Advances in Class-I C0G MLCC and SMD Film Capacitors

advertisement

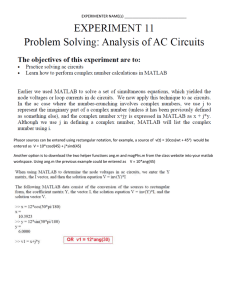

Advances in Class-I C0G MLCC and SMD Film Capacitors Xilin Xu, Matti Niskala*, Abhijit Gurav, Mark Laps, Kimmo Saarinen*, Aziz Tajuddin, Davide Montanari**, Francesco Bergamaschi**, and Evangelista Boni** KEMET Electronics Corporation, 2835 KEMET Way, Simpsonville, SC 29681 Tel: +01-864-963-6307, Fax: +01-864-963-6492, e-mail: aziztajuddin@kemet.com * SMD products, Evox Rifa Group Oyj, a Kemet Company Lars Sonckin kaari 16, 02600 Espoo, Finland Tel: + 358 50 3873205, Fax: + 358 50 83873205, e-mail: MattiNiskala@kemet.com ** SMD Products, Arcotronics Group, a Kemet Company via San Lorenzo 19, 40037 Sasso Marconi (Bologna), Italy Tel: +39 51 939 220, Fax: +39 51 939 324, e-mail: FrancescoBergamaschi@kemet.com ABSTRACT For applications requiring low dielectric losses (or low DF), low acoustic noise (no piezoelectric effect) and good temperature stability of capacitance, the top two choices are Class-I C0G MLCC and SMD film capacitors. There have been recent advances in both C0G MLCCs and SMD film capacitors. The C0G MLCCs have benefited from base metal electrodes (BME) in combination with an improved ability to stack well over 400 layers in the MLCC, and have resulted in cost effective and volumetrically efficient ratings up to 1 μF. The SMD film capacitors have seen significant advances in capacitance and voltage extensions, as well as heat resistance under lead-free soldering conditions. This paper will discuss the technical basis for advances in each of these technologies and give some guidance on the optimum areas (capacitance, size, voltage) for the application of each technology. INTRODUCTION In applications where capacitance needs to be precisely controlled over a wide temperature range with low dielectric losses or low acoustic noise, thru-hole film capacitors have been the optimum choice. These applications include digital tuning and high fidelity audio devices. Furthermore, the new Microsoft operating system - Windows Vista has strict audio-performance requirements to enhance the desktop and laptop PC audio quality and fidelity. Thus, hardware manufactures have to meet these requirements in circuit design and component selections in order to license the Windows Vista logo [1]. More recently, higher capacitance ceramic capacitors with a C0G dielectric and surface mount (SMD) film capacitors have become available. This paper describes the technological advances that have produced those solutions and gives some guidance on which solution should be selected. The Electronic Industry Association (EIA) specification for C0G dielectric, also known as NP0 (“negative-positivezero”), is that the capacitance variation from room temperature (25°C) should be within 0 ± 30 ppm/°C (or ΔC Max /C ≤ 0.3%) over the temperature range of -55°C to 125°C. The C0G dielectrics are usually non-ferroelectric materials, and exhibit linear response to voltage and temperature. Compared with Class-II dielectrics, typically X7R/X5R materials, C0G dielectrics have the advantages of high stability of capacitance over temperature and voltage, no aging, no microphonics, as well as a low dielectric loss. However, in the past, maximum capacitance values have been limited due to thick dielectric layers, and costs have been relatively high due to the use of precious metal electrodes (PME). This paper describes the advances that have allowed the use of thinner dielectric layers and the replacement of PME with base metal electrodes (BME) that allow the ceramic C0G dielectric capacitors to have competitive capacitances with film capacitors over a range of case sizes and voltages. © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA Typical plastic dielectrics for film capacitors include polypropylene (PP), polyethylene terephthalate (PET), polyethylene naphthalate (PEN), polyphenylene sulphide (PPS), and more rarely