TECHNICAL

PROCEDURE

QUIK-DRAW® PNEUMATIC

PIN-PULL MECHANISM

SUBJECT: Operating, Maintenance and Retrofit

Procedures

LIT NO: L738

DATE: March 2005

REVISION: B

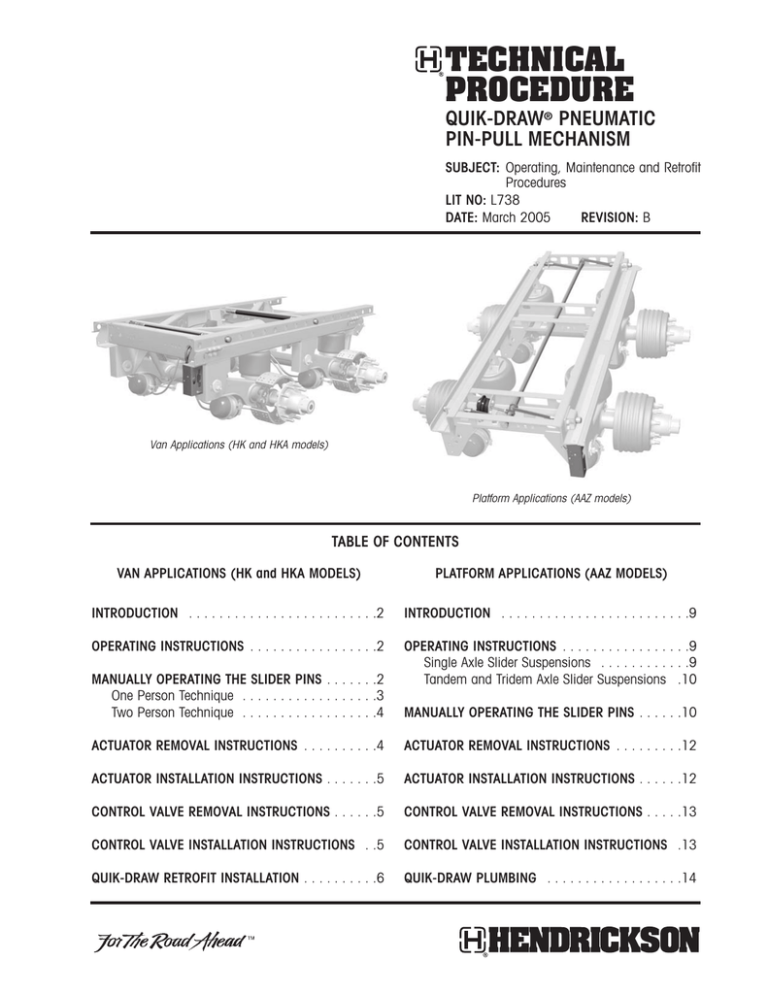

Van Applications (HK and HKA models)

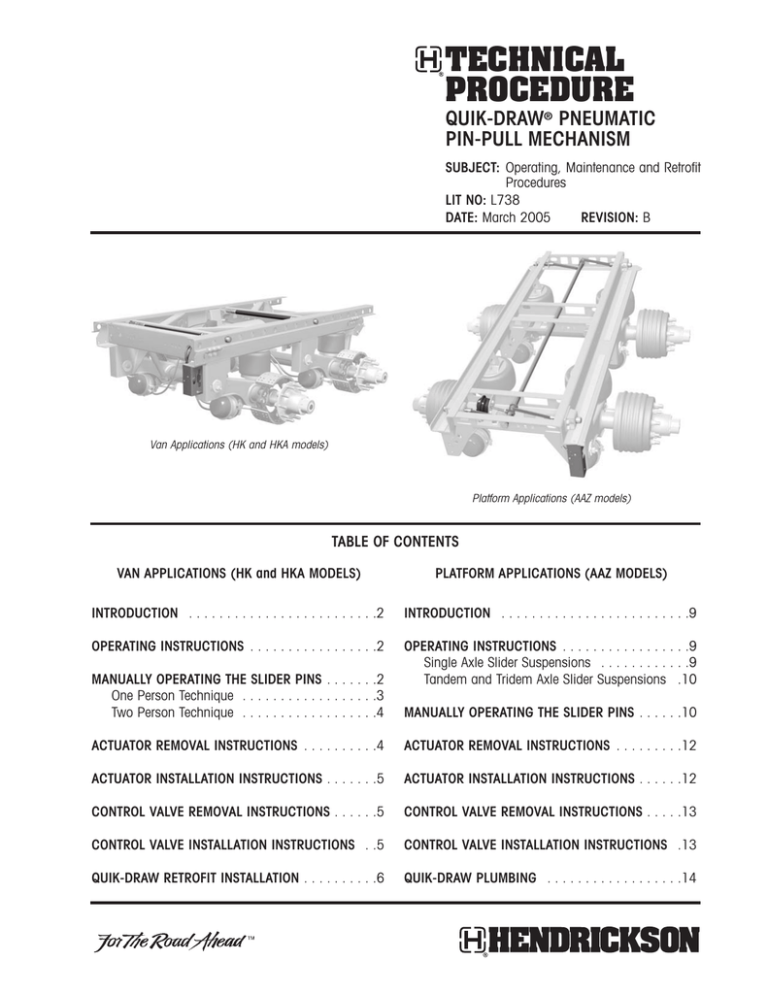

Platform Applications (AAZ models)

