tracto-technik bending machines

advertisement

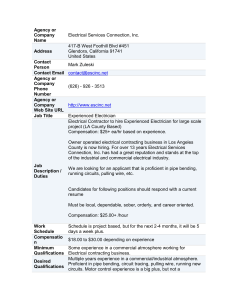

GS-HYDRO TRACTO-TECHNIK BENDING MACHINES PRODUCT OFFERING TRACTO-TECHNIK BENDING MACHINES General Information Main index Within the scope of pipe bending technology, TRACTOTECHNIK offers tailor-made solutions for pipe end working and high-performance devices for the hydraulic joining technology. PB 42 and PB 42 plus ................................................................... 4 Tubobend 48................................................................................. 5 Tubomat 642 & 648...................................................................... 6 Tubobend 80................................................................................ 7 Tubotron Line............................................................................... 8 Measuring system, Software....................................................... 9 3 TRACTO-TECHNIK BENDING MACHINES PRODUCT OFFERING PB 42 and PB 42 plus The mobile press type tube/pipe bender Features PB 42 • Free-standing and pivoting bending unit offers maximum bending space • Regulation of the bending angle by adjusting the limit switch for the hydraulic ram • Mobile push button bending control • Rugged device for mobil and flexible use • Short set-up times due to plug-in bending tools • Machine suited for simple bending applications and thick-walled tubes Additional features for PB 42 plus • Internal and external deburring unit • Integrated seating device for cutting ring assembly unit and/or flaring unit • Manual pressure adjustment according to clearly scheduled values PB 42 Technical Data PB 42 Max. tube/pipe range 42 mm 42 mm Max. stroke 300 mm 300 mm Effective bending angle PB 42 plus 170° 170° Bending speed 12 sec./300 mm 12 sec./300 mm Actuation Electro hydraulic Electro hydraulic Dimensions (LxWxH) 1100x650x1050 1200x800x1200 Weight Approx. 100 kg Approx. 200 kg 0.55 kW 1.82 kW Power requirement 4 PB 42 plus TRACTO-TECHNIK BENDING MACHINES PRODUCT OFFERING Tubobend 42 and 48 Versatile tube working machines for up to 42 and 48 mm Features/Equipment • • • • • • • Electronic control with automatic sequensing of bending angles Display of desired and actual bending angle Hydraulic mandrel retraction Length stop Machine divisible in modules for easy transportation Mobile and flexible to use Maximum tube length over mandrel 6000 mm Options • Following pressure die • Manual or automatic mandrel lubrication system • Internal and external deburring unit • Cutting ring assembly device • Flaring device • Chamfering device Tubobend 48 Technical Data Tubobend 42 Tubobend 48 Max. tube/pipe range 42 mm 48 mm Max. bending radius 90 mm 145 mm Effective bending angle Bending accuracy Bending speed Dimensions (LxWxH) Weight Power requirement 180° 180° ± 0.2° ± 0.2° 20°/sec. 20°/sec. 1800x800x1200 mm 1800x800x1200 mm Approx. 300 kg Approx. 450 kg 1.5 kW 1.7 kW 5 TRACTO-TECHNIK BENDING MACHINES PRODUCT OFFERING Tubomat 642 and 648 The professional solution for hydraulic tubing Features • Bending angle control with digital display • Hydraulic mandrel retraction • Circular saw including cooling and automatic feeding • Internal and external deburrer • Cutting ring assembly (autom. Pressure adjustment) • Mobile and flexible to use • Max. Length over mandrel 6000 mm Options • Automatic sequensing up to 8 bending angles • Plane of bend device and length stop • Digital 2-axes positioning display • Early mandrel retraction • Man./autom. Mandrel lubrication • Flaring device • Chamfering device Tubomat 642 Tubomat 648 Max. tube/pipe range Technical Data 42 mm 48.3 mm Max. bending radius 90 mm 145 mm Effective bending angle Bending accuracy Bending speed Dimensions (LxWxH) Weight Power requirement 6 180° 180° ± 0.2° ± 0.2° 20°/sec. 20°/sec. 2350x750x1200 mm 2350x850x1200 mm Approx. 600 kg Approx. 600 kg 1.5 kW 1.7 kW PRODUCT OFFERING TRACTO-TECHNIK BENDING MACHINES Tubobend 80 Powerful tube/pipe manipulator Features • Exposed bending headAutomatic sequencing of 8 bending angles • Display of desired and actual bending angle • Removable control panel • Travelling slide piece/pressure die • Adjustable clamping pressure • Hydraulic mandrel retraction • Mobile • Max. Length over mandrel 6000 mm Options • Plane of bend device and length stop • Digital 2-axes positioning display • Man./autom. Mandrel lubrication • Man./hydr. collet chuck • Early mandrel retraction • Foot switch • Bending radius extendable to 250 mm Technical Data Max. tube/pipe range Tubobend 80 76.1 mm Max. bending radius 200 mm Control Electronic Effective bending angle Bending accuracy Bending speed Dimensions (LxWxH) Weight Power requirement 180° ± 0.1° 20°/sec. 4100x850x1200 mm Approx. 