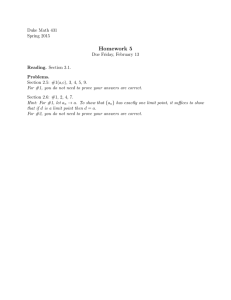

de-energised isolations checklist

advertisement

Title: DE-ENERGISED ISOLATIONS CHECKLIST Form: S2203 Version: 08/13 DE-ENERGISED ISOLATIONS CHECKLIST Prove effective isolation point on low voltage equipment during isolation To be used in conjunction with the requirements of the CS-PTW-01 Permit to Work Manual and CS-OHS-31 Electrical Safety Management Procedure. Scope of Work: Application: The act of testing to prove low voltage equipment is not energised as required by the Electrical Safety Regulation 2013 - Part 3 – Section 15 This work is restricted to proving effective isolation point by testing to prove de-energised. CHECKLIST ITEMS – To prove de-energised: 1. Authorised and Competent person must perform this work. CS-OHS-31 Electrical Safety Management, Section 2 Electrical Work. 2. A JSEA has been completed for the work to be performed. The point or points of contact has been identified and assessed as a low risk of coming into accidental contact with any live parts. This procedure cannot be used for any work where a risk rating for coming into accidental contact with any live part is higher than low. a) The JSEA has identified the electrical work; and b) specifies hazards associated with the electrical work and risks associated with those hazards; and c) describes the measures to be implemented to control the risks; and d) describes how the measures mentioned in paragraph (c) are to be implemented, monitored and reviewed. 3. The area where the testing to prove de-energised is clear of obstructions so as to allow for easy access and exit. 4. The Isolation point for the electrical equipment where the testing to prove de-energised is being conducted can be disconnected or isolated from the electricity supply is a) Clearly marked or labelled, and b) Cleared of obstruction so as to allow for easy access and exit by the worker who is to carry out the electrical work or any other competent person, and c) Capable of being operated quickly 5. Insulating gloves shall be worn with a minimum length of 360mm and be insulated to the highest potential expected. CS-OHS-34 Clause 2.3 6. A safety observer (electrical) is required to perform this work. Electrical Safety Regulation 2013 schedule 9 Definition of safety observer. 7. The electrical worker and the safety observer shall both have protection from arc flash to the level designated for the electrical work.CS-OHS-34 Clause 2.5, refer Arc flash implementation F/13/6627 and F/13/6628. 8. The testing method (including the tester used) must be safe and effective. The electrical worker carrying out the testing must understand testing procedures and be competent in the use of the tester. 9. a) The test device (CS-OHS-33 Section 2.12) must be tested for correct operation immediately before use. b) The test to prove de-energised is performed at each point of contact c) The test device must be tested for correct operation immediately after use. When conducting the testing method and a conclusive result can NOT be achieved, STOP work and obtain a permit for “Live electrical work” to investigate the source of supply. THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT Page 1 of 2 Title: DE-ENERGISED ISOLATIONS CHECKLIST Form: S2203 Version: 08/13 Testing to prove low voltage equipment is de-energised To be used in conjunction with the requirements of the CS-PTW-01 Permit to Work Manual and CS-OHS-31 Electrical Safety Management Procedure. Scope of Work: Application: The act of testing to prove low voltage equipment is not energised as required by the Electrical Safety Regulation 2013 - Part 3 – Section 15 (1) This work only applies to testing to prove de-energised at any time after the isolation has been proven. CHECKLIST ITEMS – To prove de-energised after isolation has been proven: 1. Authorised and Competent person must perform this work. CS-OHS-31 Electrical Safety Management, Section 2 Electrical Work. 2. A JSEA has been completed for the work to be performed. The point or points of contact has been identified and assessed as a low risk of coming into accidental contact with any live parts. This procedure cannot be used for any work where a risk rating for coming into accidental contact with any live part is higher that low. 3. a) The JSEA has identified the electrical work; and b) specifies hazards associated with the electrical work and risks associated with those hazards; and c) describes the measures to be implemented to control the risks; and d) describes how the measures mentioned in paragraph (c) are to be implemented, monitored and reviewed. The testing method (including the tester used) must be safe and effective. The electrical worker carrying out the testing must understand testing procedures and be competent in the use of the tester. a) The test device (CS-OHS-33 Section 2.12) must be tested for correct operation immediately before use. b) The test to prove de-energised is performed at each point of contact. c) The test device must be tested for correct operation immediately after use. 4. When conducting the testing method and a conclusive result can NOT be achieved, STOP work and obtain a permit for “Live electrical work” to investigate the source of supply. 5. A safety observer is not required to perform work under this standard procedure if the work is done in accordance with this standard procedure and the JSEA has been completed in accordance with (2) and has a residual risk rating for this work of “Low”. Electrical Safety Regulation 2013, section 22 (4) THIS DOCUMENT IS UNCONTROLLED IN HARD COPY FORMAT Page 2 of 2