Fronius IG

advertisement

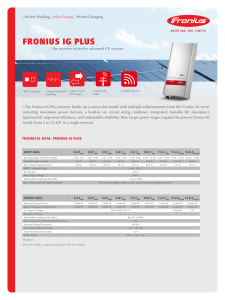

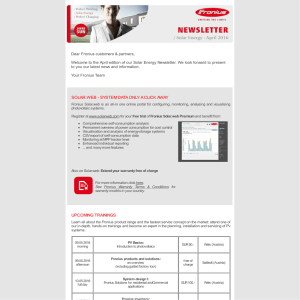

Fronius IG Grid-tied Inverters for Photovoltaic Systems Welcome to Fronius International For over 65 years, Fronius has concentrated on technologies for converting electrical energy. The company is divided into three divisions. In addition to solar technology, Fronius is a leading innovator in welding technology and battery charging systems. Fronius is an international enterprise with subsidiaries in many countries and are also supported by numerous sales partners and representatives, giving us a presence in over 60 countries worldwide. Research and development is the heart of our company in all three Fronius divisions. These are young and dynamic teams who are continually searching for innovative technological approaches and revolutionary developments to turn great ideas into efficient tools. High Frequency (HF) Technology Maximum Output in Minimum Space. The power circuit of all Fronius IG inverters is based on the High-Frequency concept. The advantages are obvious: it makes the inverter extremely compact and very powerful. Using an innovative Phase-Shift process the Fronius IG minimizes switching losses and is able to generate ultra high conversion efficiencies of 95.2 %! As a result of HF technology, the Fronius IG weighs in at 26 lbs, half the weight of the competition! Our extensive experience with HF-Transformers from the welding sector makes the Fronius IG one of the most efficient and reliable Small transformer – high power. The transformer is extremely small and able to transmit high power due to the high-frequency technology. Furthermore, the phase-shift process minimises switching losses thus ensuring high yields. PV inverters of all time. MIX™ Concept: More Power due to two Hearts Inverter X-Change concept, is a further development of the master-slave process (MS). The MS process was developed in order to obtain significantly better Power Harvest under Efficiency Increase yield, reduce operating hours. MIX™, the Master Inverter without MIX TM concept Fronius IG 4000/ 5100/ 4500-LV with MIX TM concept Extra yield part-load. Part-load conditions occur with lower irradiance, such as sunrise or sunset, dusk, heavy cloud, etc. The problem for single stage inverters is that efficiency drops significantly under part-load. The solution in the MIX™ concept is that two small power modules share the work. In part-load the “master” works Output Power in % alone. In full-load the irradiance increases and the “slave” is Increase in yield. The MIX™ concept turns part-load into full-load. Effi ciency rises and thus signifi cantly optimises yields in the partload range. switched on. However, the MIX™ concept offers even more advantages as the two power modules are used equally. The intelligent control system chooses a different master each day. This reduces the operating hours by up to 30 %. cristallin Maximum Power Point Tracking (MPPT) accuracy of 99.9 % MPP Current in A Fronius IG Module-Manager™ amorph Regardless of which PV modules you use; monocrystalline, poly or thin film, the intelligent Fronius IG Module-Manager MPP software quickly and efficiently finds the maximum power point (MPP). The software can react accurately to changes in sunlight levels and create the greatest possible energy yield from your array. For this reason, the Fronius IG family can always extract the maximum from all module types. Voltage in V The maximum. Fronius’ intelligent Module-Manager always fi nds the MPP. The result is always maximum yield. Features and Benefits Integrated DC/AC Disconnects. Each inverter comes with built-in DC and AC disconnects and in many cases eliminates the need for external disconnects reducing installation time and total system costs. With its lightweight and compact design, the Fronius IG can be easily lifted on or off the installation bracket. The standard knockouts and terminal strip saves time and expense when making electrical connections. Graphic Display and User Interface. Owning a PV system is great. Knowing exactly what it is doing is even better. A large, bright, easy to use LCD display comes standard with every Fronius IG inverter. You can view over 20 critical system parameters pertaining to the inverter and solar system operation. If a system fault has occurred, the display shows the reason for the problem, making it easy