TABLE OF CONTENTS

VAN APPLICATIONS (HK and HKA MODELS)

PLATFORM APPLICATIONS (AAZ MODELS)

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . .2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . .9

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . .2

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . .9

Single Axle Slider Suspensions . . . . . . . . . . . .9

Tandem and Tridem Axle Slider Suspensions .10

MANUALLY OPERATING THE SLIDER PINS . . . . . . .2

One Person Technique . . . . . . . . . . . . . . . . . .3

Two Person Technique . . . . . . . . . . . . . . . . . .4

MANUALLY OPERATING THE SLIDER PINS . . . . . .10

ACTUATOR REMOVAL INSTRUCTIONS . . . . . . . . . .4

ACTUATOR REMOVAL INSTRUCTIONS . . . . . . . . .12

ACTUATOR INSTALLATION INSTRUCTIONS . . . . . . .5

ACTUATOR INSTALLATION INSTRUCTIONS . . . . . .12

CONTROL VALVE REMOVAL INSTRUCTIONS . . . . . .5

CONTROL VALVE REMOVAL INSTRUCTIONS . . . . .13

CONTROL VALVE INSTALLATION INSTRUCTIONS . .5

CONTROL VALVE INSTALLATION INSTRUCTIONS .13

QUIK-DRAW RETROFIT INSTALLATION . . . . . . . . . .6

QUIK-DRAW PLUMBING . . . . . . . . . . . . . . . . . .14

QUIK-DRAW® OPERATING, MAINTENANCE AND RETROFIT PROCEDURES

VAN APPLICATIONS (HK AND HKA

MODELS)

3. Remove the optional manual stop bar (if installed

on this trailer). Place it in the body rails just in

front of the desired slider location (if repositioning

the slider forward) or just behind the desired

slider location (if repositioning the slider rearward).

INTRODUCTION

QUIK-DRAW® is a pneumatic slider pin release

mechanism designed to make slider repositioning

fast and convenient. It is controlled by a single

push/pull control valve, located on a control panel at

the forward driver’s side of the slider assembly.

QUIK-DRAW is intended to operate only when the

trailer parking brakes are engaged. To retract the

slider pins with QUIK-DRAW, first ensure the trailer

parking brakes are engaged. Then pull the

QUIK-DRAW control valve out to its fully extended

position. This causes two linear air actuators to

inflate, thereby applying continuous retract force to

the slider pins. The QUIK-DRAW system will create up

to 900 pounds of force (if required) to retract bound

slider pins. If the trailer parking brakes are not

engaged, the QUIK-DRAW control valve will not stay

in the pulled out position and the actuators will not

inflate.

4. Pull the QUIK-DRAW control valve (figure 1) out

to its fully extended position. This pneumatically

retracts the slider pins.

5. Walk around the trailer inspecting each slider pin.

Ensure that each pin is fully retracted. If necessary,

the trailer can be gently rocked forward and then

backward to fully retract bound slider pins.

6. While keeping the trailer brakes applied,

reposition the slider by slowly moving the trailer

forward or backward to the desired position.

7. Apply vehicle parking brakes.

8. Push the QUIK-DRAW control valve all the way

in. This deflates the actuators, causing the slider

pin springs to force the slider pins outward into

the slider box and body rail holes. When aligned,

the slider pins will slip into the body rail holes,

securing the slider box to the body rails.

OPERATING INSTRUCTIONS

1. Clear and keep all bystanders away from the

tractor and trailer during QUIK-DRAW operation.

Chock the trailer wheels.

9. Walk around the trailer inspecting each slider pin.

Ensure that each pin has extended through the

slider box and body rail holes (the pins will only

extend approximately 1/8 inch through the body

rail). If necessary, the trailer can be gently rocked

forward and then backward to completely engage

misaligned slider pins.

2. On a level surface, apply the trailer parking

brakes.

10. Release vehicle parking brakes and remove trailer

wheel chocks.

