Effective Protection for Demanding Applications

advertisement

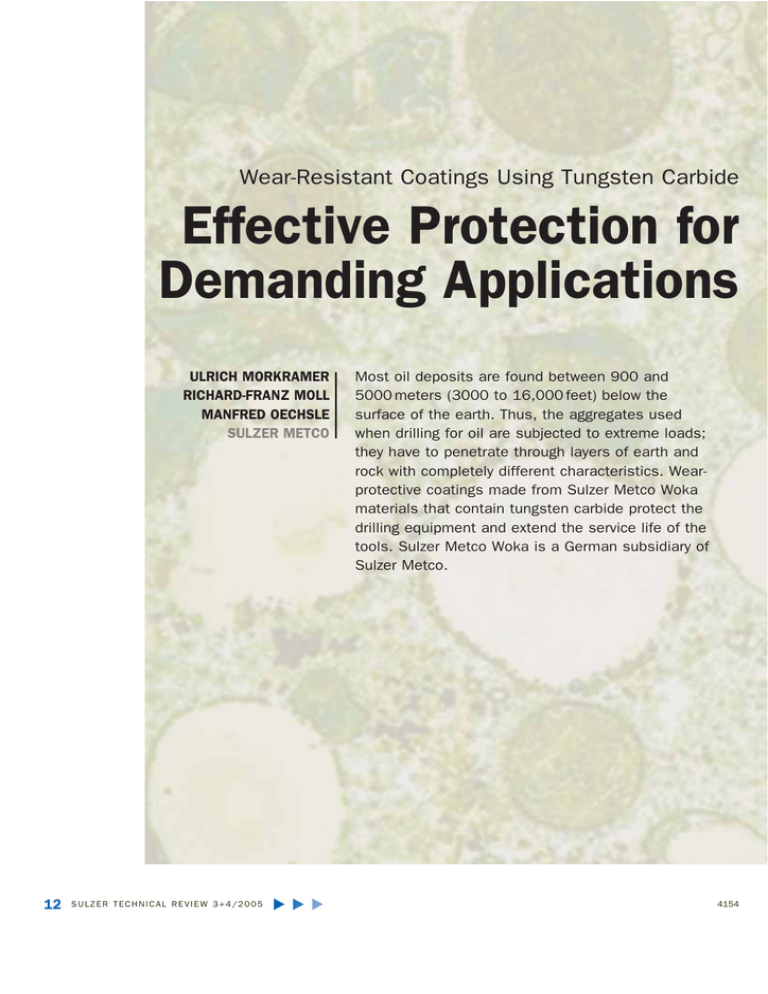

Wear-Resistant Coatings Using Tungsten Carbide Effective Protection for Demanding Applications ULRICH MORKRAMER RICHARD-FRANZ MOLL MANFRED OECHSLE SULZER METCO 12 SULZER TECHNICAL REVIEW 3+4/2005 Most oil deposits are found between 900 and 5000 meters (3000 to 16,000 feet) below the surface of the earth. Thus, the aggregates used when drilling for oil are subjected to extreme loads; they have to penetrate through layers of earth and rock with completely different characteristics. Wearprotective coatings made from Sulzer Metco Woka materials that contain tungsten carbide protect the drilling equipment and extend the service life of the tools. Sulzer Metco Woka is a German subsidiary of Sulzer Metco. 4154 Tungsten is a gray-white metal with a very high melting point and high tensile strength. Its carbon compounds, tungsten carbide WC and W2C, are almost as hard as diamond. They are particularly suitable for the manufacture of tools that are exposed to high loads, such as mining and drilling equipment (Fig. 1). The service life of drilling tools made from tungsten carbide exceeds that of steel drill bits by several times. 2 Sulzer Metco Woka delivers tungsten carbide that is tailor-made to the needs of the customers. Specialized knowledge about the behavior of the various carbide types makes it possible to systematically manufacture surfaces with specific properties. Crushed cast tungsten carbide Spherical cast tungsten carbide Macrocrystalline tungsten carbide Cemented tungsten carbide pellets Material Properties Combined Pure tungsten carbide (WC) is brittle, and is therefore mainly used in sintered cemented carbides (CC). In the production of cemented carbides, the extremely hard tungsten carbide grains are combined with a binder matrix of ductile metal by sintering—baking together of granular materials under heat and sometimes pressure. According to the desired hardness and strength of the cemented carbides, the grains of the added tungsten carbide vary in shape and size—from 0.2 µm to around 20 µm. From a chemical point of view, macrocrystalline tungsten carbide is not different from the WC used in cemented carbides. It has grain sizes of up to 200 µm and yet unchanged excellent thermal stability, making this material, which is also monocrystalline, particularly suitable for coating processes by welding. Another modification is cast tungsten carbide (WC-W2C), which is used crushed—with sharp edges—or in a spherical shape. The crushed cast tungsten carbide (CTC) is very hard and impactresistant. By contrast, due to its production method, spherical cast tungsten carbide (CTC-S), demonstrates significantly greater hardness. Cemented tungsten carbide pellets (WC-6Co) are less hard, but are considerably more ductile than spherical cast tungsten carbide. All these carbide types are used in hard facing, where the proportion and type of the various carbides has a decisive influence on the overall properties of the applied facings (Fig. 2). It takes technical know-how and experience in the correct combination of the tungsten carbide powder and the 200 µm 1 Equipment used for oil extraction is exposed to strong and diverse wear attacks. Here (left), a classification screen for the processing of oil-bearing sand in Canada, which has been coated by means of a PTA procedure. PTA hard facings, which are produced with additives from Sulzer Metco Woka, extend the service life of these tools. The enlargement shows a typical PTA powder mixture of tungsten carbide and matrix material. choice of the matrix material to be able to fulfill the specific requirements and customer specifications in a targeted manner. Thicker Layers Tungsten carbide overlay coatings can be applied by high-velocity oxygen fuel spraying (HVOF) or by welding. In general, the thinner HVOF facings, which are between 10 µm and 1000 µm thick, are used for the coating of valves and pistons and for the