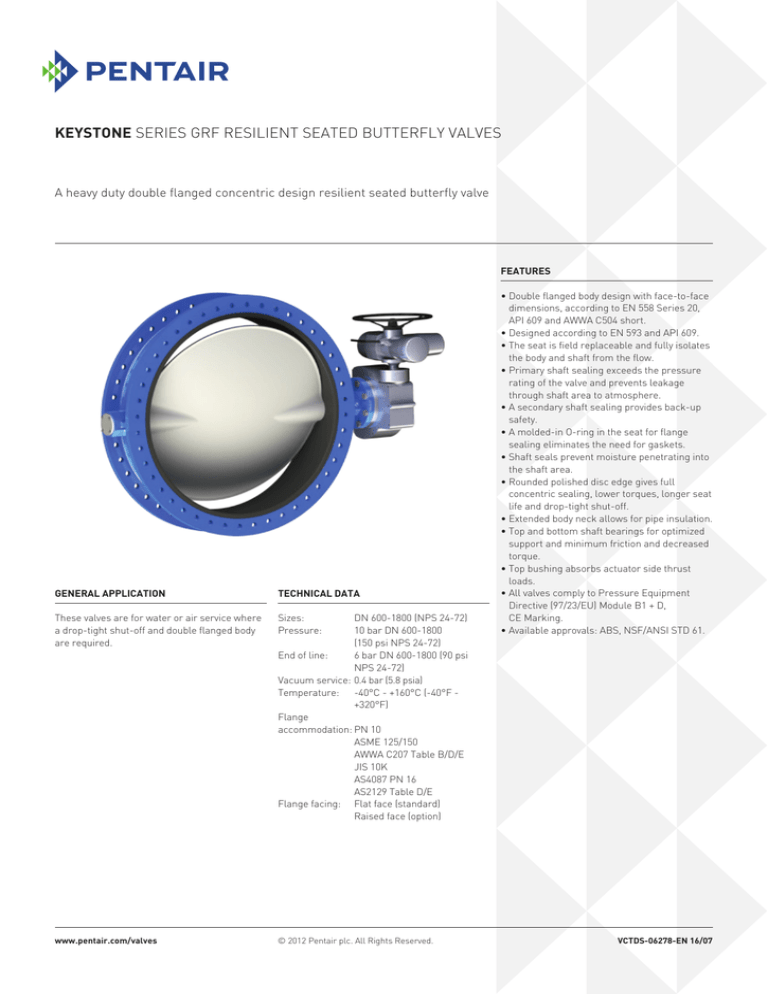

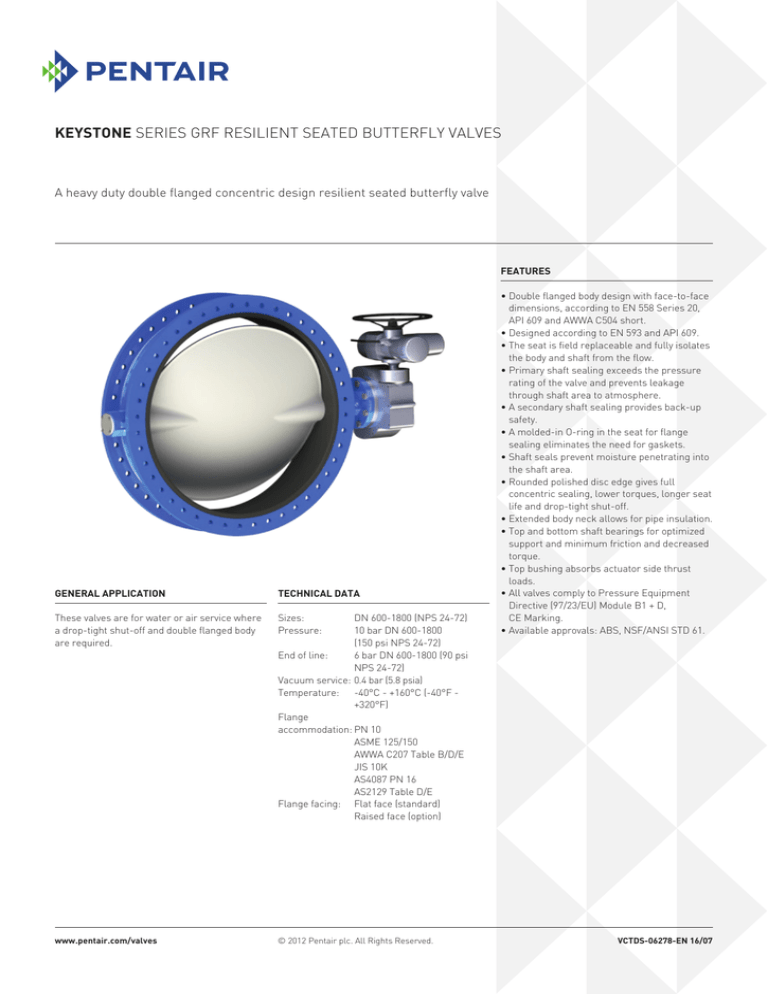

Keystone Series GRF Resilient Seated Butterfly Valves

A heavy duty double flanged concentric design resilient seated butterfly valve

Features

General application

Technical data

These valves are for water or air service where

a drop-tight shut-off and double flanged body

are required.

Sizes:

Pressure:

www.pentair.com/valves

© 2012 Pentair plc. All Rights Reserved.

DN 600-1800 (NPS 24-72)

10 bar DN 600-1800

(150 psi NPS 24-72)

End of line:

6 bar DN 600-1800 (90 psi

NPS 24-72)

Vacuum service:0.4 bar (5.8 psia)

Temperature: -40°C - +160°C (-40°F +320°F)

Flange

accommodation:PN 10

ASME 125/150

AWWA C207 Table B/D/E

JIS 10K

AS4087 PN 16

AS2129 Table D/E

Flange facing: Flat face (standard)

Raised face (option)

• Double flanged body design with face-to-face

dimensions, according to EN 558 Series 20,

API 609 and AWWA C504 short.

