L-9904-2390

Application note

RLE plane mirror application note

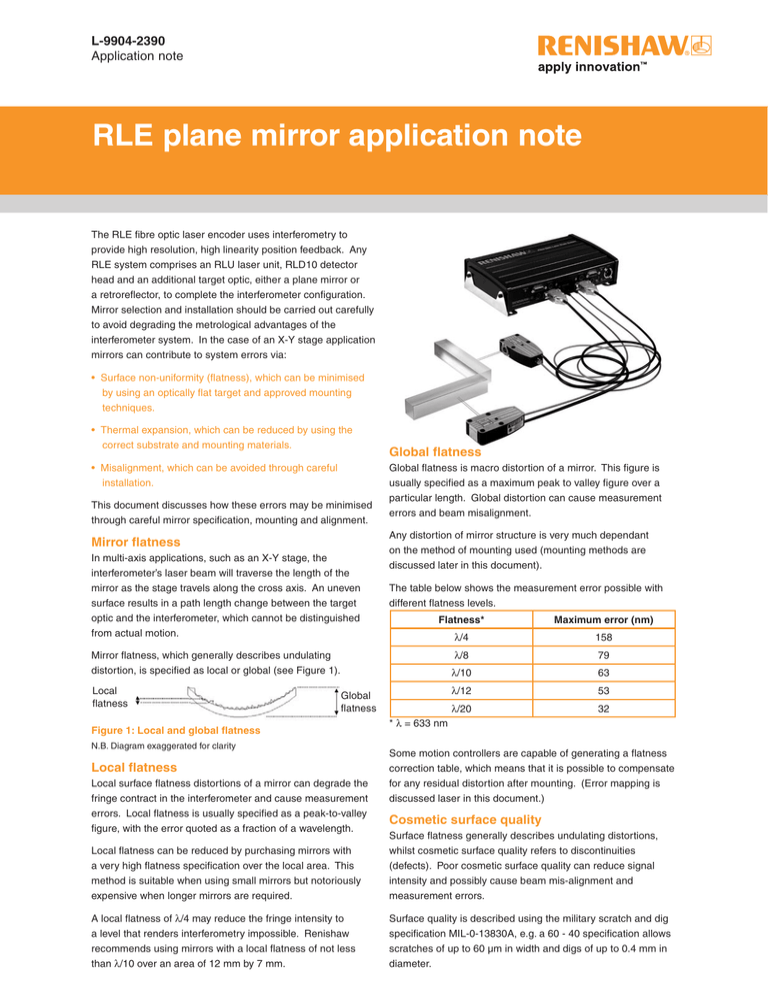

The RLE fibre optic laser encoder uses interferometry to

provide high resolution, high linearity position feedback. Any

RLE system comprises an RLU laser unit, RLD10 detector

head and an additional target optic, either a plane mirror or

a retroreflector, to complete the interferometer configuration.

Mirror selection and installation should be carried out carefully

to avoid degrading the metrological advantages of the

interferometer system. In the case of an X-Y stage application

mirrors can contribute to system errors via:

• Surface non-uniformity (flatness), which can be minimised

by using an optically flat target and approved mounting

techniques.

• Thermal expansion, which can be reduced by using the

correct substrate and mounting materials.

• Misalignment, which can be avoided through careful

installation.

This document discusses how these errors may be minimised

through careful mirror specification, mounting and alignment.

Mirror flatness

In multi-axis applications, such as an X-Y stage, the

interferometer’s laser beam will traverse the length of the

mirror as the stage travels along the cross axis. An uneven

surface results in a path length change between the target

optic and the interferometer, which cannot be distinguished

from actual motion.

Global flatness

Global flatness is macro distortion of a mirror. This figure is

usually specified as a maximum peak to valley figure over a

particular length. Global distortion can cause measurement

errors and beam misalignment.

Any distortion of mirror structure is very much dependant

on the method of mounting used (mounting methods are

discussed later in this document).

The table below shows the measurement error possible with

different flatness levels.

