UL Ti MATE ™ Range of underwater lights

advertisement

UL Ti MATE ™ Range of underwater lights™

(click on document required)

Technical

Brochure Info

UL Ti MATE 75 SA (S.S)

UL Ti MATE 75 SA (ALU)

UL Ti MATE 75 Fixed (S.S)

UL Ti MATE 75 Fixed (ALU)

UL Ti MATE 75 SA (S.S)

UL Ti MATE 75 SA (ALU)

UL Ti MATE 75 Fixed (S.S)

UL Ti MATE 75 Fixed (ALU)

UL Ti MATE 130 SA

UL Ti MATE 130 Fixed

UL Ti MATE 130 SA

UL Ti MATE 130 Fixed

UL Ti MATE 80 Xenon

UL Ti MATE 80 20w LED

UL Ti MATE 80 Xenon

UL Ti MATE 80 20w LED

Qt 80 LED

Qt 80 LED

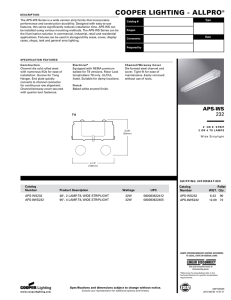

UL Ti MATE RANGE - MODEL- UL Ti MATE 130 SA

underwater lights limited™

Lamp Life - 3000 Hours - Colour Temp - 7000 K

222mm

UL Ti MATE 130 SA-W1 (250 WATT)

ORDER NUMBER-S00475-SA-V1W1

Voltage/Amps - 250 watt 198/264vac- 1.2A

Max hull thickness 120mm

Material - Aluminium Bronze and 5083 ALU

Light Level - 150w 12,000 Lumens - 250w 19,000 lms

130mm

Glass Lens - Borosilicate glass

Hole cut-out 100mm

Voltage/Amps - 150 watt 120(V3)/230(V2)volt - 1.4 /0.7.A

222mm

NOTE

UL Ti MATE 130 SA-W2 (150 WATT)

Installation Instruction:

ORDER NUMBER-S00475-SA-V2/V3W2

The hole cut-out should be 100 mm.

For Lamp Maintenance allow 170mm behind the projector lid.

Hull thickness range 12 to 120 mm.

Electrical Information:

150w - Recommended maximum distance between ballast and projector 10m.

250w - Recommended maximum distance between ballast and projector 25m.

Cable - 150w-250w High temp. silicone 3 core (Part No S00111, 0.75).

For additional information please visit our web site.

For sales telephone numbers visit www.underwaterlights.com

underwater lights limited

Lamp Type - MSD Metal Halide 150w or 250w

Max hull thickness 120mm

130mm

TECHNICAL SPECIFICATION

UL Ti MATE 130 SA

12,000 or 19,000 lumen

Hole cut-out 100mm

DESCRIPTION

This is the most flexible and powerful

“through-hull” submersible marine light for

the large sports fish yachts and is suitable for

GRP-fibreglass and wooden hulls.

The design and development of the

UL Ti MATE 130 SA gave the marine market

their wish with the internal adjustment (SA)

which allows the beam angle to be varied from

a narrow to wide beam and to universally

move the beam direction by 20 degrees from

within the projector housing.

The UL Ti MATE 130 SA has a larger aperture

which increases the light output by 25%.

We advise that the light be installed 250mm

below the minimum waterline.

The boat must be hauled out for installation,

although maintenance of the light is carried

out from inside the hull.

The light is IPX8 to 10 bar.

™

TM

Manufacturers of the Original underwater lights

Brand Marine Lighting Products since 1991

UL Ti MATE 130 SA

‘submersible through hull light’

ORDERING NUMBERS

250 WATT LIGHTS - 120V. S00475-SA-V3W1. 230V. S00475-SA-V2W1.

150 WATT LIGHTS - 120V. S00475-SA-V3W2. 230V. S00475-SA-V2W2

OPERATIONAL CONDITIONS AND CONSIDERATIONS

The UL Ti MATE 130 is serviced from inside the hull. Allow a minimum of 170mm behind the cable gland for lamp

replacements on 150w and 150mm behind the.ignitor on 250w

ELECTRICAL INFORMATION

CABLE SPECIFICATION TO PROJECTOR

150 Watt High temp silicone three core part number. S00111- 250 Watt Two core 1mm square. maximum diameter 6mm

150 WATT Max distance between ballast and projector with -10 meters.250 WATT Max distance 25 meters

.Ballast power 150 watt ballast 120/230 volt, running current 1.4/0.7.A

Part Description 130-S A

Part No

Ballast power 250 watt ballast 120/230 volt, running current 2.4/1.2.A

1: Projector lid securing plate

00283-B

Ballast will not ignite a hot lamp. The ballast has three attempts to ignite

2: M6 Nut

93381

3: 'O' Ring

00108

the lamp then will wait for four minutes before repeating the cycle.

4: Gasket NAF

00285-A

Do not attempt to remove the glass lens while afloat

5: Connecting ring

00274-C

6: Lamp holder screw

00290

7: Lamp holder (250W)

91195

7: Lamp holder (150W)

91191

8: Reflector collar bush

00288-A

9: M4 Lock nut

93374

10: Lamp (250W)

91209

10: Lamp (150W)

91210

11: Reflector adjustment rod

00284-2-D

12: Reflector complete

S91791

13: Glass retaining ring

00476-B

13A: Cap head screws

93325

14: Glass gaskets NAF

00286-A

16: Body

S00475-A

17: Compensating ring

00277

18: Securing ring

00275

19: Cap head screws

93610

20: Ignitor (250W)

S95325

21: Projector cover (250W)

00102-H

22: Gland

00107

23: Projector cover (150W)

00102-E

24: Ballast 250 watt

S00800-V1W2

24: Ballast 150 watt 230v

S00800-V2W2

24: Ballast 150 watt 120v

S00800V3W2

ELECTRONIC BALLAST COMPLETE

WITH IP65 ENCLOSURE

150 watt

250 watt

EARTH TAB AND SCREW

Recommended Spares

Lamp ( 250w = W1 )

Lamp ( 150w = W2 )

Glass with gaskets

Ballast

LENS FITTING INSTRUCTIONS

Check the glass landing surface is clean and apply a suitable silicone grease to the gaskets.

