SF 0065 SP-US - SF 0150 SP-US SF 0065-US - SF

advertisement

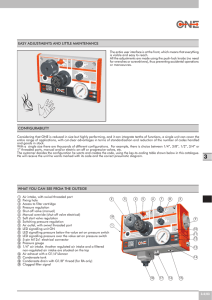

US O 0581 301000 US 08.2007 Membrane dryer VARIODRY FRL Superplus - SF 0065 SP-US - SF 0150 SP-US VARIODRY FRL SF 0065-US - SF 0150-US Type Code Series VarioDry FRL Type Code Model Membrane Dryer SF SF SF SF SF 0040-US 0050-US 0060-US 0070-US 0085-US 581 582 583 584 585 L L L L L 0581 0582 0583 0584 0585 3 3 3 3 3 01 01 01 01 01 00 00 00 00 00 0 0 0 0 0 Membrane Dryer Superplus SF SF SF SF SF 0040 0050 0060 0070 0085 581SP 582SP 583SP 584SP 585SP L L L L L 0581 0582 0583 0584 0585 3 3 3 3 3 0C 0C 0C 0C 0C 00 00 00 00 00 0 0 0 0 0 Type no. SP-US SP-US SP-US SP-US SP-US ultratroc gmbh Drucklufttechnik Postfach 2653 . D-24916 Flensburg Ochsenweg 73 . D-24941 Flensburg 2 Material no. Telefon +49 (0) 461 949 0 Telefax +49 (0) 461 949 369 e-mail: info@ultratroc.com internet: http://www.donaldson.com 08.2007 Table of contents Page 2 3 4 5 Type code Table of contents General notes and warnings Assembly and parts Filter-water-separator 1. Technical Data 2. Filter exchange 6 6 Submikcrofilter 1. Technical Data 2. Filter exchange 7 7 Membrane dryer 1. Technical Data 2. Installation 3. Adjustment 4. Maintenance 5. Dismantling 6. Reassembly 8 8 9 9 9 10 Aktivated carbon filter 1. Technical Data 2. Filter exchange 12 12 Pressure regulating valve 1. Technical Data 2. Pressure regulating 13 13 Condensate drain 1. Drain valve man./semi autom. 2. Drain valve manually 3. Drain valve automatic 14 14 14 Assembly 1. Assembly of several components 2. Fitting the mounting brackets 15 15 3 08.2007 General Notes and Warnings Follow these operating instructions exactly to ensure safe installation and operation and proper servicing. Ensure that all personnel involved in the installation, operation and servicing of this unit are well acquainted with these operating instructions. The unit must be used only in industrial applications. The equipment in which the unit is used must comply with the requirements of Standard DIN EN 983 (current edition). If there is a malfunction, pressure regulators can allow the inlet pressure to pass through unregulated. Therefore a safety pressure relief valve must be provided, set to the highest permissible outlet pressure (DIN EN 983). Installation and servicing must be carried out only by trained personnel who are familiar with all the safety requirements. Before installation, compare the technical data for the unit with the actual operating conditions, especially pressures and temperatures. Where several units are combined, the “weakest” unit is the decisive factor. Before installation, the system must always be completely depressurized and secured accordingly. Air lines must be carefully cleaned before connection to the unit. Dirt particles can cause serious malfunctions. Observe the flow direction, which is shown by an arrow symbol on the unit. If liquid, paste or fibrous materials are used for sealing the connections, these must be carefully prevented from getting into the unit. These materials can cause serious malfunctions. For cleaning, use only damp cloths (warm water with washing-up liquid). Make sure that water does not get into the unit. The unit must not come into contact with liquid solvents, acids or alkalis. Components can suffer chemical attack and subsequently burst. Dispose of used filter elements in compliance with national regulations. In the event of malfunction, please contact the customer service responsible. 3 4 08.2007 Membrane dryer assembly and parts Membrane dryer Superplus Type Art. No. 581 SP L 0581 3 0C 00 0 582 SP L 0582 3 0C 00 0 583 SP L 0583 3 0C 00 0 584 SP L 0584 3 0C 00 0 585 SP L 0585 3 0C 00 0 Pressure regulating valve 011 3978 000 includes following parts: a Mounting brackets (2 sets) 011 0996 000 Air inlet NPT 1“ Air outlet NPT 1“ Gauge 011 3987 000 a Coupling set (2x) 011 3985 000 Filter-waterseparator compl. 011 3976 000 Replacement filter 5µ 011 4079 000 (Ersatzfilter 30µ 011 4080 000) Activated carbon filter compl. 011 4052 000 Replacement filter 011 4082 000 Submicrofilter compl. 