CCP Storage: Limiting Dry Matter and Quality Losses from Harvest

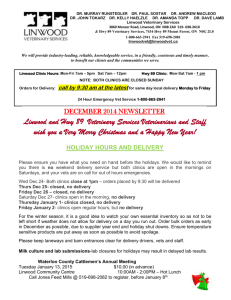

advertisement

CCP Storage: Limiting Dry Matter and Quality Losses from Harvest to Feedout Everett D. Thomas Oak Point Agronomics, Ltd. Hammond, NY 13646 INTRODUCTION Farmers pay a lot of attention to the crop inputs that influence yield and forage quality: variety and hybrid selection, fertilization and pest control, and of course the equipment needed to get the crop into the ground and then from field to silo. Yield reductions in the field are obvious, both to the farmer and to his farming neighbors, and to a lesser extent so are the in-field quality losses due to delayed harvest (hay crops) or inadequate nitrogen fertilization (grasses, corn grown for whole-plant silage) Often much less attention is paid to preserving quality and dry matter retention from harvest to feedout, though these losses can often be even more costly. For instance, a 10% dry matter loss after the crop is harvested is worse than a 10% yield loss in the field because of the additional costs involved in harvesting, transporting, and ensiling the crop. This paper will highlight several of the management factors involved in preserving forage quality from the field to the feedbunk. SILAGE INOCULANTS Bacterial silage inoculants should be considered as part of a farm’s risk management strategy—a very economical form of post-harvest “crop insurance.” A meta-analysis of silage inoculant trials—all brands of inoculant, all types of forage—found that silage inoculants “work”—their use results in increased dry matter preservation and/or increased milk production—about three-quarters of the time. Milk production (where it was measured) increased in about half the trials, with the average increase 2 pounds per cow per day. Therefore, the overall response averaged 1 pound for all trials where milk production was measured. Assuming current milk prices and the typical cost of a silage inoculant, a 1-pound milk response represents a payback of at least several dollars of milk income per dollar spent for a silage inoculant. There are many companies selling bacterial silage inoculants as well as non-bacterial silage additives including acids and enzymes. Some products are marketed as crop- 2014 Penn State Dairy Cattle Nutrition Workshop specific while others are recommended for a wide range of ensiled crops. In choosing a silage inoculant, consider the type of crop that will be stored, the approximate moisture content—some inoculants are more effective than others when crops are ensiled at less than 30% DM—and feedout procedures. There are thousands of strains of Lactobacillus plantarum, the most common homofermentative silage bacteria. Some are very effective, others not so much so. The best silage inoculants contain the most effective fermentation bacteria, often patented combinations of homofermentative and heterofermentative species; that’s what the farmer is paying for when purchasing an inoculant. Priority should be given to silage inoculants marketed by companies that back their performance claims with data, preferably from unbiased sources. The physical form of inoculant—water-soluble product or dry granules—can make a difference. Dry granules often work well with corn ensiled as whole-plant silage since the dry matter content of the forage is usually under 40%. Granules need sufficient moisture before the fermentation bacteria are activated, while an inoculant in solution is ready to start working right away. Preference should be given to water-soluble products if there’s a reasonable chance that hay crops may be over 40% DM when harvested. Using 53% DM alfalfa forage, Whiter and Kung at the University of Delaware found that compared with a water-soluble inoculant it took a granular inoculant three times as long (15 days vs. 5 days after ensiling) for the alfalfa to reach a pH of 4.5. PACKING SILAGE IN BUNKER SILOS AND DRIVE-OVER PILES Packing forage into bunker silos and drive-over piles can be as simple as a properly weighted tractor that’s also used for other jobs on the farm, or as specialized as a self-propelled “sheep’s foot” that has one primary use. Regardless of the packing equipment used, the objective is the same: pack relatively thin layers with enough weight to result in quick, efficient fermentation. I’ve seen good jobs of packing using a steel culvert filled with concrete through which an 11 axle had been inserted, a many-tired dump cart filled with stones, a wide range of tractor sizes and tire configurations, and the aforementioned sheep’s foot. Speaking of tires, a commonly asked question is: which does the best job of packing, singles or duals? The answer is that it makes little difference. Research in Kansas, New York, and Wisconsin all came to the same conclusion: no difference in silage density or dry matter losses regardless of whether the packing tractor had single tires or duals. The important factors are packing tractor weight, thickness of the layer of forage packed, and total time spent packing per ton of forage. A more practical factor on the single vs. duals question arises when the farmer is packing bunker silos where there’s a significant crown. The operator of a tractor packing a steep slope on a bunker silo with 10- or 12-foot sidewalls may very much appreciate