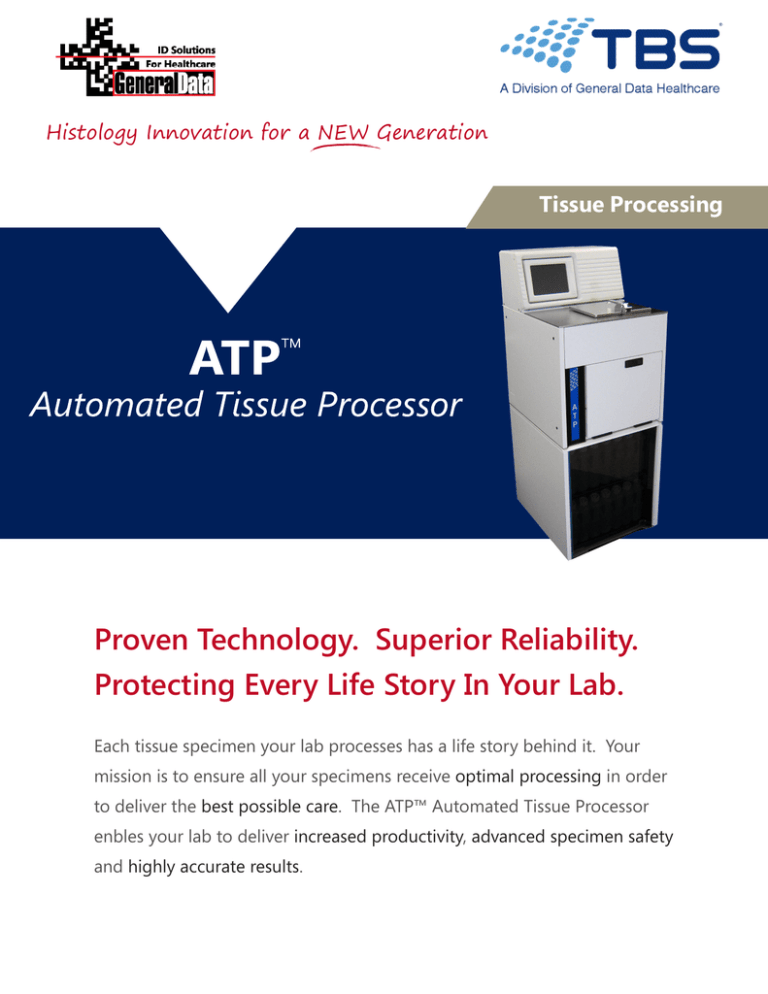

Histology Innovation for a NEW Generation

Tissue Processing

Proven Technology. Superior Reliability.

Protecting Every Life Story In Your Lab.

Each tissue specimen your lab processes has a life story behind it. Your

mission is to ensure all your specimens receive optimal processing in order

to deliver the best possible care. The ATP™ Automated Tissue Processor

enbles your lab to deliver increased productivity, advanced specimen safety

and highly accurate results.

