Exothermic Welding SystemD42–D94

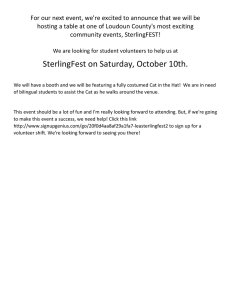

advertisement