\/RM Hydraulic 4-Roller Vrxlvl p|ate bencjjng machines

advertisement

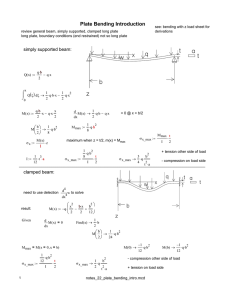

пк 05 - 1222 02 \/RM Hydraulic 4-Roller Vrxlvl p|ate bencjjng machines The Haeusler4-roller plate bending Machines The Haeusler hydraulic 4-roller plate bending machine type is todays "state of the art" technology, the result of constant development and improvement combined with more than 50 years of Haeusler experience in the world of roll bending. Many of Haeusler's 4-roller plate bending machine developments over the years are now requested industry standards. In 1965 Haeusler was the first to bring the hydraulic 4-roller plate bending machine on the market. A few years later Haeusler initiated the first hydraulic rotation drive of the top and bottom rolls. These with many other developments and a comprehensive after sales support, combined with the uncompromising quality, close customer project development and relations, has from the start made us the market leader in the world of 4-roller plate bending machine technology. The following pages give you an insight into the range of possibilities and advantages for our VRM 4-roller plate bending machine types Some practical examples produced on Haeusler 4-roller plate bending machines TheVRM bending process Feeding and automatic aligning of plate minute " Raising of entry side roller to pre-bend leading edge 2 minutes Lowering of entry side roller; raising of exit side roller 2 minutes Continuation of bending and automatic pre-bending of trailing edge 1 minute Lowering bottom roller and opening of tilting bearing 1 minute .. Total 7 minutes Advantages of the Haeusler VRM machines , Extremely long guide ways at the side rollers (protected by patents) q " ~. * Min. foundation dimensions (in width, depth and length) ,~ Hydraulic unit seperate from "•' the machine itself, for easy accessible maintenance -, All rolls sit 100% in spherical roller bearings . r r Large (oversized) rollerdiameters with small camber (min. deflection) Automatic pressure balance system between top to bottom rolls Direct drive (hydraulic) of the top and bottom rollers with automatic speed compensation (avoids plate slipping on the rolls) -, Top- and bottom rolls ' equipped with pneumatic resp. hydraulic instant brakes (highest safety factor) о Rational cone bending by our patented cone bending device Т Depending on the requirements the shortest flat end possible Ratio of flat end to machine size Automatic central lubrication 11 system Roller position devices are on both ends of bottom and side rollers Bottom roll can be adjusted by pressure or position 100% 1 * Wired with light-cables * (secure against electromagnetic influences) pre bending length 50% 1 x thickness Plate thickness 2 x thickness 3 x thickness Control Panel Real time process visualization II Automatic error detection Automatic inspection indication CNC-control (max. 30 axis) User friendly (e.g. roller adjusting (speed) over joy stick position, color screen, intuitive menu guidance etc.) On-line-diagnosis via modem Bottom and side rollers can be adjusted for pressure or position, which is displayed in absolute, relative or angle mode Cone rolling system Due to the inclination of the bottom roller, the cone blank to be rolled is clamped and transported by top and bottom rollers on the big radius. There is no firm contact between plate and rollers at the smaller radius and thus differences of circumferential speeds do not have to be compensated for. The thrust of the plate is absorbed by a special cone bending shoe creating the necessary friction to compensate for the difference in the small and big radius circumferential length. П П _oAo The Haeusler technology The patented Haeusler design allows the highest rigidity combined with far smaller machine dimensions compared to conventional technology Patented Haeusler technology HaeuslerVRM models VRM 3000x36 - VRM 400 X 3 CNC VRM bendable plate dimensions 200 150 100 50 0 1000 2000 3000 4000 5000 6000 7000 8000 Plate width (mm) I Standard plate dimension range VRM 4200 x 200 (cold bending) the worlds largest 4-roller-plate-bending machine | Special plate dimension range VRM 3000 x 25 with bridgesupport for top roller allowing increased edge setting capacity All machine dimensions (width x cold bending thickness) in mm VRM 1500 x 6 CNC automatic bending machine with plate charging, centering and shell discharging device VRM 1500X40 VRM 3000 X 150 with lateral and upper support, requiring only one operator, for bending, edge setting, bending and tack welding VRM 1200 x 14 equipped with interchangable top roller for large batch productions of symmetric and asymmetric cones VRM 6000x18 CNC VRM 3000x18 VRM 2 5 0 0 x 1 5 for vertical (large diameter) or horizontal plate bending processes VRM 8000 x 20 with top roller preloaded at both ends for line pipe production and extremly small diameter conical poles VRM 4 0 0 0 x 1 2 5 CNC Examples from our production program Three and four-roller plate bending machines in ail sizes Section and tube roll bending machines in all sizes Automatic roll bending machines Pressure vessel dished/flanged head production lines Sizing machines Welding and assembling equipment Wheel rim production lines Vessel and truck fuel tank production lines Longitudinal seam welded pipe mill (SAW) Special forming machines The Haeusler Plant in Duggingen (H) Neu - Neu - Neu Tel. +41 61 755 22 22 Fax +41 61 755 22 00 New - New - New For all enquiries please contact our Swiss Plant: German Plant HAEUSLER AC Baselstrasse 21 CH-4202 Duggingen HAEUSLER GmbH Am Rhein 15 D-7961 Rheinfelden Phone:+41 61 751 55 55 Fax: +41 61 751 66 26 Phone: +49 7623 41 44 Fax: +49 7623 4 74 56 E-mail: marketing-haeusler@swissonline.ch Internet: www.haeusler.ch