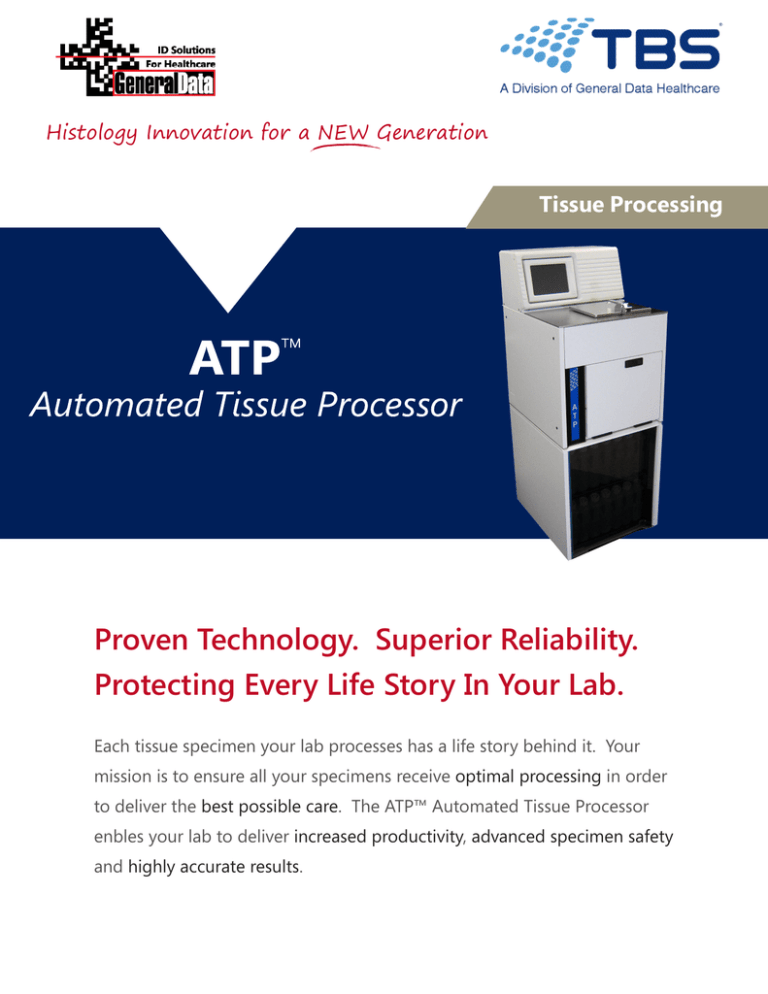

Highly Efficient Tissue

Processing Delivers Enhanced

Throughput and Accuracy

ATP1-120 or -220

Floor Model

There’s a patient’s life story behind every tissue

specimen your lab processes, and its your job to

ensure every life story receives the best possible

care. The ATP tissue processor utilizes advanced

technologies that are designed for the needs of

today’s lab - where increased reliability, efficiency,

throughput, accuracy and safety are all critical

factors for delivering the highest quality care to

your patients.

Innovative Single Rotary Valve Design Maximizes Reliability

The ATP is the only tissue processor to direct the flow of all reagents, waxes and cleaning solutions

to and from the processing chamber through a single rotary valve within a heated chamber. This

simple yet powerful design greatly increases reliability while reducing overall service costs.

Efficient Reagent Management Saves Time and Money

The ATP enables you to get the most from your investment in reagents and paraffin by efficiently

managing the use, cleaning and storage of all reagents, waxes and cleaning solutions.

Use less reagents: The ATP requires only 2.5L of reagent - much less than the other 4L

systems. Reagent carryover is no longer a problem.

Prolong paraffin life: Automatic paraffin cleaning requires no operator attention and reduces

paraffin consumption by a third or more.

ATP1-T-120 or -220

Tabletop Model

Enclosed Reagent/Pneumatic System Eliminates Noxious Vapors

Protect lab personnel from exposure to hazardous fumes. The ATP’s unique design includes an

overfill collection system so the process is totally enclosed. This design also extends the life of the

charcoal filters, so you won’t need to replace them as often.

Full Operational Control At Your Fingertips

Users can program up to 12 custom processes, including an additional reverse process, through

the touchscreen display. The entire processing schedule is easily accessed, and users can pause,

cancel or edit any step of any process at at any time. Records of each cycle can be output to a PC

or printer.

Quality Assurance For Every Processed Specimen

The ATP’s unique “bubbling” technology maximizes fluid/tissue exchange ratios so specimens are

processed completely without over-stressing. Contamination of reagents, paraffins, fluids and

charcoal filters is tabulated for processing quality. Chambers are continually monitored for proper

fill levels, and processing cycles are controlled to optimize reagent availibility.

Unique Bottle Design

Add or change regents, paraffin and cleaning fluids quickly and easily

with this innovative bottle design. Bottles can be fitted with a quickrelease coupler for added ease when attaching or detaching from the

ATP. Bottles can be purchased pre-filled, or lab personnel can easily

refill bottles from bulk reagent supply.