• Designed according to EN 593 and API 609.

• The seat is field replaceable and fully isolates

the body and shaft from the flow.

• Primary shaft sealing exceeds the pressure

rating of the valve and prevents leakage

through shaft area to atmosphere.

• A secondary shaft sealing provides back-up

safety.

• A molded-in O-ring in the seat for flange

sealing eliminates the need for gaskets.

• Shaft seals prevent moisture penetrating into

the shaft area.

• Rounded polished disc edge gives full

concentric sealing, lower torques, longer seat

life and drop-tight shut-off.

• Extended body neck allows for pipe insulation.

• Top and bottom shaft bearings for optimized

support and minimum friction and decreased

torque.

• Top bushing absorbs actuator side thrust

loads.

• All valves comply to Pressure Equipment

Directive (97/23/EU) Module B1 + D,

CE Marking.

• Available approvals: ABS, NSF/ANSI STD 61.

VCTDS-06278-EN 16/07

Keystone Series GRF Resilient Seated Butterfly Valves

Parts list

DN 600-1000

(NPS 24-40)

11

14

10

13

12

16

3

15

4

2

1

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Description

Body

Disc

Shaft

Seat

Disc screw

Disc screw O-ring

Plug

Plug circlip

Plug O-ring

Bushing

Body circlip

Shaft circlip

Body O-ring

Shaft O-ring

Bearing

Parallel key

Qty

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

6

5

15

9

7

8

Material specification

Part name

Body

Disc

Shaft

Seat

Disc screw

Disc screw O-ring

Plug

Plug circlip

Plug O-ring

Bushing

Shaft/Body circlip

Shaft/Body O-ring

Bearing

Material

Ductile iron

Ductile iron

Carbon steel

316 stainless steel

316 stainless steel

304 stainless steel

Duplex

Aluminium bronze

Nickel aluminium bronze

Ductile iron epoxy CTD

Ductile iron nylon CTD

Ductile iron FBE CTD

Ductile iron ebonite lined

431 stainless steel

Duplex

Super duplex

K500 Monel®

EPDM

NBR

Fluoroelastomer (FKM)

Duplex

EPDM

NBR

Fluoroelastomer (FKM)

Carbon steel

Stainless steel

NBR

Polyester

Stainless steel

NBR

PTFE/steel

Material specification

ASTM A536 Gr 65-45-12

ASTM A395 Gr 60-40-18

ASTM A216 WCB

ASTM A351 CF8M

ASTM A351 Gr CF8M - J92900

ASTM A351 Gr CF8 - J92600

ASTM A890 Gr 4A - J92205 - CD3MN

ASTM B148 C95200

ASTM B148 C95800

ASTM A536 Gr 65-45-12

ASTM A536 Gr 65-45-12

ASTM A536 Gr 65-45-12

ASTM A536 Gr 65-45-12

ASTM A276 Gr 431 S43100

ASTM A276 - S31803

ASTM A276 - S32750

ASTM B865 UNS N05500

Remark

Max. temp. 120°C (250°F)

Max. temp. 60°C (140°F)

Max. temp. 52°C (125°F) FBE - Fusion bond expoxy

Max. temp. 100°C (212°F)

(optional)

Food grade

Food grade

ASTM A276 - 531803

2

Keystone Series GRF Resilient Seated Butterfly Valves

Parts list

DN 1050-1800

(NPS 42-72)

10

14

13

6

12

16

17

18

3

11

1

15

4

2

5

Item

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Description

Body

Disc

Shaft

Seat

Bottom shaft

Through bolt

Bottom cover

Bottom cover screw

Bottom cover O-ring

Bushing

Bushing cover

Shaft circlip

Body O-ring

Shaft O-ring

Bearing

Parallel key

Parallel key disc shaft

Bushing cover screw

Lock nut

Qty

1

1

1

1

1

1

1

4

1

1

1

1

1

1

4

1

2

4

1

15

9

7

8

19

Material specification

Part name

Body

Disc

Shaft

Seat

Through bolt

Bottom cover

Bottom cover screw

Bottom cover O-ring

Bushing

Bushing cover

Shaft circlip

Shaft/Body O-ring

Bearing

Bushing cover screw

Lock nut

Material

Ductile iron

Ductile iron

Carbon steel

316 stainless steel

316 stainless steel

304 stainless steel

Duplex

Aluminium bronze

Nickel aluminium bronze

Ductile iron epoxy CTD

Ductile iron nylon CTD

Ductile iron FBE CTD

Ductile iron ebonite lined

431 stainless steel

Duplex

Super duplex

K500 Monel®

EPDM

NBR

Stainless steel

Ductile iron

Steel class 8.8 - Zinc plated/coated

NBR

Polyester

Steel

Stainless steel

NBR

PTFE/steel

Steel class 8.8 - Zinc plated/coated

Steel class 8 - Zinc plated/coated

Material specification

ASTM A536 Gr 65-45-12

ASTM A395 Gr 60-40-18

ASTM A216 WCB

ASTM A351 CF8M

ASTM A351 Gr CF8M - J92900

ASTM A351 Gr CF8 - J92600

ASTM A890 Gr 4A - J92205 - CD3MN

ASTM B148 C95200

ASTM B148 C95800

ASTM A536 Gr 65-45-12

ASTM A536 Gr 65-45-12

ASTM A536 Gr 65-45-12

ASTM A536 Gr 65-45-12

ASTM A276 Gr 431 S43100

ASTM A276 - S31803

ASTM A276 - S32750

Remark

Max. temp. 120°C (250°F)

Max. temp. 60°C (140°F)

