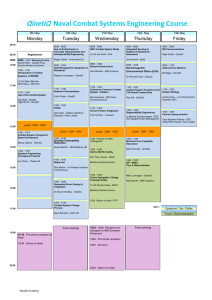

5M Wind Tunnel

advertisement

5 metre pressurised low-speed wind tunnel A high Reynolds number facility for the investigation of flow physics and the prediction of full-scale performance. • Large size makes accurate modelling of details possible • Pressurisation gives simulation of full-scale conditions for take-off and landing of combat aircraft • Segregation of compressibility and scale effects permits more accurate prediction of full-scale performance of large transport aircraft The tunnel fan Landing and take-off performance is of critical importance for both military and civil aircraft. The 5m pressurised low-speed wind tunnel has a simulation capability that is unique in the UK, and it provides high quality data that is of great value to the aerospace industry. Civil aircraft testing Aerial view of wind tunnel Main characteristics and performance • Test section size: 5m x 4.2m • Speed and Pressure Range: Maximum Mach No 0.34 Maximum Pressure 3 atmospheres • Drive Power: 12 MW continuous • Turbulence level: u1 ≈ 0.08% Test techniques and equipment • Force-Measurements: 6-component underfloor balance or internal strain-gauge balance. • Pressure-Measurements: Solid-state (EPS) multiple pressure measurement. • Flow-visualisation: Fluorescent mini-tufts, surface oilflow, photographic wake imaging, liquid crystals. • Ground-plane Simulation: False floor height remotely Particle Image Velocimetry (PIV) Picture taken during tests within EEC EUROWAKE programme controlled beneath fixed model. • Particle Image Velocimetry (PIV): Non-intrusive laser technique for flowfield investigation. • Balance Calibration Machine: Computer controlled and capable of applying maximum loads to underfloor balances and straingauge balances. • Data Acquisition: On-line plots of processed aerodynamic coefficients. Suite of data-processing programmes to suit customer requirements. Model support and force measuring system • Interchangeable cart-mounted models for rapid model changeovers. • Two underfloor balances with rotating turntable for either floormounted half-model, or full-model on various strut supports. • Rear sting support with range of available 6-component straingauge balances. Alternative stings with range of incidence up to 90°. Roll units for model and for sting to ± l80°. • By permitting depressurisation of the test section only, the 5m wind tunnel enables rapid access for model changes thereby allowing high productivity. It is used for a wide range of tests, including research into the aerodynamics of high-lift systems. helicopters, STOVL aircraft and the development of wind-tunnel techniques. Helicopter testing IT For more information please contact: Customer Contact Team QinetiQ Cody Technology Park Ively Road Farnborough Hampshire GU14 0LX United Kingdom Tel +44 (0) 8700 100942 www.QinetiQ.com © Copyright QinetiQ ltd 2002 QINETIQ/FST/CAT/PUB013051