Kevin Chau

advertisement

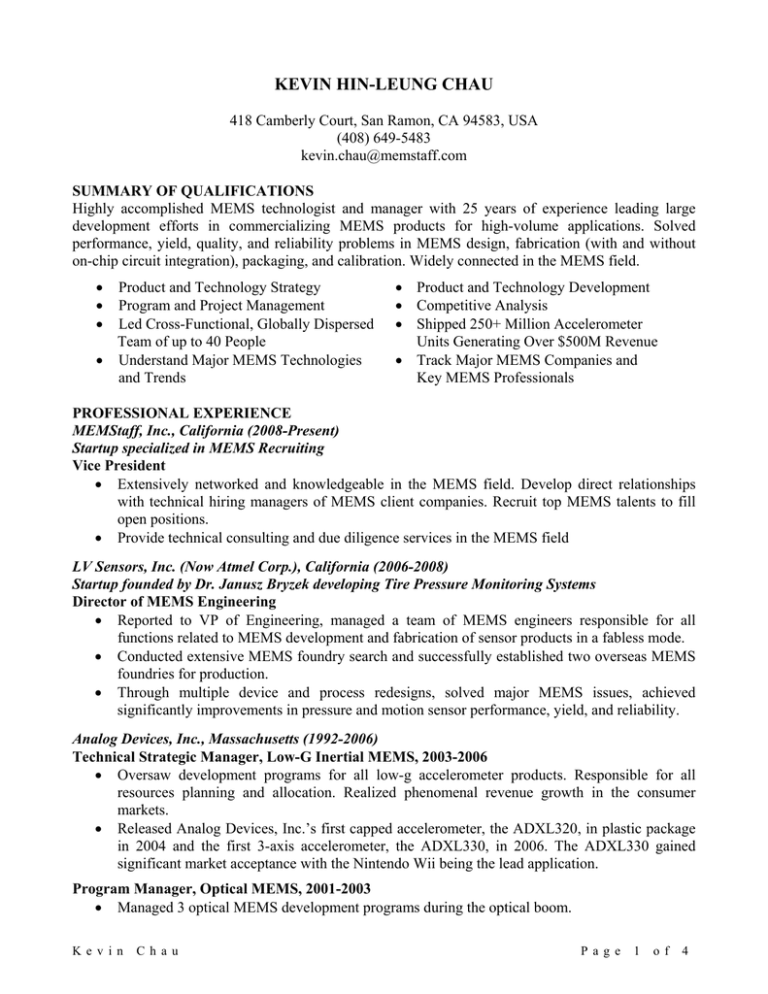

KEVIN HIN-LEUNG CHAU 418 Camberly Court, San Ramon, CA 94583, USA (408) 649-5483 kevin.chau@memstaff.com SUMMARY OF QUALIFICATIONS Highly accomplished MEMS technologist and manager with 25 years of experience leading large development efforts in commercializing MEMS products for high-volume applications. Solved performance, yield, quality, and reliability problems in MEMS design, fabrication (with and without on-chip circuit integration), packaging, and calibration. Widely connected in the MEMS field. • • • Product and Technology Strategy Program and Project Management Led Cross-Functional, Globally Dispersed Team of up to 40 People • Understand Major MEMS Technologies and Trends • Product and Technology Development • Competitive Analysis • Shipped 250+ Million Accelerometer Units Generating Over $500M Revenue • Track Major MEMS Companies and Key MEMS Professionals PROFESSIONAL EXPERIENCE MEMStaff, Inc., California (2008-Present) Startup specialized in MEMS Recruiting Vice President • Extensively networked and knowledgeable in the MEMS field. Develop direct relationships with technical hiring managers of MEMS client companies. Recruit top MEMS talents to fill open positions. • Provide technical consulting and due diligence services in the MEMS field LV Sensors, Inc. (Now Atmel Corp.), California (2006-2008) Startup founded by Dr. Janusz Bryzek developing Tire Pressure Monitoring Systems Director of MEMS Engineering • Reported to VP of Engineering, managed a team of MEMS engineers responsible for all functions related to MEMS development and fabrication of sensor products in a fabless mode. • Conducted extensive MEMS foundry search and successfully established two overseas MEMS foundries for production. • Through multiple device and process redesigns, solved major MEMS issues, achieved significantly improvements in pressure and motion sensor performance, yield, and reliability. Analog Devices, Inc., Massachusetts (1992-2006) Technical Strategic Manager, Low-G Inertial MEMS, 2003-2006 • Oversaw development programs for all low-g accelerometer products. Responsible for all resources planning and allocation. Realized phenomenal revenue growth in the consumer markets. • Released Analog Devices, Inc.’s first capped accelerometer, the ADXL320, in plastic package in 2004 and the first 3-axis accelerometer, the ADXL330, in 2006. The ADXL330 gained significant market acceptance with the Nintendo Wii being the lead application. Program Manager, Optical MEMS, 2001-2003 • Managed 3 optical MEMS development programs during the optical boom. K e v in Ch a u P a g e 1 o f 4 • Gained much experience in optical MEMS and in managing large cross-geographic projects in collaboration with high-profile start-ups. Front-End Packaging Manager, 1999-2001 • Managed the Front-End Packaging group (consisting of 5 Ph.D.’s, 1 engineer and 2 technicians) in developing wafer-level capping and anti-stiction treatment processes. These processes are all in production now. Senior Project Leader, 1994-1999; Senior Design Engineer, 