Fit the glass, gaskets and retaining ring as shown above. Hand tighten the screws with an

Allen key making sure the glass retaining ring is square. Torque the screws to 6 Nm (4.5ft/lbs)

in the sequence shown, check the ring again and re-torque the screws again to the same setting

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO WWW,REGISTER-UWL.COM

FOR TECHNICAL INFORMATION PLEASE EMAIL T@UNDERWATERLIGHTS.COM

SALES, PRODUCT INFORMATION AND NEWS GO TO

WWW,UNDERWATERLIGHTS.COM

UL Ti MATE 130 SA -1-7-2010

Part No

91209

91210

S00281-A

S00801

TM

UL Ti MATE 130 SA INSTALLATION (The UL Ti MATE 130 SA should be no less than 250mm/10” below the water line)

Qualified/Approved personnel must be used to carry out installation

Cut and prepare a 4 inch / 100 mm clearance hole for the body (16). Coat the flange of the body and the area around the

hole with 3M 4200FC sealant then slide the body into the hole. From the inside fit the compensating ring (17) and screw

the securing ring (18) up “hand tight”. Adjust the screws (19) so the compensating ring is flush to the hull and check the

sealant has flowed completely around the flange. Do “NOT” over tighten the screws as this will squeeze the sealant from

the surface. Allow the sealant to solidify and remove surplus. Finally tighten the adjustment bolts to 4Nm / 3ft.lbs

Note for cored hulls - After cutting, the exposed surfaces of the hole must be finished to form a solid surface

through it, thus protecting the internal core of the hull.

Maximum hull thickness should not exceed 4.75 inches - 120mm Minimum wall thickness 0.375inches.- 10mm

After completing the installation procedure it is highly recmmended to coat the exposed body with antifouling.

EARTHING LIGHT FOR CATHODIC PROTECTION-tighten the earth screw on the securing ring so that it

bites into the screwed barrel. Check there is continuity to the front face. This prevents galvanic corrosion.

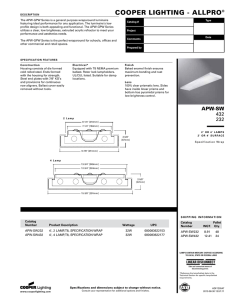

UL Ti MATE RANGE - MODEL - UL Ti MATE 130 -FIXED

underwater lights limited™

=@!>

!!Y

TECHNICAL SPECIFICATION

0$;+8//7+,&.1(66PP

&87287PP',$

Lamp Life - 3000 Hours - Colour Temp - 7000 K

Voltage - 120(V3) or 230(V2) vacAmps - 120 v = 1.4 amps 230 volt = 0.7 amps

Flush Glass Lens - Borosilicate glass

Material - Aluminium Bronze and 5083 ALU

Light Level - 150w 12,000 Lumens

PP

!"#$"

%

!&$!!'()"

NOTE

Installation Instruction:

The hole cut-out should be 100-101 mm.

For Lamp Maintenance allow 150mm behind the projector lid.

Hull thickness range 12 to 75 mm.

Electrical Information:

150w - Recommended maximum distance between ballast and projector 10m.

Cable - 150w-High temperature silicone 3 core (Part No S00111).

For additional information please visit our web site.

PP

Lamp Type - MSD Metal Halide 150w

DESCRIPTION

This is a 150 watt MSD discharge lamp

“through-hull” submersible marine light

with a flush lens for the large sports fish

boats, motor and sailing yachts and is

suitable for GRP-fibreglass and wooden

hulls.

The UL Ti MATE 130 FIXED has a larger

aperture than our original screwed fitting

which has increased the light output by

25%.

We advise that the light be installed 250mm

below the minimum waterline.

The boat must be hauled out for

installation, although maintenance of the

light is carried out from inside the hull.

The light is IPX8 to 10 bar.

™

70

Manufacturers of the Original underwater lights

Brand Marine Lighting Products since 1991

UL Ti MATE 130 Aluminium Bronze

Fixed Screwed Underwater Lights

ORDERING NUMBER FOR 230 VOLT 150WATT LIGHTS S00475-V2(H)W2

ORDERING NUMBER FOR 120 VOLT 150WATT LIGHTS S00475-V3(H)W2

UL Ti MATE 130 INSTALLATION (The UL Ti MATE 130 should be no less than 250mm/10” below the water line)

Qualified/Approved personnel must be used to carry out installation

Cut and prepare a 4 inch / 100 mm clearance hole for the body (16). Coat the flange of the body and the area around the

hole with 3M 4200FC sealant then slide the body into the hole. From the inside fit the compensating ring (17) and screw

the securing ring (18) up “hand tight”. Adjust the screws (19) so the compensating ring is flush to the hull and check the

sealant has flowed completely around the flange. Do “NOT” over tighten the screws as this will squeeze the sealant from

the surface. Allow the sealant to solidify and remove surplus. Finally tighten the adjustment bolts to 4Nm / 3ft.lbs

Note for cored hulls - After cutting, the exposed surfaces of the hole must be finished to form a solid surface

through it, thus protecting the internal core of the hull.

Maximum hull thickness should not exceed 4.75 inches - 120mm Minimum wall thickness 0.375inches.- 10mm

After completing the installation procedure it is highly recmmended to coat the exposed body with antifouling.

EARTHING LIGHT FOR CATHODIC PROTECTION-tighten the earth screw on the securing ring so that it

bites into the screwed barrel. Check there is continuity to the front face. This prevents galvanic corrosion.

OPERATIONAL CONDITIONS AND CONSIDERATIONS

The UL Ti MATE 130 is serviced from inside the hull. Allow a minimum of 170mm behind the cable gland for lamp

replacements on 150w and 150mm behind the.ignitor on 250w

ELECTRICAL INFORMATION

CABLE SPECIFICATION TO PROJECTOR

150 Watt High temp silicone three core part number. S00111

150 WATT Max distance between ballast and projector with -10 meters

.Ballast power 150 watt ballast 120/230 volt, running current 1.4/0.7.A

Ballast will not ignite a hot lamp. The ballast has three attempts to ignite

the lamp then will wait for four minutes before repeating the cycle.

Do not attempt to remove the glass lens while afloat

Part Description

Part No

1: Cable

S00111

2: Projector lid complete

S00102-C

3: "O" Ring

00108

4: Connecting Ring

00274-B

5: Body

S00475-A

6: Screws (M6X 25 ALU.)

93610

7: Gasket - NAF

00286-A

8: Glass

00281-F

9: Glass retaining ring

00476-C

10: Comp. ring

00277-A

11: Securing ring

00275-A

13: Electronic ballast-230 volt

95322-V2HW2

13: Electronic ballast-120 volt

95322-V3HW2

12: Reflector Tube with Reflector

S00273

14: Lamp (MSD-150W/70)

91210

15: Gasket - NAF

000C07-A

16: Cable gland

92010

17: Screws (M6X 16 S.S.)

