Elevated Temperature Effects on the Mechanical Properties of Age

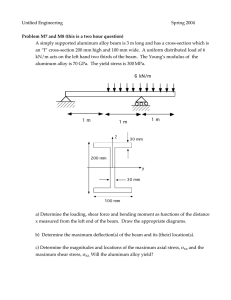

advertisement