Max. temp. 52°C (125°F) FBE - Fusion bond expoxy

Max. temp. 100°C (212°F)

(optional)

ASTM B865 UNS N05500

Food grade

Food grade

ASTM A536 Gr 65-45-12

3

Keystone Series GRF Resilient Seated Butterfly Valves

DN 600-1000

(NPS 24-40)

4 blind holes threaded

Valve dimensions (mm)

Size

(DN)

600

700

750

800

900

1000

A

585

684

734

784

884

984

B

825

925

995

1060

1175

1290

C

500

570

605

640

715

780

Shaft

D

154

165

165

190

203

216

E

210

210

210

300

300

350

F

108

108

108

140

140

129

J

459

518

551

583

659

706

L

6

6

6

6

6

6

M

651

754

810

857

957

1057

N

130

130

130

200

200

230

Q(1)

569

668

720

767

867

968

T

41

38

43

43

47

50

YY

670

775

835

880

980

1081

G

47.6

57.2

57.2

73.0

73.0

90.0

Valve dimensions (inches)

Size

(NPS)

24

28

30

32

36

40

A

23.03

26.93

28.89

30.85

34.79

38.74

B

32.48

36.42

39.17

41.73

46.26

50.79

C

19.69

22.44

23.82

25.20

28.15

30.71

D

6.06

6.50

6.50

7.48

7.99

8.50

Key

12.7 x 9.5

12.7 x 9.5

12.7 x 9.5

19.0 x 12.7

19.0 x 12.7

25.0 x 14.0

Shaft

E

8.27

8.27

8.27

11.81

11.81

13.78

F

4.25

4.25

4.25

5.51

5.51

5.08

J

17.97

20.41

21.69

22.95

25.94

27.80

L

0.24

0.24

0.24

0.24

0.24

0.24

M

25.64

29.67

31.91

33.76

37.67

42.63

N

5.12

5.12

5.12

7.87

7.87

9.06

Q(1)

22.41

26.29

28.35

30.22

34.12

38.11

T

1.62

1.50

1.69

1.69

1.85

1.97

YY

26.38

30.51

32.87

34.65

38.58

42.56

G

1.88

2.25

2.25

2.88

2.88

3.54

Top plate drilling

Tap

Bolt No.

Holes depth Adapt. Weight(2)

circle holes α

dia.

U

code

(kg)

165

4 45˚ 22.0

40

DAJ

227

165

4 45˚ 22.0

40

DAK

293

165

4 45˚ 22.0

40

DAK

350

254

8 22.5˚ 17.5

48

KAV

430

254

8 22.5˚ 17.5

48

KAV

552

298

8 22.5˚ 22.0

48

F30

732

Top plate drilling

Bolt No.

Holes

Key

circle holes α

dia.

½x⅜

6.5

4 45˚ 0.87

½x⅜

6.5

4 45˚ 0.87

½x⅜

6.5

4 45˚ 0.87

¾x½

10.0

8 22.5˚ 0.69

¾x½

10.0

8 22.5˚ 0.69

0.98 x 0.55 11.7

8 22.5˚ 0.87

Tap

depth

U

1.57

1.57

1.57

1.89

1.89

1.89

Adapt. Weight(2)

code

(lbs)

DAJ

500

DAK

646

DAK

772

KAV

948

KAV

1217

F30

1614

Notes

1. ‘Q’ dimension is the minimum allowable pipe or flange inside diameter at the centered body face to protect the disc sealing edge against damage when opening the valve.