1992-1993 • Pivotal in solving early problems in fabrication, packaging, yield, quality, and reliability, resulting in the successful release of the ADXL50, Analog Devices, Inc.’s and the world’s first integrated surface-machined accelerometer product, in 1993. • Continued to play a key role for the next several years in solving development and manufacturing problems for later generation accelerometer products as they ramped up into significant volumes. Considered to be one of a few individuals who had made Analog Devices, Inc. viable in this business (Analog Devices, Inc. had shipped more than 250 million accelerometer units when I left in 2006). • Presented the paper on “An Integrated Force-Balanced Capacitive Accelerometer for Low-G Applications” at Transducers ’95. The paper was honored at Transducers ’99 as one of the memorable papers in the conference’s 18 year history. Foxboro Company (Now Invensys), Massachusetts (1987-1992) Principal Engineer, 1991-1992 Senior Research Engineer, 1987-1991 • Developed surface-micromachined polysilicon-diaphragm pressure sensor arrays, using the sealed-cavity process licensed from Prof. Henry Guckel of the University of Wisconsin. Successfully passed device conception, idea demonstrations, feasibility, into prototype stage. Products released to production after I left. • As the principal silicon pressure sensor designer, responsible for sensor chip design, layout, and characterization. Supervised chip fabrication, packaging, and testing. University of Michigan, Ann Arbor (1980-1987) Research Assistant, 1984-1987, under Prof. Kensall Wise PhD Dissertation: An Ultraminiature Solid-State Pressure Sensor for a Multisite Cardiac Catheter • Invented a silicon-on-glass process for fabricating ultraminiature capacitive pressure sensors. The so called “Dissolved Wafer Process” has later found commercialization at Ford Microelectronics, Inc. (Accelerometers); Draper Lab. / Rockwell / Honeywell (Gyroscopes); and formed the core technologies of ISSYS (Pressure Sensors and Microfluidics). Education • University of Michigan, Ann Arbor, PhD (Electrical Engineering), 1987, GPA 8.48/9.0 • University of Michigan, Ann Arbor, MS (Electrical Engineering), 1981, GPA 8.33/9.0 • University of Hong Kong, BS (Electrical Engineering), 1980, First Class Honors Final Year Project under Prof. Patrick Y. C. Cheng: Effects of Nonuniformity of the Insulating Layer on Metal-Insulator-Semiconductor Solar Cells. Professional Activities • SPIE Symposium on Micromachining and Microfabrication (US), Conference Chair, 19951998, Symposium Chair, 1999-2003. K e v in Ch a u P a g e 2 o f 4 • • SPIE International Symposium on Microelectronics and Assembly (Singapore), Conference Chair, 2000. Taught short course on “Introduction to MEMS Technology and Devices.” SPIE International Symposium on Microelectronics and Micro Electro Mechanical Systems (Australia), Conference Chair, 1999. Personal Fluent in both Cantonese and Mandarin Chinese. Enjoy piano, Chinese chess, Chinese literature, and table tennis. Table tennis coach for the Newton Cantonese School from 2001 to 2006. Married with 3 children. U.S. Citizen. PATENTS AND PUBLICATIONS U. S. Patents: 1. X. Zhang, M. Judy, K. H.