Flatness*

Maximum error (nm)

λ/4

158

λ/8

79

λ/10

63

λ/12

53

λ/20

32

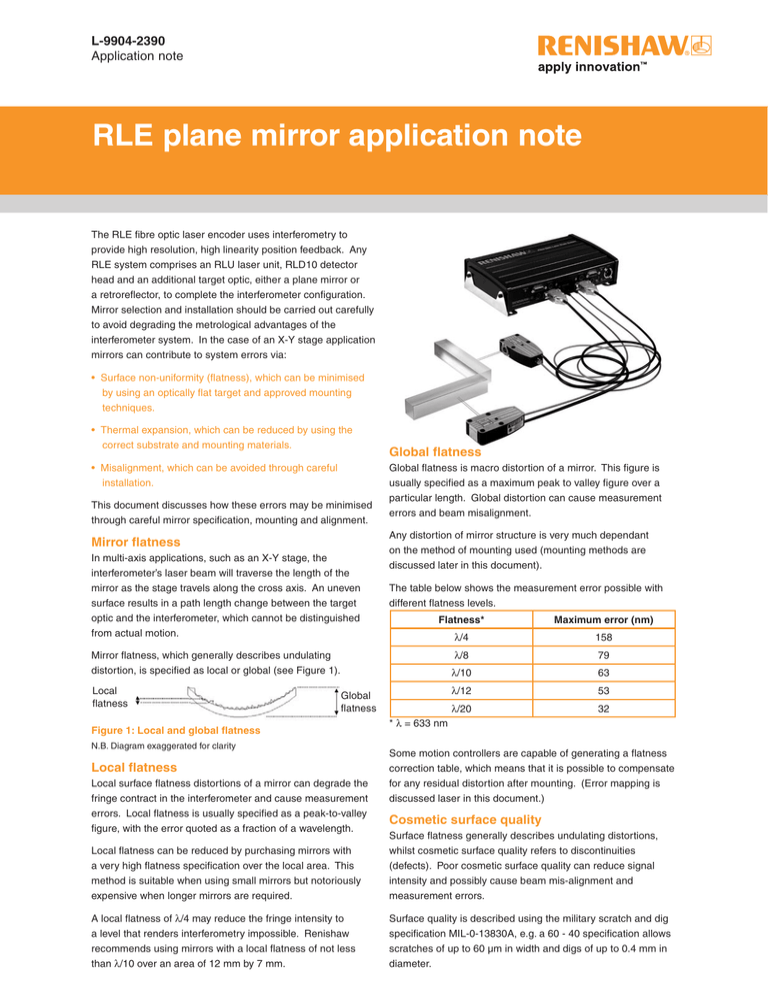

Mirror flatness, which generally describes undulating

distortion, is specified as local or global (see Figure 1).

Local

flatness

Global

flatness

Figure 1: Local and global flatness

N.B. Diagram exaggerated for clarity

Local flatness

Local surface flatness distortions of a mirror can degrade the

fringe contract in the interferometer and cause measurement

errors. Local flatness is usually specified as a peak-to-valley

figure, with the error quoted as a fraction of a wavelength.

* λ = 633 nm

Some motion controllers are capable of generating a flatness

correction table, which means that it is possible to compensate

for any residual distortion after mounting. (Error mapping is

discussed laser in this document.)

Cosmetic surface quality

Local flatness can be reduced by purchasing mirrors with

a very high flatness specification over the local area. This

method is suitable when using small mirrors but notoriously

expensive when longer mirrors are required.

Surface flatness generally describes undulating distortions,

whilst cosmetic surface quality refers to discontinuities

(defects). Poor cosmetic surface quality can reduce signal

intensity and possibly cause beam mis-alignment and

measurement errors.

A local flatness of λ/4 may reduce the fringe intensity to

a level that renders interferometry impossible. Renishaw

recommends using mirrors with a local flatness of not less

than λ/10 over an area of 12 mm by 7 mm.

Surface quality is described using the military scratch and dig

specification MIL-0-13830A, e.g. a 60 - 40 specification allows

scratches of up to 60 µm in width and digs of up to 0.4 mm in

diameter.

