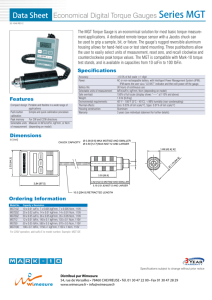

FSG Presicion Rotary Potentiometers

advertisement

Measurement and Sensor Systems with conception Precision Rotary Potentiometer Precision Rotary Potentiometer with resistance, current or voltage output Today potentiometric angular position transmitters attain a still more status with regard to the analogue measuring technique as far as high-quality measurement tasks are concerned due to the favourable value for money. They are mainly used for – Power braking control elements for railway vehicles as well as ship telegraphs – Rudder and propeller systems for ships – Control drives for systems in the field of energy management and chemical industry – Lifting gears and slewing mechanisms of cranes and excavators – Tail vanes for meteorological measurements – As dancer potentiometers for textile and paper machinery – As well as for measurements in the field of mechanical, apparatus and medical engineering Potentiometric transmitters have either a high-resolution element of conductive plastic or high-resolution gold or constantan wire with various resistance and angle values. They are available in various sizes as single-turn or multiple-turn potentiometers or in a multiple design. For adjustment of the measuring range almost all series can be provided with shorted sections, tappings and function windings. Some models are available with incorporated signal converter providing current or voltage outputs in configuration of 2, 3 or 4 wires. To ensure reliability in very dirty atmospheres, oil-filled potentiometers are available. Moreover, to provide protection for all potentiometers from mechanical damage, dusty and damp industrial atmospheres a series of housings with a protection of the types IP 40 to IP 68 is available; partly to be equipped with gearing and Iimit switches. 2 Application ranges Versions and circuit variations Series PW 1 Resistance elements as ring winding with wire winding on an anodised aluminium anchor ring can be provided with any circuit, angle and resistance values. 2 3 5 4 7 6 8 9 Series PW 1. Wiper limited by stops 2. Wiper continuous rotation over 360° with reactive winding 3. Wiper continuous rotation over 360° without reactive winding (sawtooth shape) 4. Any arrangement of shorted sections 5. Any arrangement of tappings 6. 7. 8. Special windings with characteristic curve of the linear or sin/cos type 9. Two electrically isolated windings on a winding former, angle ≤ 175° Resistance elements as straight winding with wire winding on a coated former of copper wire are used in potentiometers of the multiple-turn or linear type but also in single-turn potentiometers with active angles up to max. 350°. 1. Wiper limited by stops 2. Wiper continuous rotation over 360° only for purposes of putting into operation 4. Any arrangement of shorted sections 5. Any arrangement of tappings 1 2 4 5 Series PK Resistance elements of conductive plastic, imprinted on glassfiber reinforced supports. The max. active angle amounts to 355°. Smaller angles, tappings and shorted sections on request. 