Placement Equipment

advertisement

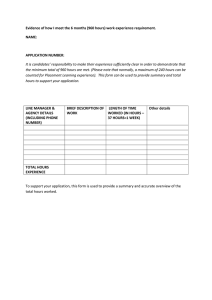

COMPONENT PLACEMENT EQUIPMENT SELECTION INTRODUCTION: Surface mount components are placed on a printed circuit board after deposition of adhesive or solder paste. Generally solder paste and adhesive are deposited at a separate work station by a screen printer or dispenser. Some placement machine also dispense adhesives. Placement equipment is commonly referred to as “Pick and Place” equipment. Several factors make it almost mandatory to use placement equipment for surface mounting. For example , many surface mount components, especially passive components , are not marked. Moreover, packages with finer and finer lead spacing or “pitches” and ball grid arrays , where the balls are hidden under the package, are being used. Finally, manual placement of surface mount components , which is neither reliable nor economical , should not be used for production. The pick and place machine is the most important piece of manufacturing equipment for placing components reliably and accurately enough to meet throughput requirements in a cost effective manner. Typically , surface mount pick and place equipment, including a full complement of feeders constitute about 50% of the total capital investment required for a medium volume surface mount manufacturing line. AUTOMATED PLACEMENT OF PARTS: Accuracy requirements almost mandate the use of auto placement machines for placing surface mount components on the board. The placement machine is the most important piece of equipment required for surface mounting. It absorbs highest capital investment , and it also determines the overall economy of manufacturing. Placement equipment can be classified based on flexibility and throughput. The flexibility to place components of many different types comes at a price: the higher the flexibility the lower the throughput. For example , robots are placement machines that provide the ultimate in flexibility. They can be used in placing surface mount components, for placing odd form of components, for solder mask or paste dispensing, for soldering and for lead tinning. Their hardware cost is relatively low, but software and hardware development can be quite expensive. Robots are very flexible , but they are extremely slow and require considerable development for each type of application. SELECTION CRITERIA FOR PLACEMENT EQUIPMENT: There are many different placement machines available and new models are constantly being introduced in the marketplace. The cost can vary from a few thousand dollars for a benchtop model to almost a million dollars for a very high speed placer. The cheaper models are generally used for prototyping but serve in production in many companies. Production placement equipment can be either flexible ,i.e. able to place surface mount components of all types, or dedicated, placing only components of certain type. Evaluation and selection of a pick and place system is a very complex process. The selection of the appropriate autoplacement machine is dictated by many factors such as the complexity of the device, the applicable packaging and equipment standards , the type and number of parts to be placed, and current and future needs for volume and flexibility. Thus one must establish some guidelines for selection of a machine. A matrix detailing the desired features versus the features of the available equipment will help reduce the number of choices for a given application. Here recommendations by existing users can be the most important selection criteria. Refer to Table A for a summary of selection criteria. Table B offers a detailed questionnaire that will help in the final selection of a pick and place machine. The questionnaire should be used to narrow the list, which can be further evaluated with some form of weighted points for features important for the given application.( for example , what kind of parts to be handled? Will they come in bulk, in a magazine, or on tape? Can this machine accommodate future changes in tape sizes? How will the board be handled? Does the equipment come with an automated board handling system? Table C shows an example of the use of weighted points for important features in the evaluation of pick and place equipment. Different weights are assigned depending on a feature’s relative importance . the maximum total points should equal 100 to make comparisons easier. A) MAXIMUM SUBSTRATE SIZE HANDLING CAPACITY Although many placement machines developed for the hybrid industries can handle only a small substrate, for surface mounting it is not uncommon to use 12 inch X 18 inch or even 18 inch X18 inch substrate. And sometimes unique board sizes such as 1 inch X 46 inches are required. So when selecting placement equipment, the maximum size of the substrate or panel that the apparatus can handle is probably the place to start. This requirement may alone eliminate many machines. Even when the substrate size is small , it is generally economical to use large panels containing multiple breakaway substrate. If fixtures are to be used for handling, their maximum size should be used instead of substrate size as the selection criterion for a pick and place machine. A) MAXIMUM FEEDER INPUT OR SLOT CAPACITY The maximum number of feeder input positions is another measure of placement equipment capacity. Since this number provides a measure of capacity to process an assembly with different part types(or different values of the same part type) in a single pass through the machine, it is very important consideration. To determine the slot or input capacity need , one must first analyze the product requirements and ascertain the maximum number of part types that will be used. (By part types we mean not only parts of different mechanical outlines but also parts of different electrical values in a given outline) Future expansion needs that can be anticipated to arise when almost all components become available in surface mount should be included in the study. A standard measure of feeder input capacity is the 8 mm tape feeder. The more 8 mm slots a machine can accommodate, the higher its input capacity. However, only a limited number of parts come on an 8 mm tape. Larger parts supplied in a tube take up multiple of 8 mm slots and the same components on tape and reel may require two to three 8 mm slots. Components