Transformer core ordering- by Stack height, number of sheets/books

advertisement

Transformer core ordering- by Stack height, number of sheets/books or Weight?

By Saif Qureishi (2013) (CEO and MD, KRYFS Power Components Ltd.)

In any Power Transformer manufacturing Company, should the core be ordered on stack height

(which is directly proportional to the cross sectional area of the core and therefore inversely

proportional to the flux density), or on the number of sheets in each leg (which would enable

production to efficiently assemble the core without shortages or mismatches in leg heights) or

should it be ordered on weight basis (which would enable purchase to effectively control the

costs).

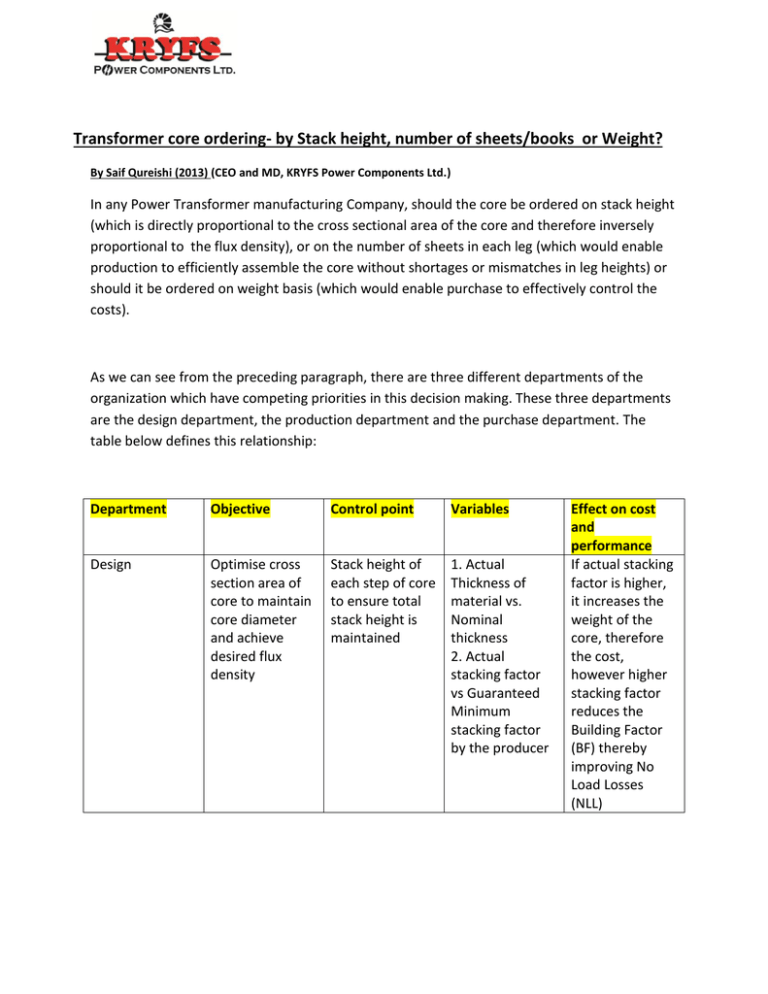

As we can see from the preceding paragraph, there are three different departments of the

organization which have competing priorities in this decision making. These three departments

are the design department, the production department and the purchase department. The

table below defines this relationship:

Department

Objective

Control point

Variables

Design

Optimise cross

section area of

core to maintain

core diameter

and achieve

desired flux

density

Stack height of

each step of core

to ensure total

stack height is

maintained

1. Actual

Thickness of

material vs.

Nominal

thickness

2. Actual

stacking factor

vs Guaranteed

Minimum

stacking factor

by the producer

Effect on cost

and

performance

If actual stacking

factor is higher,

it increases the

weight of the

core, therefore

the cost,

however higher

stacking factor

reduces the

Building Factor

(BF) thereby

improving No

Load Losses

(NLL)

Production

To build the core

such that there is

no mismatch of

height across

different legs.

No of sheets in

each leg of core

in non-step lap,

number of books

in step lap core

Actual number of

sheets / books

supplied in each

leg.

Purchase

To minimize cost

of materials by

buying exact

quantity of the

core.

Weight of the

core in KGS.

Weight of the

core as defined

by the design

department

using nominal

thickness and

minimum

guaranteed

stacking factor

by producer.

If there is

mismatch in the

number of

sheets, there is

an excess or

shortage in any

of the legs,

thereby making

it difficult to

complete the

core coil

assembly.

Shortage or

excess receipt in

core results in

either core not

being complete,

and cost

accordingly

decreasing or

increasing.

The Design department is the one where the transformer design and the core design

originates. They consider various requirements of the transformer as per the Guaranteed

Technical Particulars (GTP), of which one important parameter, the No Load loss (NLL) is

dependent on the operating flux density which in turn is dependent on the cross sectional area

of the core determined by the designer. Therefore the designer’s objective is to ensure the

cross sectional area of the core is optimal (as it is inversely proportional to the flux density and

therefore the NLL). On freezing the design of the transformer the same is translated to number

of sheets (or books in a step lap core) and weight of the core by the designer using two

variables, the thickness of the material and the stacking factor of the material.