polytetrafluoroethylene (PTFE) and polyacrylic. Thermal stability requirements for surface mounting are more stringent than for thru-hole, and PP dielectric cannot meet the requirements. While PTFE meets the thermal stability requirements, it is expensive and not easily metallized, so it is only used in specialized applications. The typical plastic materials for SMD film capacitors are PET, PEN, and PPS. This paper describes the advances that have been made in order to make film capacitors based on these dielectrics resistant not only to surface mount reflow conditions, but to the very demanding reflow conditions required for Pb-free surface mounting. EXPERIMENTAL The capacitance was measured on a HP-4284A Precision LCR meter at 1 kHz and 1 V rms . Insulation resistance (IR), temperature coefficient of capacitance (TCC), and voltage coefficient of capacitance (VCC) were measured in a Saunders & Associates 4220A temperature test chamber. The reliability of MLCCs was characterized by highly accelerated life test (HALT), in which the acceleration is accomplished by temperature and voltage stresses. The HALT test was performed at 175°C and 400 Volts for 46 hours. A sample size of 40 pieces was used for each sample. HALT time-to-failure (TTF) was recorded when IR at test temperature dropped below 3.78 MΩ. In order to evaluate the electrical noise generated from a capacitor, a test setup was required to generate a constant mechanical shock to the capacitor while monitoring the electrical noise generated from the shock. To generate the mechanical shock, the capacitor was mounted to an FR4 PCB measuring 1”x1”x0.03” and then mounted to a fixture to hold the board in place. A rod was fabricated and dropped on the PCB directly adjacent to the capacitor from a constant height. Dropping the rod on the PCB generated sufficient energy to the board to create electrical noise in the capacitor. To monitor the amount of shock delivered to the capacitor, an accelerometer was mounted on the board directly below the capacitor. The accelerometer readings were registered on a multi-channel oscilloscope. Alone, an electrically noisy capacitor will not generate enough noise to be detectable on an oscilloscope. When these capacitors are used in the input stage of an amplifier, their induced electrical noise can be amplified and delivered to the output of the amplifier. It is therefore necessary to replicate this scenario by connecting the capacitor samples to the input stage of an amplifier and monitoring its output on an oscilloscope. For this setup, two wires connected the FR4 PCB to the footprint where the capacitor would be mounted in the amplifier. When the test sample is given a mechanical shock, the electrical noise will run through the input stage and then will be amplified to the output. The signal is then put through a differential amplifier with a 20dB gain. The output from the differential amplifier is analyzed on the oscilloscope. A schematic of this measurement setup is shown in Fig. 1. Capacitor samples made from BME C0G, standard X7R, PET, PEN, and PPS material with the same capacitance of 0.22 μF were tested. Oscilloscope Differential Amplifier Signal Conditioner DUT Shock Point Amplifier Accelerometer Fig. 1. Setup for measuring electrical noise performance. © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA DISCUSSION (1) Advances in C0G MLCCs Traditional C0G dielectric materials are mainly based on the barium neodymium titanate (BNT) and compatible with PME, such as Pd or Ag/Pd. To provide a more cost effective solution, the MLCC manufacturers have mostly converted from PME to BME (mainly Ni). The BME C0G dielectrics are mainly CaZrO 3 -based materials. BNT has a dielectric constant (k) of around 70, while the k of CaZrO 3 -based materials is around 30. Intuitively, we would expect that less capacitance in a given case size would result from the switch from BNT to CaZrO 3 -based