3DSCANNING

Understanding Spot Size

for Laser Scanning

Geoff Jacobs

S

everal features of a laser scanner contribute to the level of definition it is

capable of achieving in a high-definition survey. This article provides insight into spot size, as I have found

that many professionals do not fully understand or appreciate the important subtleties of

this feature.

As reported in an earlier article (Professional

Surveyor Magazine, February 2005), several features of a scanner contribute to the level of definition or resolution that can be achieved via the

data it collects. Since the greatest differentiating

technical feature of a laser scanner, compared

to traditional survey tools, is the detail it can

collect, it helps to clearly understand these key

contributing features:

■

■

■

■

Scan density

Scan noise

Accuracy of each measurement

Spot size

Generally, the higher the scan density, the less

noisy the data, the higher the accuracy of each

measurement, and the smaller the spot size, then

the higher the definition of the survey.

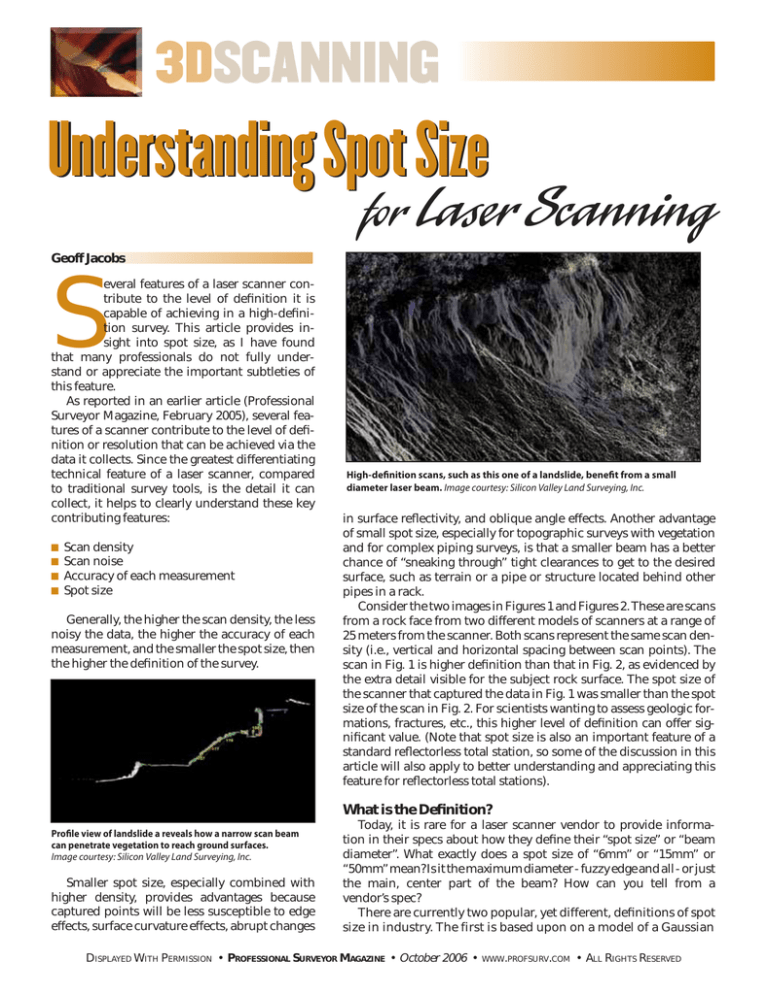

High-definition scans, such as this one of a landslide, benefit from a small

diameter laser beam. Image courtesy: Silicon Valley Land Surveying, Inc.