supplied in bulk or in waffle packs affect input slot requirements differently. Another option for compensating for insufficient input capacity is to complete the placement of components in 2 or 3 passes or to sequence many parts of the same size but differing values in the same tube feeder. This error prone approach is definitely recommended for production, where adverse effect on placement rate could not be tolerated. C) TYPE AND SIZES OF COMPONENTS Equipment selection is very dependent upon the types and sizes of components that need to be placed . For example, the equipment needed for 0805,1206 and smaller leaded components are different than equipment that must be 0603,0402,BGA and fine pitch components. Also the maximum size of components to be placed should be kept in mind. Every machine has its limits on the maximum size and weight of components it can place. In many applications , depending upon the volume requirements , it may be wise to consider two machines in an integrated line to complement each other ‘s capability. In other words, one versatile machine may not be as good a choice as two different machines each with complementary strength. D) PLACEMENT RATE AND FLEXIBILITY In inserting a placement machine or set of machines to meet production requirements, one must determine the product mix, the number and types of components per board, and the production volume. Knowing the current requirement is not sufficient. Future needs and manufacturing plans should be factored in. Thus , the placement rate is very important. Actual throughput will depend not only on the placement rate of the machine but also on the component mix and the type of feeders used. The placement rate, in turn, depends on the location of the feeders with the most widely used components. If the product mix changes significantly, it may be difficult to place feeders of the most widely used components to provide the shortest possible distance between the pick location and the board. Some machines come with software that optimizes placement head movement for the shortest overall travel time for the entire board. Another factor that slows placement rate is component testing before placement , especially if testing is done on the fly. If vision is used to locate the components, the placement rate is further reduced. Placement rate is also affected by board size and by component and feeders type used. It quickly becomes obvious that determining the actual placement rate is not easy . As a general rule the rated placement rate quoted by the vendor should be derated by 40-50 % to arrive at a conservative number. We see that placement rate can not be considered in a vacuum. Dedicated machines with limited types of parts placement capability are going to be much faster than machines that can place components of all types and sizes, test them before placement and ensure accurate placement using a vision system. E) PLACEMENT ACCURACY /REPEATABILITY As components with larger sizes and finer pitches come into common use, the need for accurate placement stands out even more. There are many ways to define accuracy, but one useful characterization is as follows: Accuracy is the greatest tolerable deviation of the component lead from the center of its corresponding land after placement. Many times suppliers specify the machine resolution, which is defined as the smallest discrete resolution the machine can discern. This does not mean that what the machine can discern can be repeated time after time , however. Repeatability instead of accuracy is amore useful guideline , then .i.e. the consistent ability of the placement head to place a part at the specified target within a specified limit. Accuracy , for all practical purpose, simply means the placement of components on land patterns within the acceptable deviation of shift. Depending on the application the maximum acceptable shift of leads or terminations from their pad generally varies from 25%[class III] to 50 % [CLASS I and II] of pad width. Some components such as BGAs self align better than others due to solder surface tension. But regardless of the components used, the misplacement should not be any more than equipment is rated for. After , placement accuracy is one of the determining factors in a machine’s performance and price. For 50 mil center packages , the pad width generally used is 25 mils, and for fine pitch packages only 12 mils or less. Thus a 6 mil accuracy requirement should be good enough for 50 mil center packages, and 3 mil placement accuracy should be good enough for fine pitch packages. This is the X-Y accuracy requirement. It alone is not sufficient because it does not take into account rotational accuracy . The accuracy requirement will vary for different applications , but a .002 to .004 inch in X-Y repeatable accuracy from the target on a 14 inch by 18 inch substrate, irrespective of programming method, and .2 to .5 degree rotational accuracy should be sufficient for most of the production application. Of course the acceptable tolerance will be much tighter for finer pitch components(under 20 mil pitch) and for any components if the interpackage spacing is very tight. F) VISION CAPABILITY One way to offset inaccuracy in placement is to use a vision system to tell how far a component lead is from its corresponding land and to instruct the machine to correct for the discrepancy. To implement the instructions of a vision system, the hardware design of the placement machine must afford the needed resolution or repeatability. The vision system is a good way to compensate for deviations in land pattern locations due to PCB manufacturing processes and poor tolerances of component manufacturing. It also can compensate for the relatively larger deviations from the reference location in larger boards. There are two types of vision systems: single-camera and two-camera system. In a one camera system , the land patterns are viewed and the placement coordinates adjusted appropriately. In a two camera system, both the component and the land patterns are viewed and compensated for. For finer pitch packages with lead pitches of 25 mils or less , it is almost mandatory to use a two-camera system that can match the land pattern with corresponding component leads. The vision alignment uses either a binary or gray scale vision imaging to determine the