materials. However, we are able to use much thinner layers of CaZrO 3 -based materials compared to BNT, and remarkably still obtain higher insulation resistance (IR) and higher reliability at a given voltage. This breakthrough has led to higher capacitance, lower cost, and robust MLCCs with C0G dielectrics [2, 3]. A comparison of the maximum capacitance offering for BME C0G with PME C0G by case size is shown in Fig. 2. Three voltage ratings, 25V, 50V, and 100V are compared. It is clear to see that the BME C0G can offer at least an order of magnitude higher capacitance than PME C0G in the same case size and same voltage rating. For example, for 25Vdc rated 1206 case size, the maximum capacitance offering of BME C0G is 100 nF, while PME C0G can only offer 10 nF capacitance. This plot also indicates that at the same capacitance and same voltage rating, the BME C0G MLCC has a much smaller case size than PME C0G MLCC, or much higher volumetric efficiency. 1000 PME 25V C0G BME 25V C0G PME 50V C0G 100 BME 50V C0G PME 100V C0G Max. CAP (nF) BME 100V C0G 10 1 0.1 0402 0603 0805 1206 1210 Case Size (EIA) Fig. 2. PME C0G vs. BME C0G: maximum capacitance offering. The reason why at the same case size and same voltage rating, BME C0G can offer much higher capacitance than PME is because of its thin, but high reliability dielectric layers. For example, the HALT reliability of two 1206 case size 103 (10nF) capacitance samples (one is PME C0G and the other is BME C0G) is shown in Fig. 3. These two samples both passed the required QA life test, which was performed at 125°C and twice rated voltage for 1000 hours. In order to make these parts fail, the HALT test was conducted at an extreme severe environment, which was at 175°C and 400V. Figure 3 shows that the BME1206-103 sample exhibits markedly longer time-to-failure (TTF) values compared to the PME1206-103. The median time-to-failure (MTTF) at HALT for PME1206-103 was 62.6 minutes, while for BME1206-103 was 869.6 minutes, more than an order of magnitude improvement in MTTF. Due to its excellent reliability, the BME 1206-103 sample is qualified as 50V rated, even though its dielectric thickness (6.97 μm) is much thinner than the PME 1206-103 sample (11.6 μm). © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA 99 Sample BME1206-103 PME1206-103 95 90 Percent 80 70 60 50 40 30 20 10 5 1 1 10 100 1000 10000 Time-to-failure (minutes) Fig. 3. HALT for PME and BME C0G MLCCs. (Please note that this HALT was run at 175°C and 400V.) With the BME C0G dielectric material and the breakthrough progress in BME thin layer processing technology, capacitance up to 1 μF C0G MLCC can be achieved in a 2824 case size. This 1 μF C0G MLCC is the highest capacitance C0G capacitor in a single chip and it is a milestone in the history of C0G based MLCCs. A photograph of this 1 μF C0G MLCC is shown in Fig. 4 and its typical properties are listed in Table I. Fig. 4. The 1st single chip 1 μF C0G MLCC in the industry. Table I. Characteristics of 2824-1μF BME C0G MLCC EIA Case Size Voltage Rating (Volts) Capacitance @ 1Vrms, 1kHz (μF) DF @ 1Vrms, 1kHz (%) TCC @ -55°C (ppm/°C) TCC @ 125°C (ppm/°C) Room Temperature IR @ 50V (GΩ) Breakdown Voltage (Volts) VCC (%) Aging Rate (%) Lead Free © 2824 50 Vdc 1.013 0.0047 -9.4 18.3 37.6 596.0 0 0 Yes 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA (2)Advances in SMD Film Capacitors SMD film capacitors are available both in Stacked and Wound constructions, and also both in Naked and Encapsulated configurations (as shown in Fig. 5 (a), (b), and (c)) in order to offer, according to the application, the smallest possible size, or the highest possible voltage, or the best possible environmental protection. (a) In Stacked & Naked configuration. (b) In Wound & Naked configuration. (c) In Encapsulated configuration. Fig. 5. Various configurations of film capacitors. The most challenging issue in using SMD film capacitors has been the lead free soldering