NH (H.R.C) FUSES AND FUSE BASES NH (H.R.C) FUSES AND

advertisement

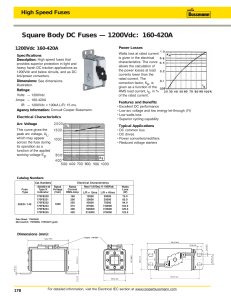

NH (H.R.C) FUSES AND FUSE BASES NH (H.R.C) Fuses NHC00-FB (6A...100A) NH00-FB (6A...160A) NH0-FB (25A...160A) 5 NH1-FB (50A...250A) NH2-FB (80A...400A) NH3-FB (250A...630A) NH (H.R.C) Fuse Bases BMC STEATIT NH00-FA NH0-FA NH1-FA NH2-FA NH3-FA CONTENTS General Information About NH (H.R.C) Fuses 2 Super Flink NH Fuses Bases 3 Technical Characteristic Dimension and Order Codes of NH (HRC) Fuses 4 Technical Characteristic Dimension and Order Codes of NH (HRC) Fuse Bases 5 Maksimum Power Loses Table 6 -2006 5/1 GENERAL INFORMATION ABOUT NH (H.R.C) FUSES General : Quartz Sand : Fuses are protective device in which the melting or more fusible elements open a circuit and interrupt the current if the current exceeds a set value for a given length of time. Federal NH (H.R.C.) fuses and fuse bases are produced in according to VDE 636, IEC 60269/EN 60269, DIN 43620 standards and CE certificate. According to the above mentioned standards the H.R.C. fuses should have a higher breaking capacity than 50 kA. Federal NH (H.R.C.) fuses have a breaking capacity of 120 kA. Federal has a wide range of H.R.C. products. Rated voltages are 500 V. AC and 440 V DC. Rated current is up to 630 A. Our products protect your panels, cables and installation reliability Figure3 gives the time-current character›st›c of the fuses. The curves show that fuse’s response time(+) which is connected with load current. It is clear from the figure that at higher current rates the response time is shorter. Federal NH fuses have characteristic of delayed and it is strong to Asynchrone motor’s openning current. It makes protection against short circuit, boasting current and opens circuit immediately. “gL/Gg” mark’s mean is line protection and this class of fuses are used for protection of cabel and conductors. From the time-current curve it is clear that fuses can operate to 1.6 time higher of its rated value and breaking capacity of circuit for a 5xIn value in 5 seconds. The melting wires (fusible element) of the fuses cartridges are produced in different shape and sizes for various current rated. Over the melting wire small chambers are put together. In case of short-circuit and over load different section with the same diameter melt down and form partical sparks. As a result of the short-circuit current is extinguished and the heat is evenly transferred along the fuse. The external body of the fuses should be resistant to the high current temperature and pressure caused arcs during the melting of the fuse wire. Therefore for this wire to melt, the current energy should be higher than the wires maximum resistance. During the process of the wire melting along and inside the length of the fuse body, the current continues to flow firstly as liquefied metal and secondly as steamed metal before eventually losing it’s energy. This is visible in the form of an arc (Fig-1) and therefore there is an immense increase of heat and pressure during this action on the inside of the fuse body. The fuse body must hold resistance to such actions otherwise will be damaged and lose its purpose. To avoid such circumstance the material used for the fuse body should be made accordingly to the IEC 672 standards. Federal fuses cartridge are produced to withstand shock temperatures and dynamic stresses. Federal fuses cartidge contacts are made from special brass and silver plated. In time the silver plate becomes dark colored. However,this is not important,because silver sulphur with current heat becomes conductive. Inside of the body is Quartz Sand. This distinctiveness of the sand is that it