Embedded Integrated Inductors With A Single Layer

advertisement

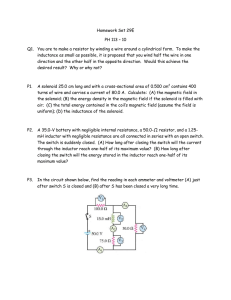

Embedded Integrated Inductors With A Single Layer Magnetic Core: A Realistic Option - Bridging the gap between discrete inductors and planar spiral inductors Dok Won Lee, LiangLiang Li, and Shan X. Wang Department of Materials Science and Engineering Department of Electrical Engineering 1 Outline I. Introduction II. Analytical Models and Inductor Design III. Fabrication of Integrated Inductors IV. Measurement of Fabricated Inductors V. Analysis of Magnetic Inductors on Si VI. Conclusion 2 Use of Inductors in Our Daily Lives • Traffic light • Red-light camera • Metal detector • RFID tag Texas Instruments Tag-itTM • Voltage regulator module • Cell phone 3 Why Integrated Inductors? Fully integrated electronics R.K. Ulrich and L.W. Schaper, “Integrated Passive Component Technology”, 2003 4 Example: Power Management DC-DC converter Passive components are discrete and occupy large areas IC containing gate driver and power MOSFETs Inductor Capacitors Enpirion EN5330 PSoC (Power-System-on-a-Chip) * 70% of pc-board area saved * R. Allen, Electronic Design, May 2004 5 Inductance Requirement for Power Management Discrete inductors ☺ Large inductance Large volume Poor AC performance 10 uH Inductance 1 uH 100 nH Planar spiral inductors ☺ Small area consumption Small inductance Limited performance in sub-GHz applications 10 nH 1 nH 100 pH 100 kHz 1 MHz 10 MHz 100 MHz 1 GHz 10 GHz Frequency From A. Ghahary, Power Electronics Technology, Aug. 2004 6 Schematics of Magnetic Inductor Designs Transmission line ☺ Small resistance Small inductance Usually two magnetic layers needed Spiral inductor ☺ Close to the planar spiral Limited inductance gain One or two magnetic layers Solenoid inductor ☺ Magnetically efficient Relatively complex structure ☺ One magnetic layer 7 Brief Rev of Integrated Magnetic Inductors Intel, Tyndall ≥ Tohoku CEA-LETI Taken from Lee et al, Embedded Inductors with Magnetic Cores, Book Chapter in press (Springer) 8 Magnetic Inductors from Stanford & Cowork P. K. Amiri, et al. Intermag 08, CV 01 Planar transmission line inductor with CoTaZr core, Q = 6 @ 700 MHz A.M. Crawford, et al. IEEE Trans. Magn. 2002, p.3168-70 Planar spiral inductor with CoTaZr core, CMOS compatibility, Q ~ 2.7 @ 1 GHz L. Li, D. W. Lee, et al. IEEE Trans. Advanced Packaging (accepted 2008) On-package solenoid inductor with CoFeHfO core, Q = 22 @ 200~300 MHz, Rdc ~ 10 mΩ D. W. Lee, et al. Intermag 08, AG 01 (invited) Planar solenoid inductor with CoTaZr core, Inductance enhancement over air core = 34x 9 Q>6 @ 26 MHz II. Analytical Models and Inductor Design I. Introduction II. Analytical Models and Inductor Design • • • • Analytical models for key device properties Material selection Optimization of design parameters Inductor design concepts III. Fabrication of Integrated Inductors IV. Measurement of Fabricated Inductors V. Analysis of Magnetic Inductors on Si VI. Conclusion 10 Schematics of Integrated Solenoid Inductor • Solenoid inductor design was mainly considered in this work. Top view Cross-section view wM lC wV wC sV tM tA tC lA, lM g gV sV wA 11 Key Device Properties • Inductance L • Resistance R • Quality factor Q Q = 2π Energy stored ωL = Power dissipation ⋅ T R • Device area • Useful bandwidth 12 Inductance of Magnetic Inductor LMC Inductance of magnetic inductor LMC: µ0 µeff N 2 wM tM µ0 µr N 2 wM tM where ∆L = = lM [1 + N d ( µr − 1)] lM N d = Demagnetizing factor of rectangular prism µeff ≡ µr 1 + N d ( µr − 1) • For a finite-sized magnetic core, there is a demagnetizing field inside the magnetic core, which effectively reduces µr. ∆Lsimulated (H) LMC = LAC + ∆L 5x10 -8 4x10 -8 3x10 -8 2x10 -8 1x10 -8 Slope = 1.01 ± 0.01 HFSS simulations Linear fit 0 0 1x10 -8 2x10 -8 3x10 -8 4x10 -8 5x10 -8 ∆Lcalculated (H) • Demagnetizing field is not uniform inside the magnetic core, and the numerical solutions should be used for µr > 1.