2. Weight may vary depending on trim materials used.

3. See installation, operation and maintenance manual (IOM) for detailed bolting information.

4

A

Q

M

YY

mm D mm A mm

mm Q

NPS

Q M

A

M

YY

1060

in mmmm1132

mmmm 1015

mmmm 1149,5

mmmm

1172,5

1155

1083

1038

1015

42 1060251 11321060 10151132 1149,5

1184

44

1038

1172,5

115510831137

10832541256

103811551273,5

48

1137

1273,5

1327

11842761399

125611841256

113712561416,5

54

1256

1416,5

13273811453

139913271338

125613991470,5

1381

56

1338

1470,5

13812801554

145313811417

133814531571,5

1482

60

1417

1571,5

155414821544

14823811663

141715541680,5

1591

1544

64

1680,5

154416631753,5

15913181736

166315911585

1664

66 1664457 17361664 158517361874,5

1585

1753,5

1785

1857

1711

0

72 1785457 18571785 17111857 1874,5

1711

72 180 457

B

T

mmYY

mm

B

T B

42,mm

5

1345

mmmm mm

42,

5

1405

1149,5 42,

51345

1345

1172,5 42,45

1510

51405

1405

1273,5 4546

1510

1685

1510

1416,5 4646

1685

1685

1745

1470,5 46

1745

47,1745

5

1855

1571,5 47,49

51855

1855

1910

1680,5

1910

1910

4950

2032

1753,5 50 2032

2032

2195

52

1874,5

J

C

mm

C T

780

mm

mm

815

42, 5

780

42, 5

870

815

45

975

870

46

975

1010

46

1010

1080

47, 5

1080

1150

49

1150

1185

50

1185

1290

52 2195 1290 52

G

mm

J C

mm

mm745

780

745777

815

777845

870

845895

975

895918

1010

918989

1080

9891038

1150

1038

1082

1185

1082

1209

12091290

R

mm

G J

90

mm mm

100

90 745

100

100 777

100

100 845

100 895

110

110 918

130

130 989

140

1038

140 140

1401082

160

1601209

F

TopplateSize

E

mm

mm

mm E

1E

TopplateSize

FISO521

R G

F R TopplateSize

P

95 mmmm

115ISO521

mm1 F30 ISO521

mmmm

mm 1350

mm mm

115

106

F30

115

F30 350

95 90 115 95

F30

350

30 350

106 115 106

130 F30

115 F30 350

F30 350

106 100

30 350

130 F30 350

F30 415

106 130 106

165 F30

106 100

30 350

165 F35 415

F30 415

45 415

106 100

165 F30

117 165 106

165 F35 415

F35 415

45 415

117 110

165 F35

138 165 117

165 F35 415

F35 415

45 415

138 130

148 165 138

165 F35

165 F35 415

F35 415

45 415

148 140

148 165 148

165 F35

148

165

F35

45 415

148 140

475

169 165 185 F35 F35 415

185

F35

475

54 475

169 160 185 169

F35

Keystone Series GRF Resilient Seated Butterfly Valves

180 0

2195

P

mm P

N

30

mmmm

30

230 30

30

230 30

45

230 30

260 45

45

260 45

45

260 45

45

260 45

45

260 45

54

300 54

N

mm N

L

230

mm mm

230

6 230

230

6 230

260

6 230

6 260

260

6 260

260

6 260

260

6 260

260

6 260

300

L

PCD

Hole dia

mm

Hole dia

No

22

mm

22

822

22

822

22

833

33

833

33

833

33

833

33

833

33

839

mm

mm

PCD L Hole PCD

dia

6 mm mm

298

mm

mm

6

298

298 6

22298

6 6

298

298

22298

6 6

356

298

22298

356

33356

6 6

356

356

33356

6 6

356

356

33356

6 6

356

356

33356

6 6

356

6

356

33356

9

406

9 300 406 9

39406

8 39

α

No

Weight

Hole dia

mm

22

22

22

33

33

33

33

33

39

α

°

22, 5

22, 5

22, 5

22, 5

22, 5

22, 5

22, 5

22, 5

22, 5

No

8

8

8

8

8

8

8

8

8

Weight

kg

735

855

1025

1406

1421

1786

1863

2243

2828

ØE

PCD

mm

298

298

298

356

356

356

356

a356

406

PCD

L

mm

6

6

6

6

6

6

6

6

9

ØN

ØE

N

mm

230

230

230

260

260

260

260

260 a

300 a

PCD

ØE

P

mm

30

30

30

45

45

45

45

45

54

ØN

E

mm

350

350

350

415

415

415

415

415

475

ØN

PCD

D

TopplateSize

ISO521 1

F30

F30

F30

F30

F35

F35

F35

F35

F35

T

D

F

mm

115

115

130

165

165

165

165

165

185

T

R

mm

95

106

106

106

117

138

148

148

169

D

G

mm

90

100

100

100

110

130

140

140

160

T

J

mm

745

777

845

895

918

989

1038

1082

1209

Key width

mm

25

28

28

28

32

36

36

36

40

ØG

Key height Key length

mm

mm

110

14

16

110

16

125

16

160

160

18

20

160

20

160

20

160

22

180

R

R

ØG

R

F

F

L

F

L

P

L

P

B

M

YY

A

B

M

Q

YY

A

Q

C

C

C

ØE

B

YY

A

Q

J

J

J

F

L

M

R

ØG

P

C

KEYSTONE

D

KEYSTONE

All information hereon is ofAlla information

proprietary hereon

nature is of a proprietary nature

confidential

the prop

confidential and the prop erty

of Pen tairand

Valves

& erty of Pen tair Valves &

Controls

B.V. loaned

Controls B.V. loaned to others

for expres

se d to others for expres sed

purposes

onl yced

and

purposes onl y and sh all not

be reprodu

orsh all not be reprodu ced or

disclosed

thout

written

disclosed wi thout written consen

t ofwithe

comp

any. consen t of the comp any.

D

KEYSTONE

Valve dimensions (mm)

YY

A

M

D

Q

Shaft

A

B

C

D

E

F

J

L

M

1050

1100

1200

1350

1400

1500

1600

1650

1800

1060

1083

1184

1327

1381

1482

D

1591

1664

1785

1345

1405

1510

1685

1745

1855

1910

2032

2195

780

815

870

975

1010

1080

1150

1185

1290

251

254

276

381

280

381

318

457

457

350

350

350

415

415

415

415

415

475

115

115

130

165

165

165

165

165

185

745

777

845

895

918

989

1038

1082

1209

6

6

6

6

6

6

6

6

9

1132

1155

1256

1399

1453

1554

1663

1736

1857

B

Size

(DN)

J

ØN

P

ØG

4 blind holes threaded

N

P

Q(1)

230 30 1015

230 30 1038

230 30 1137

260 45 1256

260 45 1338

KEYSTONE

260 45 1417

260 45 1544

260 45 1585

300 54 1711

R

T

YY

G

Key

95

106

106

106

117

138

148

148

169

42.5

42.5

45.0

46.0

46.0

47.5

49.0

50.0

52.0

1149.5

1172.5

1273.5

1416.5

1470.5

1571.5

1680.5

1753.5

1874.5

90

100

100

100

110

130

140

140

160

25 x 14

28 x 16

28 x 16

28 x 16

28 x 16

32 x 18

36 x 20

36 x 20

40 x 22

All information hereon is of a proprietary nature

confidential and the prop erty of Pen tair Valves &

Controls B.V. loaned to others for expres se d

purposes onl y and sh all not be reprodu ced or

disclosed wi thout written consen t of the comp any.

Valve dimensions (inches)

Size

(NPS)

42

44

48

54

56

60

64

66

72

A

41.73

42.64

46.61

52.24

54.37

58.35

62.64

65.51

70.28

B

52.95

55.32

59.45

66.34

68.70

73.03

75.20

80.00

86.42

C

30.71

32.09

34.25

38.39

39.76

42.52

45.28

46.65

50.79

D

9.88

10.00

10.87

15.00

11.02

15.00

12.52

17.99

17.99

E

13.78

13.78

13.78

16.34

16.34

16.34

16.34

16.34

18.70

Top plate drilling

Key

Bolt

No.