93333

Recommended Spares

Part No

Lamp (MSD-150W/70)

91210

Glass with gaskets

S00279-A

Electronic ballast

95322

ELECTRONIC BALLAST COMPLETE

WITH IP65 ENCLOSURE

EARTH TAB AND SCREW

LENS FITTING INSTRUCTIONS

Check the glass landing surface is clean and apply a suitable silicone grease to the gaskets. Fit

the glass, gaskets and retaining ring as shown above. Hand tighten the screws with a 5mm

Allen key making sure the glass retaining ring is square. Torque the screws to 6 Nm (4.5ft/lbs)

in the sequence shown, check the ring again and re-torque the screws again to the same setting

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO WWW,REGISTER-UWL.COM

FOR TECHNICAL INFORMATION PLEASE EMAIL T@UNDERWATERLIGHTS.COM

SALES, PRODUCT INFORMATION AND NEWS GO TO

WWW,UNDERWATERLIGHTS.COM

UL Ti MATE 130-FIXED 1-7-2010

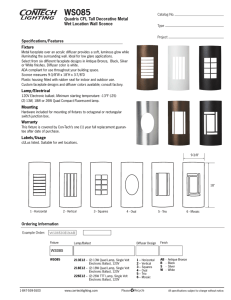

UL Ti MATE RANGE - MODEL NUMBER - S02652

underwater lights limited™

™

DESCRIPTION

This is our most popular “through-hull”

submersible marine light IPX8 rated to 10 bar for

coastal power boats and some ten thousand have

been installed world wide.

The light is suitable for installation into GRPfibreglass and wooden hulls and must be installed

below the minimum waterline.

The boat must be hauled out for installation,

although maintenance is carried out from inside

the hull.

The light has a sealed integral igniter which makes

it safer, and allows the ballast to be located away

from the bilge area.

The latest UL Ti MATE 80 can also be fitted with a

wide beam lens.

Also available in an extended version.

!""

#!!$%&"

TECHNICAL SPECIFICATION

Lamp Type - Xenon bulb

Lamp Life - 3000 Hours - Colour Temp - 7000 K

Voltage / Amp 12VDC/6.4A - 24VDC/2.5.A

!'()

*'!+9+';(+;)<;9(=+;)

Glass Lens - Borosilicate glass

Material - Aluminium Bronze and 5083 ALU

Classification - Lloyds Approved

70

Manufacturers of the Original underwater lights

Brand Marine Lighting Products since 1991

Light Output - 4,800 Lumens

!'

>

*'!+9+''

NOTEInstallation Instruction:

The hole cut-out should be 61 mm.

Hull thickness range 12-65 mm and 80-110mm.

Recommended distance between lights 1 to 2 metres

Electrical Information:

Recommend only 2 lights for each power supply cable.

See wiring diagram on opposite page.

For additional information please visit our web site.

180mm

80mm

40mm

*

*

'?@!';(+;)<?@!';9(=+;)

UL Ti MATE RANGE - MODEL NUMBER - S02652-V5/V6

underwater lights limited™

™

70

Manufacturers of the Original underwater lights

Brand Marine Lighting Products since 1991

8/7L0$7(

67$1'$5'

3$576

8/7L0$7(

%$//$67

3$576

8/7L0$7(

%$//$67

3$576

),;('&$%/(

/(1*+72)&$%/(0

)86($03

)86($03

62&.(7

62&.(7

67$5783&855(17$9ROWDJHYGF

&217,18286&855(17$

&211(&7,1*:,5(%(7:((1/$036$:*

)86(

$03

0$;/$03692/76833/<

0$5,1(*5$'(&$%/(

WIRING DIAGRAM 12V/V6

8/7L0$7(

67$1'$5'

3$576

8/7L0$7(

%$//$67

3$576

8/7L0$7(

%$//$67

3$576

),;('&$%/(

/(1*+72)&$%/(0

)86($03

)86($03

62&.(7

)86(

$03

0$;/$03692/76833/<

0$5,1(*5$'(&$%/(

62&.(7

67$5783&855(17$9ROWDJHYGF

&217,18286&855(17$

&211(&7,1*:,5(%(7:((1/$036$:*

WIRING DIAGRAM 24V/V5

UL Ti MATE 80

‘submersible through hull light’

‘Xenon’ with 55 watt Ballast

UL Ti MATE 80 Installation (Maximum hull thickness 60mm) and Operation instructions.

Qualified/Approved personnel must be used to carry out installation

Before cutting a hole in the hull, check the hull wall thickness is not greater than 60mm. The location of the holes must be

below the waterline. After cutting and finishing the hole surface, check the 60mm diameter. UL Ti MATE 80 ‘body’ (9)

can be inserted.

Note for cored hulls - After cutting, the exposed surfaces of the hole must be finished to form a solid surface

through it. Thus protecting the internal core of the hull. The wall thickness of the hole should not to less than

5mm-0.25inch. Apply 3M-4200FC sealant to the ‘body’ (9) flange. Slide the body into the hole and from inside the hull put

the ‘compensating ring’ (10) on and screw the ‘case securing ring’ (11) up hand tight. Gently tighten the adjustment screws

(6) so the compensating ring is flush to the hull and the sealant has flowed completely around the flange and hull

Do NOT overtighten the bolts as this will squeeze the sealant from the surfaces. Allow the sealant to solidify and remove

surplus. Finally tighten the bolts to 4Nm. / 3ft. lbs.

Note: Maximum ambiant operating temperature is 55C/131F of the ballast

The ballast must be installed a minimun of 24 inches (600 mm) above the bilge. Fit the ‘lamp’ (5) and assemble the

remaining parts to the ‘through-hull’ submersible marine light. Lightly grease the ‘O’ rings. When fitting a new lamp make

sure the lamp is switched off and bring the ignitor, lamp and reflector tube away and above the bilge to the

highest point before changing the lamp.

Cautionary Label-“Caution: do not operate lights unless totally submerged” must be located by the main switch.

EARTHING LIGHT FOR CATHODIC PROTECTION-tighten the earth screw on the securing ring so that it

bites into the screwed barrel. Check there is continuity to the front face. This prevents galvanic corrosion.

After completing the installation procedure it is highly recommended to coat the face of the ‘through-hull’submersible

marine light with antifouling and bond them to the anodes or a cathodic protection system.

Power supply

The 12 volt D.C ballast can operate between 11-13.5 volts. Start up current is 8 amps and 6.4 amps continuous.

The 24 volt D.C ballast can operate between 21-26 volts. Start up current is 4.5 amps and 2.5 amps continuous.

Note a maximum of two lamps can be connected to one cable supply. The correct size cable must be used and the

maximum volt drop (1.5 volts) on the cable length should be calculated using the maximum start up current.

