Development of FeOOH nanoarrays using magnetic cations

advertisement

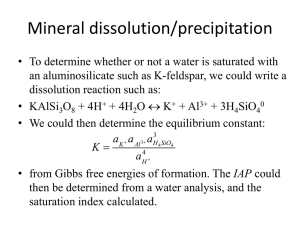

Cent. Eur. J. Chem. • 11(3) • 2013 • 358-363 DOI: 10.2478/s11532-012-0165-4 Central European Journal of Chemistry Development of FeOOH nanoarrays using magnetic cations Research Article Perla E. Garcia-Casillas*, Carlos A. Martinez-Pérez, Claudia Rodríguez González, Héctor Camacho-Montes, Santos A. Martel Estrada, Imelda Olivas Armendáriz Institute of Engineering and Technology, Autonomous University of Juarez, UACJ, 32320 Cd. Juárez, Chihuahua, Mexico Received 13 August 2012; Accepted 16 October 2012 Abstract: In this work, FeOOH arrays were obtained using two different magnetic cations. The nanoparticles were grouped into a package having different orientations through the van der Waals interaction with the magnetic cations. With Fe2+, the FeOOH nanoparticles have a rod shape with a 30-nm diameter and approximately 1-micron length, and are aligned in a star structure. With Co2+, a somatoidal shape was observed, with 20-nm diameter and 150-nm length and a pathway structure to the array. The chemical synthesis method was used to obtain the nanoarrays. The morphology and the average size of the nanorods and nanowires were determined using Field Emission Scanning Electron Microscopy (FESEM). Fourier Transform Infrared Spectroscopy (FTIR) was used to study the interaction between the nanorods and the cobalt ions. The phases of the material were identified using X-ray Diffraction. Keywords: Arrays • Synthesis • Nanoparticles • Magnetism • Ion © Versita Sp. z o.o. 1. Introduction Magnetic nanowires have drawn a lot of research interest due to their unique physical properties and potential applications in magnetic recording, spin electronics, optics, sensors and thermoelectronics devices [1-4]. Many researchers have been focused on the control and modeling of materials with dimensions of roughly 1-100 nm due to the particular and significant sizedependent properties [5-7]. This research area has been searching for unique phenomena to enable novel application of nanomaterials. Through nanotechnology, many properties of matter have been modified to enhance, for example, the strength and hardness of ceramics or the coercivity and magnetization of mixed ferrites; as well as to control optical properties by the variation of the size and microstructure of nanoclusters [8-11]. Therefore, the present leading concept in nanomagnetism is to organize surfactant-mediated nanoparticles into regular arrays. Recently, one of the most exciting areas in materials science has been the study of nanoarrays due to their 358 potential application in fields such as magnetic storage, optoelectronics, as well as electronic and memory devices [12]. The impact of array technologies on the life sciences has been important, in conjunction with bioinformatics tools, to process and analyze the large amount of data generated by modern devices. Arrays have spawned new approaches to new technological capabilities in electronics applications, optoelectronic, memory devices, etc. Magnetic-metal nanotube arrays with giant magnetoresistance may find applications as magnetic sensors with improved signal due to the larger resistance of a tube configuration with thin walls compared with nanowires of a similar diameter [13]. Many methods have been used in order to obtain arrays. Guohong and Ying synthesized an array of nanowires using an anodic aluminium oxide template [14,15]. Assembly of a Co/Fe3O4 nanoparticle array has been performed using a microelectromagnetic matrix [16], while Ni nanotube arrays have been obtained by electrochemical synthesis [17]. This paper describes the synthesis of FeOOH nanoparticles using magnetic cations, Co2+ and Fe2+. As a result, a FeOOH nanoarray * E-mail: perlaelviagarcia@yahoo.com pegarcia@uacj.mx J. G. Camacho-Meza et al. with some special magnetic properties was obtained. A mechanism for the formation of FeOOH-Fe2+ and FeOOH-Co2+ is discussed. 