Holes

length circle holes α

dia.

110

110

125

160

160

160

160

160

180

298

298

298

356

356

356

356

356

406

Shaft

F

4.53

4.53

5.12

6.50

6.50

6.50

6.50

6.50

7.28

J

29.33

30.59

33.27

35.24

36.14

38.94

40.87

42.60

47.60

L

0.24

0.24

0.24

0.24

0.24

0.24

0.24

0.24

0.35

M

44.57

45.47

49.45

55.08

57.21

61.18

65.47

68.35

73.11

N

9.06

9.06

9.06

10.24

10.24

10.24

10.24

10.24

11.81

P

1.18

1.18

1.18

1.77

1.77

1.77

1.77

1.77

2.13

Q (1)

39.96

40.87

44.76

49.45

52.68

55.79

60.79

62.40

67.36

R

3.74

4.17

4.17

4.17

4.61

5.43

5.83

5.83

6.65

T

1.67

1.67

1.77

1.81

1.81

1.87

1.93

1.97

2.05

YY

45.26

46.16

50.14

55.77

57.89

61.87

66.16

69.04

73.80

G

3.54

3.94

3.94

3.94

4.33

5.12

5.51

5.51

6.30

Key

0.98 x 0.55

1.10 x 0.63

1.10 x 0.63

1.10 x 0.63

1.10 x 0.63

1.26 x 0.71

1.42 x 0.79

1.42 x 0.79

1.58 x 0.87

Key

length

4.33

4.33

4.92

6.30

6.30

6.30

6.30

6.30

7.09

8

8

8

8

8

8

8

8

8

22.5

22.5

22.5

22.5

22.5

22.5

22.5

22.5

22.5

22

22

22

33

33

33

33

33

39

All information hereon is of a proprietary nature

confidential and the prop erty of Pen tair Valves &

Controls B.V. loaned to others for expres sed

purposes onl y and sh all not be reprodu ced or

disclosed wi thout written consen t of the comp any.

Tap

depth Adapt.

U

code

42.5

42.5

45.0

46.0

46.0

47.5

49.0

50.0

52.0

Top plate drilling

Bolt No.

Holes

circle holes α dia.

11.73

8 22.5 0.87

11.73

8 22.5 0.87

11.73

8 22.5 0.87

14.02

8 22.5 1.30

14.02

8 22.5 1.30

14.02

8 22.5 1.30

14.02

8 22.5 1.30

14.02

8 22.5 1.30

15.98

8 22.5 1.54

F30

F30

F30

F35

F35

F35

F35

F35

F40

Tap

depth

U

1.67

1.67

1.77

1.81

1.81

1.87

1.93

1.97

2.05

Key widt

kg Keyheight

mm K

width

α No Weightα° Key Weight

width Key

5 mmkg

8

735

mm25

kg 22,

mm

°

°

22,

5

8

855

22,

5

22, 5 8

735

25735

1425 28

22,55

1025

22, 5 8

85522,

28855

1628 28

22,

22,55

1025

1406

22, 5 88

1025

28

1628 28

22,

1406

22, 5 8

22,55

1406

1628 32

28

1421

22,

1421

22, 5 88

1421

32

1832 36

22,55

1786

22,

1786

22, 5 88

1786

36

2036 36

22,55

1863

22,

1863

22, 5 88

1863

36

2036 36

22,55

2243

22, 5

2243

22, 5 8

2243

36

2036 40

22, 5

8

2828

22, 5

2828

22, 5 8

2828

40

2240

DN 1050-1800

(NPS 42-72)

PCD

0

0

0

5

0

DN

NPS

D

mm

in NPS mm

DN D

DN

105 0 mm 42 in 251

mmmm

110 0105 0 44 42 254

105 251

0

120 0110 0 48 44 276

110 254

0

120 276

0

135 0120 0 54 48 381

135 381

0

140 0135 0 56 54 280

140 280

0

150 0140 0 60 56 381

150 381

0

160 0150 0 64 60 318

160

0

165 0160 0 66 64 457318

165 0

180 0165 0 72 66 457457

Weight(2)

(kg)

735

855

1025

1406

1421

1786

1863

2243

2828

Adapt. Weight (2)

code

(lbs)

F30

1620

F30

1885

F30

2260

F35

3100

F35

3133

F35

3937

F35

4107

F35

4945

F40

6235

Notes

1. ‘Q’ dimension is the minimum allowable pipe or flange inside diameter at the centered body face to protect the disc sealing edge against damage when opening the valve.

2. Weight may vary depending on trim materials used.

3. See installation, operation and maintenance manual (IOM) for detailed bolting information.

5

Keystone Series GRF Resilient Seated Butterfly Valves

Metric tables

Torque application factor categories

Application I

Clean liquid lubricating media (water, clean oils, lube oil, mineral oil, etc.); and with no deposit or chemical attack, valve operated at least once a week.

Temperature range from 0°C (32°F) to maximum temperature rating of the elastomer seat.

Application II

Other liquid media and lubricating gases (aqueous liquids, such as food and beverage, water, etc.); and with minor deposit or chemical attack,

valve operated at least once a month.

Temperature range from 0°C (-14°F) to maximum temperature rating of the elastomer seat.

Application III

a. Dry non-abrasive media or gases (non-abrasive powders and dry gas); or

b. Fluids with moderate deposit or chemical attack; or

c. Valves operated less than once a month.

Temperature range from 0°C (32°F) to maximum temperature rating of the elastomer seat.

Application IV

a. Dry abrasive media and degreasing applications (sand, cement, silicone free, oxygen cleaned); or

b. Liquids with severe deposit; or

c. Valves not frequently operated (once a year).

All above with temperature range from -10°C (-14°F) to maximum temperature rating of the elastomer seat.

