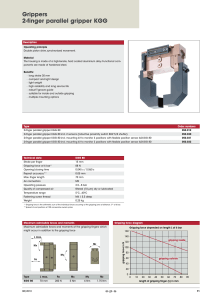

Centering accuracy ±0.05 mm or less Repeat accuracy ±0.01 mm or

advertisement

Parallel 3-Finger Mechanical Gripper HP15M Series ●Mechanical Gripper (Gripping by the use of the spring force) ●High rigidity and high accuracy realized by the use of the linear guide ●Gripping at the long point is available. ●With a hollow hole Application Bearing Gear HP15M Cylinder Gear Motor e Ext rce Fo rnal Parallel 3-Finger Mechanical Gripper Fit Tolerance for Shaft ●Centering accuracy ±0.05 mm or less ● Repeat accuracy ±0.01 mm or less ●Withstand Load, Withstand Moment Push HP15M Series Rotation Hallow Hole Positioning Pin High Accuracy Linear Guide 405 Parallel 3-Finger Mechanical Gripper HP15M Series ■ Model Code No. HP15M 16 L Series Name HP15M Series Nominal diameter Gripping Force 16 20 25 L: Low ※Please feel free to consult us about M: Medium the grip forces (spring forces) other than the ones specified on the left. H: High Parallel 3-Finger Mechanical Gripper ■Internal Structure Diagram 11 13 12 5 13 1 7 8 14 9 3 6 2 4 10 15 Parts List NO 406 Name Material Name NO Metal Material 1 Main Body Aluminum Alloy 2 Piston Rod Stainless Steel 10 Case Stainless Steel 3 Pressure Cover Aluminum Alloy 11 Knuckle Stainless Steel 4 Pressure Cover Stainless Steel 12 Roller Carbon Steel 5 Pressure Cover Stainless Steel 13 Hexagon Socket Head Bolt Stainless Steel 6 Spring Spring Steel 14 Hexagon Socket Head Bolt Stainless Steel 7 Action Lever Carbon Steel 15 Bearing Stainless Steel 8 Fulcrum Pin Carbon Tool Steel 9 Oil-impregnated Sintered Bearing ■Specifications Elastic Body to be Used Compression spring Action Type Single Acting Normally Close (External force drive at opening) Operating Temperature 0∼120 [℃] Required Lubrication Maximum Operating Cycle [Cycle/min] 180 Centering Accuracy [mm] ±0.07 Repeat Accuracy [mm] ±0.01 Not mountable Applicable Switch Model Note)1 Allowable Nominal Opening/ Gripping Extrusion Force Extrusion diameter Closing Force (At Closing) Stroke Force [mm] [mm]Note)3 [N] [N] [N] HP15M-16-L HP15M-16-M 16 3 (3∼4.8) HP15M-16-H HP15M-20-L 14 5 24 7 34 7 38 12 64 HP15M-20-H 17 88 HP15M-25-L 12 66 HP15M-20-M HP15M-25-M HP15M-25-H 20 25 5 (5∼7) 7 (6.3∼8.8) 18 95 26 138 Lever Ratio 50 300 1:1.1 130 560 1:1.1 210 870 1:1.1 Note)2 Note 1): Extrusion force is an external force required to open the levers completely by overwhelming the spring force in the closing direction. Note 2): The lever ratio is the "Extruded Distance (how much the rear rod is extruded) and the "Lever Opening Distance (Lever Opening Distance at that time) (both sides) expressed in "Extruded Distance: Lever Opening Distance". Note 3): The opening/closing stroke is a reference value. Values in the parentheses are measured values. Parallel 3-Finger Mechanical Gripper Single Acting Normally Close 3 Product Mass [g] HP15M Series Action Type 407 Parallel 3-Finger Mechanical Gripper HP15M Series ■Effective Gripping Force 8 4 2 20 40 4 2 0 60 70 20 Gripping Force [N] 15 5 0 20 40 60 5 20 0 30 60 90 40 60 0 120 30 Gripping Point L [mm] 60 90 HP15M-20-H 5 30 10 60 70 20 40 60 80 100 Gripping