is high pure, clean and unhumid. Also the sand is tightly contained in the fuse using a vibration method to lock out any air and maintain the sufficiency of sand. During melting of the wire, the sand helps cool down the arc and insulates the distance between the broken fuse wire points for quicker and more efficient energy decrease. lo: passing current, lk(t): short circuit current that will pass, if a metallic bridge be inside of fuse. lp: peak value of the short circuit current ts: fusion time t1: extinguishing time Ip NH(HRC) Fuses Bases : Fuse bases are produced in five size and steatit or BMC cartridge according to request of customers. The bases contacts are produced 00 and 0 size with clemence or screw, other sizes have only screw connection The bases contacts are made of electrolytic copper and reinforced with steel segments in addition to ›ts own compression and elasticity characteristic. Grabbing capacity of conducts is higher than other bases. If bases are put together side by side. Pertinaks seperaters which is given as accessory is used for rising of phase isolation. When fuses are placed in their bases, the fuses blade must sit on base exactly. Otherwise incapable contact will cause loss of resistance, temperature and power, failures. Conductors must be mounted for bases and cross-sections which is suitable to standars. Order Codes Size 8CB-A0000-0000 8CB-A0000-0000 8CB-A0000-0000 1 2 3 Phase seperator dimensions(mm) a b 227 116 227 116 227 116 Selective Protection (Selectivity) Selectivity means that any fault occurs in a system is eliminated by the close protection equipment so that the rest of the system continuous ›ts normal operation. Accordig to “gL/gG” operation class, NH fuses bases which have %60 nominal circuit selectivly in high short circuit current. For selectivity,fuses must be choosen according to table (Fig-2) SELECTIVE PROTECTION (SELECTIVITY) 2nd FUSE NOMINAL CURRENT OF 2th FUSE 6 10 16 20 25 32 35 40 50 63 80 100 125 160 200 250 315 400 500 NOMINAL CURRENT 1th FUSE 6 10 16 20 25 32 35 40 50 63 80 100 125 160 200 250 315 400 500 630 1th FUSE Ik(t) three phase, selective at 380 V. three phase, selective at 500 V. Selective Table Fig-2 Voltage Io Current ts tl Fig - 1 Diagram of current and voltage changing when the damage current is broken by the fuse. 5/2 -2006 315 400 500 630 200 250 100 125 160 10 16 20 25 32 40 50 63 80 1000 5000 3000 500 300 1000 100 500 300 50 30 10 5 3 1 2√2 Ip 100 630 A 400 A 250 A 160 A 100 A 50 30 5 3 0,5 0,3 Fig-3 Loading current (effective value) Ampere Time - current characteristics of NH (H.R.C) fuses “gL/gG” 700 500 300 70 100 50 30 7 10 3 Expected current 1000 7000 10000 5000 3000 1000 700 500 300 70 100 50 30 5 1 10 0,1 5 10 1 Opening time 10000 kA peak 5000 3000 Max. value of current Second 10000 6 GENERAL INFORMATION ABOUT NH (H.R.C) FUSES kA eff Fig-4 Breaking current diagram 180 200 250 315 400 100 125 300 Second 10000 4000 2000 1000 400 200 100 40 Opening time The super flink fuses are used to protected the power electronic element, such as diode, thrystor in AC and DC against overcurrent and short-circuit. Pure silver materials are used as a melting lace wire. This is the most important difference between NH (H.R.C) (fusable cut out) fuses, and LV NH (H.R.C.) fuse flinks. Increasing of temperature of super flink fuses is very high in comparison with line protection device (in operating class gL, Gg) as shown in time-current characteristics curve. (Fig-5) So that precise protection is supplied at the value of rated current. This means that these super flink fuses take into account all aspects of electrical safety. 