* Inductance enhancement: ∆L LMC − LAC A = ≈ µeff MC LAC LAC AAC ,eff Much less than µr but still significant AMC AAC,eff * D.-X. Chen et al., IEEE Trans. Magn., 41, 2077 (2005) 13 Resistance of Magnetic Inductor RMC Resistance of magnetic inductor RMC: • From the classical electromagnetism:* 1 Magnetic contribution to the energy stored E Magnetic = ∫∫∫ µ ' H 2 dV 2 Magnetic power loss PMagnetic = ∫∫∫ ωµ" H 2 dV ⎛ µ" ⎞ PMagnetic ≈ 2ω ⎜⎜ ⎟⎟ EMagnetic ⎝ µ' ⎠ • Representing in terms of the device properties: PMagnetic = ( RMC − RAC ) I 2 = ∆RI 2 where ∆R ≡ RMC − RAC EMagnetic = EMagnetic inductor − E Air core inductor = 1 1 1 LMC I 2 − LAC I 2 = ∆LI 2 2 2 2 ⎛ µ" ⎞ ∴ RMC = RAC + ∆R = RAC + ω ⎜⎜ ⎟⎟∆L ⎝ µ' ⎠ R ∆R for large ∆L ∆R for small ∆L RAC Freq. ⎛ µ" ⎞ ∆R = ω ⎜⎜ ⎟⎟ ∆L ⎝ µ' ⎠ Both ω and (µ”/µ’) increase with frequency. Hence ∆R becomes significant as the frequency increases. The more inductance enhancement we obtain by using a magnetic core, the more resistive losses we introduce at high frequencies. * R.F. Harrington, “Time-Harmonic Electromagnetic Fields”, 1961 14 Quality factor Q Quality factor of air core inductor QAC: Quality factor of magnetic inductor QMC: 10 Quality factor 8 6 LAC RAC QMC = ω LMC =ω RMC LAC + ∆L ⎛ µ" ⎞ RAC + ω ⎜ ⎟∆L ⎝ µ' ⎠ ∆L/LAC=1 ∆L/LAC=10 ∆L/LAC=30 QAC µ'/µ" 4 ∆L << LAC QMC ~ QAC at low frequencies ∆L >> LAC QMC ~ µ’/µ” at high frequencies fMC can be considered as the useful bandwidth of the magnetic inductor. 2 0 6 10 Q AC = ω 10 7 10 8 Frequency (Hz) fMC 10 9 15 Material Selection Conductor: Copper due to its low electrical resistivity Magnetic core: • Amorphous Co90Ta5Zr5 (at. %) alloy: - µ’ ~ 600 - Hc < 1 Oe - ρ ~ 108 µΩ-cm - fFMR ~ 1.5 GHz 2500 Relative permeability • Desirable properties: - High permeability - Soft magnetic material (low coercivity) - High resistivity - High ferromagnetic resonance (FMR) frequency 0.2 μm CoTaZr magnetic film 2000 µ' µ" 1500 1000 500 0 6 10 10 7 10 8 10 9 Frequency (Hz) 16 Inductor Designs “Spiral” Planar spiral inductor with or without magnetic plane “Scale-down” “Standard” N = 4.5, 8.5, 17.5 N = 4.5 Solenoid inductor with lateral parameters scaled down by a factor of 2 while maintaining vertical parameters unchanged N = 4.5, 8.5, 17.5 “Series” “Closed core” Solenoid inductor with different magnetic core arrangement or shape N = 4.5, 8.5, 17.5 17 III. Fabrication of Integrated Inductors I. Introduction II. Analytical Models and Inductor Design III. Fabrication of Integrated Inductors • Fabrication steps • Images of fabricated inductor devices • Magnetic properties of processed magnetic core IV. Measurement of Fabricated Inductors V. Analysis of Magnetic Inductors on Si VI. Conclusion 18 Image of Fabricated Wafer Wafer (4”-dia.) map Die map “Air core inductors” “De-embedding structures” “Magnetic inductors” 19 SEM Images of Fabricated Inductor Devices “Spiral” “Standard” “Scale-down” 400 µm 400 µm 400 µm “Series” 400 µm “Closed core” 400 µm 20 FIB Cross-section Images of Fabricated Inductors Top Cu layer 6.6 um Polyimide 0.5 um Magnetic core 2.2 um Polyimide 2.0 um Bottom Cu layer 4.4 um Thermal oxide 50 µm Si substrate 2 µm • FIB images confirm the successful fabrication of multi-layered inductor devices. • The successful polyimide planarization is also confirmed, resulting in the continuous magnetic core layer. 