process. The most common choices for lead free solders are different Tin-Silver-Copper (SAC) alloys. Processes using SAC solders cause extra stress, because of increased process temperatures, especially to the plastic film materials. KEMET has concentrated in developing SMD film capacitors to fulfil the lead free soldering process requirements according to International Electrotechnical Commission (IEC) 61760-1, Ed. 2, and also Jedec_020_D requirements [4]. These advances that have been obtained on SMD film capacitors have brought the maximum temperatures for reflow soldering profiles to 240°C, 255°C,and 260°C for PET, PEN and PPS capacitors respectively, as shown in Table II. The maximum allowed temperatures are linked to the melting temperature of the PEN, PET and PPS dielectrics. Other critical properties of the film dielectrics are also shown in Table II. © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA Table II. Film Dielectric Properties Film material PET Dielectric constant 3.3 Dissipation factor (%@1kHz) 0.5 > 25k Insulation resistance (MΩ*µF) Dielectric absorption (%) 0.5 Melting point (°C) 254 Max. Soldering Temp.* (°C) 240 Min. commercial thickness (µm) 0.9 (0.7) *measured on the component's upper surface. PEN 3 0.4 > 25k 1.2 266 255 1.4 PPS 3 0.05 > 50k 0.05 285 260 1.2 IEC has created a document for the processes for all SMD components, IEC 61760-1 Ed. 2, including recommended reflow soldering profiles, as shown in Fig. 6. This profile gives good advice for the electronics manufacturers, and KEMET supports it as a guideline for the safe soldering of its SMD Film Capacitors [4]. Continuous line: typical process (terminal temperature) Dotted line: process limits; Bottom process limit (terminal temperature) & Upper process limit (top surface temperature) Fig. 6. Recommended reflow soldering curve for SnAgCu solders taken from IEC 61760-1, Ed. 2 [5]. The other focus areas for the development of SMD film capacitors are to increase the capacitance value and nominal voltage, as well as the surge current withstanding capability (dU/dt). The capacitance range has been extended by development of SMD Wound Naked technology. As an example, the maximum standard offering capacitance values in PEN SMD have been improved as follows: - For 63 Vdc rating, maximum capacitance improved from 4.7 to 10 μF - For 100 Vdc rating, maximum capacitance improved from 4.7 to 5.6 μF - For 400 Vdc rating, maximum capacitance improved from 0.47 to 1.0 μF - For 630 Vdc rating, maximum capacitance improved from 0.27 to 0.56 μF. © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA Concerning the voltage range, in addition to the existing encapsulated range, a 1000 Vdc rated Stacked Naked PEN SMD series has been released to follow the trend of higher and higher voltages in application. The SMD film capacitors overall offering is therefore from 16 Vdc to 1000 Vdc. Concerning the dU/dt capability, special SMD PEN film capacitors can withstand up to 8500 V/µs at 1000 Vdc, as is needed e.g. in the HID lamp igniter applications. The standard range dU/dt values reach only to 2200 V/µs. The telecom market has special requirements for surge protection in infrastructure boards (e.g Central Office and Line Card boards). The reference standards are ITU K20 & K21 and Telcordia 1089. SMD PEN film capacitors are now available in special versions compliant to: - ITU K20 1500 V surge test (10/700 µs) - ITU K20 600 VAC test (2.2.1a&b / 2.2.2.a&b) - ITU K20 250 VAC test (2.3.1a) - Telcordia 1089 1000 V surge test (10/1000 µs & 2/10 µs) and 1500 V surge test (1.2/50 µs). (3) Comparison of C0G Ceramic and SMD Film Capacitors Due to the high volumetric efficiency of BME C0G MLCCs, their capacitance value can match those of SMD film capacitors over a range of case sizes and voltages less than or equal to 250 V [3]. A summary of the maximum capacitance offerings for 50Vdc rated KEMET BME C0G MLCC and KEMET film capacitors are