SENSORS

Delphi Mini-Switching Oxygen Sensors

Delphi Mini-Switching Oxygen Sensors provide stoichiometric

measurement of exhaust gases in gasoline and alternative fuel

engine applications to help manufacturers meet current and future

exhaust emissions standards by providing more accurate engine

control and better exhaust system diagnostics. The Mini-Switching

Sensors are based on Delphi's proven Switching Oxygen Sensor

technology, but feature a dramatic reduction in size and weight —

up to 50 percent smaller size and only about a third of the weight.

Their smaller size enables significantly reduced light-off — up to

50 percent faster — for improved emissions benefits.

Delphi Mini-Switching Oxygen Sensors, like Delphi's conventional

Switching Oxygen Sensors, feature planar element technology for

fast light-off and low cost, and they have a pumped air reference

feature to prevent air reference contamination. They also include

a zirconia-based element with planar geometry. Delphi MiniSwitching Oxygen Sensors can be used in an exhaust system in

either an engine-out or in a post-converter location.

Benefits

y

y

y

y

y

y

y

y

y

y

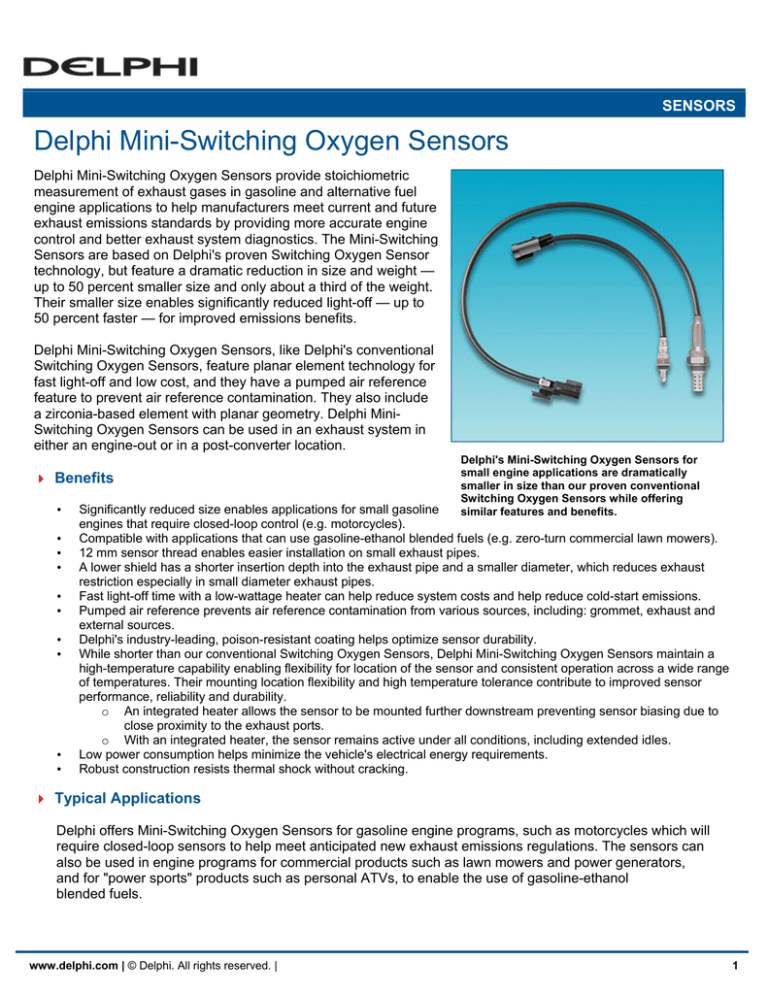

Delphi's Mini-Switching Oxygen Sensors for

small engine applications are dramatically

smaller in size than our proven conventional

Switching Oxygen Sensors while offering

similar features and benefits.

Significantly reduced size enables applications for small gasoline

engines that require closed-loop control (e.g. motorcycles).

Compatible with applications that can use gasoline-ethanol blended fuels (e.g. zero-turn commercial lawn mowers).

12 mm sensor thread enables easier installation on small exhaust pipes.

A lower shield has a shorter insertion depth into the exhaust pipe and a smaller diameter, which reduces exhaust

restriction especially in small diameter exhaust pipes.

Fast light-off time with a low-wattage heater can help reduce system costs and help reduce cold-start emissions.

Pumped air reference prevents air reference contamination from various sources, including: grommet, exhaust and

external sources.

Delphi's industry-leading, poison-resistant coating helps optimize sensor durability.

While shorter than our conventional Switching Oxygen Sensors, Delphi Mini-Switching Oxygen Sensors maintain a

high-temperature capability enabling flexibility for location of the sensor and consistent operation across a wide range

of temperatures. Their mounting location flexibility and high temperature tolerance contribute to improved sensor

performance, reliability and durability.

o An integrated heater allows the sensor to be mounted further downstream preventing sensor biasing due to

close proximity to the exhaust ports.

o With an integrated heater, the sensor remains active under all conditions, including extended idles.

Low power consumption helps minimize the vehicle's electrical energy requirements.

Robust construction resists thermal shock without cracking.