WARNING: DO NOT DRIVE THE TRAILER

WITHOUT PUSHING THE QUIK-DRAW

CONTROL VALVE IN AND VERIFYING

THAT ALL FOUR SLIDER PINS HAVE

EXTENDED THROUGH THE SLIDER

BOX AND BODY RAIL HOLES.

MANUALLY OPERATING THE SLIDER PINS

In the unlikely event of a QUIK-DRAW system

malfunction, the slider pins can still be manually

operated. You never lose the ability to reposition the

slider with QUIK-DRAW.

Control valve

Figure 1. QUIK-DRAW control valve location

2

L738B

QUIK-DRAW® OPERATING, MAINTENANCE AND RETROFIT PROCEDURES

Just as QUIK-DRAW uses air actuators to retract

slider pins, it uses coil springs to extend them. These

coil springs apply a constant outward force on the

slider pins, causing them to stay fully extended and

in position through the slider box and in the body rail

holes. Because of these coil springs, the slider pins

are intended to remain engaged even if a QUIK-DRAW

actuator malfunction occurs. To manually operate the

slider pins, use one of the following procedures:

Pry until hole is exposed

inside of flange

Flange

ONE PERSON TECHNIQUE

1. Clear and keep all bystanders away from the

tractor and trailer during QUIK-DRAW operation.

Chock the trailer wheels and apply the trailer

parking brakes.

Figure 3. Retract slider pin until hole is exposed inside of flange

7. With all four slider pins retracted, remove the

optional manual stop bar (if installed on this

trailer). Place it in the body rails just in front of

the desired slider location (if repositioning the

slider forward) or just behind the desired slider

location (if repositioning the slider rearward).

2. Look under the trailer (inside the slider frame) and

locate both front and rear QUIK-DRAW air actuators.

3. At the end of one of the actuators, insert the

corner of a pry bar in the gap between the

actuator end and the slider pin (figure 2).

8. Reposition the slider by slowly moving the trailer

forward or backward to the desired position.

4. Using a block of wood (or some other device)

between the slider frame and the pry bar for

leverage, pry back the slider pin (figure 2). Pry

until the hole in the slider pin is exposed inside the

slider pin mounting flange (figure 3).

9. Remove all devices used to retract the slider pins.

10. Walk around the trailer inspecting each slider pin.

Ensure that each pin has extended through the

slider box and body rail holes (the pins will only

extend approximately 1/8 inch through the body

rail). If necessary, the trailer can be gently rocked

forward and then backward to completely engage

bound slider pins.

5. Insert a phillips head screwdriver or ¼ × 3-inch

bolt in the exposed hole in the retracted slider pin

(figure 4) to hold the slider pin in the retracted

position.

6. Repeat steps 3 through 5 on the other three slider

pins to hold them in the retracted position.

Pry bar

(use block of

wood as fulcrum)

Screwdriver

Pry against

actuator end

Wood

Figure 4. Manually retracted slider pin

Figure 2. Using a pry bar to retract the slider pin

L738B

3

QUIK-DRAW® OPERATING, MAINTENANCE AND RETROFIT PROCEDURES

11. Release trailer parking brakes and remove trailer

wheel chocks.

10. Release trailer parking brakes and remove trailer

wheel chocks.

WARNING: DO NOT DRIVE THE TRAILER

WITHOUT VERIFYING THAT ALL FOUR

SLIDER PINS HAVE EXTENDED

THROUGH THE SLIDER BOX AND

INTO THE BODY RAIL HOLES.

WARNING: DO NOT DRIVE THE TRAILER

WITHOUT VERIFYING THAT ALL FOUR

SLIDER PINS HAVE EXTENDED

THROUGH THE SLIDER BOX AND

INTO THE BODY RAIL HOLES.

TWO PERSON TECHNIQUE

1. Apply the trailer parking brakes and chock the wheels.

ACTUATOR REMOVAL INSTRUCTIONS

2. One person is positioned under the trailer, at the

end of one of the actuators.

1. Apply the trailer parking brakes.

To remove a QUIK-DRAW air actuator:

2. Chock the trailer wheels. Completely depressurize

trailer air system by opening air tank drain valve.

3. The other person is positioned outside the trailer,

at the same actuator end as the person

underneath, pushing the slider pin inward with a

long wooden handle or pipe. The slider pin must

be pushed in far enough to expose the hole in

the pin (figure 3) to the individual underneath the

trailer.

3. Disconnect air supply line(s) from fitting(s) on

end of actuator.

4. Remove cotter pin (figure 5).

5. Remove washer (figure 5).

4. The person under the trailer inserts a phillips

head screwdriver or ¼ × 3-inch bolt in the

exposed hole in the retracted slider pin.

6. Push clevis pin (figure 5) through slider pin and

air actuator end. Reach under the frame cross

member and pull clevis pin completely out

through access hole in frame cross member.