illustrated in Fig. 7. SMD film capacitors are not readily available in case sizes smaller than 1206; BME C0G MLCCs are the capacitors of choice in that range when a low noise, high capacitance stability capacitor is needed. In the range of case sizes from 1206 to 2824, both BME C0G and SMD film capacitor are offered. The PEN film offerings are competitive with the BME C0G offerings over that range with maximum capacitance values somewhat less at the smaller end and somewhat more at the large end. The SMD PPS film capacitors offer about an order of magnitude less capacitance than the BME C0G MLCC or SMD PEN capacitors. For case sizes larger than 2824, currently only SMD film capacitors are available. 100000 KEMET C0G MLCC KEMET PEN Film 10000 KEMET PPS Film 50VDC Rated Max CAP (nF) KEMET PET Film Competitor PPS Film 1000 100 10 1 0402 0603 0805 1206 1210 1813 2220 2824 4030 5040 6054 6560 Case Size (EIA) Fig. 7. BME C0G MLCC vs. film Capacitor: 50Vdc rating maximum capacitance by case size. The offerings of KEMET BME C0G MLCC and film capacitors by voltage rating are shown in Fig. 8. Compared with BME C0G MLCCs, film capacitors can not only offer much higher capacitance at low voltage rating regions due to the availability of large case sizes, but also totally dominate the high voltage regions (> 250Vdc). This plot © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA again shows that KEMET PEN and PPS based SMD film capacitor are leading the major competitors both in maximum capacitance offerings and voltage ratings. 100000 KEMET C0G MLCC KEMET PEN Film KEMET PPS Film KEMET PET Film Max. CAP (nF) 10000 Competitor PEN Film Competitor PPS Film 1000 100 10 16 25 50 63 100 250 Voltage Rating 400 630 1000 Fig. 8. BME C0G MLCC vs. film Capacitor: maximum capacitance offering by voltage rating. Passive components, such as capacitors, in the signal path can introduce the total harmonic distortion (THD) that contributes to the system-level distortions [6]. Thus, the selection of the capacitors is critical to a successful audio design. C0G and film dielectrics do not have a piezoelectric effect due to their non-ferroelectric nature, thus can offer excellent sound quality for audio devices. To evaluate the sound quality of capacitors made from various dielectrics, electronic noise measurements were performed and the results are illustrated in Fig. 9. The film capacitors used in this test are Stacked & Naked in configuration. Basically, both of BME C0G MLCC and film capacitors almost do not generate any electrical noise. Any differences are due to the sensitivity of the measurement method. However, the electrical noise generated from the barium titanate based X7R MLCC is significantly higher than the C0G MLCC and film capacitors. This electrical noise can create further mechanical vibrations of the capacitor or even the circuit board. The translation from mechanical to electrical, then electrical back to mechanical both involve delays and can create a slight echo or distortion effect in the circuit [7]. 80 68 Electrical Noise (mV) 70 60 50 40 30 20 10 1.4 5.4 3.8 2.6 PET PEN PPS 0 BME C0G X7R Fig. 9. Electrical noise measurement results. © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA PEN and PET are very suitable in all applications in which good self-healing properties are required. Furthermore, among SMD film capacitor dielectrics, PPS is the one whose features are closest to C0G’s [3]. PPS and C0G have similar performance on capacitance & dissipation factor vs. temperature, frequency, and voltage, insulation resistance vs. temperature, and THD, etc. Thus, PPS can be called as the C0G of the film capacitors. Fig. 10, 11 and 12 show capacitance, dissipation factor (@ 1 kHz) and insulation resistance as a function of temperature (up to 175°C) for various film dielectrics. These are example measurements made for 2220 size 100 Vdc film capacitors. These graphs show that film capacitors can be used up to 150 ºC - 175 ºC ambient temperatures. The design of electronics for high temperatures needs special knowledge of the components. E.g. with capacitors, the strong decrease of insulation resistance, which is similar to all capacitor types, must be taken into consideration. 