INSTALLATION

Conduit Sealing Instructions for

Equipment in Hazardous Locations

C903M-E (10/10)

For IECEX and ATEX Only

A certified flameproof “d” sealing device, such as a stopping box with setting compound, shall be provided either in the flameproof enclosure or

immediately at the entrance thereto.

For U.S. Reference Only

This document is based on NEC installation requirements for equipment installed in hazardous locations in the United States of America.

Description

Conduit seals prevent explosions from spreading through conduit systems and igniting outside atmospheres. When properly installed and filled with a

UL-listed sealing compound, they prevent the passage of gases, vapors, or flames from spreading from a hazardous location to a nonhazardous location.

The information describes the main purposes for seal fittings:

• Restrict the passage of gases, vapors, or flames from one part of the conduit system to another area of

the system.

• Limit explosions to the sealed enclosure.

• Prevent precompression, or “pressure piling,” in conduit systems.

WARNING: Failure to follow safety instructions may cause ignition of hazardous

atmosphere resulting in serious personal injury and/or property damage.

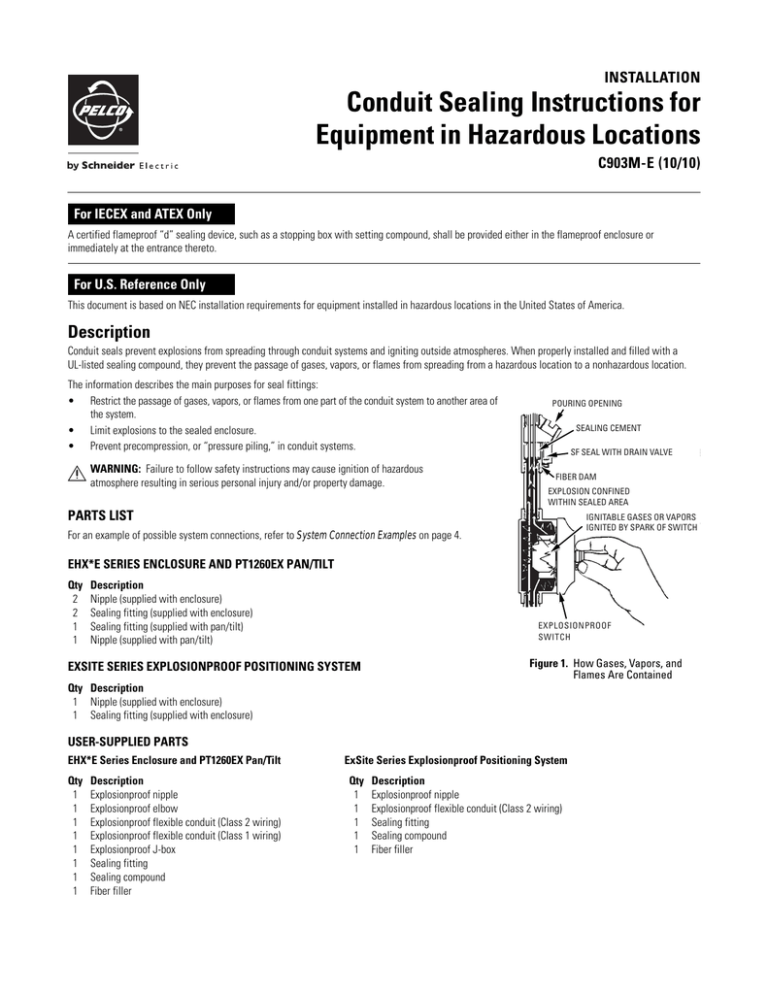

POURING OPENING

SEALING CEMENT

SF SEAL WITH DRAIN VALVE

FIBER DAM

EXPLOSION CONFINED

WITHIN SEALED AREA

PARTS LIST

IGNITABLE GASES OR VAPORS

IGNITED BY SPARK OF SWITCH

For an example of possible system connections, refer to System Connection Examples on page 4.

