Division 26 - Electrical - Northwestern University

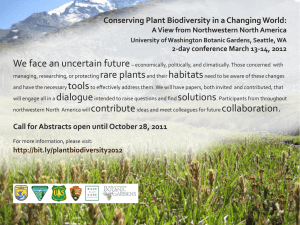

advertisement