-L. Chau, N. Kuan, T. Spooner, C. Paydenkar, P. Farrell, “Stress Mitigation in Packaged Microchips,” U.S. Application No. 11/770,369, patent pending. 2. K. H.-L. Chau, L. E. Felton, J. A. Geen, M. W. Judy, J. R. Martin, “Capped Sensor,” U.S. Patent No. 7,795,723, Sep. 2010. 3. K. H.-L. Chau and H. R. Samuels, “Method for Calibrating Accelerometer Sensitivity,” U.S. Patent No. 7,093,478, Aug. 2006. 4. K. H.-L. Chau, R. T. Howe, R. S. Payne, Y. Zhao, T. A. Core, and S. J. Sherman, “Conductive Plane Beneath Suspended Microstructure,” U.S. Patent No. 5,858,809, Jan. 1999. 5. K. H.-L. Chau, R. T. Howe, R. S. Payne, Y. Zhao, T. A. Core, and S. J. Sherman, “Conductive Plane Beneath Suspended Microstructure,” U.S. Patent No. 5,640,039, June 1997. 6. C. D. Fung, K. H.-L. Chau, P. R. Harris, J. G. Panagou, and G. A. Dahrooge, “Removing Sacrificial Material Through Temporary Channels as a Method of Making an OverpressureProtected Differential Pressure Sensor,” U.S. Patent No. 5,438,875, Aug. 1995. 7. K. H.-L. Chau, M. P. Saltmarsh, and D. A. Church, “Method for Fabricating Microstructures Using Temporary Bridges,” U.S. Patent No. 5,364,497, Nov. 1994. 8. C. D. Fung, K. H.-L. Chau, P. R. Harris, J. G. Panagou, and G. A. Dahrooge, “OverpressureProtected, Differential Pressure Sensor,” U.S. Patent No. 5,357,808, Oct. 1994. 9. C. D. Fung and K. H.-L. Chau, “Overpressure-Protected, Polysilicon, Capacitive Differential Pressure Sensor and Method of Making Same,” U.S. Patent No. 5,344,523, Sep. 1994. 10. C. D. Fung and K. H.-L. Chau, “Overpressure-Protected, Polysilicon, Capacitive Differential Pressure Sensor and Method of Making Same,” U.S. Patent No. 5,323,656, June 1994. 11. C. D. Fung, K. H.-L. Chau, P. R. Harris, J. G. Panagou, and G. A. Dahrooge, “OverpressureProtected, Differential Pressure Sensor and Method of Making the Same,” U.S. Patent No. 5,220,838, June 1993. 12. K. D. Wise and H.-L. Chau, “Ultraminiature Single-Crystal Sensor with Movable Member,” U.S. Patent No. 5,207,103, May 1993. 13. K. D. Wise and H.-L. Chau, “Ultraminiature Pressure Sensor with Addressable Read-Out Circuit,” U.S. Patent No. 5,113,868, May 1992. 14. K. D. Wise and H.-L. Chau, “Method of Making an Ultraminiature Pressure Sensor,” U.S. Patent No. 5,013,396, May 1991. 15. K. D. Wise and H.-L. Chau, “Ultraminiature Pressure Sensor and Method of Making Same,” U.S. Patent No. 4,881,410, Nov. 1989. 16. K. D. Wise and H.-L. Chau, “Multipoint Pressure-Sensing Catheter System,” U.S. Patent No. 4,815,472, Mar. 1989. K e v in Ch a u P a g e 3 o f 4 Book Sections: 1. J. G. Webster (ed.), Mechanical Variables Measurement ⎯ Solid, Fluid, and Thermal, CRC Press, 1999. Authored the section on “Pressure Measurement.” 2. J. G. Webster (ed.), The Measurements, Instrumentation and Sensors Handbook, CRC Press, 1998. Authored the section on “Pressure Measurement.” Journal Papers: 1. K. H.-L. Chau and R. E. Sulouff, Jr., “Technology for the High-Volume Manufacturing of Integrated Surface-Micromachined Accelerometer Products,” Microelectronics J., vol. 29, p. 579, 1998. 