2. Experimental procedure 2.1. FeOOH with Fe2+ In order to synthesize FeOOH, 1.3523g of FeCl3•6H2O, 0.6852 g of FeSO4•7H2O and 1.20g of (NH2)2CO were dissolved in 50 mL of deoxygenated water, then were heated at 70ºC for 1 hour with a reflux condenser. A yellow precipitate was obtained. Afterward, the temperature was increased to 90-95ºC. This condition was maintained for 18 h, followed by cooling and aging for 12 h at room temperature. 2.2. FeOOH with Co2+ Nanoparticles of FeOOH were prepared by the hydrolysis of 0.64M ferric chloride (FeCl3•6H2O) (ecc.1) and the decomposition of urea ((NH2)2CO) (ecc.2) at 90°C for 2 h, after which the solution was left for 16 h at room temperature. In order to remove residual ions, the obtained powder was centrifuged and washed several times until a pH of 7 was reached, and then was dried at 100°C. Field emission scanning electron microscopy (FESEM; JEOL 7000F) was used to analyze the morphology, and particle-size distribution was determined using Scandium software with FESEM images of the precursor and the cobalt ferrite. In order to understand the interaction mechanism between nanorods and Fe2+ and Co2+ cations, Fourier transform infrared spectroscopy (FTIR; ThermoScientific Nicolet 6700) was used. X-Ray Diffraction (XRD; PANalytical XRD84) was used to confirm the crystalline structure. The magnetic properties were measured by a vibrating sample magnetometer (VSM). Magnetic measurements were performed at room temperature in magnetic field up to 20 kOe. 3. Results and discussion 3.1. FeOOH with Fe2+ In the growth of FeOOH particles, there are many steps. In the first step, Fe3+ and Fe2+ are precipitated as amorphous materials (Fig. 1A) where some swelling is observed (Fig. 1B), indicating the nucleation of nanoparticles of FeOOH. Afterwards, small protuberances started to grow from the amorphous materials (Fig. 1C), these small rods grew inside the raw materials with a few nanometers diameter (Fig. 1D). The particles were grouped with 6 to 8 rods; these groups emerge in different directions with a star structure (Figs. 1E, 1F) takes it to an extreme of the rods. The nanorods have a 30-nm diameter and an approximate length of 1 micron. The infrared spectrum of FeOOH was obtained with the KBr pressed disk technique and is shown in Fig. 2. An intense band due to the bulk hydroxyl stretch is observed at 3140 cm-1. The OH bending bands at 892 cm-1 (δ-OH) and 795 cm-1 (γ-OH), which vibrate in and out, respectively, of the (001) plane, are important diagnostic bands and also provide information about crystallinity. The frequencies of these vibrations depend on both the OH sites and resonance phenomena [18]. In this case, the difference between the two bands is 97 cm-1, indicating well-crystallized goethite [19]. The band at 630cm-1 is due to Fe-O interaction, this vibration is affected by the morphology and crystallinity, and corresponds to a transverse moment in the (010) plane. Fig. 3 shows the XRD pattern of the particles of FeOOH with and without Fe2+. In the first case, a tetragonal phase was found of the FeOOH, corresponding to akaganeite, and some peaks corresponding to maghemite were found. When the Fe2+ was added, maghemite was the principal phase. The suggested formation mechanism is: FeCl3 + 3 H2O ⇒ Fe(OH)3 + 3HCl (1) 0 oC Fe(OH)3 ⇒ FeOOH + H2O (2) FeSO4 + 2H2O ⇒ Fe(OH)2 + H2SO4 (3) 0 oC (NH2)2CO + H2O ⇒ 2NH3 + CO2 (4) FeOOH + Fe(OH)2 ⇒ Fe3O4 (5) 3.2. FeOOH with Co2+ In this case, the particles’ shape was somatoidal. In Fig. 4, an image of the FeOOH array is shown. The particles were grouped in a package forming different routes (Figs. 4A,4B). The particle diameter was 20 nm and length averaged 150 nm (Fig. 4C). The infrared spectrum of FeOOH was obtained with the KBr pressed disk technique and is shown in Fig. 5. The spectrum shows the absorption band at ∼430 cm-1, which is the energy translation of Fe-O Stretch. This spectrum shows a wide band at ∼689 cm-1 attributed to the double band of the O-H⋅⋅⋅O bonds. The 820 cm-1 band is due to the O-H bond. These bands are related to the characteristic vibration of akaganeite (β-FeOOH). 