Point L [mm] HP15M-25-M 20 40 10 0 80 100 Gripping Force [N] 30 20 15 Gripping Point L [mm] HP15M-25-L 10 20 10 0 80 100 20 2 Gripping Point L [mm] HP15M-20-M Gripping Point L [mm] 30 4 0 60 70 Gripping Force [N] HP15M-20-L 10 40 HP15M-16-H 6 Gripping Point L [mm] Gripping Force [N] Parallel 3-Finger Mechanical Gripper Gripping Force [N] 15 8 6 Gripping Point L [mm] Gripping Force [N] HP15M Series 0 HP15M-16-M Gripping Force [N] HP15M-16-L Gripping Force [N] Gripping Force [N] 6 When the levers are full open When the levers are full closed 20 10 0 120 HP15M-25-H Gripping Point L [mm] 30 60 90 120 Gripping Point L [mm] ■Gripping Point Limit Range 30 10 5 0 20 40 60 80 100 Gripping Point L [mm] 408 HP15M-20 50 Gripping Force [N] HP15M-16 Gripping Force [N] Gripping Force [N] 15 20 10 0 30 60 90 120 Gripping Point L [mm] HP15M-25 40 30 20 10 0 30 60 90 120 150 Gripping Point L [mm] ■Gripper Attachment Method Pipe Attachment Mounting When you screw in a joint or the like into the pipe port, tighten it with the following torque. When you mount the attachment, support it with a spanner or the like so that the levers are not rattled. See the following table for the tightening torque of the mounting bolts. Bolt to be Used Maximum Tightening Torque[N・m] HP15M-16 M3×0.5 1.14 M3×0.5 0.59 HP15M-20 M4×0.7 2.7 M5×0.8 1.57 HP15M-25 M5×0.8 5.4 HP15M Series Model Pipe Port Maximum Tightening Torque[N・m] Main Body Mounting Method 1 When the through-hole of the main body is used Bolt to be Used Maximum Tightening Torque[N・m] L[mm] φ16 M3×0.5 0.59 18 φ20 M3×0.5 0.59 21 φ25 M4×0.7 1.37 21 L 2 When the mounting screw on the back side of the through-hole is used Model Bolt to be Used Maximum Tightening Torque [N・m] φ16 M4×0.7 1.37 φ20 M4×0.7 1.37 φ25 M5×0.8 2.84 Parallel 3-Finger Mechanical Gripper Model 3 When shank is used φD Model Shank Diameter[φD] φ16 φ25−0.01 −0.03 φ20 φ30−0.01 −0.03 φ25 φ30−0.01 −0.03 409 Parallel 3-Finger Mechanical Gripper HP15M Series ■Dimensions CAD data provided HP15M-16-□ Through-Hole Depth 4 HP15M Series When opened:13.3 0 When closed :10.3 0 −0.6 +1.2 (Positioning Pin) Parallel 3-Finger Mechanical Gripper Depth 10 Depth 6 Lower Hole φ3.2 Through-Hole Note)・The allowable extrusion force shall be within the specified range in use. ・Do not hit the cam and the dog against the pressure cover in use. 410 CAD data provided ■Dimensions HP15M-20-□ Through-Hole Depth 5 HP15M Series When opened:16.8 0 When closed :11.8 0 −0.6 +1.4 (Positioning Pin) Parallel 3-Finger Mechanical Gripper Depth 10 Depth 6 Lower Hole φ3.2 Through-Hole Note)・The allowable extrusion force shall be within the specified range in use. ・Do not hit the cam and the dog against the pressure cover in use. 411 Parallel 3-Finger Mechanical Gripper HP15M Series ■Dimensions CAD data provided HP15M-25-□ Through-Hole Depth 7 HP15M Series When opened:20.7 0 When closed :14.4 0 −0.8 +1.7 (Positioning Pin) Parallel 3-Finger Mechanical Gripper Depth 12 Depth 8 Lower Hole φ4.2 Through-Hole Note)・The allowable extrusion force shall be within the specified range in use. ・Do not hit the cam and the dog against the pressure cover in use. 412