25 32 40 50 63 80 NH Super flink fuses : 200 NH SUPER FLINK FUSES Operating characteristic: Super flink (Rapid) Rated voltage : AC 500 V. Operating class : gR Breaking capacity : 100 kA (effective) Dimensions of super flink fuses are same as NH fuses. 20 10 4 2 1 0.4 0.2 0.1 0.04 0.02 4000 5000 3000 2000 1000 400 500 100 40 50 30 4 NH super flink fuses are manufactured in the following size and with the following rated currents. 00, 1, 2 at 3 size and from 25 A. to 400 A. 20 0.01 Rated current : Fig-5 Load current Ampere Time - current characteristics of super flink NH (H.R.C) fuses "gR" Order codes : Type Size NHG00-FB NHG00-FB NHG00-FB NHG00-FB NHG00-FB NHG00-FB NHG00-FB NHG00-FB NHG1-FB NHG1-FB 00 00 00 00 00 00 00 00 1 1 -2006 Rated current Order Code 25 A 32 A 40 A 50 A 63 A 80 A 100 A 125 A 100 A 125 A 9CB-BH000-0025 9CB-BH000-0032 9CB-BH000-0040 9CB-BH000-0050 9CB-BH000-0063 9CB-BH000-0080 9CB-BH000-0100 9CB-BH000-0125 9CD-BH000-0100 9CD-BH000-0125 Type Size Rated current Order Code NHG1-FB NHG1-FB NHG1-FB NHG2-FB NHG2-FB NHG2-FB NHG2-FB NHG2-FB NHG2-FB NHG3-FB 1 1 1 2 2 2 2 2 2 3 160 A 200 A 250 A 200 A 250 A 280 A 315 A 355 A 400 A 630 A 9CD-BH000-0160 9CD-BH000-0200 9CD-BH000-0250 9CE-BH000-0200 9CE-BH000-0250 9CE-BH000-0280 9CE-BH000-0315 9CE-BH000-0355 9CE-BH000-0400 9CE-BH000-0630 5/3 TECHNICAL CHARACTERISTICS, DIMENSIONS and ORDER CODES of NH (H.R.C) FUSES Order code Size Rated Quantity/ current box (A) Kg./ box DIMENSIONS (mm) a1 a2 a3 a4 b e1 e2 C00 C00 C00 C00 C00 C00 C00 C00 C00 C00 C00 6 10 16 20 25 32 40 50 63 80 100 10 10 10 10 10 10 10 10 10 10 10 1.305 1.305 1.305 1.305 1.305 1.305 1.305 1.305 1.305 1.305 1.305 78.5 54 45 49 15 36 21 e3 45 NHC00-FB 9CA-BG000-0006 9CA-BG000-0010 9CA-BG000-0016 9CA-BG000-0020 9CA-BG000-0025 9CA-BG000-0032 9CA-BG000-0040 9CA-BG000-0050 9CA-BG000-0063 9CA-BG000-0080 9CA-BG000-0100 00 00 00 00 00 00 00 00 00 00 00 00 00 00 6 10 16 20 25 32 35 40 50 63 80 100 125 160 10 10 10 10 10 10 10 10 10 10 10 10 10 10 1.760 1.760 1.760 1.760 1.760 1.760 1.760 1.760 1.760 1.760 1.760 1.760 1.760 1.760 78.5 54 45 49 15 48 29.5 44.5 NH00-FB 9CB-BG000-0006 9CB-BG000-0010 9CB-BG000-0016 9CB-BG000-0020 9CB-BG000-0025 9CB-BG000-0032 9CB-BG000-0035* 9CB-BG000-0040 9CB-BG000-0050 9CB-BG000-0063 9CB-BG000-0080 9CB-BG000-0100 9CB-BG000-0125 9CB-BG000-0160 0 0 0 0 0 0 0 0 0 25 32 40 50 63 80 100 125 160 5 5 5 5 5 5 5 5 5 1.225 1.225 1.225 1.225 1.225 1.225 1.225 1.225 1.225 125 71 62 66 15 48 29.5 44.5 NH0-FB 9CC-BG000-0025 9CC-BG000-0032 9CC-BG000-0040 9CC-BG000-0050 9CC-BG000-0063 9CC-BG000-0080 9CC-BG000-0100 9CC-BG000-0125 9CC-BG000-0160 9CD-BG000-0050* 9CD-BG000-0063* 9CD-BG000-0080 9CD-BG000-0100 9CD-BG000-0125 9CD-BG000-0160 9CD-BG000-0200 9CD-BG000-0250 9CE-BG000-0080* 9CE-BG000-0100* 9CE-BG000-0125* 9CE-BG000-0160 9CE-BG000-0200 9CE-BG000-0250 9CE-BG000-0315 9CE-BG000-0400 1 1 1 1 1 1 1 1 50 63 80 100 125 160 200 250 3 3 3 3 3 3 3 3 1.300 1.300 1.300 1.300 1.300 1.300 1.300 1.300 135 71 62 68 20 54 45 51 2 2 2 2 2 2 2 2 80 100 125 160 200 250 315 400 3 3 3 3 3 3 3 3 2.005 2.005 2.005 2.005 2.005 2.005 2.005 2.005 150 9CF-BG000-0250* 9CF-BG000-0315 9CF-BG000-0400 9CF-BG000-0500 9CF-BG000-0630 3 3 3 3 3 250 315 400 500 630 1 1 1 1 1 0.980 0.980 0.980 0.980 0.980 150 NH2-FB 10 e3 e1 6 e2 73.5 62 68 25 60 57 58 10 NH1-FB 10 10 e3 e1 Compact 6 e2 73.5 62 68 32 75 69 70 NH3-FB Note : * The signed currents are manufactured on request. 