5. Repeat steps 2 through 4 on the other three pins.

WARNING: THE PERSON WORKING UNDER THE

TRAILER MUST NOW COME OUT

FROM UNDER THE TRAILER.

7. Repeat steps 4 through 6 at other end of

actuator.

8. Remove actuator.

6. With all four slider pins retracted, remove the

optional manual stop bar (if installed on this

trailer). Place it in the body rails just in front of

the desired slider location (if repositioning the

slider forward) or just behind the desired slider

location (if repositioning the slider rearward).

7. Reposition the slider by slowly moving the trailer

forward or backward to the desired position.

Clevis pin

8. Remove all devices used to retract the slider pins.

Washer

9. Walk around the trailer inspecting each slider pin.

Ensure that each pin has extended through the

slider box and body rail holes (the pins will only

extend approximately 1/8 inch through the body

rail). If necessary, the trailer can be gently rocked

forward and then backward to completely engage

misaligned slider pins.

Cotter pin

Figure 5. Air actuator fastening hardware

4

L738B

QUIK-DRAW® OPERATING, MAINTENANCE AND RETROFIT PROCEDURES

ACTUATOR INSTALLATION INSTRUCTIONS

FORWARD ACTUATOR

REAR ACTUATOR

1. Refer to figure 6 for proper actuator orientation.

Insert actuator end into slot in slider pin and

align holes.

2. Insert clevis pin in access hole in frame cross

member and through aligned slider pin/actuator

end holes.

Tee fitting

Straight fitting

3. Install washer.

4. Install cotter pin.

Figure 6. Actuator identification guide

5. Repeat steps 1 through 4 at other end of actuator.

CONTROL VALVE INSTALLATION

INSTRUCTIONS

6. Connect air supply line(s) to fitting on end of

actuator. Close drain valve on trailer air tank. Fill

the air tank and trailer air system.

1. Place control valve inside valve mounting bracket

and align mounting holes in control valve with

mounting holes in valve spacer and bracket.

7. Check air connections for leaks. Tighten as

necessary.

8. Release trailer parking brakes and remove trailer

wheel chocks.

2. Install control valve mounting bolts and locknuts.

Apply tightening torque of 5 to 8 ft. lbs. (7 to 11

N•m).

CONTROL VALVE REMOVAL INSTRUCTIONS

3. Connect air supply lines to control valve fittings.

To remove the QUIK-DRAW control valve:

4. Close drain valve on trailer air tank. Fill the air

tank and trailer air system. Check control valve

connections for air leaks. Tighten until air does

not leak from connections.

1. Chock the trailer wheels.

2. Apply the trailer parking brakes.

3. Completely depressurize the trailer air system by

opening air tank drain valve.

Control

valve

4. Mark, label or otherwise identify air supply lines

with corresponding fittings on QUIK-DRAW control

valve before disconnecting.

Disconnect

air supply

lines here

Locknuts

5. Disconnect air supply lines from fittings on

QUIK-DRAW control valve (figure 7).

6. Remove the two control valve mounting bolts and

locknuts (figure 7).

Mounting

bolts

7. Remove control valve.

Valve

spacer

Valve

mounting

bracket

Figure 7. Control valve details

L738B

5

QUIK-DRAW® OPERATING, MAINTENANCE AND RETROFIT PROCEDURES

Remove cotter pin, washer

and clevis pin

2. Remove the two handle nuts and handle bolts

from the handle assembly. Remove handle by

pulling through handle guide (figure 8).

Crank

arm

weldment

Handle

guide

3. Remove the forward locking pin link by removing

the cotter pin, washer and clevis pin from each

end of the locking pin link (figure 8).

4. Unfasten forward crank arm weldment by

removing cotter pin, washer and clevis pin

(figure 8) from slider pin.

Handle

Locking pin link

Remove handle

nuts and bolts

NOTE: Standard release mechanism shown.

Procedure for removing customer supplied

release mechanism is similar.

5. Repeat steps 3 and 4 with the rear locking pin link.

6. Cut the pipe weldment in half directly in front of

the rear crank arm weldment (figure 9).

Figure 8. Removing existing pin release mechanism

7. Remove the long forward section of pipe

weldment by pulling it out from the front of the

slider assembly (figure 9).

5. Verify proper QUIK-DRAW operation by fully

retracting and extending control valve.

8. Cut the pipe weldment in half again, this time

between the rear crank arm weldment and the

rear cross member (figure 9).

6. Release trailer parking brakes and remove trailer

wheel chocks.

QUIK-DRAW RETROFIT INSTALLATION —

VAN APPLICATIONS (HK AND HKA MODELS)

ONLY

9. Remove the short section of pipe weldment by

pulling it out from the rear of the slider assembly

(figure 9). Remove any remaining pieces of pipe

weldment.