1. Wiper limited by stops 2. Wiper continuous rotation over 360° 4. Any arrangement of shorted sections 5. Any arrangement of tappings 7. Sin/cos characteristic curve 9. Two electrically isolated windings on a winding former, angle ≤ 175° 1 2 4 5 7 9 3 Electrical specifications Version Design Model types Resistance element wire-wound PW 609 PW 611 straight-shaped straight-shaped Material of housing Synchro size Diameter of housing PW 620 PW 613 straight-shaped ring PW 1023 straight-shaped ring ring aluminium, anodised 9 11 13 20 23 22,2 mm 28 mm 36,5 mm 50,8 mm 60 mm IP code of housing IP 30 IP 30 IP 30 IP 30 IP 65 Diameter of shaft 3 / 6 mm 6 mm 6 mm 6 mm 6 / 10 mm ball-/sintered bearing ball-/sintered bearing ball bearing 0,05 Ncm 2,5 Ncm Shaft bearing ball-/sintered bearing ball-/sintered bearing Material of shaft stainless steel Adjustment speed max. Torque Torque (oil-filling) 360 U/min. 0,03 Ncm 0,04 Ncm – – – 345° max. active angle (± 0,5°) 340° 340° max. stop angle 340° 340° up to 10 kΩ up to 10 kΩ 5% 5% ± 0,5 % ± 0,5 % Value of resistance Resistance tolerance Linearity tolerance 0,05 Ncm 1 Ncm – 1 Ncm 360° 350° 360° 345° 345° up to 20 kΩ 5% 5% ± 0,2 % 360° 345° up to 20 kΩ 2% – up to 20 kΩ 2% ± 0,2 % 2% ± 0,2 % Resolution (windings)* 1033 1369 1851 2100 3434 max. 2321 max. 2321 Capacity 0,5 W 0,5 W 1W 2,5 W 1W 2,5 W 2,5W Multiple version threefold threefold Functional winding – – – – Oilfilling – – – – – Switches – – – – – Connection Weight ** Article number soldered connection/wire soldered connection/wire 15g 20 g 1114Z70 1122Z01 sixfold sixfold soldered connection / wire soldered connection / wire plug / cable 40 g 70 g 380 g 1567Z01 1560Z10 * depend on resistance value and active angle ** single version General Data Temperature range -30° C up to +80° C Test voltage 550 V, 50 Hz, 1 min. Vibration resistance 5 - 200 Hz, 10 g Shock resistance 50 g, 6 ms Life time high life time due to a patent-registered spiral wiper 10 - 100 millions cycles Fastening depend on version: Central fixing, clamp fixing, threaded holes 4 twofold 1577Z01 1570Z02 5720Z52 Electrical specifications Version Design Model types wire-wound PW 0045 PW 45 PW 45 W 3/10 PW 55 PW 70 Resistance element straight-shaped ring straight-shaped straight-shaped ring Material of housing thermoplast thermoplast brass / thermoplast thermoplast thermoset 45 mm 45 mm 45 mm £ 55 mm 70 mm 6 mm 6 mm 6 mm Hollow shaft 6 x 6 mm 6 mm sintered bearing sintered bearing sintered bearing plastic bush bearing sintered bearing 60 U/min. 360 U/min. 360 U/min. 60 U/min. 360 U/min. 0,5 Ncm / 5 Ncm 0,3 Ncm / 3 Ncm 0,5 Ncm 0,2 Ncm 0,5 Ncm – 1 Ncm – – 1 Ncm Synchro size Diameter of housing FSG design IP code of housing Diameter of shaft Shaft bearing IP 30 Material of shaft Adjustment speed Torque Torque (oil-filling) stainless steel max. active angle (± 0,5°) 280° / 345° 360° 1080° 3600° 350° 360° max. stop angle 280° / 345° 345° 1080° 3600° 345° 350° Value of resistance up to 25 kΩ up to 20 kΩ up to 25 kΩ up to 20 kΩ up to 50 kΩ 5% 2% 5% 5% 2% ± 0,5 % ± 0,3 % ± 0,1 % ± 0,5 % ± 0,15 % max. 2312 max. 2321 max. 5783 max. 21049 1620 max. 3621 1,5 W 2,5 W 2W 1,5 W 6W Multiple version – twofold twofold stackable sixfold Functional winding – – – Oilfilling – – – Switches – – – – soldered connection soldered-/screwed connection plug Faston soldered-/screwed connection 70 g 70 g 100 g 150 g 50 g 140 