Detectors for Harsh

Environments

Saint-Gobain Crystals produces a wide range of scintillation materials that are

used to build detectors to measure radiation. Some scintillators are sensitive

to moisture, others to ultraviolet light from fluorescent lamps and others to

temperature gradients.

Most “standard” scintillation detectors are designed and built to operate

under laboratory conditions. We define laboratory conditions as:

•

•

•

•

•

•

+4oC to +43oC operating temperature range

8oC/hour thermal rate of change

1 atm pressure

90% or less relative humidity

No shock or vibration exposure other than that incurred during shipment

No immersion in a fluid

Design Notes –

• Optional electronics – voltage

divider or voltage divider/

preamplifier combination and

high voltage supply – can be

integrated into the design of

these non-standard detectors.

• In addition, we can spacequalify the components and

subassemblies. Our resources

also include design modeling and

finite element analysis. Environments that have one or more conditions outside of these are

considered harsh. Standard detectors may not even operate, let alone

work properly, in these environments. Therefore, when establishing detector

specifications, it is important to identify the operating conditions your

detector will face.

Examples of Harsh Environments–

•

For operation at or below -30oC, we must select a resilient interface between

the scintillator crystal and photomultiplier tube.

•

For operation at reduced pressures, such as 100 to 200 mTorr, encapsulation

materials with reduced out-gassing properties are used. The detector interior

may be evacuated, and a bellows, pinch-off tube or vacuum valve may be

added.

•

For water immersion, the entire assembly must be waterproofed to prevent

the voltage divider from shorting out. Waterproof connectors (or waterproof

cable feed-throughs) are used.

•

For detectors subject to vibration (or impact shock), we use special

construction techniques and qualified components, including a ruggedized

PMT.

•

More complex environments require us to address several non-standard

conditions at once. Our detectors for balloon- or satellite-borne experiments

meet temperature, vacuum and mechanical requirements.

•

Our MWD (measurement while drilling) detectors survive the extreme

temperature variations, mechanical shock, and vibration encountered while

drilling through underground rock strata.