EHX*E SERIES ENCLOSURE AND PT1260EX PAN/TILT

Qty

2

2

1

1

Description

Nipple (supplied with enclosure)

Sealing fitting (supplied with enclosure)

Sealing fitting (supplied with pan/tilt)

Nipple (supplied with pan/tilt)

EXPLOSIONPROOF

SWITCH

EXSITE SERIES EXPLOSIONPROOF POSITIONING SYSTEM

Figure 1. How Gases, Vapors, and

Flames Are Contained

Qty Description

1 Nipple (supplied with enclosure)

1 Sealing fitting (supplied with enclosure)

USER-SUPPLIED PARTS

EHX*E Series Enclosure and PT1260EX Pan/Tilt

Qty

1

1

1

1

1

1

1

1

Description

Explosionproof nipple

Explosionproof elbow

Explosionproof flexible conduit (Class 2 wiring)

Explosionproof flexible conduit (Class 1 wiring)

Explosionproof J-box

Sealing fitting

Sealing compound

Fiber filler

ExSite Series Explosionproof Positioning System

Qty

1

1

1

1

1

Description

Explosionproof nipple

Explosionproof flexible conduit (Class 2 wiring)

Sealing fitting

Sealing compound

Fiber filler

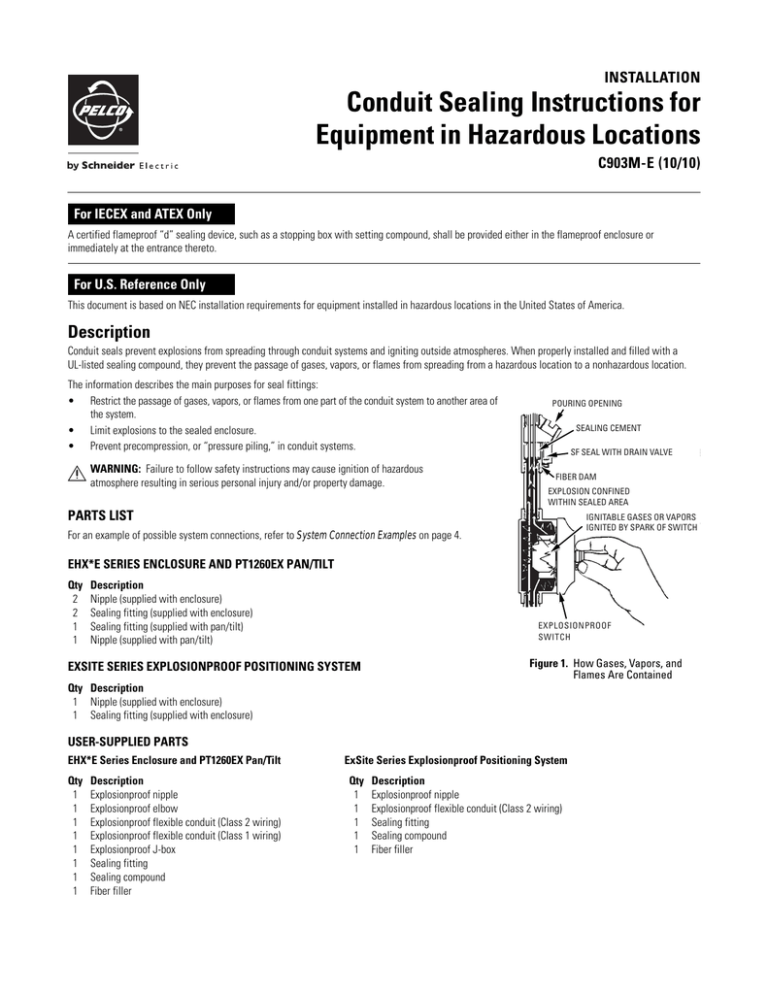

NEC SEC. 501-5 HIGHLIGHTS ON SEALING FITTING REQUIREMENTS

CLASS I, DIV. 1 AND 2

Seals must be placed in each conduit of a device that might produce arcs, sparks, or high temperatures.

SEC. 501-5(A)(1)

PERMITS

EXPLOSIONPROOF

UNIONS AND

ELBOWS BETWEEN

SEAL AND

APPARATUS

ENCLOSURE.

18 MAX

ENCLOSURE

TO BE SEALED

Figure 2. Seals Within Conduit Smaller Than 2 Inches

If the conduit is 2 inches or larger, a seal must be placed within 18 inches of the enclosure.

18 MAX

2 OR LARGER

CONDUIT

ENCLOSURE

TO BE SEALED

Figure 3. Seals Within Conduit Larger Than 2 Inches

Sealing fittings must be installed at a boundary between a hazardous and nonhazardous area. Sealing fittings must also be installed at a boundary between

a Class I, Div. 1 area and a Class I, Div. 2 area.