The van application for QUIK-DRAW can be installed

on any Hendrickson K-2® Slider subframe. Use the

following procedure to remove the existing pin release

mechanism and replace it with QUIK-DRAW:

10. Install the new QUIK-DRAW control valve

mounting bracket over the existing handle guide

bracket. Bolt them together using the two hex

head bolts, torque prevailing flange nuts and two

of the 3/8-inch washers provided in the retrofit kit

(figure 10). Install the bolts into the cutout in the

handle guide so that the hex heads are on the

1. Apply the trailer parking brakes and chock the

trailer wheels.

Rear crank arm

weldment

First cut

Slide long

section of

pipe out

Rear cross member

Pipe weldment

Slide short section

of pipe out

Forward

Second cut

Figure 9. Removing pipe weldment

6

L738B

QUIK-DRAW® OPERATING, MAINTENANCE AND RETROFIT PROCEDURES

BEFORE

AFTER

Install hex

head bolts

here

Handle guide

bracket

Control valve

mounting bracket

Recommended

location for

L712 slider

system

operating

instructions

decal

Flange screws

Valve spacer

FRONT VIEW

Torque prevailing flange nuts

FRONT VIEW

Torque prevailing flange nut

.375" flat washer

Hex head bolt

TOP VIEW

TOP VIEW

Figure 10. Installing QUIK-DRAW control valve mounting bracket

Figure 11. Installing the QUIK-DRAW control valve

outside of the bracket and the torque prevailing

flange nuts and washers are on the inside (figure

10). Torque to 30 ft. lbs. (41 N•m).

14. Install air lines, beam clip assembly, air line

looms and grommets with reference to figures 13

and 14. When installing the longer (rear actuator)

air line, start at the rear actuator and work

forward. This will provide the small slack loop

desirable at the forward actuator. Tighten air line

fittings until air does not leak from connections.

11. Mount the QUIK-DRAW control valve to the valve

mounting bracket using the two flange screws,

valve spacer and ¼ - 20 torque prevailing flange

nuts provided in the retrofit kit (figure 11). Apply

tightening torque of 5 to 8 ft. lbs. (7 to 11

N•m).

15. Verify proper QUIK-DRAW operation by

repositioning the slider per the OPERATING

INSTRUCTIONS on page two.

12. If you want manual slider pin operation capability

(as described in the MANUALLY OPERATING THE

SLIDER PINS section), you can modify the

existing slider pins or order new ones.

16. After final painting, apply the supplied L712 slider

system operating instructions decal near the

QUIK-DRAW control valve (figure 11).

If you wish to modify the existing pins, remove

all four slider pins, drill a hole in each slider pin

as shown in figure 12, deburr both ends of this

new hole and reinstall the slider pins.

.380 diameter

+.015

-.005

If you wish to order new, pre-drilled slider pins,

contact Hendrickson and specify part number:

B-25262 for 13/8-inch diameter slider pins.

B-25261 for 15/8-inch diameter slider pins.

13. Install forward and rear actuators as instructed in

the ACTUATOR INSTALLATION INSTRUCTIONS

section of this manual. Note proper actuator

orientation (rear actuator has a straight fitting,

forward actuator has a tee fitting).

L738B

1.672"

(All dimensions in inches unless noted)

Figure 12. Slider pin hole drilling details

7

QUIK-DRAW® OPERATING, MAINTENANCE AND RETROFIT PROCEDURES

Grommet

Air line

loom

Short air line

Long air line (with slack loop)

Grommet

To supply (emergency)

line

Beam clip

assembly

To air reservoir

pressure

protection valve

Figure 13. Air line installation details for van applications (HK and HKA models)

To supply (emergency) gladhand

Forward linear air actuator

QUIK-DRAW control valve

Reservoir

Spring brake relay

Pressure protection

valve

Rear linear air actuator

Figure 14. QUIK-DRAW plumbing diagram for van applications (HK and HKA models)

8

L738B

QUIK-DRAW® OPERATING AND MAINTENANCE PROCEDURES

PLATFORM APPLICATIONS

(AAZ MODELS)

just in front of the desired slider location (if

repositioning the slider forward) or just behind

the desired slider location (if repositioning the

slider rearward). Proceed to the trailer axle that

will be repositioned.

INTRODUCTION

QUIK-DRAW® is a pneumatic slider pin release

mechanism designed to make slider repositioning

fast and convenient. It is controlled by a single

push/pull control valve, located on a control panel at

the forward driver’s side of the platform slider

assembly. QUIK-DRAW is intended to operate only

when the trailer parking brakes are engaged. To

retract the slider pins with QUIK-DRAW, first ensure

the trailer parking brakes are engaged. Then pull the

QUIK-DRAW control valve out to its fully extended

position. This causes an air actuator (standard Type

12 brake chamber) to apply a continuous retraction

force to the slider pins through the actuator linkage.