21 Magnetic core shape affects permeability! B-H loops Easy Hard Relative permeability Normalized B 1.0 Permeability spectra 0.5 0.0 -0.5 -1.0 µ', blanket µ", blanket µ', processed µ", processed 600 Kerr microscope image Bottom conductor Magnetic core 400 200 0 -150 -100 -50 0 50 Field (H) 100 150 10 7 10 8 Frequency (Hz) 10 9 Easy axis 100 µm • Magnetic test structures identical to the actual magnetic cores were included in the wafer layout and processed in parallel with the inductor fabrication. • Magnetic measurements confirm that the magnetic core in the fabricated inductor maintains the desired soft magnetic properties. • The permeability spectra of blanket film and processed magnetic core structures are not identical to each other. 22 On-package Inductors on 8-inch Substrate Easy axis of CoFeHfO 12 13 21 22 23 24 31 32 33 34 42 43 Notch 23 Surface roughness affects permeability! Ra=128.6 nm Permeability spectra of patterned CoFeHfO bars on dielectric material Surface roughness of dielectric material The rough surface of dielectric material degrades the magnetic properties of CoFeHfO deposited on it (even before patterning). 24 IV. Measurement of Fabricated Inductors I. Introduction II. Analytical Models and Inductor Design III. Fabrication of Integrated Inductors IV. Measurement of Fabricated Inductors • Measurement method • Circuit model of integrated inductor • Measurement results of “Standard” inductors V. Permeability of CoTaZr Magnetic Cores VI. Conclusion 25 Device Properties of “Standard” Inductors - L Air core inductors Magnetic inductors -7 -7 1x10 1x10 N = 4.5 N = 8.5 N = 17.5 -8 -8 8x10 Inductance (H) Inductance (H) 8x10 -8 6x10 -8 4x10 N = 4.5 N = 8.5 N = 17.5 -8 6x10 -8 4x10 -8 -8 2x10 2x10 0 7 10 8 10 Frequency (Hz) 9 10 0 6 10 7 10 8 10 9 10 Frequency (Hz) • With the use of magnetic core, inductance is 70.2 nH for N = 17.5, and the inductance enhancement is as high as 34×. • The device area for N = 17.5 is 0.88 mm2, corresponding to an inductance density of 80 nH/mm2. 26 Device Properties of “Standard” Inductors - R Air core inductors Magnetic inductors 10 10 8 Resistance (Ω) Resistance (Ω) 8 N = 4.5 N = 8.5 N = 17.5 6 4 6 4 2 2 0 6 10 N = 4.5 N = 8.5 N = 17.5 7 10 8 10 9 10 0 6 10 Frequency (Hz) 7 10 8 10 9 10 Frequency (Hz) • Resistance at low frequencies is less than 1 Ω. • Resistance of magnetic inductors increases greatly at high frequencies due to the magnetic power losses. 27 Device Properties of “Standard” Inductors - Q Air core inductors Magnetic inductors 10 N = 4.5 N = 8.5 N = 17.5 8 Quality factor Quality factor 8 10 6 4 2 0 6 10 N = 4.5 N = 8.5 N = 17.5 6 4 2 7 10 8 10 Frequency (Hz) 9 10 0 6 10 7 10 8 10 9 10 Frequency (Hz) • Quality factor of magnetic inductor is above 6 at 20 MHz for N = 17.5, and the enhancement over air core is well above 10×. However, it starts to decrease as the frequency increases due to the magnetic power losses. 28 Five-Turn Magnetic Inductor on Package 29 V. Analysis of Measurement Results I. Introduction II. Analytical Models and Inductor Design III. Fabrication of Integrated Inductors IV. Measurement of Fabricated Inductors V. Analysis of Magnetic Inductors on Si • Comparison with analytical models • Effect of magnetic core shape • Effect of scaling down VI. Conclusion 30 Comparison with Analytical Models (I) Inductance (@ 10 MHz) 6x10 4x10 2x10 -9 -9 34× -9 8x10 -8 6x10 -8 4x10 -8 2x10 -8 -9 0 0 0 5 10 15 Number of turns 20 25 1.0 LMC (H) LAC (H) 8x10 -7 Resistance @ 1MHz (Ω) 1x10 1x10 Air core, measurement Air core, simulation Air core, calculation Magnetic, measurement Magnetic, simulation Magnetic, calculation -8 Coil resistance Air core, measurement Magnetic, measurement Calculation 0.8 0.6 0.4 0.2 0.0 0 5 10 15 20 25 Number of turns • The good agreements confirm that the analytic models can accurately describe the inductances of air core and magnetic inductors and their coil resistances. • It indicates that the demagnetization effect plays a major role in determining the effective permeability of the magnetic inductors. • The calculated inductance enhancement is about 30× for N = 17.5, which is very close to the observed enhancement of 34×. 