Renishaw recommends using a mirror with a scratch and dig

specification of no more than 60 - 40. For a more detailed

description of this specification, including maximum combined

length figures, please contact a Renishaw representative or

reference MIL-0-13830A.

Thermal expansion error

Mirror substrate material can contribute to measurement

error through thermal expansion, although it will usually be

negligible when compared to the expansion of the rest of

the system. In order to minimise this error, a material with a

low coefficient of thermal expansion (CTE) should be used.

The table below shows the CTE (ppm/°C) for some common

substrates and the maximum measurement error (µm)

generated by a 25 mm thick substrate over a 1 °C change.

CTE (ppm/°C)

Maximum error

(µm)

Fused silica

0.5

0.013

Zerodur™

0.1

0.003

8

0.2

Typical glass

Angular deviation

(arc sec)

Measurement

error (ppm)

Measurement

error* (ppm)

0.5

2

0.7

1

5

1.5

2

10

3

3

15

4

4

20

6

5

24

7

* for a 300 mm long mirror

• Cosine error is caused when the mirror is not perpendicular

to the axis of motion, or the laser beam is not parallel to the

axis of motion (see Figure 4).

Interferometer

Stage travel

Mirror

Mirror misalignment

In plane mirror interferometry, the position of the motion

platform is obtained by direct reference to the mirrors, which

eliminate the influence of any mechanical inaccuracies in the

motion system slideways. If mirrors are properly aligned,

linear errors, which would normally result from mechanical

deviations in straightness, orthogonality, pitch and yaw, are

removed (assuming no Abbé errors are present).

Mirror misalignment can cause three types of error: parallel,

orthogonal and cosine.

• Parallel error is caused when the mirror is not aligned

parallel to stage travel (see Figure 2).

Stage travel

Interferometer

Figure 4: Cosine error

A measurement error, x, is produced when a mirror is

misaligned such that it has an angular deviation, ø, from the

perpendicular motion axis of length L (x = L(1 - cosine ø)).

The following table shows the measurement errors possible as

a result of cosine misalignment on a 300 mm axis.

Angular deviation (arc sec)

Measurement error* (nm)

5

0.09

10

0.4

20

1.4

30

3.2

40

5.6

50

8.8

Mirror misalignment errors can be overcome in the following

ways:

Mirror

Figure 2: Parallel error

• Orthogonality error is caused when the mirror axes are not

truly orthogonal to each other (see Figure 3).

Stage travel

Stage travel

Interferometer

Figure 3: Orthogonality error

These misalignments mean that as an axis is traversed the

path difference between the cross-axis interferometer and

the mirror changes. This change is interpreted as stage

movement, which results in a measurement error.

A measurement error, x, is produced when a mirror of length L

is misaligned such that it has an angular deviation, ø, from the

parallel axis, or, ø±90, from the orthogonal mirror (x = L sine ø).

The following table shows the measurement errors possible as

a result of parallel or orthogonality misalignment.

• Carefully following a thorough alignment procedure, such as

the one detailed in this document.

• Using a mono-lithic L-mirror with a high orthogonality

specification, instead of two stick mirrors.

N.B. L-mirrors are expensive and vendors may be

unwilling to quote below 1 arcsec (1 arcsec can create a

measurement error of 5 µm/m).

• Approximately aligning the system and then compensating

for any error through a controller or compensation unit.

It is important to note that the accurate alignment of stick

mirrors, or the use of L-mirrors, can produce a mirror system

with a superior orthogonality to that of the stage axes.

Mirror mounting

Mounting is critical if mirror movement or distortion, which

results in measurement errors, is to be avoided. Mirrors can

be mounted directly to the stage, but it is more useful for

them to be secured via a mount that can assist in alignment.

Mounts are commercially available for stick mirrors, plate

mirrors and L-mirrors.