the additional stability provided by dual tires. SILO PLASTICS In evaluating silo plastics it’s all about the oxygen transmission rate (OTR). Lower numbers are better. This assumes that the basics of covering silos have been met: a plastic cover applied soon after the silo has been filled and packed, sufficient overlap between sheets, and appropriate weighting of the plastic whether tires or gravel bags. Lower OTR plastic is preferred because it results in better preservation of the top several feet of silage. There are several types of low-OTR plastic on the market, most of which are better than “regular” two-ply silo plastic. The newest silo covers have OTR that are up to 60 times less than standard silo plastic. In addition to the OTR of the product, how tightly it adheres to the surface of the silage is also important. Better adherence means lower aerobic losses. Some farmers use two layers of standard silo plastic. While this results in lower spoilage losses, less surface mold, and therefore more edible silage, two layers of standard plastic aren’t nearly as good as a single layer of low-OTR plastic. In one trial an extra layer of standard silo plastic reduced the amount of inedible silage, but not nearly as much as a single layer of a high-density, lowOTR cover. Of course, almost any cover is better than no cover at all, a fact apparently (and remarkably) still not recognized by some farmers. interfering with each other. However, a proper drive-over pile has sides that are no steeper than 3 to 1 (something apparently lost on many, if not most, California dairies). Packing tractors can drive on 3 to 1 slopes without loss of traction. Drive-over piles with steep slopes can’t be adequately packed, resulting in excessive aerobic losses. An important note on silo safety: whether bunker silo or drive-over pile, be careful when working anywhere near the face of these silos. One suggestion is for people on foot to not get any closer than three times the maximum height of the silo. And the maximum height of the silo should never be greater than the reach of the unloading equipment; this will prevent silage overhangs and the danger of a silage “avalanche.” “IT’S IN THE BAG.” OR BUNKER, PILE, OR UPRIGHT… In recent years we’ve learned that corn silage isn’t a stable forage for a considerable time after it is ensiled. We may consider fermentation to be complete after the silage has stopped heating and has reached a desired pH level, but changes in the silage continue for some months thereafter. What doesn’t change after the first few weeks is NDF digestibility, but protein digestibility, starch digestibility, and silage acid content all change. Of these, the changes in starch are the most important. Not only are the changes predictable in that they routinely occur, but they’re significant. Cumberland Valley Analytical Services found that on September 22, after corn silage had been stored for three weeks, the total acid content was 4.5%. By February 16, after 24 weeks of storage, acid content had increased to 7.5%. During this same time period, starch digestibility increased from 70% to 77%. Farmers feeding a high rate of corn silage, unless they monitor starch digestibility in their silage, would be feeding a somewhat “hotter” ration by late winter or early spring than when they first opened the silo. That’s why it’s important to make a gradual change when switching from “old crop” to “new crop” corn silage. DRIVE-OVER PILES Drive-over piles are the fastest growing form of silage storage in the U.S. They have flexible capacity, are relatively inexpensive since there aren’t any concrete walls, and two or more packing tractors can be used on the pile without 12 November 12-13 Grantville, PA Limiting dry matter and quality losses from harvest to feedout Ev Thomas Oak Point Agronomics, Hammond, NY 2 3 4 Silage inoculants 5 2014 Penn State Dairy Cattle Nutrition Workshop 13 Risks and rewards Silage inoculant economics A survey of inoculant trials including all types of silage found that milk production increased in half of the trials. Where production improved, the average daily increase was 2 lbs. of milk per cow. So for all trials, 1 lb./cow. Assume 50 lbs silage/cow/day = 40 “cow days” per ton. 40 x 1 = 40 pounds more milk per ton of silage. How much does a farmer get paid for 40 lbs. of milk milk? ? What does it cost to inoculate a ton of forage? Silage inoculants should be considered as part of a dairy’s risk management strategy. It’s crop insurance. Miner Institute inoculates every ton of ensiled forage, every year, and has been doing so for over 30 years. But there are lots of products out there: Which should you use? Start with a reputable company, one that backs its performance claims with research data. data. Fermentation bacteria The good, the bad and the ugly Inoculant form: Dry granules or soluble product? There are thousands of strains of Lactobacillus plantarum,, the primary homofermentative bacteria, as plantarum well as several other types of fermentation bacteria. Either will work if there’s enough moisture in the chopped forage. These bacteria vary greatly in their effectiveness, including how fast and how far they drop silage pH during fermentation. Inoculants applied in solution are ready to work right away, while granules need sufficient moisture before