Future Ship Powering Options: Exploring alternative Methods

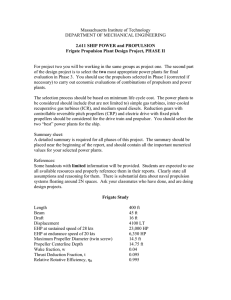

advertisement