The QUIK-DRAW system will apply up to 400 pounds

of force to all four pins simultaneously, or up to

1600 pounds of force to a single pin (if required) to

retract bound slider pins. If the trailer parking brakes

are not engaged, the QUIK-DRAW control valve will

not stay in the pulled out position and the actuator

will not operate.

4. Pull the QUIK-DRAW control valve (figure 15) out

to its fully extended position. This pneumatically

retracts the slider pins.

5. Turn the Brake Lock & Deflate valve to the dump

position. Air exhausts from the axle air springs,

and the brakes on the axle are applied and

isolated from the rest of the braking system. This

prevents the brakes from being released in the

next step.

6. Return to the tractor and release the trailer

parking brakes. This releases the brakes on all

trailer axles except the axle being repositioned,

allowing the tractor/trailer to be moved

independently of the isolated axle.

7. Slowly move the trailer forward or backward. The

isolated axle remains stationary, allowing it to be

repositioned on the trailer.

OPERATING INSTRUCTIONS FOR

HENDRICKSON AIR KIT AKSS0001

8. Apply trailer parking brakes.

SINGLE AXLE SLIDER SUSPENSIONS

1. Clear and keep all bystanders away from the

tractor and trailer during QUIK-DRAW operation.

9. Return to the repositioned axle and check the

position of the slider. The goal is to align the

slider pins with the desired positioning holes in

the web of the trailer I-beam. Repeat steps 6, 7

and 8 if necessary.

2. On a level surface, apply the trailer parking brakes.

3. Remove the optional manual stop bar (if

installed on this trailer). Place it in the body rails

10. When the slider pins are aligned with the holes

in the web of the trailer I-beam, push the

QUIK-DRAW control valve all the way in.

11. Walk around the trailer inspecting each slider

pin. Ensure that each pin has extended through

the positioning holes in the web of the trailer

I-beams (the pins will extend approximately

½ inch through the I-beam). If necessary, repeat

steps 6, 7 and 8 to gently move the trailer so

misaligned slider pins can fully extend.

12. Turn the Brake Lock & Deflate valve to the

normal position. The axle air springs re-inflate,

and the brakes on the isolated axle are

reintegrated with the rest of the braking system,

allowing them to be released in the next step.

Control valve

Figure 15. QUIK-DRAW control valve location

L738B

9

QUIK-DRAW® OPERATING AND MAINTENANCE PROCEDURES

the web of the trailer I-beams. When aligned, the

slider pins will slip into the positioning holes,

securing the platform slider to the trailer I-beams.

WARNING: DO NOT OPERATE THE TRAILER

WITHOUT REINFLATING THE

SUSPENSION AND RELEASING THE

TRAILER PARKING BRAKES.

14. Move the tractor/trailer forward or backward.

Ensure that the repositioned axle moves with the

tractor/trailer.

8. Walk around the trailer inspecting each slider pin.

Ensure that each pin has extended through the

positioning holes in the web of the trailer I-beams

(the pins will extend approximately ½ inch

through the I-beam). If necessary, the trailer can

be gently rocked forward and then backward to

completely engage misaligned slider pins.

15. Apply the vehicle service brakes. Ensure that the

repositioned axle stops with the tractor/trailer.

9. Release trailer parking brakes and remove trailer

wheel chocks.

13. Return to the tractor and release the trailer

parking brakes.

WARNING: DO NOT DRIVE THE TRAILER

WITHOUT PUSHING THE QUIK-DRAW

CONTROL VALVE IN AND VERIFYING

THAT ALL FOUR SLIDER PINS HAVE

EXTENDED THROUGH THE

POSITIONING HOLES IN THE WEB OF

THE TRAILER I-BEAMS.

WARNING: DO NOT DRIVE THE TRAILER

WITHOUT VERIFYING THAT ALL FOUR

SLIDER PINS HAVE EXTENDED

THROUGH THE POSITIONING HOLES

IN THE WEB OF THE TRAILER IBEAMS.

TANDEM AND TRIDEM AXLE SLIDER SUSPENSIONS

1. Clear and keep all bystanders away from the

tractor and trailer during QUIK-DRAW operation.

Chock the trailer wheels.

MANUALLY OPERATING THE SLIDER PINS

In the unlikely event of a QUIK-DRAW system

malfunction, the slider pins can still be manually

operated. You never lose the ability to reposition the

slider with QUIK-DRAW.

2. On a level surface, apply the trailer parking

brakes.

