Microchannel Air-Cooled Condenser

advertisement

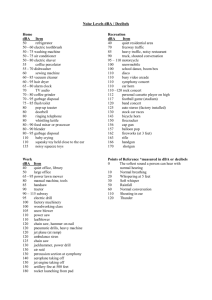

NRG & NRJ Microchannel Condensers Customer Briefing Microchannel Coil Overview WHAT IS A MICROCHANNEL COIL? Flat Streamlined Tubes One larger tube split into multiple smaller parallel ports Overall heat transfer efficiency due to Improved airside performance Higher primary surface area Reduced refrigerant side pressure drop Microchannel Coil Overview VALUE PROPOSITION, FEATURE AND BENEFITS Key Microchannel Primary Benefits Reduced Refrigerant Charge Corrosion Resistance Lighter Weight vs. RTPF Microchannel Coil Overview MICROCHANNEL APPLICATIONS Heatcraft ½-6hp Condensing Units (>150,000) Automotive Photo: Modine Website Residential Air Conditioning Rooftop Air Conditioning Chillers Microchannel Coil Overview OBSTACLES TO ADOPTION Volumes Traditionally automotive volumes All Aluminum Design Negative Connotations due to early experiences with aluminum round-tube plate fine Subject to leaks Not easily repairable Early Design Challenges Initial refrigeration implementations might not have permitted sufficient expansion and contraction Needs floating (or otherwise flexible) coil mounting design Source: Modine Website NRG & NRJ Microchannel Condensers Variable Speed EC Variable Speed EC (VSEC) WHERE ARE THESE MOTORS COMMONLY USED Fitness Equipment (treadmills, etc) HVACR equipment Large industrial machines Household electronics Variable Speed EC (VSEC) WHAT IS A EC MOTOR? Electronically Commutated (EC, ECM) Motor = Brushless DC (BLDC) Motor Just different names EC Motors are current trend in motor technology due to high efficiency up to 75% efficient 51-59% increase vs shaded-pole motors 30-35% increase vs permanent split-capacitor (PSC) Motors Variable Speed EC (VSEC) WHAT IS A VSEC MOTOR Varies Speed continuously to meet system requirements 14 Typical Operating 12 *NH* 10 Power Consumption (kW) *NL* 8 *NE* 6 NRG* 4 *NQ* 2 0 30% 40% 50% 60% 70% Load Requirement (NRG Baseline) 80% 90% 100% Variable Speed EC (VSEC) WHAT IS A VSEC MOTOR Power Consumption increases disproportionally with fan speed Source: http://www.dchuddle.com/ Variable Speed EC (VSEC) ENERGY SAVINGS Direct Condenser Power Consumption Rack Power Consumption In field test, Store B, equipped with VSEC motors, was verified to have obtained a 69% reduction in condenser energy costs and 13% reduction in rack energy costs**compared with Store A and its fixed-speed motor unit. Variable Speed EC (VSEC) ENERGY SAVINGS Electricity Expense Comparison of VSEC vs. Standard Fixed Speed Motor 13 Variable Speed EC (VSEC) ENERGY SAVINGS Motor Testing shows significant performance improvement Significant energy savings • 75% to 80% reduction in power usage Maintains constant head pressure • More stable temperature control NRG & NRJ Microchannel Condensers Product Training Microchannel Air-Cooled Condenser FIRST FIELD TRIAL INSTALLATION – JANUARY 05, 2012 15 Microchannel Air-Cooled Condenser VALUE PROPOSITION, FEATURE AND BENEFITS 238lbs Reduced Refrigerant Charge More than 70% reduction in refrigerant charge1, 2 Up to $2000 in refrigerant charge cost savings per unit2,3 = Microchannel Condenser = Round-Tube, Plate-Fin Condenser 104lbs 69lbs 40lbs 30lbs 35lbs 20lbs 10lbs 2 Fan 1Based 4 Fan 6 Fan on R-404A refrigerant charge for flooded condenser based on NRGD02A014 vs BNES02A015 at -20F ambient not include receiver, piping or manifold charge 3Based on 198 lbs of refrigerant charge reduction in comparable 8 fan units at $10 per pound price for R-404A 2Does 8 Fan Microchannel Air-Cooled Condenser VALUE PROPOSITION, FEATURE AND BENEFITS Very efficient Variable Speed EC fan motors Vary speed to match system demands Up to 10% additional savings on compressor/rack energy consumption Power Consumption (kW) *NH *NL *NE NRJ NRG *NQ Load Requirement (NRG Baseline) Microchannel Air-Cooled Condenser REPRESENTATIVE ENERGY COMPARISON – 540 RPM BNQ* NRG* NRJ* NRJ* (VFD) Unit: BNQ-D12=A069 Units: NRGD06A041 NRGD04A027 