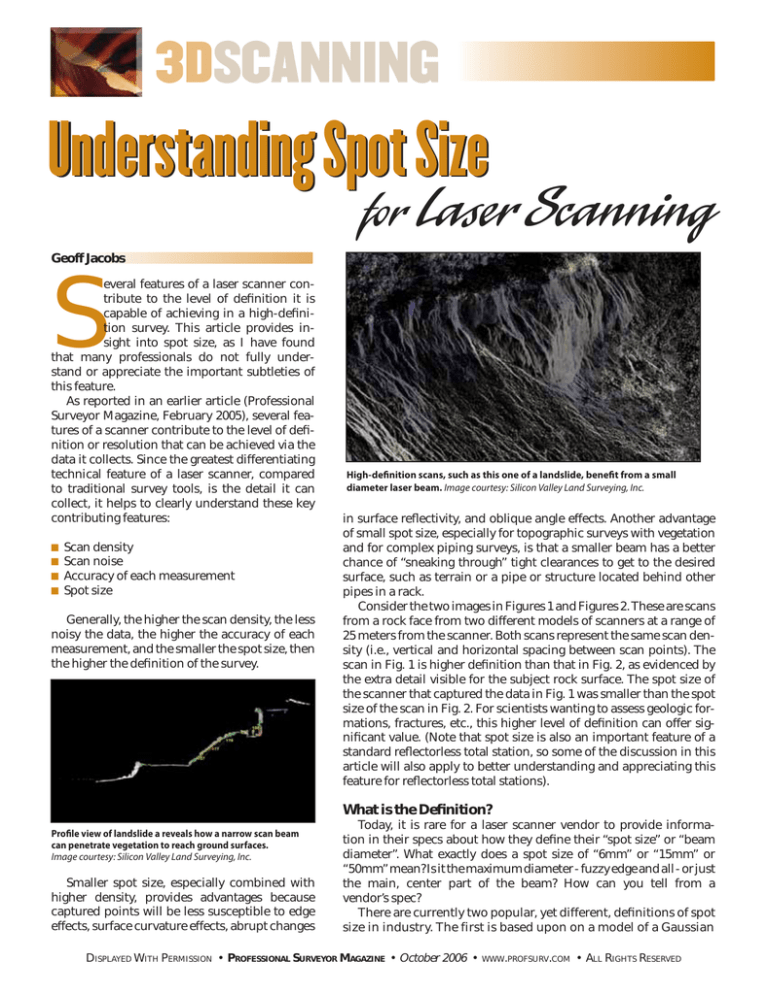

in surface reflectivity, and oblique angle effects. Another advantage

of small spot size, especially for topographic surveys with vegetation

and for complex piping surveys, is that a smaller beam has a better

chance of “sneaking through” tight clearances to get to the desired

surface, such as terrain or a pipe or structure located behind other

pipes in a rack.

Consider the two images in Figures 1 and Figures 2. These are scans

from a rock face from two different models of scanners at a range of

25 meters from the scanner. Both scans represent the same scan density (i.e., vertical and horizontal spacing between scan points). The

scan in Fig. 1 is higher definition than that in Fig. 2, as evidenced by

the extra detail visible for the subject rock surface. The spot size of

the scanner that captured the data in Fig. 1 was smaller than the spot

size of the scan in Fig. 2. For scientists wanting to assess geologic formations, fractures, etc., this higher level of definition can offer significant value. (Note that spot size is also an important feature of a

standard reflectorless total station, so some of the discussion in this

article will also apply to better understanding and appreciating this

feature for reflectorless total stations).

What is the Definition?

Profile view of landslide a reveals how a narrow scan beam

can penetrate vegetation to reach ground surfaces.

Image courtesy: Silicon Valley Land Surveying, Inc.

Smaller spot size, especially combined with

higher density, provides advantages because

captured points will be less susceptible to edge

effects, surface curvature effects, abrupt changes

Today, it is rare for a laser scanner vendor to provide information in their specs about how they define their “spot size” or “beam

diameter”. What exactly does a spot size of “6mm” or “15mm” or

“50mm” mean? Is it the maximum diameter - fuzzy edge and all - or just

the main, center part of the beam? How can you tell from a

vendor’s spec?