protection of pump impellers. The extremely abrasive conditions in mining and oil drilling demand thicker coatings and better bonding than are possible with spray processes. For example, the plasma-transferred arc (PTA) process using multilayer Protection against Different Types of Wear In order to effectively use a coating to protect the surface of a tool against wear, it is necessary to know what types of wear the tool might be subjected to. Solid body abrasion (A), erosion through fluid attack (B), and impact or cavitation (C) are A) Abrasion possible types of wear. In most cases, however, the wear mechanisms are extremely complex. The decisive factor for a successful coating is a good match in terms of the type, quantity, form, and size distribution of the carbide used. B) Erosion C) Impact and cavitation SULZER TECHNICAL REVIEW 3+4/2005 13 Cathode Cathode holder Ignition Plasma gas Cooling 3 In the PTA procedure, the base material that is to be coated and the matrix material for the coating are melted in a controlled manner. The hard components of the coating— for example, tungsten carbide grains—thereby retain their structure. Carrier gas Current source Protective gas Direction of welding technique can produce facings with thicknesses of up to 10 mm and more. PTA is an advanced coating procedure in which the powder is applied to the base material in a controlled protective gas atmosphere (Fig. 3). The transferred arc melts the base material in a controlled manner and thereby produces an extraordinarily strong metallurgical bond between the coating and the base material. Over and above the PTA procedure, all the classical processes for deposition welding are used for the production of wear protection coatings. Specific Coating Drill bits, such as those used in deep drilling, are exposed to a wide variety of wear attacks. Two of the greatest loads that this kind of drilling tool must withstand are impact with pieces of rock at the 4 The requirements for the surface affect the composition of the welding additives. For the illustrated roller bit, coatings are required with both high impact stability and high erosion resistance. 14 teeth of the drill bit and erosion through the fine-grain outbreak flushed upwards past the drill head (Fig. 4). The hardness and ductility of the coating can be specifically adjusted by selecting the correct tungsten carbide. Where high abrasion resistance is required, a hard facing can be applied; a suitably matched carbidematrix combination will be chosen for locations where ductility is essential. The characterization of such hard facings takes place according to standardized test procedures, for example, through the “G65” test of the international standardization organization ASTM International. For welded coatings, Sulzer Metco Woka offers an additive containing tungsten carbide in the form of filled tubular rods, wires, or flexible welding rods. These can then be melted by oxy-acetylene processes or by arc welding, and applied to the surface. The PTA procedure, on the other hand, makes use of materials in powder form that are mostly a mixture of different tungsten carbide and matrix alloys. The complete product range fulfills the relevant industrial standards, DIN EN ISO 9001 and AS 9100. Increased Service Life Better wear characteristics bring substantial advantages in operation. Inventory can be reduced as a result of extended service life. The extremely high costs resulting from long downtimes and tool changes during deep drilling can thereby be minimized. Sulzer Metco Woka’s highly wear-resistant coating materials containing tungsten carbide therefore lead to considerable savings for customers in the oil and gas industry. Contact 500 µm Coating with higher impact stability SULZER TECHNICAL REVIEW 3+4/2005 500 µm Coated roller bit Coating with higher erosion resistance Sulzer Metco Woka GmbH Manfred Oechsle Im Vorwerk 25 36456 Barchfeld Germany Phone +49 (0)36961 861 13 Fax +49 (0)36961 861 33 manfred.oechsle@sulzer.com