1600 kg 6.0 kW 7 TRACTO-TECHNIK BENDING MACHINES PRODUCT OFFERING Tubotron Line PLC/CNC controlled tube bending machines We can also supply CNC controlled tube bending machines that meet the highest demands on quality where design, performance and fabrication are concerned. They are the perfect solution for both, serial production or flexible single production of tube bending parts. All functions are automated and the speed of all axes can be programmed free. Depending on the machine type, tubes & pipes with an outside diameter from 4 mm up to 170 mm can be bent economically and fully automatically. Due to the latest tooling concepts and control techniques even the most complicated tube shapes can be produced at minimal throughput times and with maximum finishing precision. Tubotron 170 Tubotron 50 8 PRODUCT OFFERING TRACTO-TECHNIK BENDING MACHINES Measuring System Software Automated production of template pipes The fabrication of template pipes is one of the most time consuming and cost-intensive job routings in the shipbuilding and offshore industry. Optimisation of these job routings can be achieved by means of automatization. Software solutions for the piping industry Besides the machine technology our product range contains a complete software solutions for piping, which supports the whole digital chain of a pipe’s lifecycle. This means integration of engineering, procurement, production, installation, operating and maintenance for pipe systems. The software pack combines the generation of isometric drawings, the work preparation and the production control for the pre-production of pipes. Our unique system solution provides automated and economic production of template pipes without the need of making any pattern or mockup. It was specially developed in order to streamline the job routings when fabricating template pipes. The geometry of the template pipe is measured quickly and precisely on-site (e.g. on board ship) with a 3D isometry system. This device consists of plug-in elements, which are built-in between two connecting points (flanges or sleeves) according to the planned pipe course. Via notebook and the included measuring software the planned pipe course is evaluated directly on site. If the pipe has to be installed between two flanges, even the verification of the fitting and welding of the flanges to the pipe can be done in the pipe workshop. This tasks are enabled by an electromechanical 3D positioning device, which simulates the exact installation situation in the pipe workshop. The system carries out a three-dimensional seek of two flanges according to the on-site flange situation measured before. The template pipe now can be positioned between the flanges and tacked to them. It organizes the material and time management and supplies all the required production documents for the pipe workshop. In combination with ERP/MRP-systems, PDM-systems and especially standard accountancy systems, all data and isometrics necessary for carrying out the project and its control are produced, working packs are created, production times and costs are determined, additional material is calculated and work schedules are set up. All results for project and data management, quality control and NC machine triggering are available as automated, machinereadable files. Remarkable reduction of working expenditure and production times will result from a flexible use of these easy-to-handle and practice oriented application solutions, thus leading to considerable cost savings in the whole piping process. The template pipe is transported to the jobsite with a maximum grade of prefabrication. It only has to be mounted between the flanges. Because of very high accuracies of both devices and the possibility to carry out collision checks already during the measurement of the pipe isometry, all template pipes measured and fabricated by this system can be inserted on-site at perfect fit. 9 PRODUCT OFFERING Notes 10 TRACTO-TECHNIK BENDING MACHINES GS-Hydro is the original provider of non-welded piping solutions with numerous benefits for a wide variety of ­demanding applications. The company operates globally in more than twenty-five countries through own companies and partners. ­GS-Hydro supplies complete piping systems with engineering, products, prefabrication, services and documentation. 8990306613 Product Offering Tracto-Technik Bending Machines, January 2015 GS-Hydro system offering GS-Hydro sales@gshydro.com www.gshydro.com • leak-free • reliable • highest level of cleanliness • small space requirement • prefabrication • fast and easy on-site installation • zero-fire hazard •