Zener Diode Temperature Dependency: Application Note

advertisement

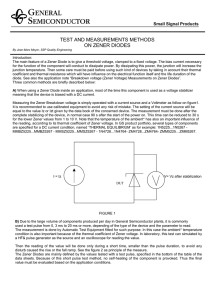

VISHAY SEMICONDUCTORS Zener and Suppressor Diodes Application Note Temperature Dependency of Zener Voltage External warm up phase Internal warm up phase 46.0 V 45.5 V Thermal coupling: Diode position between the heat sinks Iz A B C Vz A 45.0 V Thermal Equilibrium pulsed D 44.5 V Iz = 10mA B Zener Voltage 44.0 V A B C D C 43.5 V Iz = 5mA D 43.0 V 42.5 V A B C D Iz = 1mA 42.0 V 41.5 V TAmbient (heat sink) = 25°C 41.0 V 0.00001 s 0.0001 s 0.001 s 0.01 s 0.1 s 1s 10 s 100 s Pulse duraon 22268 Fig. 1 - Zener Voltage Change vs. Pulse Duration Phase 1: Internal warm up phase The current starts to heat the silicon of the p/n junction and charge the caloric capacitance of the material around the junction. The heat moves from the warm junction through the silicon chip to the metal contact inside the glass package to the terminals of the wire. With the rising temperature, the Zener voltage increases according to the temperature coefficient (TC). Document Number: 84810 Revision: 01-Oct-10 For technical questions within your region, please contact one of the following: DiodesAmericas@vishay.com, DiodesAsia@vishay.com, DiodesEurope@vishay.com www.vishay.com 1 APPLICATION NOTE The Zener voltage (VZ) of a Zener or avalanche diode depends on the diode’s junction temperature. Any current running through the p/n junction barrier generates the electrical power of: P = IZ * VZ This electrical power is equivalent to the thermal power applied to this junction. Depending on the duration and the intensity of the current, the applied thermal energy increases and heats the junction. The upper diagram shows the Zener voltage change of a BZX85C43 Z-Diode in a DO-41 wired glass package during a constant current pulse. The diode is mounted between large heat sinks (copper blocks) with a stable temperature of 25 °C. Application Note Vishay Semiconductors Temperature Dependency of Zener Voltage Phase 2: External warm up phase The heat leaves the package and moves through the wires to the heat sink. In contrast to phase 1, during phase 2 thermal resistance can be influenced by the customer. The shorter the wires, the lower the additional thermal resistance to the heat sink with defined low temperature and vice versa. Phase 3: The thermal equilibrium The material along the following thermal path from the junction to the heat sink is now completely charged up; the junction temperature and thus the Zener voltage are now stabilized. The diagram shows that the test conditions are important in defining the Zener voltage of a Zener diode: • the Zener test current IZ • the junction temperature right before the pulse test • the point in time during the current pulse at which the voltage is measured APPLICATION NOTE • the junction-to-ambient thermal resistance. Document Number: 84810 Revision: 01-Oct-10 For technical questions within your region, please contact one of the following: DiodesAmericas@vishay.com, DiodesAsia@vishay.com, DiodesEurope@vishay.com www.vishay.com 2