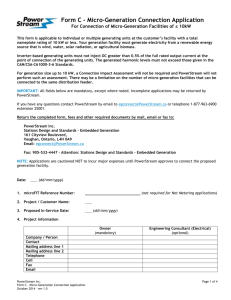

Embedded Generation Technical Interconnection

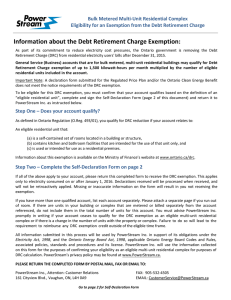

advertisement