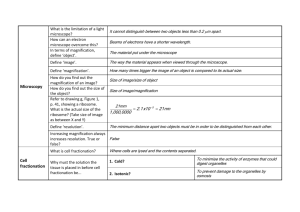

The Basics of Scanning Electron Microscopy The small scanning

advertisement

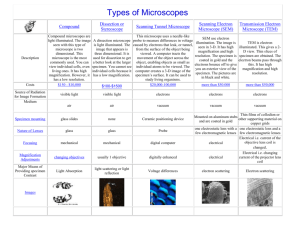

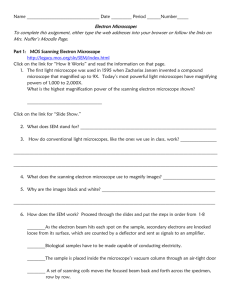

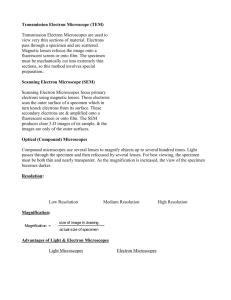

The Basics of Scanning Electron Microscopy The small scanning electron microscope is easy to use because almost every variable is pre-set: the acceleration voltage is always 15kV, it has only a single type of electron detector, a single aperture, a set working distance, and minimal atmospheric controls (you can let a little air into the scope to control charging, but you can’t control the amount). Essentially, all an operator can do is change the magnification, brightness, and contrast. The S-3400N puts control back into the hands of the operator. The advantage is fine control of every parameter and the ability to make sharply-focused, high-resolution images of a wide range of specimens. The disadvantage is that the “click and image” simplicity of the TM-1000 now becomes a multivariable problem with multiple answers. Not impossible, but more challenging. A couple of words of advice - GO SLOW! Be patient and ask lots of questions. There is a lot to learn here and you don’t have to know everything to get started. It is possible to get an image on the S-3400N just as quickly as you did on the small SEM - the main difference being that there is so much more you can do with it. There is a lot of information written below and the good news is you don’t have to understand everything the first time you read it. It is meant as a general reference to be utilized over time and as you use and become more familiar with the S3400-N, the information should become more useful in making the images you want to make. Magnification This one is pretty obvious and you will be delighted to learn that all you have to do is spin one knob to magnify an image. (See photo at end of this document.) The SEM is capable of magnifications of up to 300,000x but don’t expect to do much work there. Higher magnifications require special specimen preparation and some expensive machinery which I hope to have in the lab someday, but we don’t have now. Just like on a light microscope, the lower the magnification the more area you see and the more slowly things happen, so low magnification is the place to begin. Always start out at the lowest magnification possible you when begin imaging. When you see light, but can’t get anything into focus, it is probably because you left the magnification at some high setting. Brightness and Contrast The ABCC (Automatic Brightness and Contrast Control) button is your friend - use it. (See photo at end of this document.) As you change settings on the scope you will often be left with a dark or totally whited-out screen. This is normal. Click on the ABCC button and poof - there is your image again. The ABCC button will get you close, but you will still want to manually adjust the brightness and contrast to get the best image. Brightness and contrast are not the same thing, and be aware that as you increase contrast you are also increasing the chances that a specimen will charge or begin to get brighter and brighter until all detail is lost. As you take more and more images, you will develop your own tastes as to what makes a great image. Working Distance Working distance is the distance from the pole piece, the place where the electron beam enters the chamber, to the focal point of the beam. Basically, you can think of this as the distance from the pole piece on the SEM to the specimen. When you set the working distance you are telling the SEM where to expect the specimen to be. As you work with the SEM you will notice that focusing the SEM changes the working distance. This is because you have told the SEM where to focus and now are moving the specimen to meet that distance. This is exactly what you do with a light microscope by moving the stage up and down, the difference being that the focal length of a glass lens is fixed. You can change the focal length (working distance) of the electron microscope. When you mount a specimen in the SEM, you set its highest point to a standard height of 45 mm. The more carefully you set the standard height, the closer the manual Z-axis reading will match the working distance. It will probably never actually match, but it will be close enough for you to be able to see something in focus (at least close to focus). Setting the standard height will also keep you from crashing the specimen into the pole piece – something that will break the SEM and cost thousands if not tens of thousands of dollars to fix. (If you want to see me upset, break my SEM!) The working distance you choose is important because working distance is inversely related to resolution. Short working distances = Higher resolutions Longer working distances = Lower resolutions So what is resolution? Resolution is the ability of an optical instrument to show a space between two objects. In other words, it is the ability to tell that you are looking at two different objects instead of one larger object. Think about visible light. The way that you know that there is a space between two objects is when you can see light between them. On an electron microscope the same thing is true of an electron beam. The electron beam has to be small enough to go between two objects before you can tell that they aren’t connected. Now back to working distance. The obvious question here is why would you ever want lower resolution? The answer is related to depth of