for the user or installer to troubleshoot and repair. Reliable-Rugged-Built to Last. Fronius IG inverters are built in an ISO 9001 facility. As a world leading manufacturer of HF welding equipment, Fronius builds products that can withstand the test of time in harsh environments with heavy use. That know-how is built into each and every Fronius IG inverter. Built to last by a company that has been around long enough to know. Plug and Play Digital Technology. Just like a Personal Computer, Fronius IG inverters come with 3 expansion slots that allow you to add features, such as external sensors and remote displays. Fronius DATCOM: Data Communication Features for your PV System. Remote data communications and data logging features can easily be added to transform your Fronius IG inverter into a sophisticated data Photo: Stromaufwärts acquisition system and weather monitoring station. For complete specifications and configurations please see the Fronius DATCOM Specification Sheet. Controlling Energy: Fronius IG The Fronius IG inverter has gained broad market acceptance due to its advanced High Frequency technology which offers high efficiency, precision MPP-tracking, and active cooling, all of which results in superior energy production from photovoltaic systems. High Efficiency + High Reliability + HF Technology + MPPT-Efficiency + Active Cooling All manufacturing, assembly and testing of the Fronius IG inverters occurs at Fronius’ ISO 9001 factory. The result - superior quality control, high product availability, and quick response time. = More energy harvested from your solar power system! Fronius IG Technical Data INPUT DATA 2000 3000 2500-LV 4000 5100 4500-LV 1.5 - 2.4 kWp 2.1 - 3.3 kWp 1.8 - 2.7 kWp 3.0 - 4.8 kWp 4.1 - 6.1 kWp 3.5 - 5.3 kWp 33.2 A 29.3 A Fronius IG Recommended PV-power Max. input voltage (at 1000 W/m² 14°F (-10°C) in open circuit operation) 500 V MPPT voltage range 150 ... 450 V Max. usable input current 13.6 A 18.0 A 16.9 A Admissible conductor size (DC) 26.1 A No. 14 - 4 AWG No. of DC input terminals 3 (screw terminals) No. of MPP trackers 1 2000 3000 2500-LV 4000 5100 4500-LV 2000 W 2700 W 2350 W 4000 W 5100 W 4500 W Fronius IG Nominal AC output voltage Operating AC voltage range default (-12 / +10 %) 208 V 240 V 208 V 212 - 264 V 183 - 229 V 212 - 264 V 183 - 229 V 8.3 A 11.3 A 11.3 A 16.7 A Max. continuous utility backfeed current Nominal output frequency 60 Hz Operating frequency range 59.3 - 60.5 Hz Total harmonic distortion (THD) Number of phases 4500-LV 94.5 % 93.5 % 1 GENERAL DATA No. 14 - 6 AWG Fronius IG 2000 Max. effi ciency 3000 2500-LV 95.2 % CEC effi ciency 93.5 % 4000 94.4 % 94.0 % 95.2 % 93.0 % 94.0 % Consumption in standby (night) 94.4 % < 0.15 W Consumption during operation 7W 12 W Enclosure type NEMA 3R Unit dimensions (W x H x D) 16.5 x 18.5 x 8.7 inch (418 x 470 x 223 mm) Weight 16.5 x 28.3 x 8.7 inch (418 x 720 x 223 mm) 26 lbs. (11.8 kg) Admissible ambient operating temperature 41.8 lbs. (19 kg) -13° ... +122°F (-25° ... +50°C) Cooling Controlled forced ventilation, variable speed fan Disconnects Standard Code Compliant DC & AC disconnects UL 1741-2005, IEEE 1547-2003, IEEE 1547.1, ANSI/IEEE C62.41, FCC Part 15 B, NEC Article 690, C22.2 No. 107.1-01 (September 2001), California Solar Initiative - Program Handbook - Appendix C: Inverter Integral 5 % Meter Performance Specifi cation PROTECTION DEVICES Ground fault protection Fronius IG 2000 3000 2500-LV 4000 5100 4500-LV Internal GFDI (Ground Fault Detector/Interruptor); in accordance with UL 1741-2010 and NEC Art. 690 DC reverse polarity protection Over temperature 5100 1 (at nominal output power) Admissible conductor size (AC) Islanding protection 21.6 A <5% Power factor (cos phi) Compliance 21.3 A 0A Internal diode Internal; in accordance with UL 1741-2005, IEEE 1547-2003 and NEC Output power derating / active cooling Fronius USA, LLC 10421 Citation Drive, Suite 1100 Brighton, MI 48116 E-Mail: pv-us@fronius.com www.fronius-usa.com YOUR FRONIUS DISTRIBUTOR SOLIGENT 800-967-6917 www.soligent.net Text and illustrations are technically correct at the time of going to print. The right to make modifications is reserved. This document may not be copied or reproduced in any form, not even in part, without prior written consent of Fronius International GmbH. Max. continuous output current 240 V 40,0006,2302 v02 2011 as09 OUTPUT DATA Maximum continuous output power @ 40°C