For calculating the number of sheets or books in the core, it is a pretty straight forward formula

of dividing the core diameter by the sheet thickness into the stacking factor. The sheets in each

individual step are also calculated by the same formula:

# of sheets = {CD / (ST*SF)}

Where CD is Core Diameter in mm

ST is Sheet thickness in mm and

SF is stacking factor as given by the mill.

Core weight is calculated by again using the same variables of sheet thickness and Stacking

factor by the following formula:

Core weight = Weight of Core = (3 X Window Height + 4 X Leg Center + 2 X Maximum Width) X Nett

(effective) Cross section area X Density.

Where, Nett (effective) cross section area = stacking factor × {side limb cross section area + center limb

cross section area + yoke plate cross section area}

And Density = ( Weight of sample in gms) / (length x width x thickness in cm)

As can be seen from the above, the two variables Sheet thickness and stacking factor are used

in both calculations and therein lies the root cause of the dilemma on how to order the core,

whether on stack height, number of sheets or the core weight.

Let us examine the two variables viz, the sheet thickness and the Stacking factor a little more in

detail to understand why they are not constant and classified as variables.

While nominal sheet thickness of CRGO is defined by each mill, the process of cold rolling

material cannot produce sheet thickness of exactly same thickness without any variation. The

IEC 60404-8-7 or IS 302 (2006) and other international standards on CRGO all permit a

thickness variation of CRGO upto 10 % of nominal thickness. Therefore CRGO steel of grade M3

which should have a nominal thickness of 0.23 mm. However practically the steel can have a

thickness from 0.215 mm to 0.255 mm i.e. 0.23 mm +/- 0.023 mm (tolerance as defined by IEC).

In reality however most mills maintain a much tighter thickness tolerance than permitted.

However the fact is that the thickness of material does vary within the same grade and also

within the same coil in a typical range of 2 to 3 % of the nominal defined thickness. Most mills

also give lower thickness material as a standard to have better core loss, because core loss is

directly proportional to thickness (For example the actual thickness of AK steel M3 material is

0.215 mm instead of 0.23 mm (as defined by standard)).

The next variable that designers use to calculate the weight of the core is the stacking factor.

Stacking factor is defined as

Effective height/ stack height

Where, stack height is the measured height of the stack under certain pressure

The effective height is the actual height of iron (magnetic material) in the stack

Stacking factor is not a guaranteed value by the mill, and it is mentioned by most Mills as

“Minimum stacking factor”, which is actually much lower than the actual stacking factor of the

material. For example, the Russian mill Viz Steel defines the Minimum guaranteed stacking

factor on it’s MTC as 94.5%, however in reality the stacking factor is more than 97.5 %. Thus if a

designer was to use the Minimum guaranteed stacking factor of 94.5% instead of the actual

average stacking factor of 97.5%, he would under-calculate the core weight by approximately

3.2% (3/94.5).

The actual range of stacking factor of different mills (versus the minimum guaranteed by the

mills in their MTC or catalogue) is shown in Annexure.

As can be seen from the data provided, it is not at all an easy task to predict the weight from

the stack thickness in any particular grade without perusing the actual data of the particular

mill. Using the nominal thickness as defined for the particular grade or the minimum stacking

factor as defined under IEC will lead to under or over prediction of the core weight, thereby

creating a disparity in the purchase order quantity and the stack height of the core received.

So how does any transformer manufacturer practically resolve this seemingly tricky problem?

Which one of the 3 parameters should be used to order transformer core? If stack height is

used, the chances are of mismatch of sheets/books and higher weight, if sheets/books are

used, chances are of increase or decrease in stack height, thereby reducing/increasing the flux

density. And if core weight is used, chances are that there may be differences in the height of

the different legs due to mismatch in the number of sheets.

Conclusion

In 20 years of experience of supplying transformer lamination core to various large Power (1200

KV ) and small distribution transformer (11 KV) manufacturers in India and abroad, we have

found that this problem is magnified for higher power transformer range.

There is no one solution to this tricky issue and it depends on the transformer manufacturer

and the organizational objectives.

If the Design department requires the right Stack height irrespective of the other considerations

then stack height would be the solution.

If the production department requires equal height for each leg then it would be the number of

books that would be the solution.

If the purchase department mandates that cost control is the only criterion then the weight of

the core would be the solution.

However in our experience the most optimal solution is as follows:

Post designing the core and determining the stack height with nominal values of thickness and

stacking factor, calculate the number of books (step lap core) or sheets (non step lap core) with

actual thickness and stacking factor using the values given in the Annexure. This will maintain

stack height and give you the exact number of books/ sheets in each leg. So the design and

production requirements both are satisfied. Now it is easy to calculate the weight and

communicate the same to the purchase department, using the actual stacking factor values

from the table provided. Also provide for a margin of + 0.5 % on weight, because of the

variation of thickness and stacking factor within a tight range as explained above.