359 Development of FeOOH nanoarrays using magnetic cations Figure 1. 360 (a) (b) (c) (d) (e) (f) FeOOH array with Fe2+ interaction. (a) Amorphous material, (b) little swelling in amorphous material, (c) protuberance started grow, (d) small rods grew inside the raw materials, (e) and (f) star structure of FeOOH. J. G. Camacho-Meza et al. 100 90 80 % Transmitance 70 60 50 40 30 20 10 0 3900 3400 2900 2400 1900 Wave number (cm-1) 1400 900 400 Figure 2. FTIR spectra of FeOOH nanoparticles with Fe2+. Figure 3. X-ray diffraction pattern of FeOOH with and without Fe2+. (a) Figure 4. (b) (c) SEM image of FeOOH arrays with Co2+ interaction. 361 Development of FeOOH nanoarrays using magnetic cations 120 % Transmitance 100 80 60 40 20 0 3900 Figure 5. 3400 2900 2400 1900 Wave number (cm-1) 1400 900 400 FTIR spectra of FeOOH with Co2+. Figure 6. X-ray diffraction pattern of FeOOH with and without Co2+. The ∼3400 and ∼1640 cm-1 bands are due to OH- and H-O-H stretch of H2O. Additional bands were found (2940, 1380, 1520, 1640 cm-1), which are attributed to the KBr. When the cobalt was added, the 820 cm-1 band due to the O-H bond disappeared, indicating a possible interaction with the cobalt; however, no more bands were detected, so we can assume the cobalt can be bound to the oxygen by van der Waals forces. For this reason, the formation of the nanoparticle arrays could be attributed to the presence of cobalt ions. The crystallinity of the FeOOH nanoparticles has been altered with the added Co2+; in Fig. 6, the DRX pattern of FeOOH shows the crystalline planes of tetragonal akaganeite, βFeOOH, but when Co2+ was added, the FeOOH particles were amorphous. 362 Suggested formation mechanism: Fe+3 + 3OH- ⇒ Fe(OH)3 (6) Fe(OH)3 ⇒ FeOOH + H2O (7) Co2+ + 2OH- ⇒ Co(OH)2 (8) 2FeOOH + Co(OH)2 ⇒ CoFe2O4+ 2H2O (9) 4. Conclusion The influence of magnetic cations in the synthesis of FeOOH nanoparticles was studied. The formation of star and pathway arrays was obtained by the van der J. G. Camacho-Meza et al. Waals interaction of FeOOH particles with Fe2+ and Co2+ using chemical synthesis. The particle shape was modified by the presence of these cations, and the kinetics of formation of the rods and somatoidal particles of FeOOH were studied. Acknowledgments The authors are very grateful to the Science and Technology Council of México for financial support through the project CONACYT SEP-2004-C01-47290. References [1] A. Fert, L. Piraux, J. Magn. Magn. Mater. 200, 338 (1999) [2] D.J. Sellmyer, M. Zheng, R. Skomski, J. Phys.: Condens. Matter 13, R433 (2001) [3] K. Nielsch, R.B. Wehrspohn, J. Barthel, J. Kirschner, U. Go sele, S.F. Fischer, H. Kronmu ller, Appl. Phys. Lett. 79, 1360 (2001) [4] J. Maller, K.Y. Zhang, C.L. Chien, T.S. Eagleton, P.C. Searson, Appl. Phys. Lett. 84, 3900 (2004) [5] A.N. Shipway, E. Katz, I. Willner, Chem. Phys. 1, 18 (2000) [6] C.L. Haynes, A.D. McFarland, L. Zhao, R.P. Van Duyne, G.C. Schatz, L. Gunnarsson, J. Prikulis, B. Kasemo, M. Ka, J. Phys. Chem. B, 107, 7337 (2003) [7] A.A.J. Yin, J. Li, W. Jian, A.J. Bennett, J.M. Xu, Appl. Phys. Lett. 79, 1039 (2001) [8] H. Awaji, S.-M. Choi, E. Yagi, Mech. Mater. 34, 411(2002) [9] B. Parvatheeswara Rao, O. Caltun, W.S. Cho, C.-O. Kim, Ch.G. Kim, J. Magn. Magn. Mater. 310, E812 (2007) [10] D.S. Mathew, R.S. Juang, Chem. Eng. J., 129, 51(2007) [11] R.H. Magruder III, R.F. Haglund, Jr., L. Yang, J.E. Wittig, J. Appl. Phys. 76, 708 (1999) [12] J. Zhao, L. Mi, H. Hou, X. Shi, Y. Fan, Mater. Lett. 61 4196 (2007) [13] D.M. Davis, M. Moldovan, D.P. Young, M. Henk, X. Xie, E.J. Podlaha, Electrochem. Solid St. 9 C153 (2006) [14] G. Mu, N. Chen, X. Pan, H. Shen, M. Gu, Mater. Lett. 62, 840 (2008) [15] Z. Li-Ying, X. De-Sheng, F. Jie, J. Magn. Magn. Mater 305, 228 (2006) [16] L. Chitu, S. Luby, E. Majkova, P. Hrkut, A. Satka, Superlattice Microst. 44, 528 (2008) [17] X.W. Wang, Z.H. Yuan, S.Q. Sun, Y.Q. Duan, L.J. Bie, Mater. Chem. phys. 112, 329 (2008) [18] P. Cambier, Clay. Miner. 21, 191 (1986) [19] U. Schwertmann, E. Murad, Clay. Clay. Mine. 31, 277 (1983) 363