offset between the components center and the placement nozzle center. This system works fine for peripheral packages since the lead outline is projected as part of the package outline. The binary system does not work well for ball grid arrays(BGA). Since balls are hidden underneath the package, it can not correct for any variation in tolerances between the package edge and the location of the balls. The gray scale imaging system uses front lighting(as opposed to back lighting in the binary imaging system) which allows the camera to pick up any surface features along with a clear view of all the balls underneath the package. This allows alignment based on the location of the balls instead of depending upon the location of the package edge. The important key elements of vision system are field of view, resolution and the level of gray scale. The level of gray scale, generally up to 256 levels of gray scale imaging, is applicable only to the gray scale imaging system. The component lighting and the processing speed are also important for throughput. Most systems also come with lead coplanarity inspection as a part of the vision system. For fine pitch, both the binary and gray scale systems will work, but for BGAs and any other area array packages such as CSP(Chip scale packages) and flipchip, the gray scale vision system is required. No matter which vision system is used , the field of view and the resolution must accommodate the size and the pitch of the component. Most systems can accommodate 38 mm maximum size and 20 mil lead pitch. A) ADHESIVE DISPENSING CAPABILITY Nonconductive adhesive is used to hold components in place before wave soldering. The adhesive is dispensed, the component is placed and the board is heated to cure the adhesive, thus ensuring that the components will withstand the rough action of the wave during wave soldering. There are various ways to dispense adhesive, but the most commonly used are stenciling and syringing . For syringing , an adhesive dispensing system using a syringe is generally an integral part of pick and place equipment, although dedicated adhesive dispensers are also used. When the pick and place machine is used for adhesive dispensing, either dedicated adhesive dispensing heads with their own X-Y table can be used , or the component placement X-Y table can be shared for adhesive dispensing. The later option is cheaper but slower because the placement head will either be dispensing adhesive or placing components. For very high volume applications , it may be preferable to use a stencil printer which is less expensive rather than tie up an expensive placement machine. H) OTHER IMPORTANT SELECTION CRITERIA Many other features of a pick and place machine are very important for most applications and thus should be considered. 1) The pick up mechanism can have a vacuum nozzle or mechanical jaws or both. Most machines pick up parts with a vacuum nozzle but use jaws to center components before placement. 2) The pickup head should be able to sense that the part has been picked up. If this fails to happen , machine operation should halt. This is an important feature because components can be held too tightly or too loosely if tolerances of either the components or the tape cavity are poor. 3) The control system for the placement head should allow CAD downloading of components locations but should allow for manual editing of adhesive placement locations and part pickup and placement locations. 4) The placement head should have programmable Z axis travel. The pickup head should be able to place the parts onto the adhesive or the solder paste within the preprogrammed Z axis displacement. The displacement force should be minimal, to avoid damage to the parts or the substrate. 5) Flexible placement systems should be able to accept such commonly used feeders as 7 and 13 inch reels, tubes and bulk and waffle packs. 6) The advance mechanism for the reels should be adjustable in 4 mm increments because in a given feeder width, the feeder pitches vary in 4mm increments. This allows the use of the same feeder for a given tape width but with varying tape pitches. 7) An important feature that may be very desirable is on-line programming capability for PLDs (Programmable Logic Devices).Currently these devices are programmed off-line and then put in a tube for placement. Since PLDs generally have high fallout rates the pick and place system must be able to test them before placement. The need for this feature may not exist if devices are programmed during final testing. AVAILABLE PLACEMENT EQUIPMENT Commercially available placement machines can be classified into four major categories: a) High throughput b) High flexibility c) High flexibility and high throughput essentially by combining two similar machines – typically one of them with a vision system, and d) low cost and throughput but with high flexibility. I have simplified this issue considerably. One can make a case for many more categories depending upon various levels of features such as price, throughput and flexibility. No particular category of machine is the best for every application. Some companies require one machine from each category to meet various product needs. For example , one manufacturing line may need a flexible machine for product development and medium production, whereas another line may call for one machine with low or medium flexibility and one with high flexibility to provide a good balance between throughput and flexibility requirements. The issues discussed in questionnaire(fig B) should be used for a detailed evaluation of these or other machines before a final selection is made. A) EQUIPMENT WITH HIGH THROUGHPUT High throughput generally means less flexibility. In the past , a low flexibility machine used to be the one that placed only passive components such as resistors and capacitors. Now very high speed placement machines are available that are still intended for passive devises but are modified to be able to place small active devices. They are still referred to as chip shooters but they have the flexibility to handle larger packages such as SOIC,PLCC and SOJ. Their throughput can vary widely(10,000 to 60,000 components per hour) depending upon the equipment make and the model and component mix. The placement rate will be lower when larger components are placed. An example of