field. Depth of field (or depth of focus) is a term that refers to the depth of the specimen you can have in focus at one time. One of the great advantages of a scanning electron microscope is its tremendous depth of field. The two pictures below are of the same ant. The image on the left was taking with a dissecting scope. Notice that the body of the ant is in focus, but the legs which are below the body and the antenna which are above the body, are out of focus. The image on the right was made with the scanning electron microscope. Notice how almost the entire image is in focus. Image of small ant taken with a light dissecting scope. Notice that the top of the body is in focus, but the legs and antennae are out of focus. Image of the same ant taken with the scanning electron microscope. Notice that almost the entire ant is in focus and you can see much more detail. If, on the other hand, I want to show the surface of an insect wing on high magnification, I am not worried about depth, because the surface of the wing is relatively flat, so I choose a short working distance. When you begin imaging, you will always set the working distance at 10mm. This is not some magic WD or a set rule, it is just a WD that has worked well for me and will maximize your chances of successfully seeing something when you begin imaging. In general a short working distance approaches 6 mm and a long working distance is between 20 and 35 mm. The cool thing is that you get to choose what gives the best image. In the image above you can see that the working distance is set at 9.9 mm, yet the increased depth of field is evident. Working distance is changed by moving the specimen in the Z direction - that means up and down. BIG WARNING! As you move the specimen along the Z axis you MUST watch the TV monitor on the scope so that you do not bump into the pole piece and BSE detector. There is a camera that shows what is happening inside of the SEM that is there just for movement along the Z axis. Why? Because if you crash the specimen into the pole piece of the scope you will destroy the BSE (backscatter electron detector) - a multi-thousand dollar mistake. Don’t do it!!! Here is one more not-so-dire warning about that TV monitor. The camera is an infrared camera which means that the inside of the chamber is illuminated with infrared radiation - not visible light. Unfortunately, the BSE detector is sensitive to IR which means that if the camera is on all you will see is a solid white screen. (More on BSE and SE detectors below.) Not a problem for the SEM, but a little frustrating until you remember to turn it off, because no matter what you do all you will see is a solid white screen. (I speak from experience.) Probe Current The next parameter you can control is known as probe current. Think of probe current as the size of the electron beam. The smaller the probe current, the smaller the size of the beam and the greater resolution you can attain. (There are several factors that affect resolution, but it is a good way to think about probe current.) If you want to see more detail – get greater resolution – you should lower the probe current. There is a trade-off however. Lowering the probe current decreases the signal and increases noise. A noisy image has lots of static or graininess to it. Depending on what you are imaging and what you are trying to see, you may have to live with a grainy image. As an SEM operator, you will be the judge of how much noise to signal you can stand. It may not be the prettiest picture, but if it shows you what you want to see then go with it. When you begin imaging a new specimen set the probe current to 50. Again, this is not written in stone, but is a good initial setting which will maximize your chance of seeing an image. Acceleration Voltage Acceleration voltage is the energy that is coming out of the electron gun. On the S3400-N you can choose almost any acceleration voltage between 300V and 30,000V. The voltage on the SEM is rated in kilovolts (kV). A kilovolt is 1000 volts so on the electron microscope you will see 0.30 kV to 30 kV. From experience I can tell you that, our SEM doesn’t work well below 0.50 kV. You are welcome to try it, but if you get a message saying “Zero Emission, Check Filament”, you need to increase the acceleration voltage. Acceleration voltage is related to electron return. When you scan an object with an electron beam, the atoms of the object absorb that energy and give off their own electrons – electron return. The beam of electrons coming from the electron gun is the primary beam and one type of electrons given off by the atoms of the specimen are called secondary electrons. To get the electrons from the electron gun to the specimen, the specimen is mounted on a metal stub. That stub is positively charged. Negatively charged electrons are attracted to the positively charged specimen and move toward it. Electrons that are not absorbed by the specimen ideally should travel to the positively charged mounting stub. To insure that this happens, specimens in the SEM are usually coated with a very thin layer of gold and palladium. Unfortunately, at this time Eastfield does not have a machine that coats specimens. In addition, many of our specimens will be non-conductive. The electrons from the primary beam will not be easily removed and the specimen can become charged. As more and more electrons are added to the specimen, it will not only give off secondary electrons (which we want) but will also give off the electrons from being charged. The result is