Application Note

Nitrous Oxide (N2O)

Contaminant Detection Using

MultiGas™ Purity Analyzer

Note #01/03

CUSTOMER PROBLEM

• Detection of H2O, NH3, NO, NO2, CO2, CO and CH4 to low ppb levels in high purity bulk N2O gas

• Improve quality of high purity bulk N2O gas production

• Increase product yield and performance

BACKGROUND

High purity bulk N2O is used as an oxygen source for chemical vapor deposition (CVD) of silicon dioxide layers in semiconductor

processing, as well as in LCD production. It has been proven that trace impurities in N2O have detrimental effects on device

performance. To monitor trace impurities in N2O, methods such as gas chromatography with discharge ionization detection have

been used to quantify CO, CO2, CH4 and H2O. However, this method is difficult to incorporate into production environments

since different columns and oven temperature programs are required to complete the analysis. For polar gas impurities such as NOx

and NH3 the chromatography is difficult, thus leading to higher detection limits than desired. One added disadvantage to gas

chromatography is that it cannot sample the gas stream continuously and cannot provide real-time analysis.

SOLUTION

The MKS MultiGas Purity Analyzer is a real-time, fully calibrated system for monitoring trace impurities in bulk gases, such as

N2O. The Purity Analyzer has been proven to monitor trace levels of H2O, NH3, NO, NO2, CO2, CO and CH4 in 100% N2O

gas, all in real-time and in production environments. The typical detection limits of selected contaminants in N2O are as follows:

Contaminant

H2O

Typical Detection Limit

10 ppb

NH3

NO

NO2

5 ppb

20 ppb

10 ppb

CO2

CO

CH4

2 ppb

10 ppb

15 ppb

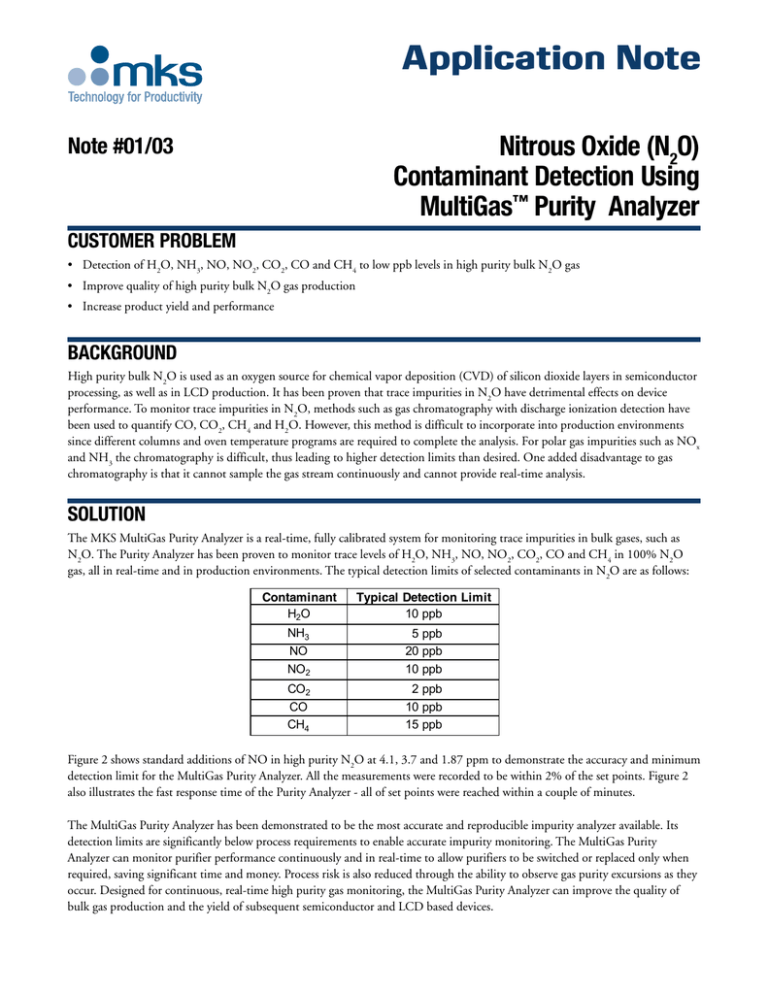

Figure 2 shows standard additions of NO in high purity N2O at 4.1, 3.7 and 1.87 ppm to demonstrate the accuracy and minimum

detection limit for the MultiGas Purity Analyzer. All the measurements were recorded to be within 2% of the set points. Figure 2

also illustrates the fast response time of the Purity Analyzer - all of set points were reached within a couple of minutes.

The MultiGas Purity Analyzer has been demonstrated to be the most accurate and reproducible impurity analyzer available. Its

detection limits are significantly below process requirements to enable accurate impurity monitoring. The MultiGas Purity

Analyzer can monitor purifier performance continuously and in real-time to allow purifiers to be switched or replaced only when

required, saving significant time and money. Process risk is also reduced through the ability to observe gas purity excursions as they

occur. Designed for continuous, real-time high purity gas monitoring, the MultiGas Purity Analyzer can improve the quality of

bulk gas production and the yield of subsequent semiconductor and LCD based devices.

Page 2

Application Note

SOLUTION (CONT'D)

Multiple NO Additions in N2O

MultiGas Purity

5

NO Generator Setpoints

4.5

NO Concentration (ppm)

4

3.5

3

2.5

2

1.5

1

0.5

0

-0.5

8:52 PM

10:48 PM

12:43 AM

2:38 AM

4:33 AM

Time

Figure 1: Spectral analysis of NO (blue) in 100% N2O (yellow)

illustrates the MultiGas Purity differentiation capabilities.

Figure 2: Chart of NO additions to high purity N2O. Figure used

with permission from BOC Edwards, Phoenix, AZ.

BENEFITS

The MultiGas Purity analyzer provides numerous benefits to high purity gas manufacturers, semiconductor manufacturers, and

LCD manufacturers:

• Improved product yield and performance at fabs

— Purifiers switched or replaced only when needed, not before

— Greater use of bulk cylinders

— Early warning of process gas purity upset

• Continuous measurement of N2O purity in real-time, in production environments - no lab analysis required

• ppb level impurity detection limits that are significantly below process requirements for accurate impurity detection

REFERENCE MATERIALS

MKS Publications:

MultiGas Purity datasheet

For further information, call your local MKS Sales Engineer or contact the MKS Applications Engineering Group at 800-227-8766.

MultiGas™ is a trademark of MKS Instruments, Inc., Wilmington, MA.

App. Note #01/03 - 4/03

© 2003 MKS Instruments, Inc.

All rights reserved.

Gas Analysis/FTIR

651 Lowell Street

Methuen, MA 01844

978.682.4567

MKS Global Headquarters

90 Industrial Way

Wilmington, MA 01887-4610

978.284.4000

800.227.8766 (in U.S.A.)

www.mksinst.com