HAZARDOUS AREA

NONHAZARDOUS AREA

ENCLOSURE

TO BE SEALED

NONHAZARDOUS AREA

SEAL MAY BE POSITIONED

ON EITHER SIDE OF BOUNDARY

HAZARDOUS AREA

NO UNION, COUPLING, BOX, OR FITTING IN CONDUIT

IS PERMITTED BETWEEN SEALING FITTING AND

POINT WHERE CONDUIT LEAVES HAZARDOUS AREA

ENCLOSURE TO BE SEALED

Figure 4. Sealing the Enclosures

Other NEC Requirements:

• Splices and taps are not to be used in sealing fittings.

• Where moisture may accumulate in system, an approved method must be provided to remove such accumulation.

• Depth of sealing compound should be to trade size of conduit, having a minimum thickness of 5/8 of an inch.

Installation

1. Run the conductors through the fitting.

2. Pack the sealing fitting with fiber filler. In a horizontal run, place the fiber filling at both ends of the fitting (refer to Figure 5); in a vertical run, fill only

the bottom end (refer to Figure 6).

Fiber filler makes a dam that keeps the sealing compound in the chamber of the sealing fitting while it cures and hardens. The fiber dam is also used

to separate the individual conductors so the sealing compound seals around each conductor. If the electrical conductors are not properly separated,

gases can migrate through the seal, making the seal ineffective.

SEALING COMPOUND

SEALING

COMPOUND

FIBER FILLER

FIBER FILLER

Figure 5. Horizontal Fitting, Damming and Sealing

Figure 6. Vertical Fitting, Damming and Sealing

3. Prepare the sealing compound. Use sealing compound suitable for the application and follow the instructions supplied by the sealing compound

manufacturer.

4. Pour the sealing compound into the fitting.

System Connection Examples

NOTE: The following illustrations of system connections are provided only as a guideline. Actual connections are dictated by local authorities and the A&E

specifications of the site. Pelco makes no recommendations on the connection of this system in a hazardous location.

ì

Nipples (supplied with enclosure)

î

Sealing fittings (supplied with enclosure)

ï

Explosionproof nipple

ñ

Explosionproof elbow

ó

Explosionproof flexible conduit, for Class 2 wiring

r

Explosionproof flexible conduit, for Class 1 wiring

s

Explosionproof J-box, for connection of pan/tilt and

Class-1 camera; for ease of wire pulls, locate as close to

the pan/tilt as possible

ENCLOSURE

t

Sealing fitting, for separation of hazardous and

nonhazardous locations

u

Sealing fitting (supplied provided pan/tilt)

~í

Nipple (supplied with pan/tilt)

PAN/TILT

Figure 7. EHX*E Enclosure and PT1260EX Pan/Tilt

ì

Nipple (supplied with enclosure)

î

Sealing fitting (supplied with enclosure)

ï

Explosionproof nipple

ñ

Explosionproof flexible conduit, for Class 2 wiring

ó

Sealing fitting, for separation of hazardous and nonhazardous

locations

EXSITE

POSITIONING

SYSTEM

Figure 8. ExSite Series Explosionproof Positioning System

WARNING: Be sure to seal the cable entry conduit fitting with the appropriate sealant (not supplied) during installation.

REVISION HISTORY

Manual #

C903M

C903M-A

C903M-B

C903M-C

Date

9/92

11/94

6/03

8/04

C903M-D

C903M-E

4/10

10/10

Comments

Original version.

Revised format to two columns. Added an example system connection containing a figure and parts description.

Added "For U.S. reference only." Changed "Example System Connection" to "System Connection Example." Changed "EHX" to EHX*E."

Document rewritten and reformatted. Added information about NEC installation requirements, and added Introduction. Added another figure and parts

description. Some information removed.

Document rewritten and reformatted. Added "EECEX and ATEX Only" information. Added Parts List and User-Supplied Parts.

Added a warning to install appropriate sealant.

The materials used in the manufacture of this document and its components are compliant to the requirements of Directive 2002/95/EC.

Pelco, Inc. Worldwide Headquarters 3500 Pelco Way, Clovis, California 93612 USA

USA & Canada Tel (800) 289-9100 Fax (800) 289-9150

International Tel +1 (559) 292-1981 Fax +1 (559) 348-1120

www.pelco.com

Pelco, the Pelco logo, and other trademarks associated with Pelco products referred to in this publication are trademarks of Pelco, Inc. or its affiliates. All other product names and services are the property of their respective companies.

Product specifications and availability are subject to change without notice.

©Copyright 2010, Pelco, Inc. All rights reserved.

![Wrapping Machine [VP] OPP film wrapping for flat](http://s2.studylib.net/store/data/005550216_1-6280112292e4337f148ac93f5e8746a4-300x300.png)