VDC

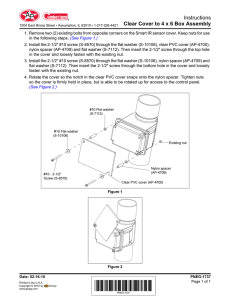

advertisement