Notes

1. For applications with temperatures above or below the guidelines above, please consult factory.

2. For dry service valves it is suggested to use U/C discs (reduced diameter) when service conditions are less than 3.5 bar (50 psi).

Valve seating and unseating torques (Nm)

Application

ΔP (bar)

I

3.5

7

10

3.5 (U/C)

II

3.5

7

10

3.5 (U/C)

III

3.5

7

10

3.5 (U/C)

IV

3.5

7

10

3.5 (U/C)

600

700

1700

1979

2373

1020

Valve size (DN)

1050

1100

1200

750

800

900

1000

1350

1400

1500

1600

1650

1800

2494

2943

3575

1497

2967

3521

4302 (1)

1780

3495

4169

5120

2097

4422

5275

6479

2653

5831

7022

8704

3498

6428

7742

9595

3857

7505

9114

11385

4503

8931

10846

13548

5359

11982

14657

18433

7189

12885

15762

19824

7731

16469

20393

25935

9881

19692

24511

31316

11815

20942

26066

33304

12565

27338

34331

44212

16403

1877

2153

2542

1126

2736

3180

3804

1642

3245

3793

4565 (1)

1947

3811

4479

5419

2287

4822

5667

6858

2893

6325

7506

9172

3795

6973

8275

10111

4184

8103

9699

11951

4862

9643

11542

14222

5786

12882

15538

19286

7729

13854

16710

20741

8312

17581

21481

26988

10548

20957

25749

32514

12574

22287

27383

34578

13372

28938

35898

45728

17363

2055

2328

2710

1233

2978

3417

4034 (1)

1787

3523

4065 (1)

4828 (1,2)

2114

4127

4788

5719 (2)

2476

5222

6059

7237

3133

6819

7990

9640

4091

7517

8808

10627

4510

8701

10285

12518

5221

10354

12239

14896

6212

13782

16420

20139

8269

14822

17658

21658

8893

18692

22569

28041

11215

22221

26987

33713

13333

23632

28699

35852

14179

30539

37465

47244

18323

2322

2589

2963

1393

3341

3772

4378 (1)

2005

3940

4473 (1)

5223 (1,2)

2364

4601

5252

6168 (2)

2761

5822

6646

7805

3493

7560

8715

10342

4536

8334

9608

11401

5001

9598

11162

13367

5759

11421

13283

15907

6853

15133

17742

21418

9080

16274

19080

23034

9765

20359

24202

29621

12216

24118

28844

35510

14471

25649

30674

37763

15389

32940

39815

49519

19764

Notes

3.5 U/C refers to reduced diameter disc option.

1. Use a minimum of Class 8.8 steel bolts to connect actuator to valve.

2. Duplex shaft not suitable for these conditions, use only 431 stainless steel or super duplex.

Maximum allowable shaft torques (Nm)

Shaft material

431SS (ASTM A276 - Gr 431 S43100)

Duplex (ASTM A276 - S31803)

Super duplex (ASTM A276 - S32750)

600

700

750

800

5086

3815

4366

6312

4734

5418

7128

5346

6118

7088

5316

6084

900

1000

1050

14740 18900 16065

11055 14175 12049

12652 16233 13789

Valve size (DN)

1100

1200

19680

14760

16892

23280

17460

19982

1350

1400

1500

1600

1650

1800

34848

26136

29911

34848

26136

29911

44928

33696

38563

52080

39060

44702

52080

39060

44702

73920

55440

63448

6

Keystone Series GRF Resilient Seated Butterfly Valves

Imperial tables

Valve seating and unseating torques (in lbs)

Application

ΔP (psi)

I

50

100

150

50 (U/C)

II

50

100

150

50 (U/C)

III

50

100

150

50 (U/C)

IV

50

100

150

50 (U/C)

Valve size (NPS)

42

44

48

24

28

30

32

36

40

54

56

60

66

72

15043

17518

21007

9026

22076

26045

31641

13246

26264

31164

38074 (1)

15758

30933

36899

45315

18560

39137

46688

57340

23482

51608

62153

77033

30960

56893 66429 79048 106048 114045 145764 174289

68519 80668 95994 129723 139507 180496 216937

84924 100766 119912 163148 175453 229545 277173

34136 39858 47429 63629 68427 87458 104574

185350

230705

294764

111210

241959

303858

391305

145175

16617

19059

22498

9970

24218

28142

33670

14531

28723

33572

40404 (1)

17234

33731

39638

47966

20239

42679

50155

60695

25607

55980

66433

81175

33589

61713 71720 85344 114016 122615 155601 185482 197253

73238 85847 102157 137524 147896 190126 227894 242357

89491 105778 125876 170697 183572 238865 287777 306041

37028 43032 51206 68410 73569 93361 111289 118352

256125

317726

404726

153675

18191

20600

23989

10915

26361

30239

35700 (1)

15817

31183

35979 (1)

42734 (1,2)

18710

36529

42378

50617 (2)

21918

46220

53622

64050

27732

60352

70713

85317

36208

66534 77010 91640 121985 131185 165439 196675 209157

77957 91027 108321 145325 156286 199757 238852 254010

94057 110790 131841 178246 191690 248185 298381 317318

39920 46206 54984 73191 78711 99263 118005 125494

270291

331594

418147

162175

20552

22912

26226

12331

29575

33385

38744 (1)

17745

34872

39591 (1)

46229 (1,2)

20923

40727

46487

54593 (2)

24436

51533

58823

69083

30920

66911

77134

91530

40147

73764 84946 101084 133937 144039 180195

85035 98795 117566 157026 168870 214203

100907 118308 140788 189569 203868 262165

44259 50967 60650 80362 86423 108117

64

213465

255288

314287

128079

227012

271490

334234

136207

291540

352396

438277

174924

Notes

50 U/C refers to reduced diameter disc option.

1. Use a minimum of ASTM A193 Grade B7 steel bolts to connect actuator to valve.

2. Duplex shaft not suitable for these conditions, use only 431 stainless steel or super duplex.

Maximum allowable shaft torques (in lbs)