Typical Applications

Delphi offers Mini-Switching Oxygen Sensors for gasoline engine programs, such as motorcycles which will

require closed-loop sensors to help meet anticipated new exhaust emissions regulations. The sensors can

also be used in engine programs for commercial products such as lawn mowers and power generators,

and for "power sports" products such as personal ATVs, to enable the use of gasoline-ethanol

blended fuels.

www.delphi.com | © Delphi. All rights reserved. |

1

Delphi Mini-Switching Oxygen Sensors

Specifications

Performance Parameters

Rich voltage

Lean voltage

Rich to lean response time

Lean to rich response time

Static lambda

Sensor light-off or time to activity

Heater power at 13.5 V, 450°C exhaust

Heater in-rush current at 21°C, 13.5 V

13.5 V Applied Heater

>720 mV

<120 mV

<100 ms

<80 ms

1.004

<8 seconds

4 watts

<1 amp maximum

(Target performance at 450°C exhaust. For reference only.)

Availability

In serial production. Engineering samples are available to

manufacturers as part of the Delphi Multec® Electronic Fuel

Injection engine management system for small engines.

Contact Delphi for more information.

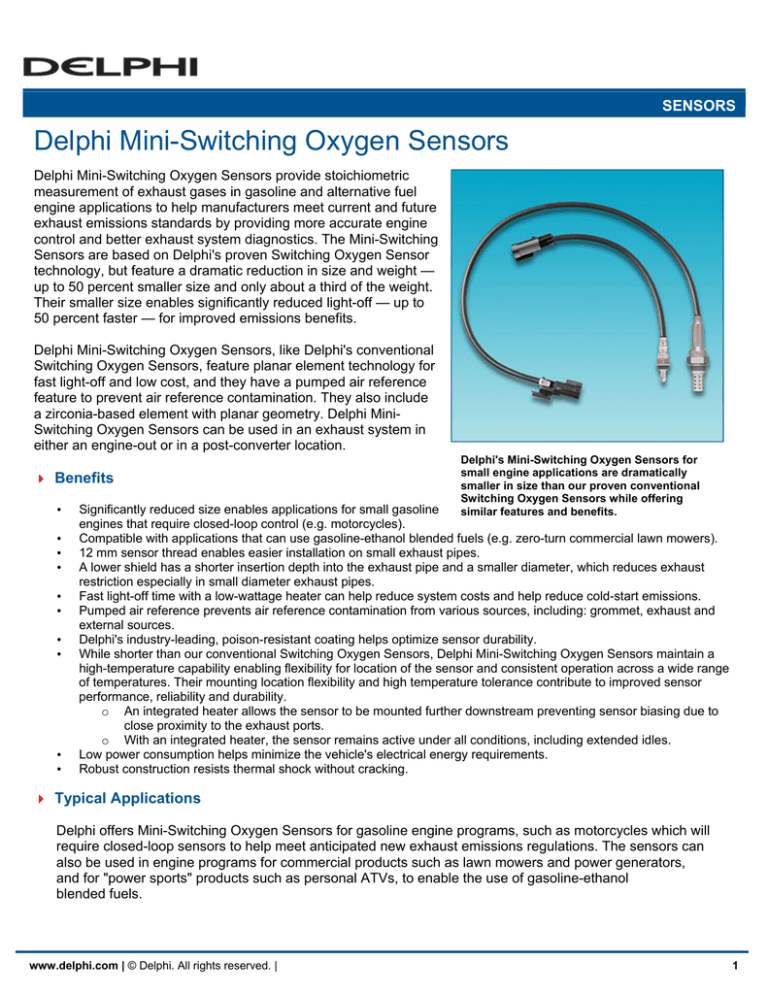

Performance Advantages

Delphi's Mini-Switching Oxygen Sensors offer

significant size reduction to enable improved

packaging for small gasoline engine applications.

The smaller size and weight of the Delphi Mini-Switching

Oxygen Sensors allow significant flexibility in small engine

programs. They offer performance advantages versus

conventional conical sensor technology including, faster light-off time and a low-wattage heater. They can

also help achieve lower cold-start emissions compared with conical sensor designs.

Compared to other switching oxygen sensors, Delphi Mini-Switching Oxygen Sensors (and Delphi's

conventional Switching Oxygen Sensors) offer a pumped air reference feature. They also feature

waterproofing, a high-temperature internal seal which helps provide robust reliability, and Delphi’s industryleading poison-resistant coatings.

Delphi's cost-competitive Mini-Switching Oxygen Sensors can help manufacturers develop products that

provide excellent value and deliver outstanding performance.

The Delphi Advantage

Delphi has one of the industry's most complete portfolios of sensors and a thorough understanding of

systems integration. Delphi offers global manufacturing capabilities for sensors and the benefits of more

than 30 years' experience in powertrain sensors research and production. Delphi has produced hundreds

of millions of exhaust sensors and can provide manufacturers with the necessary support and high quality,

high value products tailored to specific requirements.

As a global leader in engine management systems technology, Delphi can help manufacturers around the

world meet emissions requirements, improve fuel economy and enhance performance. Delphi is a source

for high value solutions and our systems expertise is built into every product. Delphi's flexible engineering

approach encourages collaboration. And, Delphi has a thorough understanding of markets around the

world and a global network of resources.

www.delphi.com | © Delphi. All rights reserved. |

2