80439-666-01B

06/2006

Seneca, SC USA

Instruction Bulletin

ENGLISH

Replaces 80439-666-01A, 08/1998

Disconnect Assembly Replacement

F- and K-Frame Circuit Breakers or 100 A and 200 A Disconnect Switches in

Model 6 Motor Control Centers (MCCs)

Class 8998

Retain for future use.

INTRODUCTION

This bulletin provides instructions for replacing an MCC disconnect assembly.

These instructions are applicable only to disconnect assemblies in Model 6

MCCs that contain:

•

•

•

•

-

F- and K-Frame Thermal-Magnetic Circuit Breakers (15–250 A),

F- and K-Frame Molded Case Switches (100–250 A),

F- and K-Frame Mag-Gard® Motor Circuit Protectors (3–250 A), and

100 A and 200 A Disconnect Switches used in fusible units.

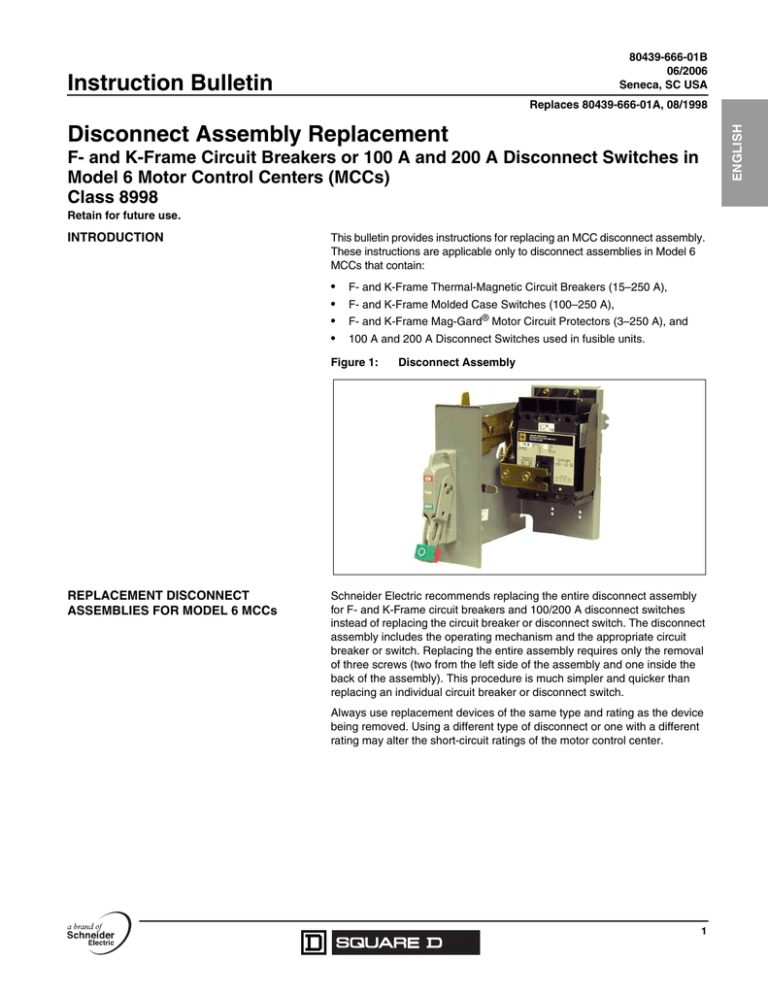

Figure 1:

REPLACEMENT DISCONNECT

ASSEMBLIES FOR MODEL 6 MCCs

Disconnect Assembly

Schneider Electric recommends replacing the entire disconnect assembly

for F- and K-Frame circuit breakers and 100/200 A disconnect switches

instead of replacing the circuit breaker or disconnect switch. The disconnect

assembly includes the operating mechanism and the appropriate circuit

breaker or switch. Replacing the entire assembly requires only the removal

of three screws (two from the left side of the assembly and one inside the

back of the assembly). This procedure is much simpler and quicker than

replacing an individual circuit breaker or disconnect switch.

Always use replacement devices of the same type and rating as the device

being removed. Using a different type of disconnect or one with a different

rating may alter the short-circuit ratings of the motor control center.

1

Disconnect Assembly Replacement

Replacement Disconnect Assemblies for Model 6 MCCs

80439-666-01B

06/2006

Refer to the following tables for a listing of replacement assemblies.

