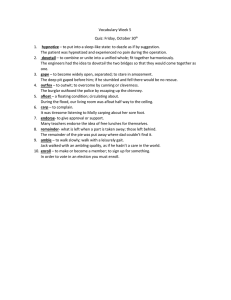

Angle Joints: Woodworking Techniques & Construction Details

advertisement

Angle Joints Joints used in box-like constructions, where the members are usually joined end to side, with their edges flush. (i) CORNER ANGLE JOINTS Chiefly used on the exterior corner in box-like constructions. such as solid cabinets, boxes, drawers, etc. 1. Simple Butt. The ends or edges of the members are shot and butted together at right angles and nailed, screwed or glued. Generally used in packing case construction 2. Rebated Butt The end of one piece is fitted into a rebate worked across the end of the other piece. It is an improvement the butt joint, as it provides two nailing surfaces and more gluing surf ace. Used in boxes, cheap cabinets, book shelves, cheap drawers, carcases for veneered work etc. 3. Tongued and Trenched or Dado Joint. Stronger than the angle lap joint. A bared faced tongue is worked on the end of one member to it fit into a trench cut the face of the other member. Used in box construction, corners of cabinets and cheap drawers. 4. Locked Rabbet Drawer Joint Locked rabbet drawer joints fasten the front of a drawer securely to the sides. They may be made on a table saw with a dado blade or with a router mounted in a table with the bit shown below. 5. Mitred Joint. This is the simplest method of connecting the end grain of pieces (the same thickness and of similar sections, e.g., mouldings) to form an angle so that no end grain is seen. Used for external and internal angled where little strength is required, skirting boards, plinths, etc. The joint is frequently strengthened by a “slip feather'' or “tongue'' inserted in a groove cut along the joint, or by keys which are pieces of veneer glued into saw kerfs across the corner of the joint. 6. Rebated and Mitred Angle Joint. Each piece is rebated and the ends mitred to form a fairly strong angle joint (with two nailing surfaces) , which does not show any grain on the external surfaces. The shoulders act as stops while assembling. Used in box construction, plinths and corners of cabinets. 6. Dovetailed Joints. These are the strongest form of angle joint used in cabinet work. The joints consist of (i) one or more dovetails cut on the end of one member, and (ii) a number of projections called pins on the end of the other piece, which are cut to fit into the recesses (pin sockets) on each side of the dovetails. The strength of the joint depends upon the shape of the dovetails (which can only be pulled away from the pins in one direction), and the added amount of gluing surface compared with other angle joints. The gluing surface can be altered as required by increasing the number of dovetails until they approximate the sizes of the pins. The interlocking of the tails and pins and the increased gluing surface of dovetail joints makes them one of the strongest joints for box-like constructions. (a) Single Dovetail Joint. (May also be used as a framing joint) This joint consists of only one dovetail fitting into a dovetail socket in the second piece. A very strong joint used for narrow pieces, such as brackets, top and bottom rails of carcases, etc. Where it is necessary to hide the end grain of the dovetail the joint is some times lapped. (b) Common Dovetail Joint or Through Dovetail Joint This is the strongest form of angle joint. It has two or more dovetails. End grain is seen on both sides of the joint. Used in making strong boxes, rails of tea trays, in carcase construction and for fixing the backs of drawers to the sides. (c) Lapped Dovetail Similar to the common dovetail joint, differing to the extent that a lap is left on the outside of the pins to cover the end grain of the dovetail tails. (d) Secret Dovetail Joint In this dovetail joint there is a double lap on both sides of the joint, which is mitred to hide all end grain. Assembled the joint has the appearance of a plain mitred joint. Used in high-class cabinet work, jewel boxes, the etc., where both appearance and strength of joint are required. 7. Comb Joint or Box Pin Joint Consists of a series of alternate notches and square pins of the same width which interlock in the assembled joint. Used in box construction. If required in numbers they are made by machinery, 8. Scribed Joint An internal angle joint used in preference to the mitred joint at the junction of mouldings where the inside angle of the joint only is seen. E.g. on skirting boards, cornices, etc., which meet at the corners of a room, and on mouldings surrounding door panels. The joint is formed by cutting the end of one piece of moulding to fit over the shape or profile of the other piece. This joint does not show the effects of shrinkage. (ii) ANGLE JOINTS OTHER THAN CORNER JOINTS Where one piece meets another but not at an end, with the faces of the pieces at right angles such as shelves and partitions in cupboards, etc. 1. Dowelled Joints May be used to strengthen butt joints 2. Housed Joints The housed joint consists of sinking the end or edge of one member into a trench or groove in the face of another member. Used chiefly for fixing shelves or divisions in bookcases, cabinets, treads of step ladders, stairs, etc. (a) Through or Full Housing Joint - The whole end or edge is fitted into a through trench and the joint is visible on both sides. (b) Stopped Housing Joint – In better class work this joint is used in preference to the through housing, for improved appearance. The end of the trench is stopped back from the front edge, and the end of the shelf notched to suit, so that in the assembled joint the trench is not seen. (c) Dovetail Housing Joint Used where a stronger joint is required. The end of the shelf is dovetailed on one or both sides and fitted into a dovetailed trench. If only one side is dovetailed it may be called a barefaced dovetail.