20 0.02 PEN PPS PET 15 Tan Delta DC/C (%) 10 5 0 -50 -25 PEN PPS PET 0.016 0 25 50 75 100 125 150 175 0.012 0.008 0.004 -5 0 -50 -10 -25 0 25 50 75 100 125 150 175 Temperature (°C) Temperature (°C) Fig. 10. ΔC/C vs. temperature. Fig. 11. Tan δ vs. temperature. 1000000 IR (MOhm) 100000 10000 1000 100 PEN PPS PET 10 1 25 50 75 100 125 150 175 Temperature (°C) Fig. 12. Insulation resistance vs. temperature. Similar to the C0G material, PPS dielectric also has high stability over temperature and humidity. To demonstrate this stability, endurance (life) tests were made at 155 ºC for 2000 hours and damp heat steady state tests were made at 40 ºC / 93 %RH for 5000 hours [8]. These test results are shown in Fig. 13 and Fig. 14, respectively. There is a small humidity dependence of the capacitance value, but very little further capacitance change during long service in extreme conditions. Under practical use conditions the capacitance value stays within one percent (1%) capacitance band during the life time of the capacitor. © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA Damp Heat Steady Stage Test 40 ºC / 93 % RH SMC Metallized PPS Capacitor 220 nF / 50 VDC Endurance Test at 155 ºC @ 25 VDC SMC Metallized PPS Capacitor 3.9 µF / 50 VDC 0 100 200 500 1000 Capacitance Change (%) Capacitance Change (%) 0 -0.1 -0.2 -0.3 -0.4 -0.5 1.6 2000 AVG MAX AVG 1.4 MAX 1.2 MIN 1 0.8 0.6 0.4 0.2 0 MIN 0 -0.6 Time (hours) Fig. 13. Endurance test at 155 ºC for PPS capacitor. 1000 2000 3000 4000 5000 Time (hours) Fig. 14. Damp heat steady state test for PPS capacitor. Having discussed the primary characteristics of case size, maximum capacitance value, and voltage rating, we now turn to secondary characteristics such as dielectric absorption, self healing capability, etc. PPS based film capacitors have one significant advantage over the ceramic based C0G MLCC: the dielectric absorption. Dielectric absorption is a measure of the reluctance of the dielectric to give up its electrons. In other words, it is the charge or voltage remains in the capacitor after the discharge. In exact term, it is a ratio of the recovered voltage after discharge to the applied charging voltage [9]. Dielectric absorption is intrinsic to the materials, not to the manufacturing process. Usually the higher the dielectric constant, the greater is the dielectric absorption. The dielectric absorption for typical dielectric materials is shown in Table III. The dielectric adsorption of BME C0G is 10 times higher than that of the PPS film. This can make the PPS film capacitors an important factor in some critical sample and hold type circuits, such as in some accurate analog to digital conversion applications. Table III. Dielectric Absorption for Typical Dielectric Materials Materials X5R/X7R/Z5U BME C0G PET Film PEN Film PPS Film Dielectric Absorption (%) 1.0~1.8 0.5 0.2~0.5 0.8 0.02~0.05 SMD film capacitors are renowned for high reliability vs. vibrations, bending tests, thermal and mechanical shocks. The stacked construction and the intrinsic elasticity of the plastic raw material are key factors in this feature. The self-healing property, furthermore, makes SMD film capacitors the choice for applications involving high energy and voltage spikes (e.g. ballast, HID lamps ignitors, surge protection…). The typical failure mode of SMD film capacitors is open circuit. Finally, there are still chances to enlarge the maximum size (and capacitance/voltage) for the future. A comparison of the KEMET BME C0G MLCC and various film capacitors are summarized in Table IV for circuit designers’ reference. The properties are ranked in a 1 to 3 star scale. The more stars, the