Just as QUIK-DRAW uses an air actuator to retract

slider pins, it uses coil springs to extend them. These

coil springs apply a constant outward force on the

slider pins, causing them to stay fully extended and

in position through the positioning holes in the web

of the trailer I-beams. Because of these coil springs,

the slider pins are intended to remain engaged even if

an air actuator malfunction occurs.

3. Remove the optional manual stop bar (if installed

on this trailer). Place it in the body rails just in

front of the desired slider location (if repositioning

the slider forward) or just behind the desired

slider location (if repositioning the slider

rearward).

4. Pull the QUIK-DRAW control valve (figure 15) out

to its fully extended position. This pneumatically

retracts the slider pins.

To manually operate the slider pins, use the following

procedure:

5. Walk around the trailer inspecting each slider pin.

Ensure that each pin is fully retracted. If necessary,

the trailer can be gently rocked forward and then

backward to fully retract misaligned slider pins.

6. Reposition the slider by slowly moving the trailer

forward or backward to the desired position.

1. Begin with slider operation as described in the

SINGLE AXLE SLIDER SUSPENSIONS or TANDEM

AND TRIDEM AXLE SLIDER SUSPENSIONS

sections, but stop when the “pull the QUIK-DRAW

control valve out” step is reached. Instead of

pneumatically retracting the slider pins, use the

following three steps to manually retract them.

7. Push the QUIK-DRAW control valve all the way

in. This causes the slider pin springs to force the

slider pins outward into the positioning holes in

2. Look under the trailer (at the front of the platform

slider frame) and locate the hexagonal bolt head

on the end of the pipe weldment (figure 16).

10

L738B

QUIK-DRAW® OPERATING AND MAINTENANCE PROCEDURES

3. Using a 1½-inch wrench on the hexagonal bolt

head, rotate the pipe weldment counterclockwise

approximately 1/8 turn, or until the hole in the

slider pin is visible on the inboard side of the

slider pin cage assembly (figure 16). If the slider

pins are free to move, it will require

approximately 60 ft. lbs. (81 N•m) of torque to

rotate the pipe weldment. Hold the pipe weldment

in this rotated position for the next step.

Starting state

Hexagonal bolt head (not shown)

rotated clockwise

4. Insert a phillips head screwdriver or ¼ × 3-inch

bolt in the exposed hole in one of the retracted

slider pins (figure 17). This will hold all of the

slider pins in the retracted position because they

are all interconnected by the locking pin linkage.

5. Continue with slider operation as described in the

SINGLE AXLE SLIDER SUSPENSIONS or TANDEM

AND TRIDEM AXLE SLIDER SUSPENSIONS

sections, but stop when the “push the QUIKDRAW control valve in” step is reached. Instead

of pneumatically extending the slider pins, use

the following step to manually extend them.

Hole in slider pin must be

exposed on the inboard side

of the slider pin cage

assembly

6. Remove the screwdriver or other device used to

retract the slider pins.

Slider pin

7. Finish slider operation as described in the

SINGLE AXLE SLIDER SUSPENSIONS or TANDEM

AND TRIDEM AXLE SLIDER SUSPENSIONS

sections.

Hole

Slider pin

cage assembly

Hexagonal bolt head

Figure 17. Manually operating the slider pins

Figure 16. Hexagonal bolt head location

L738B

11

QUIK-DRAW® OPERATING AND MAINTENANCE PROCEDURES

ACTUATOR REMOVAL INSTRUCTIONS

To remove the QUIK-DRAW air actuator:

8. Remove actuator through opening in top of frame

crossmember.

1. Apply the trailer parking brakes.

ACTUATOR INSTALLATION INSTRUCTIONS

1. Inspect the new actuator to ensure that the

distance from the center of the clevis pin to the

mounting surface of the actuator is 5.93 (±0.03)

inches (figure 19). If not, loosen the jam nut

attaching the yoke to the push rod of the

actuator, and adjust to the proper length. Tighten

the jam nut to 20-30 ft. lbs. (27-41 N•m) of

torque.

2. Chock the trailer wheels. Completely depressurize

the trailer air system by opening air tank drain

valve.

3. Disconnect the air supply line from the fitting on

the bottom of the actuator.

4. Remove cotter pin and washer from clevis pin

attaching curbside front slider pin to actuator

linkage (figure 18).

2. Remove the air fitting from old actuator and

install into new one. Connection must be air

tight.

5. Push clevis pin through holes in slider pin and

actuator link. Reach under frame cross member

and pull clevis pin completely out through

access hole in frame cross member.

3. Remove the cotter pin and clevis pin from the

yoke on the push rod of the new actuator.

4. Remove the 11/16-inch nuts from the threaded

studs on the actuator.

6. Remove cotter pin and clevis pin attaching

actuator yoke to crank arm on actuator linkage

(figure 18).

