Hydraulics and HWH Systems

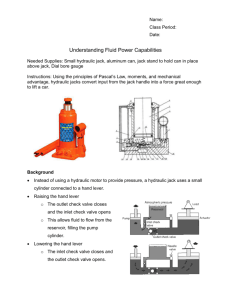

advertisement