There are currently two popular, yet different, definitions of spot

size in industry. The first is based upon on a model of a Gaussian

DISPLAYED WITH PERMISSION • PROFESSIONAL SURVEYOR MAGAZINE • October 2006 •

WWW.PROFSURV.COM

• ALL RIGHTS RESERVED

3DSCANNING

which its intensity equals 1/e2 x Imax

where:

e = mathematical constant

(approx. 2.7183)

Imax = maximum intensity of

laser beam

It turns out that 1/e2 approximately

equals 0.135 or 13.5 percent. So based

on a Gaussian diameter definition, a

“6mm diameter beam” means that at a

beam diameter of six millimeters, the

intensity of the beam is 13.5 percent of

the maximum intensity at its center. The

full beam actually extends beyond this

diameter, but the vast majority of the

Figure 2: Rock face scan with

Figure 1: Rock face scan with smaller

beam’s energy is within this diameter. In

larger spot and more noise.

spot and less noise

a sense, using a scientific, Gaussian diameter definition of beam diameter for

Images courtesy: UCLA Department of Earth and Space Sciences

laser scanner specification purposes is

distribution of the beam’s intensity, or irradivery conservative.

ance, across its diameter. Surveyors, engineers,

The second type of definition of beam diameter is the full-width

physical scientists, and statisticians should all

half-height or FWHH-based definition. This definition asks the quesbe generally familiar with the concept of Gaustion, “At what diameter of the beam is the intensity of the beam equal

sian distribution as a type of statistical distributo 50 percent of its maximum, center intensity, Imax?” Clearly, this

tion with the familiar bell-shaped graphical repdefinition results in a smaller beam diameter value than that based

resentation. Basically, the Gaussian model of a

on the Gaussian diameter.

laser beam characterizes the beam’s maximum

intensity as being at the center of the beam, with

Either the Gaussian or FWHH definition is relevant as long as you

intensity falling off in a Gaussian profile as you

compare apples to apples for different scanners. However, for those

go outward (See Fig. 3). Many laser beams conwho like to pore over manufacturers’ specs, be careful. Unless a venform to this profile. The best laser beams, ones

dor is clear about how they define their spot size, there is no way to

that give the minimum spot size over range, are

know if the spot sizes being compared are based on the same defialways Gaussian in profile, what physicists call

nition. There are currently no standards in the survey industry that

diffraction limited.

cover this aspect, so vendors are free to define spot size however they

The second popular definition is the width

like, using Gaussian diameter, FWHH diameter, or some other basis

of the beam at the half-intensity points. This

that they prefer. (Note that these kind of issues, such as how scan resis a more general definition that can be apolution relates to beam size, will be considered in the standards initiplied to any beam intensity profile, not just

ative on 3D Imaging Systems under the auspices of ASTM. Until such

Gaussian profiles.

standards are in place, however, users are advised to do additional

homework to properly understand vendor specifications).

100

Spot Size as a Function of Range

PERCENT IRRADIANCE

80

60 FWHH-based

beam size

40

Gaussian-based

20 beam size

13.5

– 1.5W – W

0

W

1.5W

CONTOUR RADIUS

Figure 3: Gaussian Irradiance Profile

Scientific professionals in the field of optics universally refer to a beam’s diameter as its

Gaussian diameter, the diameter of the beam at

Another factor that complicates things for those doing their

homework is the fact that a beam’s diameter varies as a function of its

distance from

the

scanner.

Un m o d i f i e d ,

1

irradiance surface

W

e3

the diameter

e

W0

c con

ptoti

of a laser beam

asym

will

natural0

W0

ly tend to inZ

crease with disW0

tance (see Fig.

4). So all oth- Figure 4: If left unmodified, the beam waist radius, W0, tends

er factors be- to increase with range, Z

ing equal, the

definition of a scan will be less clear further away from the scanner

(decreasing scan density as a function of increasing distance compounds this effect). The beam diameter from such scanners can easily grow to 10X or even more over the specified range of the scanner!