Shaft material

431SS (ASTM A276 - Gr 431 S43100)

Duplex (ASTM A276 - S31803)

Super duplex (ASTM A276 - S32750)

Valve size (NPS)

24

28

30

32

36

40

42

44

48

54

56

60

64

66

72

45010 55860 63100 62750 130500 167279 142187 174183 206045 308431 308431 397646 460947 460947 654247

33770 41900 47300 47050 97900 125459 106643 130637 154534 231323 231323 298235 345710 345710 490685

38640 47950 54150 53850 112000 143674 122043 149507 176856 264735 264735 341311 395646 395646 561562

7

Keystone Series GRF Resilient Seated Butterfly Valves

Metric tables

Flowrate co-efficients - Kv values

Size (DN)

10°

20°

30°

40°

Disc opening (degrees)

50°

60°

70°

80°

90°

600

700

750

800

900

1000

1050

1100

1200

1350

1400

1500

1600

1650

1800

349

475

545

620

785

969

1068

1172

1395

1766

1899

2180

2480

2638

3139

894

1216

1396

1589

2011

2483

2737

3004

3575

4524

4866

5586

6355

6759

8043

1871

2547

2924

3327

4211

5197

5732

6290

7486

9475

10189

11697

13309

14153

16844

3357

4569

5245

5968

7553

9325

10280

11283

13428

16994

18276

20981

23871

25386

30212

5689

7744

8890

10114

12801

15803

17423

19122

22757

28802

30975

35558

40457

43025

51204

9140

12440

14281

16248

20564

25389

27656

30353

36122

45717

49167

56441

64218

68294

81275

14723

20040

23005

26174

33127

40897

50010

54886

65319

82670

88907

102061

116123

123494

146968

26357

35875

41183

46857

59303

73214

85811

94178

112079

141850

152552

175124

199252

211900

252178

30583

41626

47785

54369

68811

84953

95862

105209

125208

158466

170422

195637

222591

236721

281717

Note

Kv = The volume of water in m3/hr that will pass through a valve with a pressure drop of 1 bar at 20°C

Pressure-temperature diagram

Seat material

Disc

material

EPDM

All metal

EPDM

All metal

NBR/NBR white All metal

FKM

All metal

Size range Valve

(DN)

rating**

Body material

DI A536 65-45-12/ CS A216

WCB/ SS A351 CF8M

DI A395 60-40-18

DI A536 65-45-12/ CS A216

WCB/ SS A351 CF8M

DI A536 65-45-12/ CS A216

WCB/ SS A351 CF8M

600-1800

Std / EOL

600-1800

Std / EOL

600-1800

Std / EOL

600-1000

Std / EOL

­

-40

-28

-18

0

Temperature (°C)

50

100

120

130

150

160

10 bar / 6 bar

10 bar / 6 bar

10 bar / 6 bar

10 bar / 6 bar

6 bar / 4 bar

** Standard / End of line

Temperature performance coated disc

Disc material

DI A536 65-45-12 / A395 60-40-18

DI A536 65-45-12 / A395 60-40-18

DI A536 65-45-12 / A395 60-40-18

DI A536 65-45-12 / A395 60-40-18

Coating

DI epoxy coated

DI nylon coated

DI FBE coated

DI ebonite coated

Size range (DN)

600-1800

600-1800

600-1800

600-1800

°C

-28 to 120 / -40 to 120

-28 to 60 / -40 to 60

-28 to 52 / -40 to 52

-28 to 100 / -40 to 100

Possible flange drillings

Flange drilling

EN 1092

ISO 2084

ASME B16.5

ASME B16.1

ASME B16.47A

AWWA C207

MSS SP44

ASME B16.47B

JIS B2210

JIS B2210

AS2129

AS4087

AS2129

600

PN 10

PN 10

Class 150

Class 125

Class 150

Table B/D/E

Class 150

Class 150

10K

5K

Table D

PN 16

Table E

700

750

N/A

N/A

800

900

N/A

Valve size (DN)

1050

1100 1200

N/A

N/A

See B16.47A

N/A

N/A

1000

1350

N/A

N/A

1400

1500

N/A

1600

1650

N/A

N/A

N/A

N/A

N/A

N/A

See B16.5

Notes

Standard possible for all versions

O

Optional, contact factory

N/A Not applicable

N/A

N/A

O

O

O

O

O

O

N/A

N/A

N/A

N/A

N/A

N/A

O

O

O

O

O

O

N/A

N/A

O

N/A

N/A

1800

N/A

N/A

N/A

N/A

N/A

N/A

N/A

O

O

N/A

N/A

N/A

Data is valid for flat face flanges. For raised face, please consult factory.

DN 1600 is not available with ASME drilling. See above chart for drilling details.

See installation, operations and maintenance manual (IOM) for detailed bolting information.

8

Keystone Series GRF Resilient Seated Butterfly Valves

Imperial tables

Flowrate co-efficients - Cv values

Size (NPS)

10°

20°

30°

40°

Disc opening (degrees)

50°

60°

70°

80°

90°

24

28

30

32

36

40

42

44

48

54

56

60

64

66

72

403

549

630

717

908

1120

1235

1355

1613

2041

2195

2520

2867

3049

3629

1034

1406

1614

1837

2325

2871

3164

3473

4133

5231

5625

6458

7347

7814

9299

2163

2945

3380

3846

4868

6008

6626

7272

8654

10953

11780

13523

15386

16362

19472

3881

5282

6064

6899

8732

10780

11885

13044

15523

19647

21129

24255

27597

29349

34927

6577

8953

10277

11692

14799

18269

20143

22107

26309

33297

35809

41108

46771

49740

59195

10566

14382

16510

18784

23773

29351

31973

35090

41760

52853

56840

65250

74240

78953

93960

17021

23168

26595

30259

38297

47280

57815

63452

75514

95572

102782

117990

134246

142768

169906

30471

41474

47610

54170

68558

84640

99203

108876

129571

163989

176361

202455

230349

244971

291535

35356

48123

55243

62854

79550

98212

110823

121629

144749

183198

197019

226170

257331

273666

325685

Note

Cv = The volume of water in U.S.gpm that will pass through a valve with a pressure drop of 1 psi at 60°F