011 3981 000 Replacement filter 011 4081 000 Barrel nipple (2x) 011 4065 000 Membrane dryer Type Art. No. 581 L 0581 3 01 00 0 582 L 0582 3 01 00 0 583 L 0583 3 01 00 0 584 L 0581 3 01 00 0 585 L 0585 3 01 00 0 Replacement Membrane module 010 3155 000 (2x) 010 3155 000 (3x) 010 3155 000 (4x) 010 3155 000 (5x) 010 3155 000 (5x) 5 08.2007 Filter- water-separator 1. Technical Data Characteristics Port size NPT 1" Installation vertical Pore size of filter element Condensat capacity max µm standard: 5 on request: 30 cm3 130 Condensate drain Medium and ambient temperature (Ice formation must be avoided! ) automatic T min °C -10 T max °C +50 (+60 bei 12,5bar kg 0,9 Operating pressure range Ps min bar 0,5 Inlet Ps max bar 17,5 Volume flow (at 6,3bar and dP=1bar) Vmax l/min 11400 m3/h 684 Weight Pneumatic characteristics 2. Filter exchange 3 6 08.2007 Submicrofilter 1. Technical Data C haracteri sti cs Port si ze G1 Installati on verti cal C ondensate capaci ty max cm3 130 C ondensate drai n Medi um and ambi ent temperatures (Ice formati on must be avoi ded! ) automati c T mi n °C -10 T max °C +50 (+60 bei 12,5bar kg 1,5 Wei ght Pneumati c characteri sti cs Operati ng pressure range Ps mi n bar 0,5 Inlet Ps max bar 17,5 Recommended flow (at 6bar) Vmax l/mi n 3850 m3/h 230 Pressure drop at recommended flow dp bar ab 0,1 (new element) D egree of fi ltrati on at recommended flow % over 99,99999 related 0,01µm Resi dual oi l amount mg/m3 <0,01 (i nput conc. 3mg/m3) 2. Filter exchange 7 08.2007 Membrane dryer 1. Technical Data Characteristics System Drying by highly selective water vapour-permeable membrane (hollow fibres), using the partial pressure differential between the inside and the outside of the membrane. Port size G1 Installation Medium and ambient temperature in any position T min °C +2 T max °C +60 Medium filtered air to ISO 8573-1, quality classes 1-1 Type Dryer modules (+ 1 return pipe) Weight kg 581 582 583 584 585 2 3 4 5 5 9,5 12,5 15,5 18,5 18,5 Pneumatic characteristics Operation pressure range Ps min bar 5 inlet Ps max bar 15 l/min 1083 1333 1667 2083 2500 m3/h 65 80 100 125 150 l/min 3600 4500 5600 7000 8400 m3/h 216 270 336 420 504 dTpd K 20 (at Inlet conditions to DIN ISO 7163: Ps=7bar, Ts=35°C, Tamb=35°C) % 10 (only when there is air flow) dP bar 0,3 Vmin Volume flow (Inlet conditions to DIN ISO 7163: Ps=7bar, Ts=35°C, Tamb=35°C Vmax Pressure dew point reduction Purge air consumption Pressure drop 2. Installation instruction 3 8 08.2007 Membrane dryer 9 08.2007 Membrane dryer 3 10 08.2007 Membrane dryer 11 08.2007 Activated carbon filter 1. Technical Data Characteristics Port size G1 Installation vertical Condensate capacity max cm3 Condensate drain Medium and ambient temperatures (Ice formation must be avoided! ) 130 manually T min °C -10 T max °C +50 (+60 bei 12,5bar kg 1,5 Weight Pneumatic characteristics Operating pressure range Ps min bar 0,5 Inlet Ps max bar 17,5 Recommended flow (at 6bar) Vmax l/min 3850 m3/h 230 Pressure drop at recommended flow dp bar 0,1 mg/m3 0,003 Residual oil amount 2. Filter exchange 3 12 08.2007 Pressure regulating valve 1. Technical Data Characteristics Port size G1 Installation beliebig Medium and ambient temperatur (Ice formation must be avoided! ) T min °C -10 T max °C +60 kg 1,2 Weight Pneumatic characteristics Operating pressure range P1 min bar 0 inlet P1 max bar 17,5 Operating pressure range P2 min bar 0,5 outlet P2 max bar 17,5 Flow (at p1=10bar on p2=6,3bar and dp=1bar) Vmax l/min 20000 m3/h 1200 2. Pressure regulation S S S S 13 08.2007 Condensate drain 1. Drain valve manually / semi automatic OFF ON AUTO < 0,2 bar OFF: The valve is closed and the condensate is captured inside the bowl. ON: Push the black handle piece upwards into position “ON” and the condensate will drain from the bowl. AUTO: The valve performs the semi- automatic function. When the bowl pressure drops below 0,2bar, the valve opens automatically and the condensate will drain from the bowl. If the bowl pressure rises above 0,8bar, the valve closes again and the condensate is captured inside the bowl. Push the black handles together, and the condensate will drain from the bowl. 2. Drain valve manually 3. Drain valve semi automatic / automatic < 0,3 bar semi automatic 3 14 automatic (Floater) 08.2007 Assembly 1. Assembly of several components 2. Fitting the mounting brackets 15 08.2007