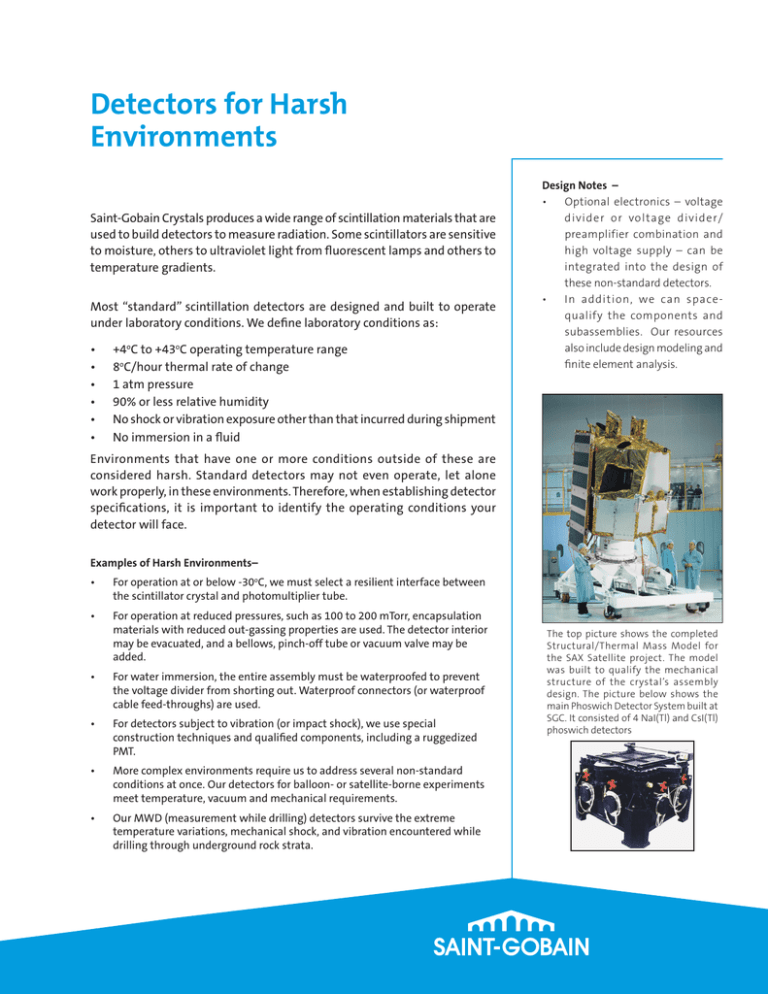

The top picture shows the completed

Structural/Thermal Mass Model for

the SAX Satellite project. The model

was built to qualify the mechanical

structure of the crystal’s assembly

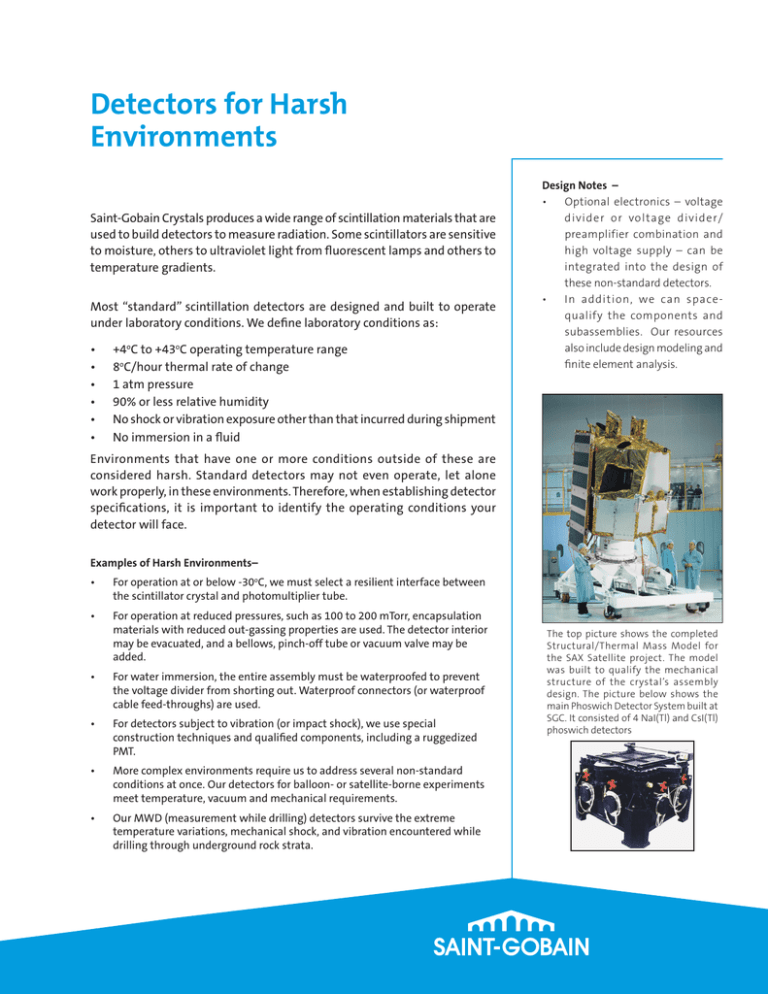

design. The picture below shows the

main Phoswich Detector System built at

SGC. It consisted of 4 NaI(Tl) and CsI(Tl)

phoswich detectors

Detectors for

Harsh Environments

USA

Saint-Gobain Crystals

17900 Great Lakes Parkway

Hiram, OH 44234

Tel: (440) 834-5600

Fax: (440) 834-7680

Europe

Saint-Gobain Crystals

104 Route de Larchant

BP 521

77794 Nemours Cedex, France

Tel: 33 (1) 64 45 10 10

Fax: 33 (1) 64 45 10 01

P.O. Box 3093

3760 DB Soest

The Netherlands

Tel: 31 35 60 29 700

Fax: 31 35 60 29 214

Japan

Saint-Gobain KK, Crystals Division

3-7, Kojimachi, Chiyoda-ku,

Tokyo 102-0083 Japan

Tel: 81 (0) 3 3263 0559

Fax: 81 (0) 3 5212 2196

China

Saint-Gobain (China) Investment

Co, Ltd

15-01 CITIC Building

19 Jianguomenwai Ave.

Beijing 100004 China

Tel: 86 (0) 10 6513 0311

Fax: 86 (0) 10 6512 9843

India

Saint-Gobain Crystals and

Detectors

Sy. No. 171/2, Maruthi Industrial

Estate

Hoody Rajapalya, Whitefield Main

Road

Bangalore 560048 India

Tel: 91 80 42468989

Fax: 91 80 28416501

www.crystals.saint-gobain.com

Manufacturer reserves the right to alter specifications.

©2002 -14 Saint-Gobain Ceramics & Plastics, Inc. All rights reserved.

(05-14)