ENGLISH

NEMA/EEMAC SIZE 1–4 combination starters with Mag-Gard magnetic only circuit breakers

NEMA/EEMAC Size 5 combination starters with KA-Frame (250 A maximum) Mag-Gard magnetic only circuit breakers

To replace this circuit breaker: Order this disconnect assembly: To replace this circuit breaker: Order this disconnect assembly:

FAP3600311M

FAP3600712M

FAP3601513M

FAP3603015M

FAP3605016M

M6DSAMG003M11

M6DSAMG007M12

M6DSAMG015M13

M6DSAMG030M15

M6DSAMG050M16

FAP3610018M

KAP3625025M

KAP3625029M

KAP3625031M

M6DSAMG100M18

M6DSAMG250M25

M6DSAMG250M29

M6DSAMG250M31

NEMA/EEMAC Size 1–4 combination starters with thermal-magnetic circuit breakers

NEMA/EEMAC Size 5 combination starters with KA-Frame (250 A maximum) thermal-magnetic circuit breakers, main and branch feeder circuit breakers through 250 A

For dual-mounted circuit breaker units, contact your Schneider Electric field sales representative. Not applicable to Compact® 6 units.

To replace this circuit breaker: Order this disconnect assembly: To replace this circuit breaker: Order this disconnect assembly:

FAP36015

FAP36015

FAP36020

FAP36020

FAP36025

FAP36030

FAP36030

FAP36040

FAP36040

FAP36050

FAP36050

FAP36060

FAP36060

M6DSATM015M

M6DSATM015M

M6DSATM020M

M6DSATM020M

M6DSATM025M

M6DSATM030M

M6DSATM030M

M6DSATM040M

M6DSATM040M

M6DSATM050M

M6DSATM050M

M6DSATM060M

M6DSATM060M

FAP36070

FAP36080

FAP36080

FAP36090

FAP36090

FAP36100

FAP36100

KAP36110

KAP36125

KAP36150

KAP36175

KAP36200

KAP36225

KAP36250

M6DSATM070M

M6DSATM080M

M6DSATM080M

M6DSATM090M

M6DSATM090M

M6DSATM100M

M6DSATM100M

M6DSATM110M

M6DSATM125M

M6DSATM150M

M6DSATM175M

M6DSATM200M

M6DSATM225M

M6DSATM250M

NEMA/EEMAC Size 1–4 combination starters with disconnect switches

To replace this

disconnect switch:

Order this disconnect assembly:

To replace this

disconnect switch:

Order this disconnect assembly:

30 A

60 A

M6DSAFS030M ➀

M6DSAFS060M ➀

100 A

200 A

M6DSAFS100M ➁

M6DSAFS200M ➁

To replace this

disconnect switch:

Order this disconnect assembly:

100 A

200 A

M6DSAFS100M ➁

M6DSAAS250M ➁

Main and branch feeder disconnect switches through 200 A

To replace this

disconnect switch:

Order this disconnect assembly:

30 A

30 A

60 A

60 A

M6DSAFS030M ➀

M6DSAFS030M ➀

M6DSAFS060M ➀

M6DSAFS060M ➀

➀ Voltage form must be added:

U212: 0-250V, Class H

Y712: 0-250V, Class R

U213: 600V

➁ Does not include fuse clips. Refer to “Modifications” on page 3.

Replacement of the operating mechanism is not required for NEMA/EEMAC

Size 5 combination starters with:

•

•

•

•

•

2

LA frame (400 A max.) circuit breakers

NEMA/EEMAC Size 5 combination fusible starters

NEMA/EEMAC Size 6 combination starters

Main and branch circuit breakers over 250 A

Main and branch feeder disconnect switches over 200 A

© 1998–2006 Schneider Electric All Rights Reserved

Modifications

Disconnect Assembly Replacement

Replacing the Disconnect Assembly

Order a replacement circuit breaker or automatic molded case switch of the

same type as the original device. To order an FH/KH type high-interrupting

circuit breaker instead of the standard FA/KA type circuit breaker, add form

Y532 to the disconnect assembly number.

Example: To replace an FHP36100, order an M6DSATM100M Y532.

These modifications also may be added to disconnect assemblies when

required:

Y74

Y301

Y303

Y312

Y532

U341

REPLACING THE DISCONNECT

ASSEMBLY

Single pole interlock on operating mechanism

Current limiting module (for starter units Size 1–3)

Current limiting module (for 15–100 A branch feeders)

Class R fuse clips

High interrupting circuit breaker

Extra high interrupting circuit breaker

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices. See NFPA 70E.