g 1511Z07 1500Z05 1302Z10 1300Z10 1573S10 1700Z04 Resistance tolerance Linearity tolerance Resolution (windings)* Capacity** Connection Weight Article number soldered connection * depend on resistance value and active angle ** single version 5 Electrical specifications Version Design Model types conductive plastic PK 609 PK 611 PK 613 PK 613-G16 Resistance element conductive plastic Material of housing aluminium, anodised Synchro size Diameter of housing PK 620 PK 1023 9 11 13 20 23 22,2 mm 28 mm 36,5 mm 50,8 mm 60 mm IP code of housing IP 30 IP 30 IP 30 IP 30 IP 65 Diameter of shaft 3 / 6 mm 6 mm 6 mm 6 mm 6 / 10 mm ball-/sintered bearing ball-/sintered bearing ball bearing Shaft bearing ball-/sintered bearing ball-/sintered bearing Material of shaft stainless steel Adjustment speed max. Torque Torque (oil-filling) 1000 U/min. 0,03 Ncm 0,04 Ncm 0,05 Ncm 0,05 Ncm 2,5 Ncm – – – 1 Ncm – max. active angle (± 0,5°) 345° 345° 350° 5632° 355° 355° max. stop angle 340° 340° 345° 5632° 345° 345° ± 20 % ± 20 % ± 10 % ± 10 % Value of resistance Resistance tolerance Linearity tolerance 1 kΩ up to 10 kΩ ± 2 % / ± 0,5 % ** ±10% ± 2 % / ± 0,2 % ** ±1,5%/±0,15%** Resolution Capacity ± 0,5% ± 1,5 % / ± 0,1 % ** ± 1,5 % / ± 0,1 % ** almost infinite 1W 0,5 W 0,5 W threefold threefold Oilfilling – – – – Switches – – – – Multiple version sixfold onefold 1W 1W sixfold twofold Functional curve Connection Weight* Article number soldered connection/wire soldered connection/wire soldered connection / wire soldered connection/wire plug / cable 15 g 20 g 40 g 120 g 70 g 380 g 1105Z02 / 1125Z01 1120Z02 1565Z02 2720Z50 1575Z02 5710Z52 * single version ** linearised version General data Temperature range -30° C up to +80° C Test voltage 550 V, 50 Hz, 1 min. Vibration resistance 5 - 200 Hz, 10 g Shock resistance 50 g, 6 ms Life time high life time due to a patent-registered spiral wiper 10 - 100 million cycles Fastening depend on version: Central fixing, clamp fixing, threaded holes 6 Potentiometric circuit and its characteristic curves Standard winding A Wiper continuous rotation, without reactive winding, only at beginning and end led out separately U u 11 - 12 13 α + 11 - Center tapping for benchmark 11 u 11 - 12 13 U U+ 12 1 U 12 2 α + U- + Winding with 2 different resistance segments for buckled characteristic curves E 0 11 - 12 1 U + α + Shorted section within winding 11 G 8a2 360° Shorted section within winding u 11 - 12 + H - A + U 13 U sin 12 2 - - cos 8a3 U 12 U u 2 sin α 13 U F 8a1 u 2 cos α u 11 - 12 W2 α 360° U- 8a2 U 12 u Sealed sin/cos functional windings with 90° offset wipers - W1 D 8a1 U+ 12 α 360° + Sealed winding with 2 opposite tappings and 2 opposite wipers continuous rotation - 10 - C 13 U α + 8a2 12 11 + U A - U12 U u 12 - 12 1 2 11 - u 11 - 12 U 12 B U + α 13 7 Designs PW / PK 611 PW / PK 609 24.6 19 6 h7 12.2 6 12 6.1 14 14 6 h7 28 22.2 PW / PK 620 PW / PK 613 47.6 33.32 6 h7 6.1 12.2 12.2 6.1 14 14 6 h7 50.8 36.5 PW / PK 1023 PW 0045 6 h7 50 f7 24 M12x0,75 13 58 24 10 h7 32 42 / M4 45 60 TK- 20 8 65 PW 45 PW 45W 3/10 6 h7 M10x1 6 h7 46,5 27,5 20,5 8 24 12 h6 5 32 45 45 M4 PW 55 PW 70 12 h6 5,95 -0,02 3,2 27,5 8 24 7,2 2,5 6 h7 6 +0,05 70 M4 46 50 55 PW 70M 30 h6 2 50 80 L 24 6 h7 M4 L 50 70 90 110 130 150 MI MII MIII MIV MV MVI 9 Angular Position Transducers Type series PW / PK … -MU Angular position transducers, equipped with resistance elements of wire or plastic resistance elements with integrated R/I or R/V converter for current or voltage output, optional with a configuration of 2, 3 or 4 wires. UB mA IA 4-wire system with galvanic isolation Also available with galvanic isolation between supply and output signal as far as version with 4 wires is concerned. 