Dry/Wet Riser Maintenance

advertisement

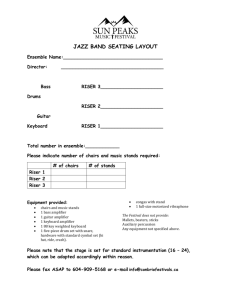

Dry/Wet Riser Maintenance Dry/Wet Riser Maintenance About Dry/Wet risers What are dry and wet risers systems used for? Where do we find dry/wet risers? Dry/wet risers are intended for the use of the Fire Service to provide a readily available means of delivering considerable quantities of water to extinguish or to prevent the spread of fire. If your fire risk assessment concludes that you may need the intervention of the Fire Service to fight a fire, you must ensure that your riser systems or hydrants are working properly. Dry risers will be found: Before installation of dry or wet rising mains, the local Authority and Fire Officer must be consulted to ascertain their exact requirements. • in buildings over 18 metres above ground level. • in low level buildings where there are excessive distances from entrances (60m) Wet risers will be found in buildings over 60 metres above ground level. Industrial Commercial Telecommunications Education Retail Hospitals / NHS What is the difference between dry riser and wet riser? (Dry/wet risers are often called Rising Mains) Dry riser: system of valves and pipework which enables the Fire Service to pump water on to upper floors of a building. Wet riser: system of valves and pipework which are kept permanently charged with water. A Dry Riser System Air Release Valve What does a dry/wet riser system look like? Landing Valve Typical dry/wet risers contain the following components: • large vertical pipe of 100 mm diameter that can run internally or externally to the building • twin inlet connection at street level boxed in a steel cabinet with glazed door for dry riser only • outlet valves at each landing • automatic air release valve at the highest point to provide automatic bleeding of air from the system when it is filled with water Landing Valve • pump for wet riser only Why do dry/wet risers need to be serviced? External Wall • risers are prone to neglect and vandalism • severe penalties should the rising main fail to work for the Fire Service • leaking from a wet riser could cause substantial damage Gate Valve Landing Valve BS 5306 Part 1 1976 recommends for dry risers: Steel Cabinet with Glazed Door 25mm Drain Valve Ground Floor • a visual inspection every six months • an annual pressure test BS 5306 Part 1 1976 recommends for wet risers: • 2 visual inspection services per year • 2 electric pump inspection services per year • 1 flow test per year (if applicable) What can I expect from the mechanical service engineer visit? Chubb Fire’s offer for dry/wet riser servicing • On arrival, our engineer will report to the authorised person and explain the reason for the visit Dry Riser • Our service engineer will service the dry/wet riser in compliance BS 5306 Part 1 1976 • After the service, the service label will be completed by the engineer • A service certificate including the inspection details will be issued to the customer. For any major faults found at the time of the service, the customer will be issued by our office a document including our recommendations and cost implication • Only when the service work is carried out will an invoice be raised The maintenance process Dry riser annual pressure test service • Carry out a visual inspection service from roof to ground floor of the entire system Chubb Fire provides two types of service in accordance with BS 5306 Part 1 1976: • Visual inspection service • Annual pressure test service (that includes a visual inspection service) Wet Riser Chubb Fire provides three types of service in accordance with BS 5306 Part 1 1976: • Visual inspection service • Electric pump service • Flow test The Chubb Fire Riser System maintenance package Chubb Fire operates a nationwide network of specialist mechanical service engineers. Chubb Fire Riser System maintenance package includes: Standard Support from our 24 hour customer service centre Availability of our engineers 24 hours a day, 365 days a year Servicing in accordance with BS 5306 Part 1 1976 12 months warranty for additional fitted equipment • No appreciable loss in pressure (0.5 bar) shall be seen whilst the test is in progress or the test shall be failed Review of your dry/wet risers system requirements against latest standards • Drain dry riser completely on completion Engineer call out charges Additional charges apply Wet riser flow test service Fitting of replacement parts as a result of normal wear and tear* Additional charges apply • Carry out a visual inspection service Rapid response to all emergency call outs • Carry out flow test in pump room if built in Flow test arrangement exists Additional charges apply * All parts supplied are approved to BS 5041. • Test the riser with water and pressurise to 10 bars measured at the inlet for a period not less than 15 minutes • Whilst test is in progress check entire system for any obvious leakage • Carry out flow test at roof hydrant if conditions allow • Check pressure of system using installation built in pressure gauge arrangement Why choose Chubb Security and Fire Protection • A company you can trust. One hundred and eighty years of history and innovation have made Chubb into a global leader in security and fire protection. The name Chubb is synonymous with fire protection and security solutions. Prevent fire Fire risk assessment Fire risk management Fire training • A company with resources. Chubb employs over 40,000 people around the world and sales exceed £1.5bn per year – supplying systems and services to most of the FTSE 100 companies. Gas detection Service and maintenance Detect fire • National service with local back-up. Chubb can design, install, maintain and monitor systems using the latest technologies. With a nationwide team of local engineers, Chubb can look after the needs of single sites or high street multiples. • Working to suit your individual needs. With a fire risk assessment led approach, Chubb can work with businesses large and small to help them comply with the latest fire, health and safety regulations. Fire detection systems 24/7 fire alarm monitoring Contain fire Fire extinguishers Hose reels Fire extinguishing systems Sprinklers • Flexible approach to financing. A range of purchase and rental options allows Chubb customers to choose a payment method suitable for their business. Escape fire Emergency lighting • Maintaining and raising standards to ensure customers comply. Chubb is BS EN ISO 9001 approved for the manufacture and maintenance of fire extinguishers and only provides approved fire safety signs. Chubb is also independently audited to British Standards by the BSI. Training • Government approved. Chubb Fire is the approved supplier of fire protection for the NHS and for Central and Local Government offices, schools and universities. Electronic Security Voice alarms Fire safety signs Security Personnel www.chubb.co.uk Call 0800 32 1666 Although great care has been taken in the compilation and preparation of this leaflet to ensure accuracy, the publishers cannot in any circumstances accept responsibility for errors, omissions or advice given in this publication. Readers should be aware that only Acts of Parliament and Statutory Instruments have the force of law and that only the courts can authoritatively interpret the law. GCF554M/07/04