Units: NRJD06A041 NRJD04A027 Units: NRJD06A041 NRJD04A027 kWh Consumed: 22,180 Energy Cost: $2,218 kWh Consumed: 12,435 Energy Cost: $1,244 kWh Consumed: 80,971 Energy Cost: $8,097 kWh Consumed: 23,571 Energy Cost: $2,357 Unit: BNQ-D04A023 Units: NRGD04A027 Units: NRGD04A027 Units: NRGD04A027 kWh Consumed: 12,201 Energy Cost: $1,220 kWh Consumed: 3,436 Energy Cost: $344 kWh Consumed: 33,535 Energy Cost: $3,354 kWh Consumed: 7,300 Energy Cost: $730 Total kWh Consumed: 34,381 Energy Cost: $3,438 kWh Consumed: $15,871 Energy Cost: $1,587 kWh Consumed: 114,506 Energy Cost: $11,451 kWh Consumed: 30,871 Energy Cost: $3,087 Microchannel Energy Savings - $1,851 N/A $351 Medium Temperature Low Temperature Assumptions: 1.) Climate information per ASHRAE Std 550 – US avg 2.) Energy rate: $0.10 cents per kWh Microchannel Air-Cooled Condenser REPRESENTATIVE ENERGY COMPARISON – 1140 RPM Significant energy savings opportunities by upgrading to higher efficiency, energy efficient motors • Variable Speed EC (VSEC) 1140RPM vs Replacement Condensers Existing Condenser BNH-D08-A058 Assumptions: Location: Atlanta, GA Energy Cost: $0.11/kWh Replacement Condenser Annual Energy Savings (kWh) Annual Energy Savings (USD) BNE-D08-A062 57,270 kWh $6,300 NRG-D08-A054 72,896 kWH $8,019 Microchannel Air-Cooled Condenser VALUE PROPOSITION, FEATURE AND BENEFITS Significant Sound Reduction Up to 3.4 dBA vs standard *NE* series condenser at 10ft. More than 50% reduction in sound intensity Sound by Percentage of Max Speed 30% 50% 70% 100% (255 rpm) (425 rpm) (595rpm) (850rpm) BNE @ 100% NRG Advantage NRGD02A014 44.3 dBA 50.6 dBA 57.6 dBA 66.5 dBA 69.9 dBA 3.4 dBA NRGD04A027 47.3 dBA 53.7 dBA 60.6 dBA 69.5 dBA 72.9 dBA 3.4 dBA NRGD06A041 49.1 dBA 55.4 dBA 62.4 dBA 71.3 dBA 74.7 dBA 3.4 dBA NRGD08A054 50.3 dBA 56.7 dBA 63.6 dBA 72.5 dBA 75.9 dBA 3.4dBA Microchannel Air-Cooled Condenser VALUE PROPOSITION, FEATURE AND BENEFITS Low Profile Over 25% lower cabinet height1 • May reduce need for visibility fencing and/or walls 26” Microchannel Air-Cooled Condenser 1vs. 20” comparable Round Tube Plate Fin Air Cooled Condenser 35” 20” Standard Air-Cooled Condenser Microchannel Air-Cooled Condenser VALUE PROPOSITION, FEATURE AND BENEFITS Reduced Weight More than 20% reduction in unit weight • May reduce need for structural supports • Reduction in shipping costs NRG* Model 1vs. Weight *NE* Model Weight Reduction % NRGD02A014 510 BNES02A015 640 20% NRGD04A027 1015 BNED04A031 1390 27% NRGD06A041 1520 BNED06A046 2060 26% NRGD08A054 2005 BNED08A062 2730 27% comparable Round Tube Plate Fin Air Cooled Condenser Microchannel Air-Cooled Condenser VALUE PROPOSITION, FEATURE AND BENEFITS Corrosion Resistance Monometal coil • Virtually eliminate galvanic corrosion Coastal Performance Comparison Heat Transfer Capacity (BTUH) Heat Transfer Capacity (BTUH) Uncoated Coil 30,000 25,000 20,000 Significant decrease in capacity due to corrosion after one year 15,000 10,000 5,000 0 Microchannel Coil 30,000 25,000 No significant change in performance after one year 20,000 15,000 10,000 5,000 0 0 0.01 0.02 0.03 Air Horsepower (hp) 0.04 0.05 0 0.01 0.02 0.03 Air Horsepower (hp) 0.04 0.05 Microchannel Air-Cooled Condenser VALUE PROPOSITION, FEATURE AND BENEFITS Corrosion after 1 Year in Coastal Application Microchannel Coil Round-Tube, Plate-Fin BASELINE AFTER 1 YEAR OF EXPOSURE Microchannel Air-Cooled Condenser VALUE PROPOSITION, FEATURE AND BENEFITS Corrosion Resistance Monometal coil • Virtually eliminate galvanic corrosion Accelerated Corrosion Testing 6,000 5234 5,000 Time to Failure 4,000 3,000 2759 2,000 1,000 0 Round Tube – Plate Fin with E-Coat Microchannel Time to Failure= time (hours) until capacity is degraded by 15% Microchannel Coil remained “functional” for 89% longer than Round Tube – Plate Fin coated with E-Coat Accelerated Corrosion Test Repeated, Cyclic Exposure to: 1. Salt Fog 2. High Humidity – Hot Ambient 3. High Humidity – Cold Ambient 4. Low Humidity – Low Ambient Questions?