Versatile Cassette Baskets

The ATP includes a combination of baskets that provide maximum

specimen throughput while optimizing processing quality. The baskets

enable multiple cassette arrangements depending on specimen type

or need, and can handle everything from small runs to over 300

cassettes.

Product Specifications:

Capacity

Max. 350 Cassettes

Containers

Quantity

Capacity/Type

Temperature

Paraffin

4. plus 1 reserve

2.5L - 3.0L

50 to 60o C (±1)

Reagent

10

2.5L - 3.0L

Amb to 45o C (±1)

Cleaning

2

1 Clearant / 1 Dehydrant

Filteration

2

Charcoal

Display:

8” Diag. Color VGA (640 x 480) display w/ built-in touch-screen controller

Fluid Exchange:

Adjustable bubble rate: off, 15, 20 or 30 min. intervals

Vacuum: -700mBar (-70KPa)

Pressure: +250mBar (+25KPa)

Dimensions

Floor Model (53 x 21 x 24)in; (134 x 53 x 60)cm

Tabletop Model (31 x 42 x 24)in; (77 x 105 x 60)cm

Weight:

Actual: 264lbs, 120kg

Shipping: 330lbs, 150kg

Electrical:

100-120VAC, 50/60Hz; 8Amp; 220-240VAC, 50/60Hz; 4Amp. For International shipments, specify requirements.

Warranty:

1-Year, parts & labor

How To Order:

Catalog #

Description

ATP1-120

Floor model; w/ two cassette baskets (ATP1-B150) and 1 bulk cassette basket (ATP1-BB); Certification: TUV; Specifications: 100-120VAC, 50/60Hz; 8Amp

ATP1-220

Floor model; w/ two cassette baskets (ATP1-B150) and 1 bulk cassette basket (ATP1-BB); Certification: CE; Specifications: 220-240VAC, 50/60Hz; 4Amp

ATP1-T-120

Tabletop model; w/2 cassette baskets (ATP1-B150) and 1 bulk cassette basket (ATP1-BB); Certification: TUV; Specifications: 100-120VAC, 50/60Hz; 8Amp

ATP1-T-220

Tabletop model; w/2 cassette baskets (ATP1-B150) and 1 bulk cassette basket (ATP1-BB); Certifications: CE; Specifications: 220-240VAC, 50/60Hz; 4Amp

ATP1-B150

Basket, regular, stainless steel, cassette capacity-150, w/cover, organizer springs & dividers for cassette separation

ATP1-BB

Basket, bulk, stainless steel, cassette capacity-200-220 random or 350 stacked

ATP-CFB

Charcoal Filter Bottles, w/activated charcoal; 2/cs

ATP1-BR

Bottles, wax/reagent, HDPE, reusable w/internal drain tubes & quick connector couplers, w/caps; 6/cs

ATP1-BD

Bottles, w/out quick connector nozzles, w/caps, HDPE; 6/cs

Related Products:

Consumables:

Reagents:

SHURMark® Cassettes, SHURTrack® Cassettes

POLYFin® Paraffin Wax, PARAGard® Paraffin Repellent, Alcohols, Formalin & Xylene Substitute

More Information

PH: 800.733.5252 ext.6473

www.trianglebiomedical.com

General Data Healthcare helps labs enhance

productivity and improve workflow with

innovative products, solutions and support that

focus on delivering better patient safety & care.

©2013 General Data Healthcare, inc. All rights reserved. Specifications are current at the time of publication; however, they are subject to change without notification. All trademarks and registered

trademarks are property of General Data Healthcare, Inc., Cincinnati, Ohio, USA.

General Data Healthcare, Inc.

4354 Ferguson Drive, Cincinnati, OH 45245

Phone: 800.733-5252 ext. 6473

Email: talktous@general-data.com

www.general-data.com/hc

TBS - A Division of General Data Healthcare, Inc.

3014 Croasdaile Drive, Durham, NC 27705

Phone: 919.384.9393 Fax: 919.384.9595

Email: tbs@general-data.com

www.trianglebiomedical.com