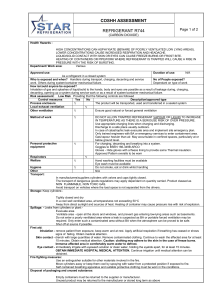

Commercial CO2 Refrigeration Systems

advertisement