high placement equipment is shown in fig D. For maximum machine uptime, some machines have multifeeder banks. This allows feeders to be loaded on one bank while the equipment is still in operation. The machine shown has 80 feeder banks or four 40 feeder banks for added flexibility. The numbers 40 or 80 in the feeder bank refer to maximum number of 8 mm reels that a particular bank can accommodate. So in effect this machine can accommodate 160 different 8mm tapes. For maximum throughput it is also important that the feeders be easily accessible and allow rapid reel changes. The throughput is generally increased by multiple heads. Some manual machines have single heads with multiple nozzles whereas others have multiple heads but only one nozzles per head. The machine shown in fig E has multiple heads but only one nozzle per head. It is important to remember that the nozzle size must be different sized components. For example a chip shooter placing 0402 and 0603 size parts needs to use a different nozzle than when placing 1206 or 0805 size parts or larger active devices. So the configuration of heads and the number of nozzles in each head determines the placement rate. B)EQUIPMENT WITH HIGH FLEXIBILITY Equipment with high flexibility has lower throughput. Thus the equipment in this category is almost the opposite of the equipment described in the preceding section. The high flexibility machines are of the sequential type in which components are placed one at a time. The equipment can place almost all types of components from a chip to a large PLCC including fine pitch and BGAs. Their throughput depends upon the type of components being placed but it is relatively low. The machines in this category are very accurate for placement. They are generally modular and can be used alone or in conjunction with equipment in other categories to meet differing manufacturing requirements. Some of the machines have unique features such as online testing of passive components and vision capability without much loss of placement speed for passive components. Different machines have different levels of flexibility. For example, some equipment is limited only to different sizes and types of conventional surface mount components. Then there are machines that have a common platform for all types of components including flip chip and TAB. An example of such a machine is shown in fig F. It has a broad range of capability from 0402 size chips to 304 pin fine pitch components as well as BGA. An example of BGA being placed by such a machine is shown in fig G. It can also place a flip chip. Using the same platform , the machine is so flexible that it can be fitted with different placement and soldering heads for TAB as shown in fig H. TAB leads are very fragile and flexible and should be soldered immediately after placement. With application of force and heat, the thermode shown in figure solders the leads in place. Sufficient space between packages must be allowed for the theremode. This process is generally the last step in the assembly of the board. In buying a highly flexible machine I will carefully consider whether I will ever use the option that I am paying for. As is the case in buying gadgets some options may appear appealing but may not be worth paying for because they are really not needed. There is no substitute for spending the effort to thoroughly evaluate my current and future needs before deciding on a particular machine. This is especially true when buying a placement machine since they generally account for about half of the total investment in the SMT line. C) EQUIPMENT WITH HIGH FLEXIBILITY AND THROUGHPUT As noted before , either a machine is fast but not flexible or flexible but not fast. In manufacturing environment, many time one needs both speed and flexibility. To get both, two machines- one with high throughput and the other with great flexibility are installed in the same line. A more common approach to achieving both throughput and flexibility is to combine two complementary machines in a given line. Both machines are essentially similar except that one is fitted with a vision system. One machine is used for smaller components and the other machine is used for larger and fine pitch and BGA components. As is the case with other categories, the cost of combined machines can very significantly among different manufacturers. The total throughput of the combined machines can very widely(10,000 to 60,000 or more components per hour) depending upon the equipment make and model and component mix. An example of two machines acting as one machine is shown in fig H. the advantage of this arrangement is one can get sufficient feeder input slot to populate a board with over 100 different types of components. The placement rate will be lower when larger components are placed. Also depending on requirements and budget only one machine can be purchased first and the second machine can be added later as needed. D) EQUIPMENT WITH LOW COST AND THROUGHPUT BUT HIGH FLEXIBILITY So far I have been discussing expensive machines. There is a need for low cost machines as well, for the use in laboratory, for quick turnaround prototype work, and also for low volume production. The cost of such machines varies widely but is considerably lower than the cost of the machines discussed in preceding sections. Even though these machines are relatively inexpensive, if other equipment in the line are properly selected, the general rule of thumb about the placement machine costing about half the cost of total line still applies. Equipment in these category may offer an inexpensive way to get into the surface mount business and when production volume picks up , it can be used for prototyping or as a short term back up for the production machines. In many applications it can be used in production if volume requirements are low. Some companies use these machines in larger numbers as a substitute for an actual production machine; if one of them is down , the others can still get products out the door. Typically the machines in this category have throughput in the range of 1000-4000 components per hour. An example of a placement machine in this general category is shown in fig I. It can accommodate over 100 feeders(8 mm) and large board sizes. For placing fine pitch components, it is important to purchase the vision option.