Part Description

Part No

1: Ballast 12 vdc 55 watt

95304

1: Ballast 24 vdc 55 watt

95305

2. Igniter

95306

3.'O' Ring (40mm)

02007

4.'O' Ring (50mm)

02008

5: Xenon lamp 55 watt

91012

6: Adjustment screws

93335

7: Gasket

02009

8: Lens

02010

9: UL Ti MATE 80 Body

S02652

10: Compensating ring

02602

11: Securing ring

02603-B

12: Reflector with tube

S02605

13: Lamp holder securing ring 02608-A

QT LED 80

CONNECTION

POWER SUPPL

EARTH

EARTH

EARTH TAB AND SCREW

BALLAST PLUG POSITION

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO WWW,REGISTER-UWL.COM

FOR TECHNICAL INFORMATION PLEASE EMAIL T@UNDERWATERLIGHTS.COM

SALES, PRODUCT INFORMATION AND NEWS GO TO

WWW,UNDERWATERLIGHTS.COM

Ul Ti Mate 80 S02652 1-9-2010

TM

LAMP TYPE - XENON DISCHARGE 55 WATT

ORDERING NO FOR 12 VOLT - S02652-V6W5 & 24 VOLT - S02652-V5W5

UL Ti MATE 80 Extended

‘submersible through hull light’

‘Xenon’ with 55 watt Ballast

UL Ti MATE 80 Extended Installation (Maximum hull thickness 120mm) and Operation instructions.

Qualified/Approved personnel must be used to carry out installation

Before cutting a hole in the hull, check the hull wall thickness is not greater than 120mm. The location of the holes must

be below the waterline. After cutting and finishing the hole surface, check the 60mm diameter. UL Ti MATE 80 ‘body’

(9) can be inserted.

Note for cored hulls - After cutting, the exposed surfaces of the hole must be finished to form a solid surface

through it. Thus protecting the internal core of the hull. The wall thickness of the hole should not to less than

5mm-0.25inch. Apply 3M-4200FC sealant to the ‘body’ (9) flange. Slide the body into the hole and from inside the hull

put the ‘compensating ring’ (10) on and screw the ‘case securing ring’ (11) up hand tight. Gently tighten the adjustment

screws (6) so the compensating ring is flush to the hull and the sealant has flowed completely around the flange and hull

Do NOT overtighten the bolts as this will squeeze the sealant from the surfaces. Allow the sealant to solidify and remove

surplus. Finally tighten the bolts to 4Nm. / 3ft. lbs.

Note: Maximum ambiant operating temperature is 55C/131F of the ballast

The ballast must be installed a minimun of 24 inches (600 mm) above the bilge. Fit the ‘lamp’ (5) and assemble the

remaining parts to the ‘through-hull’ submersible marine light. Lightly grease the ‘O’ rings. When fitting a new lamp

make sure the lamp is switched off and bring the ignitor, lamp and reflector tube away and above the bilge to the

highest point before changing the lamp.

Cautionary Label-“Caution: do not operate lights unless totally submerged” must be located by the main switch.

After completing the installation procedure it is highly recommended to coat the face of the ‘through-hull’submersible

marine light with antifouling and bond them to the anodes or a cathodic protection system.

Power supply

12 VOLT BALLAST- 12 volts DC- 6.4 amps. : 24 VOLT BALLAST- 24 volts DC- 2.5amps

Note a maximum of two lamps can be connected to one cable supply. The correct size cable must be used and the

maximum volt drop (1.5 volts) on the cable length should be calculated using the maximum start up current.

LAMP CHANGE - To change the lamp undo the ‘grub screw’ (3) and remove the ‘reflector tube’ (12). Insert the lamp

into the ‘lamp holder’ (2) and replace the ‘reflector tube’ (2) and tighten the ‘grub screw’ (3).

Part Description

Part No

1: Ballast 12 vdc 55 watt

95304

1: Ballast 24 vdc 55 watt

95305

2. Lamp Holder

95306

3. Grub screw

93308

4.'O' Ring (50mm)

02008

5: Xenon lamp 55 watt

91012

6: Adjustment screws

93335

7: Gasket

02009

8: Lens

02010

9: UL Ti MATE 80 Body

S02652-XT

10: Compensating ring

02602

11: Securing ring

02603-B

12: Reflector with tube

S02605-XT

13: Lamp holder securing ring 02608-A

S02605-XT

3

S02605-XT

BALLAST PLUG

POSITION

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO WWW,REGISTER-UWL.COM

FOR TECHNICAL INFORMATION PLEASE EMAIL T@UNDERWATERLIGHTS.COM

SALES, PRODUCT INFORMATION AND NEWS GO TO

WWW,UNDERWATERLIGHTS.COM

UL Ti MATE 80 Extended - S02652-XT - 1-9-2010

TM

LAMP TYPE - XENON DISCHARGE 55 WATT

ORDERING NO FOR 12 VOLT - S02652-XT-V6W5 & 24 VOLT - S02652-XT-V5W5

UL Ti MATE RANGE - MODEL NUMBER - S02860 underwater lights limited™

UL Ti MATE 80 LED

1,400 lumen

TECHNICAL SPECIFICATION

Lamp Type - 7 x single 110 lumen LED122mm

3

Lamp Life - 30,000 Hours - Colour Temp - 7200K

2

8

Classification - Lloyds Approved

60mm

Glass Lens - Borosilicate glass

82mm

Voltage/Amps - 12vdc/1.6 A - 24vdc/0.8 A

4

Material - Aluminium Bronze and 5083 ALU

5

6

9

7

1

Light Output - 1,400 Lumens

NOTEInstallation Instruction

The hole cut-out should be 61 mm.

Hull thickness range 12-65mm

Recommended distance between lights 1 to 2meters.

Electrical Information

See diagram opposite. The 12/24vdc driver is integral,

just connect the red wire to the +VE and black wire to

the -VE 12/24vdc power supply.

Maximum number of lights on one supply cable TWO

For additional information please visit our web site.

- VE BLACK

+ VE RED

POWER SUPPLY 12 VOLTS DRIVER

24 VOLTS DRIVER

MAXIMUM 2 LAMPS ON THE SAME SUPPLY CABLE.

THE 12-24 VDC DRIVER CAN OPERATE BETWEEN MIN 10

VDC 10.5 (-5%) 28.5 (+ 5%) MAX 30 VDC

Max 2 lamps on the

same supply cable

For sales telephone numbers visit www.underwaterlights.com

underwater lights limited

DESCRIPTION

The UL Ti MATE 80, 20W LED is a

“through- hull” submersible marine light

rated IP68 to 10 bar.

The light is suitable for small boats and

can be installed into GRP-fiberglass and

wooden hulls.

It must be installed below the minimum

waterline.

The boat must be hauled out for

installation, although maintenance of the

LED is carried out from inside the hull.

The LEDs are available in blue, red,

green or white.

The LED driver is integral with the light.

™

TM

Manufacturers of the Original underwater lights

Brand Marine Lighting Products since 1991

UL Ti MATE 80 Alu-Bronze

‘submersible through hull light’

20 Watt LED

UL Ti MATE 80 Installation (Maximum hull thickness of 65mm) and Operation.

Qualified/Approved personnel must be used to carry out installation.