3- or 4-wire system All types of transducers are provided with rear trimmer to match output signal within wide ranges to the respective angular deflection. UB mA IA UB 2-wire system mA IA Electrical specifications Type series PW / PK 613-MU – Voltage output PW / PK 620-MU 0 - 10 and 2 - 10 V respectively Load resistance ≥ 2 kΩ Current voltage 0 - 20 and 4 - 20 mA respectively Load resistance ≤ 600 Ω Supply voltage 18 - 33 V DC mA V 0% 100 % mA V – 2-, 3- or 4-wire system max. 1 % / 10 K; typically: 0,5 % /10 K TC ± 0,2 % Linearity PW / PK 613-MU / 620-MU ± 0,1 % ± 0,1 % 0% PW / PK 1023-MU 50 f7 47,6 -0,02 10 h7 58 45,6 24 14 6 h7 60 50,8 TK- 42 / M4 20 10 50 % approx. 80 mA Current consumption 4-wire system galvanically isolated Zero point and rise to be adjusted via trimmer PW / PK 1023-MU 65 10 % 100 % Specifications of protective housings Mechanical data Series A 42.5 30h6 5.9 6h6 ~125 Pg9 62 76 8 Housing alu, grey coated IP code IP 40 or IP 65 Shaft stainless steel Bearing friction 0,8 Ncm Weight ca. 0,4 … 1 kg Article number 1708Z03 Housing suitable for accommodation of any potentiometer of type series PW70 in single design. 2 16 60 Mechanical data Series G 90 20.4 ~28 Pg9 -0.012 6-0.018 6 32.4 5.3 69.5 Tk- 80 90 alu, grey coated IP 40 or IP 65 Shaft stainless steel Bearing 2 ball bearings Bearing friction IP 40 = 0,1 Ncm IP 65 = 1,5 Ncm Gearing 1:1 up to 1:10 * 1:1 up to 25:1 * 26:1 up to 125:1 ** Weight approx. 1 kg Article number 3601Z02 30 h9 45 27 97 107 6.5 3.5 2 Housing IP Code 17 13 116 Housing suitable for accommodation of any transmitter size up to 54 mm outside diameter. * free from backlash, ** low backlash Series GS 120 Mechanical data 25° 54 25° 24 6 4 Element for pressure compensation 21 10 85 7/3x120° 10 h6 40 h9 120 h9 160 ±0.5 Length according to order Tk- 145 Housing alu, grey coated IP Code IP 65 Shaft stainless steel Bearing 2 ball bearings Bearing friction 1,5 Ncm Gearing 1:1 up to 216:1 * 1:1 up to 1296:1 ** 1:1 up to 1:10 *** 10 12 Weight ca. 2,5 kg Article number 1892Z Housing suitable for accommodation of any transmitter size up to 70 mm outside diameter. * free from backlash, ** low backlash *** free from backlash or low backlash 11 Berlin Fernsteuergeräte Kurt Oelsch GmbH Jahnstraße 68 + 70 D-12347 Berlin Phone +49 (0 30) 62 91 - 1 Fax +49 (0 30) 62 91 - 277 Headquarter in Berlin Kablow Factory in Kablow FSG Fernsteuergeräte Meß- und Regeltechnik GmbH OT Kablow Mühlenweg 2 -3 D-15712 Königs Wusterhausen Phone +49 (0 33 75) 269 - 0 Fax +49 (0 33 75) 269 - 277 Heppenheim 082011 Fernsteuergeräte Kurt Oelsch GmbH & Co.KG Weiherhausstraße 10 D-64646 Heppenheim Phone +49 (0 62 52) 99 50 - 0 Fax +49 (0 62 52) 72 05 - 3 Factory in Heppenheim info@fernsteuergeraete.de www.fernsteuergeraete.de 12