Renishaw stick mirror mounts

Renishaw supply three point kinematic mounts for mirrors

of up to 350 mm in length and 25 mm square cross section,

which allow fine pitch and yaw adjustment. The mounts are

constructed to minimise errors due to differential expansion

and have reliable positional locks that provide clamping to

overcome acceleration, deceleration and bump forces.

Adjustment sensitivity

Yaw sensitivity*

Pitch sensitivity

0.5 arcsec / degree of rotation

< 1 arcsec / degree of rotation

• Finely adjust the pitch of the Y-mirror to allow the laser to

reflect back into the interferometer output (set to a suitable

resolution), move the X-axis along full travel and align the

mirror yaw for minimum count difference between end limits.

4. Engage the locking mechanism on the Y-mirror.

5. Align the X-axis mirror and interferometer parallel to the Yaxis by repeating steps 1, 2, 3 and 4.

3-point levelling

stand

True square

X-mirror

* for a 350 mm long mirror

Y-mirror

For more information regarding Renishaw mirror mounts,

please contact a Renishaw representative or refer to

M-9904-2179.

Y-travel

Autocollimator

X-travel

Figure 6: Set-up terminology

Figure 5: Renishaw stick mirror mount

Typical alignment procedure

The following instructions demonstrate one method of aligning

two plane mirrors to an X-Y stage*. It is assumed that the

person performing the procedure is familiar with the test

equipment, all mechanical adjustments of the motion stages

have been completed, the RLD10 detector heads are fully

mounted and the axes are fully operational.

The pitch of the mirrors is now aligned and they are parallel

to the axes of travel. However, the mirrors are aligned to

the mechanical orthogonality of the X and Y-axes, which

may not provide you with the ultimate accuracy. The mirrors’

orthogonality can be aligned to the precision of a true square,

which can provide accuracy to better than 0.5 arcsec.

Orthogonality alignment

Suitable equipment and recommended specification:

• Optical autocollimator - should have an aperture > 75 mm

and a resolution of at least 0.1 arcsec.

Suitable equipment and recommended specification:

• Master true square - should have an orthogonality of less

than 0.5 arcsec and be traceable to a calibration standard,

e.g. Starett-Weber Corporation produce a true square that

is traceable to National Institute of Standard and Technology

(NIST).

• Electronic indicator with a resolution of at least 0.1 µm

• Levelling stand.

1. Install the Y-mirror in its mount.

1. Align the true square onto the levelling plate in the centre of

the X and Y mirrors.

• Mount the autocollimator to the system base so that its

field of view is over both the Y-mirror and true square front

surface. It is important that the centre line field of view

coincides with the mirror / true square boundary. Ensure

the collimator is stable, free from vibration and that the

equipment has had adequate time to thermally adjust to the

measuring environment before performing any adjustments.

* If a vertical axis of motion is located under the mirrors a different

method of pitch alignment may be necessary.

2. Align the Y-interferometer parallel to Y-axis travel (remove

Y-interferometer cosine error):

• Move the Y-axis (with the X-axis movement locked) to

achieve the shortest separation between the Y-axis

interferometer and the mirror. Attach an alignment target

on the mirror surface so that the laser beam is on the target.

Move the axis to the further position from the RLD10 and

adjust the pitch and yaw of the RLD10 so the laser spot

does not exhibit any translation from the target. N.B. this

can be an iterative process and may require multiple near

and far field adjustment for the best alignment.

3. Align the Y-axis mirror parallel to the X-axis travel:

• Remove the target and visually align the Y-mirror so it is

parallel to the X-axis travel. (Alternatively lock the Y-axis

and position an electronic indicator on the front surface of

the mirror outside the optical aperture to prevent surface

damage. Move the X-axis along full travel and align the

mirror yaw for a zero reading at the end limits.

• Visually align the Y-mirror pitch so the mirror is perpendicular

to the X-Y plane.

• Block the front surface of the square and align the collimator

to the Y-mirror to obtain zero pitch and yaw measurements

(0.0 arcsec).

• Block the front surface of the mirror and view the pitch and

yaw of the true square. Adjust the true square until a zero

reading on the autocollimator is achieved.