Before cutting a hole in the hull, check the hull wall thickness is not greater than 65mm and that the

location of the holes are below the waterline. After cutting and finishing the hole surface, check the ‘body’(5) can be

inserted into the 60mm diameter hole. You are now ready for installation.

Note for cored hulls - After cutting, the exposed surfaces of the hole must be finished to form a solid surface

through it. Thus protecting the internal core of the hull. The wall thickness of the hole should not to less than

5mm-0.25inch. Apply 3M-4200FC sealant to the ‘body’ (5) flange. Slide the body into the hole and from inside the

hull put the ‘compensating ring’ (6) on and screw the ‘securing ring’ (7) up hand tight. Gently tighten the adjustment

adjustment screws (2) so the compensating ring is flush to the hull and the sealant has flowed completely around the

flange and hull. Do NOT overtighten the screws as this will squeeze the sealant from the surfaces. Allow the sealant

to solidify and remove surplus. Finally tighten the bolts to 4Nm. / 3ft. lbs. Fit the lamp and assemble the remaining

parts to the UL Ti MATE 80. Lightly grease the ‘O’ ring and gasket.

Cautionary Label-“Caution: do not operate lights unless totally submerged” must be located by the main

switch.

After completing the installation procedure it is highly recommended to coat the face of the ‘through-hull’

submersible marine light with antifouling and bond them to the anodes or a cathodic protection system.

EARTHING LIGHT FOR CATHODIC PROTECTION-tighten the earth screw on the securing ring so

that it bites into the screwed barrel. Check there is continuity to the front face. This prevents galvanic

corrosion.

Part Description

Part No

1. 'O' Ring (50mm dia)

02008

2.Adjusment screws

93306

3. Gasket

02009

4. Glass lens

02010

5. Ultimate 80 Body

S02650

6. Compensating Ring

02602-A

7. Securing Ring

02603

8. LED tube

S02605-LED

9: Lamp holder securing ring

02608-B

122mm

3

2

60mm

82mm

8

4

5

UL Ti MATE 80

CONNECTION

EARTH

6

7

9

1

POWER SUPPLY

EARTH

EARTH TAB AND SCREW

Power Supply and CONNECTION

20 Watt 12 Volt LED unit requires 1.60 Amps

20 Watt 24 Volt LED unit requires 0.80 Amps

Ensure the the polarity of the positive and the negative is correct so that the integral driver is not damaged

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO WWW,REGISTER-UWL.COM

FOR TECHNICAL INFORMATION PLEASE EMAIL T@UNDERWATERLIGHTS.COM

SALES, PRODUCT INFORMATION AND NEWS GO TO

WWW,UNDERWATERLIGHTS.COM

UL Ti MATE 80 AB2-AL-15-09-10

TM

ORDERING NUMBERS : -S02860

QT 80

cute in size big on light

Qt LED 80 Installation (Maximum hull thickness 60mm) and Operation instructions.

The QT 80, is a “through- hull” submersible marine light and is delivered ready for installation. Maintenance

of the LED is carried out from inside the hull. The light is suitable for installation into GRP-fiberglass and

wooden hulls. LED output 5,500 lumens -Colour temperature of 7,200K. Other colours are available also RGB.

Qualified/Approved personnel must be used to carry out installation

Before cutting a 60mm hole in the hull, check the hull wall thickness is not greater than 60mm. The location of

the holes must be below the waterline. After finishing the hole surface, check the Body (1) can be inserted.

Note for cored hulls - After cutting, the exposed surfaces of the hole must be finished to form a solid surface

through it. Thus protecting the internal core of the hull. The wall thickness of the hole should not to less than

5mm-0.25inch. Apply 3M-4200FC sealant to the ‘Body’ (1) flange. Slide the body into the hole and from inside

the hull put the ‘compensating ring’ (2) on and screw the securing ring’ (3) up hand tight. Gently

tighten the adjustment screws (6) so the compensating ring is flush to the hull and the sealant has flowed

completely around the flange and hull

Do NOT overtighten the bolts as this will squeeze the sealant from the surfaces. Allow the sealant to solidify

and remove surplus. Finally tighten the bolts to 4Nm. / 3ft. lbs.

When all parts are assembled and the sealant has cured tighten the cover (5) to secure the heatsink (4) into the

body. If this is not done it will cause overheating of the LED and the LED could fail.

EARTHING LIGHT FOR CATHODIC PROTECTION-tighten the earth screw on the securing ring so that it

bites into the screwed barrel. Check there is continuity to the front face. This prevents galvanic corrosion.

Cautionary Label-“Caution: do not operate lights unless totally submerged” must be located by the main switch.

After completing the installation procedure it is highly recommended to coat the BODY (1) face with

antifouling and bond them to the anodes or a cathodic protection system.

1-BODY FOR

WIDE LENS

Part Description

1: Body

2: Compensating ring

3: Securing ring

4: LED Heat sink

5: Screwed cover

6: Adjustment screws

7: Nitrile 'O' ring

1-BODY FOR

WIDE LENS

2-COMPENSATING RING

2-COMPENSATING RING

3-SECURING RING

3-SECURING RING

4-LED HEAT SINK

5-COVER

4-LED HEAT SINK

7-'O' RING

5-COVER

60MM

80MM

7-'O' RING

6-M6 CAP

HEAD BOLT

84MM

Drivers for Qt 80

EARTH TAB AND SCREW

Part No

Supply 230 vac Output 24vdc - 3.3amps QT D-8599981E

Supply 24-48dc - Output 24vdc - 3.3amps QT D-5599981E

Qt LED 80 & NARROW BEAM (65deg) LUX CHART

(lux) FLAT (130deg) LUX CHART

530

1020

3400

65 DEG

1m

2m

80 DEG

5,500 LUMEN

QT LED 80

CONNECTION

1M - 1000

2M - 330

3M - 230

POWER SUPPL

3m

1650

530

360

5,500 LUMEN

(lux)

TECHNICAL SPECIFICATION

Qt LED 80 & WIDE BEAM (80deg) LUX CHART

EARTH

EARTH

Lamp types - Single LED chip- 5,500 lm- 7,200K (Cool White)

Also available in blue, green, and red

VDC. LED Driver - Min 22- Max 28vdc maximum current 3.3amps.

Glass lens - Borosilicate wide beam glass as standard

24 dc DRIVER

QTD-5599981E

Bezel Material - Aluminium Bronze & 5083 ALU.

LED lamp life - 20,000 hours @ 60° C

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO

SALES, PRODUCT INFORMATION AND NEWS GO TO

QT LED 80 17-04-2012

WWW.QTLED/REG.COM

WWW,QTLED.COM

QT 80

cute in size big on light

DESCRIPTION

The QT 80, is a “through- hull” submersible marine

light tested at front of glass to IP68 at 10 bar. The

light is suitable for installation into GRP-fiberglass

and wooden hulls.

