Electronic Engineering Department of the City University of Hong Kong specially the Centre for Electronic Packaging and Assemblies, Failure Analysis and Reliability Engineering and the Materials and Metallurgical Engineering Department of BUET. The authors also like to thank the BISF Ltd. for supplying the necessary raw materials and Bangladesh University of Engineering and Technology for allowing them to conduct some experiments in their laboratory. References [1] R.C. Buchanan, Ceramic Materials for Electronics – Processing Properties and Application, second edition, Marcel Dekker, New York, 1991, p. 1. [2] J.A. McPhee, S.J. Macgregor, J.R. Tidmarsh, Annual report: Conference On Electrical Insulation and Dielectric Phenomena, IEEE Dielectr. Insulat. Soc. II (2000). [3] K.H. Schuller, J. Mater. Educ. 4 (1982) 526–529. [4] S.P. Chaudhury, J. Br. Ceram. Soc. 73 (2) (1974) 37–41. [5] I.A. Aksay, J.A. Pask, J. Am. Ceram. Soc. 58 (11–12) (1975) 507– 512. [6] W.M. Carty, U. Senapati, J. of Am. Ceram. Soc. 81 (1) (1998) 3–20. [7] W.D. Kingery, H.K. Bowen, D.R. Uhlmann, Introduction to Ceramics, second edition, Wiley, New York, 1975, p. 534. [8] P.J. Harrop, Dielectrics, first edition, Wiley, New York, 1972 (Chapters 1–6). [9] F.M. Clark, Insulating Materials for Design and Engineering Practice, second edition, Wiley, New York, 1962 (Chapter 16). [10] ASTM (D3755).