they become activated. Seldom a problem with corn silage since it’s almost always harvested at less than 40% DM. Can be a problem with hay crop silages that are over 40% DM---delayed action. The best silage inoculants contain the most effective bacteria. bacteria Effect of inoculant form on ensiled pH of 52% DM alfalfa 6.5 Packing silage 6 5.5 Control Liquid 5 Granular 4.5 4 0 5 10 15 Days after ensiling Whiter and Kung, 1998 14 November 12-13 Grantville, PA 13 14 Duals vs. single tires Research in NY, Wisconsin and Kansas found no difference between singles and duals in silage density or dry matter loss. Important factors: Weight of packing tractor(s), packing layer thickness, total packing time spent per ton of silage. However, when packing on silo slopes, especially on over--filled bunker silos, duals may be preferred due to over tractor operator safety. 15 Silo plastic makes a difference Cover material Standard white/black SiloStop 2-Step clear SiloStop 1-Step white/black High density plastic: 60 times better OTR than standard black plastic. Thickness 5.0 mil 1.8 mil 4.5 mil OTR 1811 30 10 Michigan State University However, the oxygen transmission rate of the plastic doesn’t always predict how it will perform on the silo. 17 2014 Penn State Dairy Cattle Nutrition Workshop 15 Silo plastic economics What about two layers of standard 5-mil plastic? Meta--analysis, 41 studies: 1.8 mil high density, Meta low OTR vs. standard 5 mil plastic In top 2 feet of silage: 11% DM loss for 1.8 mil HD vs. 20 % DM loss for 5 mil. Overall DM savings from low OTR plastic (depending on silo dimensions) 2.52.5-5%. 90’ x 210’ bunker silo: Net gain $4500$4500-9000. 2.52.5-5% reduction in spoilage loss is better than a 2.52.5-5% increase in crop yield. Assuming 20 ton/A corn silage yield, that’s better than a 0.5 - 1 ton increase in yield. Every year! DM loss, % Surface mold, inches Inedible silage, % Single layer 5 mil Double layer 5 mil + 5 mil Single layer 1.8 mil HD 14.4 6.0 12.5 3.7 7.4 <0.1 20.1 14.0 3.5 Silage density 37 lbs/cubic foot. Storage time: 175 days 20 A California stack silo. Would you drive up and down these sides? Near Sacramento, California. Did they run out of tires…or ambition? Note spoilage layer! 21 22 Central Valley, California A drive-over pile, done right. This is a 2-to-1 slope, not 3-to-1 16 November 12-13 Grantville, PA Face management 20+ foot high silo, but the loader could reach 14-15’ high. A recipe for disaster. Silage facers: Rakes vs. rotary cutters Farmers claim that rakes are faster: One said he could unload 44-5 times as much silage with a rake than with a rotary cutter. One trial found no meaningful temperature difference in either haylage or corn silage. Rotary cutters don’t have much effect on corn silage particle size, but they do reduce haylage particle size. Silage bags Silage bags Practical for many farm sizes. Mold problems possible if grass silage is ensiled at 40+% DM . Silage density isn’t as high as in uprights, bunker silos or drivedrive-over piles. It still pays to inoculate forages in silage bags. Perhaps not L. buchneri products though— though—small feeding face. Corn silage in bags can be a problem— problem —pests! High moisture corn in bags is even worse. 2014 Penn State Dairy Cattle Nutrition Workshop 17 Corn silage in silage bags Birds quickly discover which silage bag(s) contain corn silage, peck holes in them looking for the grain. How to prevent “pecker hole” problems? Get a couple of cans of black spray paint and paint a squiggly line on top of any bag containing corn silage. Birds apparently think it’s a big snake and avoid it—no more damaged bags. Sounds crazy but it works. Delay feeding new crop corn silage. Corn silage is not stable! Months in silo 2 4 6 Starch digestibility, % 53 54 59 Protein digestibility, % 39 36 34 8 10 64 69 43 47 32 European research, 15 bunker silos Corn silage digestibility, 3-week rolling average (CVAS) Date Storage week 7 hour starch digestibility, % 30-hour NDF digestibility, & September 0 63 59 Sept. 22 (4.5% total acids) 3 70 61 Oct. 13 6 71 61 Nov. 3 9 72 61 Nov. 24 12 74 61 Dec. 15 15 76 60 Jan. 5 18 77 60 Jan. 26 21 76 61 Feb. 16 (7.5% total acids) 24 77 61 March 9 27 77 2012 Cumberland Valley Analytical Services, 61 Why does starch digestibility increase in the silo? Kernels soften as they imbibe moisture. “Juicing up.” Kernels with no hard starch are more digestible. Chemical changes are also happening to kernel starch. Kernel Processing Score increases with time. Acetic and lactic acid increase for 6 months after ensiling—4.5% at week 3, 7.5% at week 24. ensiling— One high producing herd removed several pounds of corn meal from the ration and milk production increased increased.. 34 Making good silage is expensive Using silage inoculants, proper packing, and high quality silo plastic are all expensive and timetime-consuming. Silo inoculants are frequently not used, particularly by custom operators, and it’s a real pain to put on silo plastic and weight it down properly. To save time and input cost: Don’t do any of those things: Just low it into a pile and simply take what you get. But here’s what you’ll get: Near Chazy, N.Y. Not Miner Institute! 36 18 November 12-13 Grantville, PA 75 70 65 60 55 50 1 2 3 4 29% DM 34% DM 41% DM 5 37 2014 Penn State Dairy Cattle Nutrition Workshop 19