Take care not to move the true square again as it is now the

reference for all remaining mirror adjustments.

2. Align the X-axis mirror parallel to the perpendicular surface

of the true square.

• Move and mount the autocollimator to the perpendicular

side of the machine, allowing its field of view to fall over the

X-axis mirror and true square. Ensure the centre line of the

Renishaw plc

Old Town, Wotton-under-Edge,

Gloucestershire GL12 7DW

United Kingdom

T +44 (0) 1453 844302

F +44 (0) 1453 844236

E laser.products@renishaw.com

www.renishaw.com

field of view coincides with the mirror / true square boundary.

• Cover the X-mirror and align the collimator to get a zero

reading (0.0 arcsec) from the front surface of the true

square. DO NOT move the true square.

• Block the true square and, viewing the X-mirror through the

collimator, adjust the yaw of the mirror for a zero reading.

Identification and ordering

Plane mirrors

Renishaw supply plane stick mirrors up to 300 mm in length

in multiples of 10, which meet the following specification

(DS/9904/1492/01A):

λ/10 over 100 mm

< 0.5 µm over 500 mm

Zerodur™

Hard oxide dielectric

L* (+ ~ 20 mm) × 25 × 25

3. If a locking function is provided on the mirror mounts*,

carefully tighten while reading the autocollimator to ensure

the mirror has not moved.

Local flatness

Global flatness

Substrate

Mirror coating

Dimensions

* some locking mechanisms may have a slight effect on the mirror

* L = optical aperture (working length)

alignment and must be considered when performing adjustments.

Upon completion of the above steps it is highly recommended

to bring the collimator back to the Y-axis mirror set-up and

perform the measurements again to verify nothing has

changed to affect the orthogonality.

Error mapping

As mentioned earlier in this document, orthogonality errors

and macro-mirror distortion can sometimes be compensated

for using the motion controller.

• Compensating for mirror distortion

A typical method involves locking one axis in place and,

using the stage interferometer and mirror, monitoring any

cross axis displacement as the axis is traversed. At the

same time, the stage motion is monitored independently

of the mirror, for way straightness deviations. If these two

readings are subtracted from each other any mechanical

variations will be isolated from the mirror deformation,

allowing the mirror’s distortion profile to be calculated.

Way straightness can be monitored down to 0.1 µm using a

calibration laser (or RLD10 with no internal optics (RLD10A3-XX)) and straightness optics (see Figure 7). If higher

precision mapping is required, a master should be used.

For a more detailed specification, please contact a Renishaw

representative.

Stick mirrors may be ordered directly from Renishaw using the

part numbering protocol shown below.

Y = modified for Renishaw mounts

N = not modified for Renishaw mounts

Part

number

RPM10 - Y X X X X

If your application demands a higher specification, please

contact a Renishaw representative.

Mirror mounts

Renishaw supply adjustable mirror mounts for stick mirrors of

up to 350 mm total length and 25 mm square cross section.

(For a more detailed specification, please contact a Renishaw

representative.)

Stick mirror mounts may be ordered directly from Renishaw

using the part number below.

S = stick mirror mount

Part

number

Laser source

Optical aperture

(mm) (< 300 mm,

multiples of 10 only)

RAM10 - S X - 0 1

Mirrors used in the Renishaw mounts must have location

features added to the base, so, if using mirrors not supplied by

Renishaw, it is advisable to contact a Renishaw representative

for further advice.

Stage

travel

Interferometer

Figure 7: Monitoring way straightness

• Compensating for mirror distortion and orthogonality

A typical method maps the system to a master on the

stage, e.g. a four-point standard such as a wafer calibrated

with fuducials. The master, in conjunction with a vision

system, can be used to obtain the constants for a crossaxis algorithm that the motion controller can then employ to

perform compensation.

Renishaw reserves the right to change specifications without notice.

© 2005 Renishaw plc. All rights reserved.

For worldwide contact details, please visit our

main website at www.renishaw.com/contact

Printed in England 0805 Part No. L-9904-2390-01