31 Comparison with Analytical Models (II) Trade-off between ∆L and ∆R “Standard” with N = 17.5 10 12 ∆R (Ω) 6 Measurement Calculation 8 4 2 0 0.0 5.0x10 -8 1.0x10 ∆L (H) -7 1.5x10 -7 8 6 6 4 4 2 2 0 6 10 10 7 10 8 Quality factor 8 ⎛ µ" ⎞ ∆R = ω⎜⎜ ⎟⎟∆L ⎝ µ' ⎠ Resistance (Ω) 10 20 MHz 40 MHz 60 MHz 10 R measured R calculated Q measured Q calculated 0 9 10 Frequency (Hz) • Permeability spectra of the processed magnetic core are used for the calculations of resistance and quality factor of the magnetic inductor. • The excellent agreements between the calculation and measurement results directly confirm the validity of the proposed analytical models. 32 Effect of Magnetic Core Shape (I) “Series” Inductance (H) “Closed core” 2.0x10 -7 1.5x10 -7 1.0x10 -7 5.0x10 -8 Inductance (@ 10 MHz) Standard, measurement Standard, simulation Series, measurement Series, simulation Closed core, measurement Closed core, simulation “Standard” 0.0 0 5 10 15 20 Number of turns • For a given number of turns, the inductance of the “series” inductor is nearly doubled from those of the “standard” inductor, indicating that the “series” inductor can be viewed as two “standard” inductors connected in series. 33 Effect of Magnetic Core Shape (II) Inductance (@ 10 MHz) “Closed core” “Two bars” -7 2.0x10 Closed core, measurement Closed core, simulation Two bars, simulation -7 Inductance (H) 1.5x10 -7 1.0x10 -8 5.0x10 0.0 0 µ’ = 600 5 10 15 20 Number of turns • Simulation results indicate that the effective shape of the closed magnetic core should be viewed as two parallel magnetic bars closed by two “bad” soft magnets. • Hence, the closed magnetic core is not effective in improving the magnetic flux closure significantly, and it can be explained by the tensor nature of permeability of the magnetic core. 34 Effect of Scaling Down 6x10 -8 5x10 -8 4x10 -8 3x10 -8 2x10 -8 1x10 -8 Resistance 10 N = 4.5 N = 8.5 N = 17.5 8 Resistance (Ω) Inductance (H) Inductance 6 4 2 0 10 N = 4.5 N = 8.5 N = 17.5 6 10 7 10 8 Frequency (Hz) 10 9 0 6 10 10 7 10 8 10 9 Frequency (Hz) • Inductance is 48.4 nH at 10 MHz for N = 17.5, and the device area is reduced by a factor of four to 0.22 mm2, resulting in the inductance density to 219 nH/mm2. • The coil resistance is not affected by the scale-down and is measured to be 0.57 Ω for N = 17.5 at 1 MHz. 35 Bridging the Gap 10 uH Discrete inductors Inductance 1 uH 100 nH Integrated magnetic inductors 10 nH 1 nH Planar spiral inductors 100 pH 100 kHz 1 MHz 10 MHz 100 MHz 1 GHz 10 GHz Frequency 36 Summary High-performance integrated magnetic inductors were successfully designed and fabricated: • For the coil resistance less than 1 Ω and the device area below 1 mm2, the inductance as high as 70.4 nH was obtained on Si, corresponding to the inductance enhancement of 34× over the air core equivalent, and the inductance density reached 219nH/mm2. For DC resistance ~ 10 mΩ and device area of ~14 mm2: Q ~ 25 at 200 MHz for magnetic inductor on package. An analytical model can accurately describe the actual device properties: • The fundamental trade-offs (∆L vs ∆R) of the integrated magnetic inductors are well understood. The inductor device properties can be further optimized (by materials or design) for a given application or frequency range. 37