There are three types of lenses for different beam

widths - the standard is wide 95 deg, flat 130deg and

narrow 70deg.

The standard LED produces 5,500 lumens -Colour

temperature of 7,200K. Other colours are available,

also RGB.

The light must be installed below the minimum

waterline. The boat must be out of the water for

installation. Maintenance of the LED is carried out

from inside the hull.

The LED driver is fitted into an enclosure and is

mounted remotely.

Note this light can be driven at low outputs to suit

boat battery power.

1-BODY FOR

WIDE LENS

2-COMPENSATING RING

3-SECURING RING

4-LED HEAT SINK

80MM

7-'O' RING

60MM

5-COVER

6-M6 CAP

HEAD BOLT

84MM

Standard QT LED 80 - with wide beam lens

LED Output 5,500 lumen, 7,200K

Order Number QT LED-80-24vdc

TECHNICAL SPECIFICATION

Lamp types - Single LED chip- 5,500 lm- 7,200K (Cool White)

Mains Power LED Driver -100-265vac. Output 24vdc, maximum current 3.3amps Order No. QTD-8599981E

VDC. LED Driver - Min 22- Max 28vdc maximum current 3.3 amps

Order No. QTD-5599981E

Glass lens - Borosilicate wide beam glass as standard

Bezel Material - Aluminium Bronze & 5083 ALU.

Qt LED 80 & NARROW BEAM (65deg) LUX CHART

(lux) FLAT (130deg) LUX CHART

LED lamp life - 20,000 hours @ 60° C

NOTE-

530

1020

3400

65 DEG

1m

Installation Instruction

The hole cut-out should be 61 mm.

Hull thickness range 12-65mm

Recommended distance between lights 1 to 2meters.

The light is supplied with 3 meters of 6mm

2m

5,500 LUMEN

1M - 1000

2M - 330

3M - 230

3m

80 DEG

1650

530

360

5,500 LUMEN

LUX CHART

(lux)

Qt LED 80 & WIDE BEAM (80deg) LUX CHART

diameter, 2 core marine grade cable.

For VDC power supply the maximum number of

lights on one supply cable of AWG 10 is TWO

(See wiring diagram opposite)

For additional information please visit our web site.

Earthing instruction

After the light has been installed tighten the earth

screw on the securing ring sothat it bites into the

screwed barrel. Check there is continuity from the

earth tab to the front face of the light. This is very

important to stop galvanic corrosion of the front face

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO

SALES, PRODUCT INFORMATION AND NEWS GO TO

QT LED 80 17-04-2012

AWG 10 - CABLE

Qt LED 80 LED

24 VDC POWER SUPPLY

WWW.QTLED/REG.COM

WWW,QTLED.COM

UL Ti MATE RANGE - MODEL - UL Ti MATE 75 FIXED 150W

underwater lights limited™

27mm

168mm

115mm

Order Number Flush-STEEL S00300-75-ICE-V2/V3W2

Order Number Flush-ALU S00600-75-V2/V3W2

TECHNICAL SPECIFICATION

75mm

168mm

Lamp Type - MSD Metal Halide 150w

115mm

120mm

Lamp Life - 3000 Hours - Colour Temp - 7000 K

Voltage/Amps - 150 watt 120(V3)/230(V2) - 1.4/0.7.A

Ballast - 150 watt electronic in IP 65 Enclosure

Order Number 30 deg. STEEL S00330-75-ICE-V2/V3W2

Order Number 30 deg. ALU S00630-75-V2/V3W2

105mm

Glass Lens - Borosilicate glass

168mm

115mm

Light Level - 150w 12,000 Lumens

140mm

Material - Steel and 5083 ALU

NOTE

Installation Instruction:

40mm

The hole cut-out should be cut to suit the insert

Order Number 50 deg. STEEL S00350-75-ICE-V2/V3W2

angle. Maximum hull plate thickness should be

Order Number 50 deg. ALU S00650-75-V2/V3W2

12mm for the flush and 20mm for the 30 & 50

degree.

For Lamp Maintenance allow 60mm behind the cable gland.

Electrical Information:

150w - Recommended maximum distance between ballast and projector 10m.

Cable - High temp. silicone 3 core (Part No S00111).

For additional information please visit our web site.

For sales telephone numbers visit www.underwaterlights.com

underwater lights limited

UL Ti MATE 75

30 degree

120mm

DESCRIPTION

The UL Ti MATE 75 Fixed is a “through-hull”

submersible marine light for welding into aluminium and steel hulls. Maintenance of the light

is carried out from inside the hull.

It does not include the SA 'Super Adjustable' unit

and has been introduced to compete fairly with

other fixed lights on the market. The lens aperture is exactly the same as the SA to give the

same maximum light output.

This new light is also shorter in length to the SA

unit so that it is easier to fit into those small

areas.

We advise that the light be installed minimum

250mm below the waterline when the yacht is

loaded with 50% fuel and 50% water, and that the

light be angled 15 degrees downwards. To

achieve this there are 3 modelsFlush, 30 degree and 50 degree.

The stainless steel model comes as standard with

Ice Class Lloyds Approval and has been pressurised to 80 bar. The aluminium model is IPX8

to 10 bar. The range is also GL Approved.

™

TM

Manufacturers of the Original underwater lights

Brand Marine Lighting Products since 1991

UL Ti MATE 75

316L STAINLESS STEEL AND 5083 ALUMINIUM

ORDERING NUMBERS

FLUSH - S00300-75-ICE. 30 DEG - S00330-75-ICE. 50 DEG -S00350-75-ICE

FLUSH - S00600-75. 30 DEG - S00630-75. 50 DEG -S00650-75

WITH 120 (V3) / 230 (V2) VOLT BALLAST AND 150W (W2) WATT LAMP.

OPERATIONAL CONDITIONS AND CONSIDERATIONS

The UL Ti MATE 75 is serviced from inside the hull. Allow Do not attempt to remove the glass lens while afloat.

access for maintenance and space for ventilation.

The projector must be correctly assembled with lid

Do not use the LIGHT in dry-dock or out of the water

secured to the UL Ti MATE 75 whilst afloat.

Allow a minimum of 70mm behind the projector lid

(item 2) for lamp replacements.

UL Ti MATE 75 to be fitted 250mm below the yachts water

line when loaded with 50% fuel and 50% freshwater onboard.

ELECTRICAL INFORMATION

Cable specification from electronic ballast to projector (Pt.No. S00111)

Shielded 3 core, Temperature -60C to +180C, Voltage 2000 volts.

Maximum distance between ballast and projector with the shield

earthed 10 meters.