a specimen that begins to glow brighter and brighter and becomes distorted. Specimen charging is very unwelcome and can even keep you from being able to record an image. (Continues on next page.) Lily pollen showing charging at 50Pa Charging eliminated by increasing atmosphere to 80Pa One way to reduce or eliminate charging is to a lower the acceleration voltage. Fewer electrons in means less charging. Because of charging you will do most of your secondary electron (SE) imaging between 1.0kV and 2.0kV. As with almost everything on an electron microscope, this is not a hard and fast rule. I do a lot of imaging at 0.80kV and even up to 5.0kV. The only way to find out is to try it. Changing voltages takes a minute or so, but it is well worth experimenting until you find that magic kV that gives you the images you want. A second way to eliminate charging is to use the backscatter electron (BSE) detector. When you hit a specimen with the primary beam, not only are secondary electrons produced, but so are backscatter electrons. Backscatter electrons come from deeper within the specimen. These electrons may bounce around inside of the specimen before coming back out to be detected. (Some of them never make it back out and cause the release of X-rays. These X-rays can be used to determine the chemical composition of the specimen using an EDS system. No need to worry, the instrument is shielded to contain the X-rays.) We don’t have an EDS system on our SEM, but the cool thing about BSE detectors is that they can work with a little bit of atmosphere inside of the SEM. Our S3400-N is a variable pressure or environmental SEM, meaning you can control the atmospheric pressure inside the specimen chamber. Of most interest to you is the fact that allowing some atmosphere into the chamber allows the electrons that cause charging to be removed. Standard atmospheric pressure on the earth is 101,300 Pascals (Pa). At full vacuum, the chamber of our SEM will be at 1.5 x10-3 Pa (0.0015 Pa). That is the vacuum at which the SE detector operates. The S3400-N allows you to operate between 6 and 270 Pa using the BSE detector. The important thing for you to remember is that if charging is a major problem, switch to the BSE detector and add atmosphere. The BSE detector is slower to make an image and a little harder to work with, but the lack of charging outweighs the difficulties. Increasing acceleration voltage increases resolution, but be aware that two problems can occur at higher accelerations voltages. First, there is a lot of energy in the electron beam and it can destroy the specimen. This is called beam damage. Higher the magnification means more energy is focused in each unit of area, so beam damage occurs as you zoom in. If your specimen is charging or causing beam damage, you will see a rectangle on the screen as you decrease magnification. If you see this rectangle, you need to decrease acceleration voltage. Second is edge effect. The electron beam can be diffracted by sharp edges causing a decrease in focus. You may also see some edge blooming – bright glowing on the edges of the specimen. It is not intuitive, but I can often get a better image at 10 kV or 12 kV than I can at 20 kV. When you begin imaging insects, either us 1 kV SE, or 10 kV BSE. Aperture The last parameter to consider on the SEM is which aperture to use. The aperture on an electron microscope is a metal strip that has a series of progressively small holes through which the electron beam passes. The smaller the hole, the more coherent the electron beam is – the fewer unfocused electrons reach the specimen. This means that the electron return is coming only from the spot we want, so you see it more clearly – better resolution. Aperture Setting Size of aperture 0 1 2 3 4 Aperture removed from electron path m m m m So why not use the smallest aperture all of the time? Again we have a tradeoff between resolution and amount of signal. Yes, you can get better resolution with a higher aperture, but you will also have a dimmer image with more noise. Below 1000x, set the aperture to 0. Above 1000x, use aperture 1, 2, or 3. (Continues on next page) Initial settings and conditions When I first began working with the scanning electron microscope I had many frustrating days. Sometimes I would work for hours and never be able to get a single image. There is no reason for you to repeat my mistakes or replicate by learning curve. I have given you a lot to think about, but have developed a set of initial conditions that will yield an image almost every time. Until you are an independent operator of the SEM I strongly suggest you begin with the following initial conditions. SE Mode (set on “Conditions” tab on right hand screen) 1. Maximum specimen height set to 45 mm 2. Acceleration voltage = 1 kV 3. Probe current = 50 4. Aperture = 0 5. Working distance = 10 mm 6. Magnification = Lowest 7. Mechanical stage: x = 30, y = 20, (with camera on) z = 10 BSE Mode (set on “Conditions” tab on right hand screen) 1. Maximum specimen height set to 45 mm 2. Acceleration voltage = 10 kV 3. Probe current = 50 4. Aperture = 0 5. Working distance = 10 mm 6. Magnification = Lowest 7. Atmosphere = 40 Pa 8. Mechanical stage: x = 30, y = 20, (with camera on) z = 10 9. Turn off the camera before turning on the electron beam If you follow the parameters above you will see your specimen on screen. You still have lots to do, but at least you will see something. (Continues on next page) Additional Illustrations: Main computer interface for the SEM Control Panel for SEM