connect

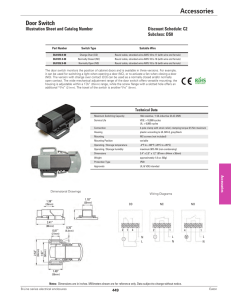

advertisement