6 Reasons Why Organizations Should Consider Saving Space and

advertisement

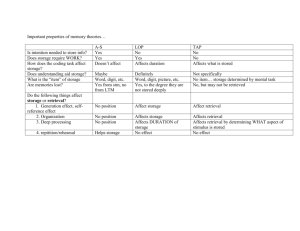

S A P I E N T A U T O M A T I O N The Intelligent Material Handling Company 6 Reasons Why Organizations Should Consider Saving Space and Time with Vertical Storage and Retrieval Systems W H I T E P A P E R S E R I E S 30 South Pine Street | Doylestown, PA 18901 | info@GetSapient.com | www.GetSapient.com 877.451.4044 215.489.7820 Subsidiary of MDCI W H I T E W P A P E R S E R I E S hat is the value of unused space? It can have significant value for companies that choose to take advantage of it in storage facilities. Automated storage and retrieval systems, such as Vertical Carousels and Vertical Lift Modules (VLM) take advantage of unused overhead space to recover 60% to 85% of the floor space typically required by shelving and drawer systems. Vertical storage and retrieval systems, such as Sapient Automation’s Viper® VLM and Avenger® Vertical Carousel, are designed with rotating shelves that move up or down in response to operator commands, delivering items at an ergonomically positioned window for easy removal. Because of their vertical design, these systems can be used to link multiple operations located on different floors, further reducing the amount of space required for storage and retrieval activities while improving workflow. Saving Space Saves Time and Money The space savings benefits of vertical storage and retrieval systems, however, are just a small piece of the savings potential of these systems. There are a number of reasons why reducing the amount of space required by storage and retrieval systems can result in significant savings in time and money. Space Savings (sq ft) Space Savings (percentages) Ceiling Height Eliminated Shelving Sections 461 - 472 82% 20’ 45 - 49 317 - 328 The floor space recovered with the installation of vertical storage and retrieval systems can often be re-allocated from 569 - 616 cost-associated functions of inventory to value-increasing 713 - 724 821 - 868 production operations. Improved space utilization can also to 929 extend the useful life of existing facilities, eliminating the need 76% 85% 88% 89% 91% 15’ 25’ 30’ 35’ 40’ 31 - 35 59 - 65 73 - 80 87 - 94 to 100 for expensive square footage expansion to meet growth requirements. Their small unit footprint makes vertical systems Reason 1: Conventional static storage systems like shelving especially valuable for point-of-use storage and Just-in-Time require employees to spend up to 70% of their time traveling (JIT) applications. aisles searching for items. Vertical automated storage and S P A C E S A V I N G S 30 South Pine Street | Doylestown, PA 18901 | info@GetSapient.com | www.GetSapient.com 877.451.4044 215.489.7820 2 Subsidiary of MDCI W H I T E P A P E R S E R I E S retrieval systems deliver items automatically to the operator, inventory management and control software, picking accuracy eliminating wasted walk and search time. The access area of can improve to 99.99%. vertical systems is ergonomically designed to present stored items at an ideal height for picking, usually about waist high. Reason 3: Redundant or non-essential handling can be reduced Typically, an operator’s walk and search time is reversed from with vertical systems. Throughput improves, and the time that of conventional systems to 70% picking and only 30% saved results in less operating cost and improved customer dwell time. In many applications, this reversal of walk and service. Vertical storage and retrieval systems can be integrated search time can reduce labor requirements by up to 66%. with ERP and WMS software to provide precise inventory Even with a smaller workforce, productivity can increase by an management. average of more than 2.5 times in typical applications. Reason 4: Since vertical systems are totally enclosed and Reason 2: Vertical storage lockable, they protect products from external hazards and and retrieval systems also reduce product damage and pilfering. Because of this, offer increased picking inventories can often be reduced. Access to vertical storage speed and accuracy when and retrieval systems can be controlled and tracked making it compared with rack and shelving systems. Intuitive controls and software allow organizations to use batch picking and integrated pick-to-light technology to improve throughput up to 500% in some applications. With the addition of position indicators, information displays, bar code scanning devices, S P A C E S A V I N G S 30 South Pine Street | Doylestown, PA 18901 | info@GetSapient.com | www.GetSapient.com 877.451.4044 215.489.7820 3 Subsidiary of MDCI W H I T E P A P E R S E R I E S easy to keep specific items or groups of items secure from unauthorized personnel. Making ‘Green’ Bottom Line Viable Going “green” with sustainable design and construction makes sense for the environment, but it’s sometimes difficult to justify. Reason 5: By reducing the amount of space required for storage and retrieval operations, companies can construct smaller, more energy efficient buildings, shrinking the construction footprint by up to 15% in some cases, conserving Return on investment for vertical storage and retrieval natural resources and reducing maintenance costs. This systems can be as fast as 18 months. improved space utilization helps reduce energy costs, which Vertical storage and retrieval systems are deigned to helps reduce an organization’s overall carbon footprint. significantly reduce to space necessary for storage and retrieval operations, allowing that recovered floor space to be used in revenue generating operations. However, there are other benefits as well, and when those benefits are combined with space savings, the resulting reduction in costs and improvement in productivity can boost the performance of any business. Sapient Automation, a subsidiary of MDCI, is a leading provider of automated storage and retrieval systems for manufacturing, distribution, warehouses, institutions, retail and wholesale. For information about the Vertical Storage and Retrieval Systems, please call 888-451-9711, email: Reason 6: The ergonomic location of the access area also info@getsapient.com or visit the Sapient Automation web contributes to employee safety since this positioning design site at www.GetSapient.com. eliminates the bending, climbing and stretching associated with conventional shelving and rack systems. This can reduce the potential for injuries and the resulting Workers’ Compensation claims and workdays lost to recovery. S P A C E S A V I N G S 30 South Pine Street | Doylestown, PA 18901 | info@GetSapient.com | www.GetSapient.com 877.451.4044 215.489.7820 4 Subsidiary of MDCI 9952_0_0411