Pressure-temperature diagram

Seat material

Disc

material

EPDM

All metal

EPDM

NBR/NBR

white

All metal

FKM

All metal

All metal

Body material

DI A536 65-45-12/ CS A216 WCB/

SS A351 CF8M

DI A395 60-40-18

DI A536 65-45-12/ A395 60-40-18/

CS A216 WCB/ SS A351 CF8M

DI A536 65-45-12/ A395 60-40-18/

CS A216 WCB/ SS A351 CF8M

Size range Valve

(NPS)

rating**

24-72

Std / EOL

24-72

Std / EOL

24-72

Std / EOL

24-40

Std / EOL

­

-40

-20

0

32

Temperature (°F)

122

212

248

266

302

320

150 psi / 90 psi

150 psi / 90 psi

150 psi / 90 psi

150 psi / 90 psi

90 psi / 60 psi

** Standard / End of line

Temperature performance coated disc

Disc material

DI A536 65-45-12 / A395 60-40-18

DI A536 65-45-12 / A395 60-40-18

DI A536 65-45-12 / A395 60-40-18

DI A536 65-45-12 / A395 60-40-18

Coating

DI epoxy coated

DI nylon coated

DI FBE coated

DI ebonite coated

Size range (NPS)

24-72

24-72

24-72

24-72

Possible flange drillings

Flange drilling

EN 1092

ISO 2084

ASME B16.5

ASME B16.1

ASME B16.47A

AWWA C207

MSS SP44

ASME B16.47B

JIS B2210

JIS B2210

AS2129

AS4087

AS2129

24

PN 10

PN 10

Class 150

Class 125

Class 150

Table B/D/E

Class 150

Class 150

10K

5K

Table D

PN 16

Table E

28

30

N/A

N/A

32

36

N/A

°F

-20 to 250 / -40 to 250

-20 to 140 / -40 to 140

-20 to 125 / -40 to 125

-20 to 212 / -40 to 212

Valve size (NPS)

42

44

48

N/A

N/A

See B16.47A

N/A

N/A

40

54

N/A

N/A

56

60

N/A

64

N/A

72

N/A

See B16.5

Notes

Standard possible for all versions

O

Optional, contact factory

N/A Not applicable

66

N/A

N/A

N/A

N/A

N/A

N/A

O

O

O

O

O

O

N/A

N/A

N/A

N/A

N/A

N/A

O

O

O

O

O

O

N/A

N/A

O

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

O

O

N/A

N/A

N/A

Data is valid for flat face flanges. For raised face, please consult factory.

NPS 64 is not available with ASME drilling. See above chart for drilling details.

See installation, operations and maintenance manual (IOM) for detailed bolting information.

9

Keystone Series GRF Resilient Seated Butterfly Valves

Selection guide

Example

Series

GR

GR

F

600

D

1

2

E

A1

K(2)

B0

UC

Body style

F

Flanged

Size DN (NPS)

600 (24)

800 (32)

700 (28)

900 (36)

750 (30)

1000 (40)

1050 (42)

1100 (44)

1200 (48)

1350 (54)

1400 (56)

1500 (60)

1600 (64)

1650 (66)

1800 (72)

Body material

D

Ductile iron ASTM A536

N

Ductile iron ASTM A395

S

W

Carbon steel ASTM A216

N

Nickel aluminium bronze

E

W

Q

Ductile iron / FBE CTD(3)

Ductile iron / nylon CTD

Ductile iron / ebonite lined

7

L

Super duplex

K500 Monel®

316 stainles steel

Disc material

1

316 stainless steel

2

3

5

6

304 stainless steel

Aluminum bronze

Ductile iron / epoxy CTD (DN 350-900/NPS 14 - 36)

Duplex

Shaft

2

431 stainless steel

6

Duplex

Seat

E

EPDM (Food grade)

N NBR (Food grade)

F

Fluoroelastomer (FKM)(1)

Flange drilling

A1 ASME 125/150

AW AWWA C207 Table B/D/E

D2 DIN PN 10

J2 JIS 10K

AD AS4087 PN 16 (AS2129 Table D)

AE AS2129 Table E

Mounting

K

Keystone mount (for DN 600-900/NPS 24-36)

I

ISO 5211 (for DN 1000-1800/NPS 40-72)

Actuation

B0 Bare shaft

G1 Gear

C1 Chainwheel

P1

P2

E

Pneumatic DA

Pneumatic SR

Electric

Special (If none leave blank)

UC Under cut disc for 3.5 bar or less pressure

NSF NSF/ASME STD 61

P

Special body coating

MTR Material certifications

NP Non PED certified

Notes

1. Fluoroelastomer (FKM) available in size up to DN 1000 (NPS 40) only.

2. Valves in size DN 600-900 (NPS 24-36) are Keystone topplate mounting.

Valves in size DN 1000-1800 (NPS 40-72) are ISO 5211 topplate mounting.

3. FBE = Fusion bond epoxy

10

PENTAIR VALVES & CONTROLS

www.pentair.com/valves

All Pentair trademarks and logos are owned by Pentair plc. All other brand or product names are trademarks or registered marks of their respective owners.

Because we are continuously improving our products and services, Pentair reserves the right to change product designs and specifications without notice.

Pentair is an equal opportunity employer. © 2016 Pentair plc. All rights reserved.