R e s is tors - S p a c e Sa vin g , Ba c k C o n ta c t

advertisement

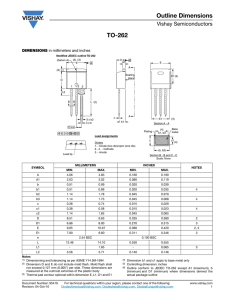

V i sh ay I n t e rt e ch n o l o g y, I n c . I INNOVAT AND TEC O L OGY BCR N HN Thin Film Resistor O 19 62-2012 Resistors - Space Saving, Back Contact Thin Film, Back Contact Resistor Key Benefits • • • • • Requires only one wire bond, thus saving space Second electrical connection is made through the back of the chip Chips can be attached either eutectically or with conductive epoxy Smaller footprints than alternative configurations Tighter tolerances available upon request APPLICATIONS • Hybrid packages Resources • Datasheet: BCR - http://www.vishay.com/doc?61023 • For technical questions contact efi@vishay.com One of the World’s Largest Manufacturers of Discrete Semiconductors and Passive Components PRODUCT SHEET 1/2 VMN-PT9012-1202 This document is subject to change without notice. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 V i sh ay I n t e rt e ch n o l o g y, I n c . I INNOVAT 19 www.vishay.com 62-2012 BCR BCR www.vishay.com O L OGY BCR AND TEC N HN Thin Film Resistor O Vishay Electro-Films Vishay Electro-Films Thin Film, Back Contact Resistor Thin Film, Back-Contact Resistor Thin Film, Back-Contact Resistor FEATURES Resistors - Space Saving, Back Contact FEATURES • Wire bondable • Only one wire bond required • Only one wire bond required Small size: 0.020 inches square • Small size: 0.020 inches•square • Wire bondable • Resistance range: 10 •toResistance 1 M range: 10 to 1 M • Oxidized silicon substrate for good silicon power substrate dissipationfor good power dissipation • Oxidized • Resistor material: Tantalum nitride,material: self-passivating • Resistor Tantalum nitride, self-passivating Product may not be to scale Product may not be to scale • Moisture resistant • Moisture resistant he Back Contact Resistor (BCR) Contact series single-value The Back Resistor (BCR) series single-value back-contact resistor chip chips is one of the smallest chips • Case size: 0202 ack-contact resistor chip is one of the smallest www.vishay.com • Case size: 0202 www.vishay.com vailable. available. APPLICATIONS Thewire BCR requires one wire bond thus saving hybrid APPLICATIONS he BCR requires only one bond thus only saving hybrid DIMENSIONS in inches pace. space. EFIwidely BCR resistor are widely used in hybrid DIMENSIONS in inches Vishay EFI BCR resistor Vishay chips are used in chips hybrid The BCRs manufactured using Vishay Electro-Films he BCRs are manufactured using are Vishay Electro-Films packages where space is limited. The bottom connection is The bottom connection is packages where space is limited. EFI) sophisticated thin film equipment and manufacturing (EFI) sophisticated thin film equipment and manufacturing made the substrate back of the chip to the substrate made by attaching the back of by theattaching chip to the echnology. The BCRs are 100 % electrically and% electrically technology. The BCRstested are 100 tested andor with conductive either eutectically epoxy. or The single wire either eutectically with conductive epoxy. The single wire sually inspected to MIL-STD-883, method to 2032 class H visually inspected MIL-STD-883, method class H notched bond 2032 is made to the padison the top of the chip. pad (Theon the top of the chip. (The bond made to the notched r K. or K. other rectangular pad on the toprectangular of the chippad is aon viathe hole, other topa of the chip is a via hole, a low-ohmic contact connecting the resistor to connecting the bottom the of resistor to the bottom of 0.020 low-ohmic contact the chip.) the chip.) Vis TEMPERATURE TEMPERATURE COEFFICIENT OF RESISTANCE, VALUES, AND TOLERANCES COEFFICIENT OF RESISTANCE, VALUES, AND TOLERANCES Standard Tolerances PARAMETER Total Resistance Range Standard Tolerances TCR TCR PARAMETER Total Resistance Range VALUE UNIT VALUE UNIT 10 to 1M 10RANGE to 1M TYPICAL RANGE TYPICAL 10±Ω0.2, to 29 300.2, Ω to±81 Ω ± 1,%± 