2. K. H.-L. Chau, S. R. Lewis, Y. Zhao, R. T. Howe, S. F. Bart, and R. G. Marcheselli, “An Integrated Force-Balanced Capacitive Accelerometer for Low-G Applications,” Sensors and Actuators, vol. A54, p. 472, 1996. 3. K. H.-L. Chau, C. D. Fung, P. R. Harris, and J. G. Panagou, “Over-Range Behavior of SealedCavity Polysilicon Pressure Sensors,” Sensors and Actuators, vol. A28, p. 147, 1991. 4. H.-L. Chau and K. D. Wise, “An Ultraminiature Solid-State Pressure Sensor for a Cardiovascular Catheter,” IEEE Trans. Electron Devices, vol. ED-35, p. 2355, Dec. 1988. 5. H.-L. Chau and K. D. Wise, “Noise Due to Brownian Motion in Solid-State Pressure Sensors,” IEEE Trans. Electron Devices, vol. ED-34, p. 859, Apr. 1987. 6. H.-L. Chau and K. D. Wise, “Scaling Limits in Batch-Fabricated Silicon Pressure Sensors,” IEEE Trans. Electron Devices, vol. ED-34, p. 850, Apr. 1987. 7. H.-L. Chau and Y. C. Cheng, “Modification of Open-Circuit Voltage of Metal-InsulatorSemiconductor Solar Cells Due to a Nonuniform Insulating Layer,” J. Appl. Phys., vol. 53, p. 4544, June 1982. 8. Y. C. Cheng and H.-L. Chau, “Effects of Nonuniformity of the Insulating Layer on MIS Solar Cells,” IEEE Electron Device Lett., vol. EDL-1, p. 191, Oct. 1980. Conference Papers: 1. J. Weigold and K. Chau, “Evolution and Acquisition of Talent in the MEMS Industry,” paper presented the 2010 COMS Conference, Albuquerque, New Mexico, Aug. 2010. 2. T. Juneau, T. Chen, T. Brosnihan, S. Rajaraman, K. Chau, and M. Judy, “Single-Chip 1x84 MEMS Mirror Array for Optical Telecommunication Applications,” paper presented at the 2003 SPIE Symposium on Micromachining and Microfabrication, San Jose, California, Jan. 2003. 3. K. H.-L. Chau, S. R. Lewis, Y. Zhao, R. T. Howe, S. F. Bart, and R. G. Marcheselli, “An Integrated Force-Balanced Capacitive Accelerometer for Low-G Applications,” paper presented at the Transducers ’95 Conference, Stockholm, Sweden, June 1995. 4. S. J. Sherman, W. K. Tsang, T. A. Core, R. S. Payne, D. E. Quinn, K. H.-L. Chau, J. A. Farash, and S. K. Baum, “A Low Cost Monolithic Accelerometer; Product/Technology Update,” paper presented at the 1992 IEDM Conference, San Francisco, California, Dec. 1992. 5. K. H.-L. Chau, C. D. Fung, P. R. Harris, and G. A. Dahrooge, “A Versatile Polysilicon Diaphragm Pressure Sensor Chip,” paper presented at the 1991 IEDM Conference, Washington D.C., Dec. 1991. 6. K. H.-L. Chau, C. D. Fung, P. R. Harris, and J. G. Panagou, “High-Stress and Overrange Behavior of Sealed-Cavity Polysilicon Pressure Sensors,” paper presented at the 1990 Solid-State Sensor and Actuator Workshop, Hilton Head Island, South Carolina, June 1990. 7. H.-L. Chau and K. D. Wise, “An Ultraminiature Solid-State Pressure Sensor for a Cardiovascular Catheter, paper presented at the Transducers ’87 Conference, Tokyo, Japan, June 1987. 8. H.-L. Chau and K. D. Wise, “Scaling Limits in Batch-Fabricated Silicon Pressure Sensors,” paper presented at the Transducers ’85 Conference, Philadelphia, Pennsylvania, June 1985. K e v in Ch a u P a g e 4 o f 4