• This equipment must be installed and serviced only by qualified

electrical personnel.

• Turn off all power supplying this equipment before working on or

inside equipment.

• Always use a properly rated voltage sensing device to confirm that

power is off.

• Replace all devices, doors, and covers before turning on power to

this equipment.

Failure to follow these instructions will result in death or serious injury.

To replace the disconnect assembly, follow these steps:

1. Turn off all power supplying the equipment, and follow lockout/tagout

procedures before working on or inside equipment. Always use a

properly rated voltage sensing device to confirm the power is off.

2. Remove the unit containing the disconnect assembly from the MCC. For

instructions on removing the unit, refer to the Model 6 instruction bulletin

(no. 80459-641-01_) that was shipped with the MCC.

3. Once the unit has been removed, disconnect the load side power wiring

from the circuit breaker or disconnect switch.

© 1998–2006 Schneider Electric All Rights Reserved

3

ENGLISH

80439-666-01B

06/2006

Disconnect Assembly Replacement

Replacing the Disconnect Assembly

80439-666-01B

06/2006

4. Remove and retain the two 10-32 x 1/2 in. screws from the unit bottom

plate, and tilt the unit bottom plate down (Figure 2).

ENGLISH

5. Remove and retain the three 12-24 x 1/2 in. mounting screws used to

mount the disconnect assembly to the unit saddle and the 10-32 x 3/8 in.

screw used to mount the disconnect assembly to the unit support angle

(if applicable). See Figure 2 for the location of this mounting hardware.

Next, remove the disconnect assembly from the unit.

Figure 2:

Location of Mounting Hardware and 12-24 Mounting Screws

Unit support angle

12-24 mounting screws

10-32 mounting screw

12-24

mounting

screw

Unit bottom plate

Unit bottom plate

10-32 x 1/2 in. flat head screws

Mounting Hardware

12–24 Mounting Screws

6. Locate and mount the bracket on the disconnect in the same position as

the original assembly using the two 10-32 x 3/8 in. screws provided. For

the correct mounting position, refer to the original disconnect assembly

and Figure 3 below and Figure 4 on page 5. For assemblies

manufactured before August 1998, see Figure 3. For assemblies

manufactured after August 1998, see Figure 4.

Figure 3:

Mounting Bracket Location for Assemblies Manufactured before August 1998

Mounting

bracket

Mounting

bracket

Original Assembly

4

Replacement Assembly

© 1998–2006 Schneider Electric All Rights Reserved

80439-666-01B

06/2006

Mounting Bracket Location for Assemblies Manufactured after August 1998

ENGLISH

Figure 4:

Disconnect Assembly Replacement

Replacing the Disconnect Assembly

Mounting

bracket

Mounting

bracket

Replacement Assembly

Original Assembly

7. Mount the bracket on the new disconnect assembly using the two

10-32 x 3/8 in. screws provided. See Figures 5 and 6 for the correct

mounting relationship between the bracket and disconnect assembly.

Figure 5:

Mounting the Bracket on the New

Disconnect Assembly

Figure 6:

Detail A

Mounting bracket

See Detail A

10-32

hardware

part number

21427-17121

10-32 x 3/8 in. hardware

part number 21427-17121

© 1998–2006 Schneider Electric All Rights Reserved

5

Disconnect Assembly Replacement

Replacing the Disconnect Assembly

80439-666-01B

06/2006

8. Place the new disconnect assembly in the unit saddle, and mount it

using the three 12-24 x 1/2 in. screws (Figure 7).

ENGLISH

Figure 7:

Mounting the Replacement

Assembly

12-24 x 1/2 in.

screws

9. Reconnect the load side power wiring to the circuit breaker or

disconnect switch. Torque all connections according to the

specifications provided on the circuit breaker or disconnect switch.

10. Return the unit bottom plate to its original position, and replace the two

10-32 x 1/2 in. screws from step 4 in the unit bottom plate (Figure 8).

Figure 8:

Replacing the Flat-Head Screws in the Unit Bottom Plate

10-32 x 1/2 in. screws

11. Reinstall the unit in the MCC, and replace any doors or barriers before

re-energizing the equipment. Refer to the Model 6 instruction bulletin

(no. 80459-641-01_) for instructions regarding reinstalling the MCC unit.

Schneider Electric USA

1990 Sandifer Blvd.

Seneca, SC 29678 USA

1-888-SquareD (1-888-778-2733)

www.us.SquareD.com

Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

© 1998–2006 Schneider Electric All Rights Reserved