2, ± 5 0.5, ± 0.1, ±Ω 0.5, ± 1, ± 2, ±±5 0.1, ± TYPICAL RANGE TYPICAL RANGE Ω to 29ΩΩ 82 10 Ω to 819 % TYPICA TYP 30 Ω 82 % ppm/°C ± 25, ± 50, ± 100, ± 250 ± 25, ± 50, ± 100, ± 250 ppm/°C Note Note • Notched area represents top bonding • Notched shaded area represents top bonding pad. The backside of the shaded chip constitutes the second resisto Tightest Standard Tolerance Available Tightest Standard Tolerance Available 5% 2% 1% 0.5 % 0.2 %5 % 2% 1% 0.5 % 0.2 % ± 100 ppm/°C ± 250 ppm/°C ± 100 ppm/°C ± 250 ppm/°C 20 Ω 50 Ω Back of Chip 360 kΩ 1 MΩ 200 kΩ 620 kΩ 360 kΩ 1 MΩ 200ΩkΩ200 Ω620 1 kΩ 100 Ω Ω 1 kΩ 100 Ω 200 10 20 Ω 50 Ω Bond Pad ± 25 ppm/°C ± 50 ppm/°C ± 25 ppm/°C ± 50 ppm/°C 10 Ω SCHEMATIC 0.1 % 0.1 % 2% 1% 0.5 % SCHEMATIC MECHANICAL SPECIFICATIONS PARAMETER PARAMETER PARAMETER Noise, MIL-STD-202, MethodNoise, 308 MIL-STD-202, Method 308 100 to 250 k 100 to 250 k < 100 or > 251 k < 100 or > 251 k VALUE Chip Thickness PARAMETER VALUE Chip Size 0.020" x 0.020" ± 0.002" (0.50 mm x 0.50 Chip Thickness VALUE UNIT UNIT 0.010" ± 0.003" (0.253 mm ± 0.0 Chip Substrate Material OxidizeddB silicon, 10 kÅ minimum - 35 typ. dB Resistor Material - 20 typ. Bonding Pad SizeTantalum nitride, self-passiva ± 0.5 max. R/R % % Number of Pads 0.004" x 0.004" (0.100 mm x 0.1 % Pad Material ± 1.0 max. R/R % 1 - 55 to + 125°C Backing °C 10 kÅ minimum aluminum (15 kÅ minimu % Recommended Attachment ± 0.25 max. R/R % Method 3 kÅ minimum gold % ± 0.5 max. R/R % Eutectic or conductive epo V 200 V STANDARD STANDARD ELECTRICAL SPECIFICATIONS ELECTRICAL SPECIFICATIONS Chip Size MECHANICAL SPECIFICATIONS Revision 08-Aug-11 Chip Substrate Material - 35 typ. Resistor Material - 20 typ. Moisture resistance, 106 Pad Size Moisture resistance, MIL-STD-202, Method 106 MIL-STD-202, Method ± 0.5 max. R/R Bonding Stability, 1000 h, + 125 °C, 125 mW 1000 h, + 125 °C, 125 mW Stability, Number of Pads± 1.0 max. R/R Operating Temperature Range - 55 to + 125 Operating Temperature Range Pad Material Thermal Shock, MIL-STD-202, Method F 107, Test Condition Method ± 0.25 max. R/R Thermal Shock, MIL-STD-202, F 107, Test Condition Backing High Temperature Exposure, High + 150Temperature °C, 100 h Exposure, + 150 °C, 100 h ± 0.5 max. R/R Recommended Attachment Method Dielectric Voltage BreakdownDielectric Voltage Breakdown 200 GLOBAL PART NUMBER INFORM Insulation Resistance 1012 min. Insulation Resistance 1012 min. Global Part Number: BCR50000FKAHWS 75 max. Operating Voltage 75 max. V Operating Voltage V GLOBAL PART NUMBER INFORMATION Global Part Number Description: BCR 5K 1 DC Power Rating at + 70 °C (Derated to Rating zero atat ++ 175 W DC Power 70 °C) °C (Derated to zero at +Part 175 °C) 0.250 W Global Number:0.250 BCR50000FKAHWS B ClassCH, WS 5 0 Global BCR 5K 1 %,max. 100 R/R ppm/°C, Al term., 5 x Rated Power Short-Time Overload, 25 °C, 5s ± 0.25 Description: max. R/R % 5 x Rated + Power Short-Time Overload, + 25 °C, 5Part s Number ± 0.25 %R Revision: 08-Aug-11 B C R 5 0 0 0 0 F K A Document Number: 61023 Document Number: 61023 RESISTANCE VMN-PT9012-1202 MODEL RESISTANCE MULTILPLIER For technical questions, contact: efi@vishay.com For technical questions, contact: efi@vishay.com CODE VISUA RESISTANCE THIS DOCUMENT IS SUBJECT TODOCUMENT CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT THIS IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS TOLERANCE TCRDOCUMENT MODEL RESISTANCE MULTILPLIER TERMINATION (per MIL BCR ARE SUBJECT TO SPECIFICARE DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 This document is subject to change without notice. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT ARE SUBJECT CODE (ppm/°C)First 4 digits areTO B = 0.01 CODE Metho 20 x 20 size significant figures A = 0.1 SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000 0=H 1 =C BCR First 4 digits are B = 0.01 E = ± 25 of resistance B = 0.1 %back contact G = Gold evision: 08-Aug-11 PRODUCT SHEET 1 1 2/21 For technical questions, contact: efi@vishay.com