5/4 -2006 TECHNICAL CHARACTERISTICS, DIMENSIONS and ORDER CODES of NH (H.R.C) FUSE BASES BMC Steatit NH00-FA Order code : 9CB-C0 00-0000 (BMC) 9CB-A0 00-0000 (Steatit) C - with screw K - with clemens X - with screw Size : 00 Rated current : 160 A Quantity/box : 5 Kg./box : 0.795 (BMC) 1.060 (Steatit) Dimensions (mm) : a : 120 e : 23.5 b: 32.5 f : M8 c : 54 g: 25 d: 101 h: 7.5 5 Order code : 9CC-C0 00-0000 (BMC) C - with screw K - with clemens X - with screw Size :0 Rated current : 160 A Quantity/box : 5 Kg./box : 1.020 Dimensions (mm) : a : 170 e : 30.5 b: 32 f : M8 c : 64.5 g: 25 d: 150 h: 7.5 BMC NH0-FA BMC Steatit Order code : 9CD-C0C00-0000 (BMC) 9CD-A0C00-0000 (Steatit) Size :1 Rated current : 250 A Quantity/box : 3 Kg./box : 1.375 (BMC) 1.845 (Steatit) Dimensions (mm) : a : 200 f : M10 b: 47.5 g: 25 c : 82 h: 10.5 d: 175 k : 30 e : 35 NH1-FA BMC Steatit Order code : 9CE-C0C00-0000 (BMC) 9CE-A0C00-0000 (Steatit) Size :2 Rated current : 400 A Quantity/box : 3 Kg./box : 1.740 (BMC) 1.950 (Steatit) Dimensions (mm) : a : 225 f : M10 b: 47.5 g: 25 c : 88 h: 10.5 d: 200 k : 30 e : 35 NH2-FA BMC Steatit Order code : 9CF-C0C00-0000 (BMC) 9CF-A0C00-0000 (Steatit) Size :3 Rated current : 630 A Quantity/box : 3 Kg./box : 2.280 (BMC) 2.750 (Steatit) Dimensions (mm) : a : 240 f : M12 b: 47.5 g: 25 c : 99 h: 10.5 d: 210 k : 30 e : 37 NH3-FA -2006 5/5 MAXIMUM POWER LOSSES TABLE Power Losses : Power losses of NH Fuse which reaches the steady state temperature, when the rated current passing through the circuit. When the rated current passing through fuses, the temperature of connecting terminal (i.e for NH (HRC) 00 size Size Rated current (A) 00 00 00 00 00 00 00 00 00 00 00 00 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 3 3 3 3 3 6 10 16 25 32 40 50 63 80 100 125 160 25 32 40 50 63 80 100 125 160 40 50 63 80 100 125 160 200 250 125 160 200 250 315 400 250 315 400 500 630 and 160 A rated current) should not exceed 65 K. The power losses of Federal Fuses are below the IEC standars. This values are shown at the table on below table comparatively. Maximum power losses values TS EN 60269 IEC 60269 VDE 0636 Federal 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 16 W 16 W 16 W 16 W 16 W 16 W 16 W 16 W 16 W 23 W 23 W 23 W 23 W 23 W 23 W 23 W 23 W 23 W 34 W 34 W 34 W 34 W 34 W 34 W 48 W 48 W 48 W 48 W 48 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 12 W 16 W 16 W 16 W 16 W 16 W 16 W 16 W 16 W 16 W 23 W 23 W 23 W 23 W 23 W 23 W 23 W 23 W 23 W 34 W 34 W 34 W 34 W 34 W 34 W 48 W 48 W 48 W 48 W 48 W 7.5 W 7.5 W 7.5 W 7.5 W 7.5 W 7.5 W 7.5 W 7.5 W 7.5 W 7.5 W 7.5 W — 16 W 16 W 16 W 16 W 16 W 16 W 16 W 16 W 16 W 23 W 23 W 23 W 23 W 23 W 23 W 23 W 23 W 23 W 34 W 34 W 34 W 34 W 34 W 34 W 48 W 48 W 48 W 48 W 48 W 1.7 W 2.0 W 2.2 W 2.7 W 3.5 W 4.2 W 4.5 W 5.8 W 6.6 W 8.5 W 10.0 W 12.0 W 3.4 W 4.0 W 5.0 W 5.7 W 7.2 W 7.5 W 8.5 W 10.0 W 14.0 W 5.3 W 6.0 W 7.2 W 7.5 W 9.0 W 10.0 W 13.0 W 17.5 W 23.0 W 10.0 W 12.0 W 17.5 W 20.3 W 25.0 W 30.0 W 22.0 W 25.0 W 31.0 W 35.0 W 42.0 W For 00 and 0 size, fuse bases are produced in three models for easy connection to cables. With double side screw : For multi wires or bars (Fig-6a). With double side bridge terminal : For single core wires (Fig-6b). With one side screw and another side terminal : For single core wires or bars (Fig-6c). Fuse should be fixed properly to fuse base. Otherwise there can be an increase in the contact resistance, heating of contact, power losses and many other kind of faults. BMC (Bulk Moulding Compound) It is moulding material which is look like dough, reinforce with rather tall fiber and it is a composite material which has adjustment features through changing contribution material according to demand features. 5/6 NH 00-FA NH 0-FA NH 00-FA NH 0-FA NH 00-FA NH 0-FA Fig-6a Fig-6b Fig-6c BMC is from termoset plastic family and it has the same features with bakelite and melamine. It’s process conditions and products have superiority and it is durable for dynamic power and thermal shock. -2006