Ballast power 120/230 volt 150 watt ballast - running current 1.4/0.7A

Ballast will not ignite a hot lamp. The ballast has a cycle of three

attempts to ignite the lamp then will wait for four minutes before repeating

the cycle. Install ballast in a dry space. Maximum ambient temperature 40C

ELECTRONIC BALLAST

Part Description

1; Projector Cable

2; Projector lid complete

3; "O" Ring

4; Projector case

5; Lamp (150w MSD)

6; Reflector

7; AB2 Connecting ring

8; Gaskets

8A; Gaskets

9; S.S.316L Body

9; Alu 5083 Body

10; S.S. M6 socket screws

10; Ti. M6 socket screws

11; S.S. Glass retaining ring

11; Alu Glass retaining ring

12; Gaskets

13; Glass

14; Electronic ballast 120V

14; Electronic ballast 230V

14A; Enclosure

Recommended Spares

Lamp

Glass with gaskets

Electronic ballast

Part No

S00111

S00C102-B

00108

00101-B

91210

91791-C

00503-75-A

00285-A

000C07-B

003XX-75

006XX-75

93334

93460-SC

00304-ICE 75B

00604-75B

00286-A

00281

95322-V3-H

95322-V2-H

00806-A

Part No

91210

S00281

S00801

140 mm

30 DEGREE

50 DEGREE

FLUSH

00604-75B

LENS FITTING INSTRUCTIONS

Check the glass landing surface is clean and apply a suitable silicone grease to the gaskets. Fit

the glass, gaskets and retaining ring as shown above. Hand tighten the screws with a 5mm

“Allen key” making sure the glass retaining ring is square. Torque settings for all retaining

screws - 10 Nm (7.5 ft/lbs). Torque the screws in the sequence shown. Check the ring again

and re-torque the screws again to the same torque setting.

00304-ICE-75B

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO WWW,REGISTER-UWL.COM

FOR TECHNICAL INFORMATION PLEASE EMAIL T@UNDERWATERLIGHTS.COM

SALES, PRODUCT INFORMATION AND NEWS GO TO

WWW,UNDERWATERLIGHTS.COM

UL Ti MATE 75 ICE S.S + UL Ti MATE 75 ALU-1-9-2010

UL Ti MATE RANGE - MODEL - UL Ti MATE 75 SA 150W-250W

underwater lights limited™

TECHNICAL SPECIFICATION

Lamp Type MSD Metal Halide 150w-250w

UL Ti MATE 75 SA STEEL

Flush

UL Ti MATE 75 SA ALU

30 degree

124mm

210mm

120mm

27mm

Order Number Flush-STEEL S00300-75-SA-ICE-V2/V3W2- W1

Order Number Flush-ALU S00600-75-SA-V2/V3W2- W1

75mm

210mm

Voltage/Amps - 150 watt 120(V3)/230(V2) - 1.4/0.7.A

124mm

120mm

Lamp Life - 3000 Hours - Colour Temp - 7000 K

Voltage/Amps - 250 watt- 198/264vac- 1.2A

Glass Lens - Borosilicate glass

Order Number 30 deg. STEEL S00330-75-SA-ICE-V2/V3W2-W1

Order Number 30 deg. ALU S00630-75-SA-V2/V3W2-W1

105mm

210mm

124mm

Light Level -150w 12,000 Lumens - 250w 19,000 Lumens

140mm

Material - Steel and 5083 ALU

NOTE

Installation Instruction:

40mm

Order Number 50 deg. STEEL S00350-75-SA-ICE-V2/V3W2-W1

The hole cut-out should be cut to suit the insert

Order Number 50 deg. ALU S00650-75-SA-V2/V3W2-W1

angle.

Maximum hull plate thickness should be 12mm for the flush and 20mm for the 30 & 50 degree.

For Lamp Maintenance allow 170mm behind the cable gland.

Electrical Information:

150w - Recommended maximum distance between ballast and projector 10m.

250w - Recommended maximum distance between ballast and projector 25m.

Cable - 150w-250w High temp. silicone 3 core (Part No S00111, 0.75).

For additional information please visit our web site.

For sales telephone numbers visit www.underwaterlights.com

underwater lights limited

DESCRIPTION

This is a “through-hull” submersible marine

light for welding into aluminium and steel

hulls. Maintenance of the light is carried out

from inside the hull.

Our patent pending internal SA ( Super

Adjustable) unit allows the beam angle to be

varied from a narrow to wide beam, and to

universally move the beam direction by 20

degrees from within the projector housing.

We advise that the light be installed 250mm

below the minimum waterline when the yacht

is loaded with 50% fuel and 50% water, and

that the light be angled 15 degrees downwards.

To achieve this there are 3 modelsFlush, 30 degree and 50 degree.

The UL Ti MATE 75 SA has a larger aperture

which increases the light output by 25%.

The stainless steel model comes as standard

with Ice Class Lloyds Approval and has been

pressurised to 80 bar. The aluminium model is

IPX8 to 10 bar. The range is also GL Approved.

™

TM

Manufacturers of the Original underwater lights

Brand Marine Lighting Products since 1991

316 S.S. UL Ti MATE 75 SA-ICE

‘submersible through hull light’

ORDERING NUMBERS

FLUSH - S00300-75-SA-ICE. 30 DEG - S00330-75-SA-ICE. 50 DEG -S00350-75-SA-1CE

WITH 120 (V3) / 230 (V2) VOLT BALLAST AND 150W (W2) OR 250W (V2,W1) WATT LAMP.

UL Ti MATE™ to be fitted a minimumof 250mm below the yachts water

line when loaded with 50% fuel and 50% freshwater onboard

ELECTRICAL INFORMATION

150 WATT Maximum distance between ballast and projector -10 meters

250 WATT Maximum distance between ballast and projector - 10 meters.

Ballast power 150 watt ballast 120/230 volt, running current 1.4/0.7.A

Ballast power 250 watt ballast 230 volt, running current 1.2.A

Ballast will not ignite a hot lamp. The ballast has a cycle of three atempts

to ignite the lamp then will wait for six minutes before repeating the cycle.

Ballast must be installed in dry space. Maximum ambient temperature 40C

DO NOT swich ballast on and off.

TM

OPERATIONAL CONDITIONS AND CONSIDERATIONS

The UL Ti MATE 75 SA is serviced from inside the hull.

Do not attempt to remove the glass lens while afloat.

Allow access for maintenance and space for ventilation.

The projector must be correctly assembled with lid

Do not use the UL Ti MATE™ in dry-dock or out of water

secured to the UL Ti MATE™ whilst afloat.

Allow a minimum of 170mm behind the cable gland for

lamp replacements on 150w and 150mm behind the.ignitor on 250w.

120 & 230 VOLTAGE SUPPLY FOR 150 & 250

WATT ELECTRONIC BALLAST COMPLETE

WITH ENCLOSURE .