DISPLAYED WITH PERMISSION • PROFESSIONAL SURVEYOR MAGAZINE • October 2006 •

WWW.PROFSURV.COM

• ALL RIGHTS RESERVED

3DSCANNING

To calculate or estimate how large the beam

will grow, vendors of these types of scanners usually specify the diameter of the beam at the exit

of the scanner and then provide a divergence

value. Typically stated in milliradians, or mrad,

this reflects how fast the size of the beam grows

as a function of distance. For example, a beam

with a starting diameter of 10mm and a divergence value of 3 mrad will have a beam diameter

of 160mm at a range of 50m from the scanner.

For scanners that use this approach - and

many do - users may have to move the scanner

around the site frequently to achieve the spot

size and level of definition they want. Of course,

each setup and tear-down takes time, so this has

a direct impact on field productivity.

Collimated Beams

A second approach that some vendors use

is to collimate the laser beam. The idea here is

to insert a simple, non-moving beam expander

(i.e. lens) that acts like a reverse telescope such

that the beam stays relatively small over much of

the scanner’s useful range. In this case, a beam

may exit the scanner at 6mm, for example, narrow down to 3 or 4mm at 25m range, and then increase back to 6mm at 50m range. Past 50m, the

beam diameter will increase at a slightly higher rate than if the beam had not been collimated. The benefit is that the beam diameter will be

<6mm from its exit point all the way out to 50m

and it will still be smaller well beyond 50m than if

the beam had not been collimated. With this approach, all surfaces in the <50m range are captured with a spot size <6mm. Users don’t have

this, setup I want to achieve a spot size of Xmm at a distance of Ym”

and then dials it in. On the surface, this approach may seem attractive, but it has potential drawbacks. To achieve a focused, small

spot size further away, the beam will have to be larger closer to the

scanner. So objects in the near-field will be captured with a bigger

spot size, in some cases much larger depending on conditions. The

same holds true for objects much further away. A second potential

drawback is that variable beam expanders are moving, mechanical devices that can introduce additional error into each individual measurement and have to be calibrated over the full range of focus. So, while the visual definition of a particular object may appear

better to the eye, the actual measurement accuracy may suffer. Another drawback is cost and reliability, as these approaches add cost

and complexity to the optics system. Specifying the accuracy of such

systems is also a challenge, as accuracy specs have to state the extent to which a beam is being focused for a particular measurement

accuracy claim.

Try it Out

Regardless of how vendors specify their scanners with respect to

spot size (or any other feature), some vendors are more conservative

in their specs than others. So two scanners specified with the same

spot size, and all other factors being equal, can still show differences

in the level of definition achieved.

A scan beam that has a small diameter over a long, useful range

can provide users with significant benefits in both the level of definition achieved and field productivity. Those evaluating laser scanning should be careful to understand the basis of vendors’ specs for

this key feature and how a given scanner’s spot size changes with distance from any given scanner. Testing scanners and talking with peers

who have used different types of scanners can also help in assessing

this factor.

W0

beam expander

–

W(–ZR) = √2W0

–

GEOFF JACOBS is a senior vice president, strategic

marketing for Leica Geosystems, HDS, Inc. and also a

contributing writer for the magazine.

W(ZR) = √2W0

ZR

ZR

Figure 5: Focusing a beam expander to minimize beam

radius and spread over a specified distance

to worry about spot size being too big within

the 50m range. This type of approach can minimize the number of times the scanner has to

be moved around the site to achieve the desired

level of survey definition.

A third technical approach to optimizing spot

size is to apply a variable beam expander in the

path of the laser beam. The user can say, “From

DISPLAYED WITH PERMISSION • PROFESSIONAL SURVEYOR MAGAZINE • October 2006 •

WWW.PROFSURV.COM

• ALL RIGHTS RESERVED