RBS

Rotational ball seat

Applications

■■

High-inclination wells

■■

Low-fracture pressure formations

■■

Well applications where liner string

consists of additional pressure-actuated

tools, such as external casing packers

(ECPs)

Benefits

■■

■■

■■

Minimizes risk of ball-seating failure in

horizontal sections

■■

■■

■■

Since the RBS is run in the setting string, it reduces formation pressure surges that are experienced when conventional liner toe ball seats shear. Once the liner hanger has been set and

the RBS sheared, a full-bore ID allows normal cementing operations, including the passage of

drillpipe wiper plugs.

Saves operation time in long liners

because ball does not have to reach

liner toe

Reduces risk of fracturing formation

because of sharp rise in equivalent

circulating density (ECDs) when conventional liner toe ball seats shear

Features

■■

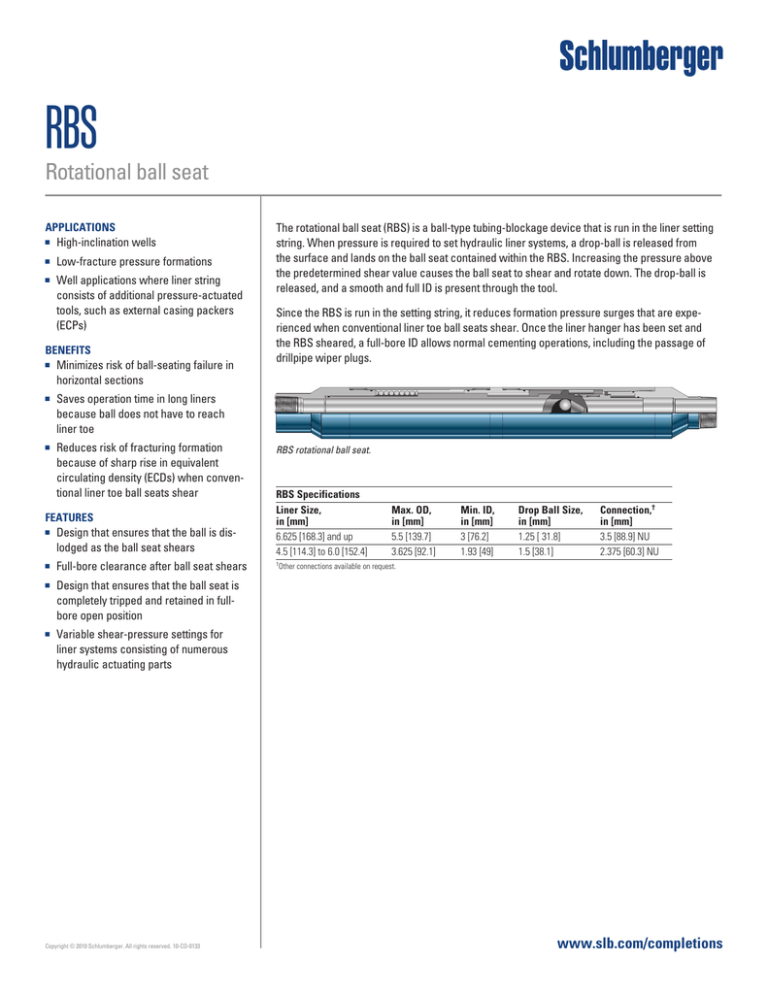

The rotational ball seat (RBS) is a ball-type tubing-blockage device that is run in the liner setting

string. When pressure is required to set hydraulic liner systems, a drop-ball is released from

the surface and lands on the ball seat contained within the RBS. Increasing the pressure above

the predetermined shear value causes the ball seat to shear and rotate down. The drop-ball is

released, and a smooth and full ID is present through the tool.

Design that ensures that the ball is dislodged as the ball seat shears

Full-bore clearance after ball seat shears

RBS rotational ball seat.

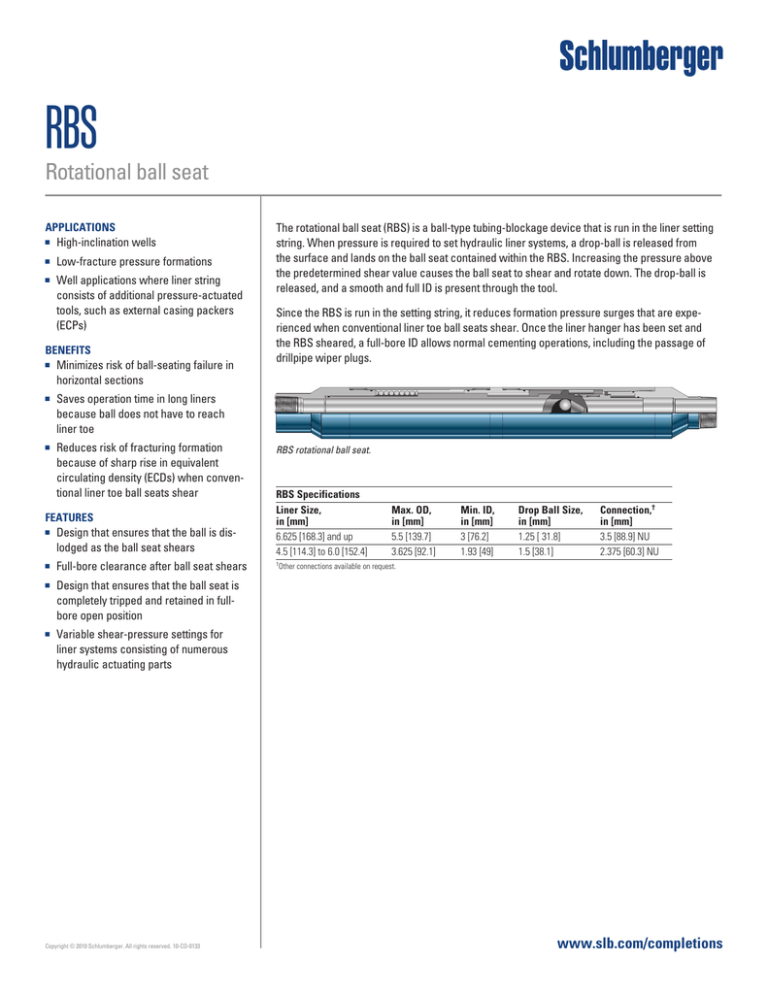

RBS Specifications

Liner Size,

in [mm]

6.625 [168.3] and up

4.5 [114.3] to 6.0 [152.4]

†Other

Max. OD,

in [mm]

5.5 [139.7]

3.625 [92.1]

Min. ID,

in [mm]

3 [76.2]

1.93 [49]

Drop Ball Size,

in [mm]

1.25 [ 31.8]

1.5 [38.1]

Connection,†

in [mm]

3.5 [88.9] NU

2.375 [60.3] NU

connections available on request.

Design that ensures that the ball seat is

completely tripped and retained in fullbore open position

Variable shear-pressure settings for

liner systems consisting of numerous

hydraulic actuating parts

Copyright © 2010 Schlumberger. All rights reserved. 10-CO-0133

www.slb.com/completions