CABLE SPECIFICATION TO PROJECTOR

High tempereture (180C) silicone

screened three core. Cable diameter 9mm

PART NUMBER

S00111-180 EWKF 3G0,0.75

Part Description 75-SA

1: Projector lid securing plate

2: M6 Nut

3: 'O' Ring

4: Gasket NAF

5: Connecting ring

6: Lamp holder screw

7: Lamp holder (250W)

7: Lamp holder (150W)

8: Reflector collar bush

9: M4 Lock nut

10: Lamp (250W)

10: Lamp (150W)

11: Reflector adjustment rod

12: Reflector complete

13: Gasket NAF

14: AB2 Connecting ring

15: Projector barrel

16: Gasket NAF

30: Glass gaskets NAF

31: Glass lens

39: Body Flush (s.s)

40: Body 50 deg (s.s.)

41: Body 30 deg (s.s.)

42: Glass retaining ring

43: Cap head screws

Part No

00283-B

93381

00108

00285-A

00274-C

00290

91195

91191

00288-A

93374

91209

91210

00284

S91791

00285-A

00503-75-A

00101-C

000C07-B

00286-A

00281

S00300-75 ICE

S00350-75-B ICE

S00330-75 ICE

S00350-75 ICE (40)

Part Description 75-SA

22: Gland

23: Projector cover

24: Ballast 250 watt 230v

24: Ballast 150 watt 230v

24: Ballast 150 watt 120v

Part No

92011

00102-E

S00820-V2 W1

S00800-V2W2

S00800-V3W2

S00330-75 ICE (41)

FLUSH

150 & 250 watt

Recommended Spares

Lamp ( 250w = W1 )

Lamp ( 150w = W2 )

Glass with gaskets

Ballast

Part No

91209

91210

S00281-A

S00300-75 ICE (39)

00304-ICE 75B

93334

LENS FITTING INSTRUCTIONS

Check the glass landing surface is clean and apply a suitable silicone grease to the gaskets. Fit

the glass, gaskets and retaining ring as shown above. Hand tighten the screws with a 5mm

“Allen key” making sure the glass retaining ring is square. Torque settings for all retaining

screws - 10 Nm (7.5 ft/lbs). Torque the screws in the sequence shown. Check the ring again

and re-torque the screws again to the same torque setting.

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO WWW,REGISTER-UWL.COM

FOR TECHNICAL INFORMATION PLEASE EMAIL T@UNDERWATERLIGHTS.COM

SALES, PRODUCT INFORMATION AND NEWS GO TO

WWW,UNDERWATERLIGHTS.COM

UL Ti MATE 75-SA-ICE-SS-H-14-10-2011

5083 ALU

UL Ti MATE 75 SA

‘submersible through hull light’

ORDERING NUMBERS

FLUSH - S00600-75-SA. 30 DEG - S00630-75-SA. 50 DEG - S00650-75-SA

WITH 120 (V3) / 230 (V2) VOLT BALLAST AND 150W (W2) OR 250W (V2,W1) WATT LAMP.

ELECTRICAL INFORMATION

150 WATT Maximum distance between ballast and projector -10meters

250 WATT Maximum distance between ballast and projector - 25 meters.

Ballast power 150 watt ballast 120/230 volt, running current 1.4/0.7.A

Ballast power 250 watt ballast 230 volt, running current 1.2.A

Ballast will not ignite a hot lamp. The ballast has a cycle of three atempts

to ignite the lamp then will wait for six minutes before repeating the cycle.

Ballast must be installed in dry space. Maximum ambient tmperature 40C

DO NOT switch ballast on and off.

TM

OPERATIONAL CONDITIONS AND CONSIDERATIONS

The UL Ti MATE 75 SA is serviced from inside the hull.

Do not attempt to remove the glass lens while afloat.

Allow access for maintenance and space for ventilation.

The projector must be correctly assembled with lid

Do not use the UL Ti MATE™ in dry-dock or out of water

secured to the UL Ti MATE™ whilst afloat.

Allow a minimum of 170mm behind the cable gland for

.....lamp replacements on 150w and 150mm behind the.ignitor

.....on 250w

UL Ti MATE™ to be fitted 250mm below the yachts water

line when loaded with 50% fuel and 50% freshwater onboard.

150 WATT ELECTRONIC BALLAST COMPLETE

WITH ENCLOSURE. SEE

BALLAST SHEET FOR FURTHER INFORMATION

CABLE SPECIFICATION TO PROJECT

High temp silicone three core part

number. S00111

Part Description 75-SA

Part No

1: Projector lid securing plate

00283-B

2: M6 Nut

93381

3: 'O' Ring

00108

4: Gasket NAF

00285-A

5: Connecting ring

00274-C

6: Lamp holder screw

00290

7: Lamp holder (250W)

91195

7: Lamp holder (150W)

91191

8: Reflector collar bush

00288-A

9: M4 Lock nut

93374

10: Lamp (250W)

91209

10: Lamp (150W)

91210

11: Reflector adjustment rod

00284212: Reflector complete

S91791

13: Gasket NAF

00285-A

14: AB2 Connecting ring

00503-75A

15: Projector barrel

00101-D

16: Gasket NAF

000C07-B

30: Glass gaskets NAF

00286-A

31: Glass lens

00281

39: Body Flush (alu)

S00600-75

40: Body 50 deg (alu)

S00650-75-B

41: Body 30 deg (alu)

S00630-75

42: Glass retaining ring

00604-75-B

43: Cap head screws

93460-SC

S00650-75

Part Description 75-SA

22: Gland

23: Projector cover

24: Ballast 250 watt

24: Ballast 150 watt 230v

24: Ballast 150 watt 120v

Part No

92010

00102-E

S00820-V2W1

S00800-V2W2

S00800-V3W2

Recommended Spares

Lamp ( 250w = W1 )

Lamp ( 150w = W2 )

Glass with gaskets

Ballast

Part No

91209

91210

S00281-A

S00801-V2/V3

S00650-75

S00600-75

150-250 watt

FLUSH

LENS FITTING INSTRUCTIONS

Check the glass landing surface is clean and apply a suitable silicone grease to the gaskets. Fit

the glass, gaskets and retaining ring as shown above. Hand tighten the screws with a 5mm

“Allen key” making sure the glass retaining ring is square. Torque settings for all retaining

screws - 10 Nm (7.5 ft/lbs). Torque the screws in the sequence shown. Check the ring again

and re-torque the screws again to the same torque setting.

PLEASE REGISTER YOUR PRODUCT WARRANTY DIRECT TO WWW,REGISTER-UWL.COM

FOR TECHNICAL INFORMATION PLEASE EMAIL T@UNDERWATERLIGHTS.COM

SALES, PRODUCT INFORMATION AND NEWS GO TO

WWW,UNDERWATERLIGHTS.COM

UL Ti MATE 75-SA-ALU-H-14-10-2011