5. Install the actuator through the opening in the top

of the front frame cross member, and onto the

mounting bracket inside the cross member. The

threaded studs on the mounting surface of the

actuator must pass through the holes in the

7. Using an 11/16-inch wrench, remove the two nuts

attaching the actuator to the mounting bracket

inside the frame cross member (figure 18).

Crank arm

Actuator yoke

Remove cotter pin,

washer and clevis

pin here

Remove cotter pin

and clevis pin here

Remove

Figure 18. Actuator removal details

12

L738B

QUIK-DRAW® OPERATING AND MAINTENANCE PROCEDURES

CONTROL VALVE REMOVAL INSTRUCTIONS

Clevis pin

Jam nut

To remove the QUIK-DRAW control valve:

Yoke

1. Chock the trailer wheels.

2. Apply the trailer parking brakes.

Push rod

3. Completely depressurize the trailer air system by

opening air tank drain valve.

Cotter pin

4. Mark, label or otherwise identify air supply lines

with corresponding fittings on QUIK-DRAW control

valve before disconnecting.

5.93" ± 0.03"

5. Disconnect air supply lines from fittings on

QUIK-DRAW control valve (figure 20).

Figure 19. Verifying actuator free length

6. Remove the two control valve mounting bolts and

locknuts (figure 20).

mounting bracket. The crank arm on the actuator

linkage must fit between the tangs of the actuator

yoke, and the holes in the yoke must line up with

the hole in the crank arm.

7. Remove control valve.

CONTROL VALVE INSTALLATION

INSTRUCTIONS

1. Place control valve inside valve mounting bracket

and align mounting holes in control valve with

mounting holes in valve spacer and bracket.

6. Reinstall the clevis pin in the actuator yoke,

ensuring that it passes through the hole in the

crank arm.

7. Reinstall the cotter pin to secure the clevis pin.

8. Reinstall the 11/16-inch nuts onto the threaded

studs of the actuator, and tighten to 32-38 ft. lbs.

(43-52 N•m) of torque.

Valve mounting bracket

9. Swing the previously-disconnected actuator link

upward, until the clevis pin hole lines up with the

holes in the curbside slider pin. The end of the

actuator link must fit into the slot in the slider pin.

10. Reinstall the clevis pin, washer, and cotter pin

previously removed.

11. Connect air supply line to fitting on bottom of

actuator. Close drain valve on trailer air tank. Fill

the air tank and trailer air system.

Control valve

Valve spacer

12. Check air connections for leaks. Tighten as

necessary.

13. Release trailer parking brakes and remove trailer

wheel chocks.

Figure 20. Control valve installation details

L738B

13

QUIK-DRAW® OPERATING AND MAINTENANCE PROCEDURES

2. Install control valve mounting bolts and locknuts.

Apply tightening torque of 5 to 8 ft. lbs. (7 to 11

N•m).

5. Verify proper QUIK-DRAW operation by fully

retracting and extending control valve.

6. Release trailer parking brakes and remove trailer

wheel chocks.

3. Connect air supply lines to fittings on control

valve.

QUIK-DRAW PLUMBING — PLATFORM

APPLICATIONS (AAZ MODELS) ONLY

4. Close drain valve on trailer air tank. Fill the air

tank and trailer air system. Check control valve

connections for air leaks. Tighten until air does

not leak from connections.

Install air lines and beam clip assemblies with

reference to figures 21 and 22.

Beam clip assembly

To supply (emergency)

line

To air reservoir

pressure protection

valve

Figure 21. Air line installation details for platform applications (AAZ models)

14

L738B

QUIK-DRAW® OPERATING AND MAINTENANCE PROCEDURES

To supply (emergency) gladhand

Air actuator

QUIK-DRAW control valve

Spring

brake

relay

Reservoir

Pressure

protection

valve

Figure 22. QUIK-DRAW plumbing diagram for platform applications (AAZ models)

L738B

15

www.hendrickson-intl.com

Trailer Suspension Systems

250 Chrysler Drive, Unit #3

Brampton, ON L6S 6B6 Canada

905.789.1030

Fax 905.789.1033

L738 Rev B 03-05

Trailer Suspension Systems

2070 Industrial Place SE

Canton, OH 44707-2600 USA

866.RIDEAIR (743.3247)

330.489.0045

Fax 800.696.4416

Trailer Suspension Systems

Ave. Rogelio González Caballero #850-B

Parque Industrial STIVA Aeropuerto

Apodaca, N.L., C.P. 66600 Mexico

(52) 81 8156 1300

Fax (52) 81 8156 1301

Information contained in this literature was accurate at the time of publication. Product changes may have been made after the copyright date that are not reflected.

© 2005 Hendrickson USA, L.L.C. (U.S. Rights) Hendrickson International Corporation (Rights Outside U.S.) All Rights Reserved