better the property. © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA Table IV. Comparison of BME C0G MLCC and Film Capacitors Maximum Capacitance Offering Volumetric Efficiency Dissipation Factor (DF) Q -factor Working Temperature Range Temp. Capacitance Coefficient Voltage Capacitance Coefficient Dielectric Absorption Breakdown Voltage Self Healing After Breakdown Insulation Resistance Sound Quality (no piezo effect) RoHS Compatibility Lead Free Solderability Flexibility High Voltage (>500V) Cap Offering 1 BME C0G (1) PPS Film PEN Film PET Film With the open mode design or Flex-Termination SUMMARY 1. KEMET C0G MLCCs and SMD film capacitors lead in the industry. KEMET can offer both high CV BME C0G MLCCs and SMD film capacitors for critical applications. Film capacitors offerings include the popular PET, PEN and PPS plastic dielectrics. BME C0G MLCCs can cover the capacitance range of <= 1μF and case size range of small to middle, while film capacitors mainly cover the middle to large case size and very high capacitance range. Film capacitors also well cover the high voltage region (> 250Vdc). Thus, the BME C0G MLCC and film capacitor actually are complementary to each other in applications requiring high capacitance stability and low piezoelectric noise. 2. Despite of the relatively low dielectric constant compared with the PME C0G, BME C0G MLCC still can achieve much higher capacitance in the same case size due to the breakthroughs of the BME technology. Additionally, BME C0G MLCCs exhibit much higher IR and better HALT performance than the PME C0G MLCCs even with a thinner dielectric layer. The BME C0G MLCCs also have the advantage of relatively low materials cost. 3. Metallized plastic film SMD capacitors are products to be considered in applications with the following requirements: high temperature up to 175 °C, low THD and narrow tolerance (e.g. noise reduction headsets and precision filtering as PLL loop filter), high energy involved (e.g. power supplies and DC-links), high reliability vs. vibrations and thermal shocks (e.g. automotive), piezoelectricity / pop up effect to be avoided (e.g. high quality audio systems), high dU/dt capability together with high voltage (e.g. HID igniters in Xenon lamps), voltage surges with high energy capabilities (e.g. lighting over voltages protection in DSL infrastructures). © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA REFERENCES [1] Microsoft, Windows Vista Logo Program Device Requirements, 11/20/2007, p8-11, www.microsoft.com/whdc/ winlogo/hwrequirements.mspx#. [2] X. Xu, et al., “High CV BME C0G,” p179-188, Proceedings of the 27th Symposium for Passive Components (CARTS USA 2007), Albuquerque, NM, USA, 2007. [3] X. Xu, et al., “BME C0G MLCCs: The High Capacitance Class-I Solution,” p277-284, Proceedings of the 21st Symposium for Passive Components Conference (CARTS Europe 2007), Barcelona, Spain, 2007. [4] M. Niskala, “Soldering of SMD Film Capacitors in Practical Lead Free Processes,” p163-171, Proceedings of the 21st Symposium for Passive Components (CARTS EUROPE 2007), Barcelona, Spain, 2007 [5] IEC Publication 61760-1, Ed. 2: Standard Method for the specification of surface mounting components (SMDs), International Electrotechnical Commission, 2006, Geneva, Switzerland. [6] K. Schmidt, “Choose Capacitor Types to Optimize PC Sound Quality,” p77-84, EDN, April 12, 2007. [7] J. Prymak, “Piezoelectric Effects Ceramic Chip Capacitors (Singing Capacitors),” 2006-08 Arrow Asian Times Article. [8] K. Saarinen, et al., “SMD Plastic Film Capacitors for High Temperature Applications,” p187-191, Proceedings of the 24th Symposium for Passive Components (CARTS USA 2004), San Antonio, TX, USA, 2004. [9] KEMET Capacitor Training and Reference Guide, 2002 edition. © 2008 ECA (Electronics Components, Assemblies & Materials Association), Arlington, VA Proceedings CARTS USA 2008, 28th Symposium for Passive Electronics, March, Newport Beach, CA