AQ At = mcAT At ΔQ Δt = kA(T −T0) d

advertisement

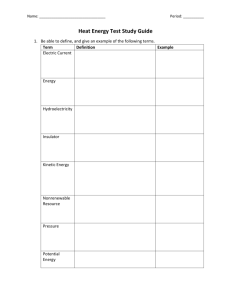

HOME HEATING Heat Loss or Gain of an Insulated Container Take‐Home Experiment Write Up Task 1a: Measuring and Modelling Heat Loss of an Insulated Container According to Newton’s Law of cooling, the rate of heat loss from an object should be proportional to the difference in temperature between that object and its surroundings. Heat is transferred in three ways: conduction, convection and radiation. Conduction, the most relevant to our experiment, is the transfer of heat from high temperature to low temperature by the direct contact of atoms or molecules. Convection is the transfer of heat by gases or liquid in motion and radiation is the transfer of heat through space (for example heating of Earth by the Sun). Thus to model heat transfer of this container, measured heat loss: ΔQ mcΔT = Δt Δt will be compared to predicted heat loss due to conduction: € ΔQ kA(T − T0 ) = Δt d To measure heat loss, a Styrofoam container filled with water was heated in a microwave (about one € minute on high). The container was made from one Styrofoam cup and one Styrofoam bowl, purely out of the convenience of using readily available materials (See Figure 1). Figure 1: The insulated container was made from a Styrofoam cup and bowl glued together. An oven thermometer measured the temperature of the water through a hole in the top. Physics and Astronomy Outreach Program at the University of British Columbia The cup was filled with water and the bowl was glued to its top with epoxy glue. The cup should be filled very full so that the water touches the top (the bowl) but does not leak out of the hole in the top. A marble was also added to enable stirring. A hole was drilled into the top of the container so that a digital oven thermometer could measure the temperature of the water. The surface temperature of the container was measured with an infrared thermometer. It was found that the top, bottom and sides were at slightly different temperatures, so each was recorded. The hot water was then left to cool to room temperature and the temperature of the water and the surfaces of the container, were recorded at different time intervals – once a minute to start with, and every 5 or 10 minutes later, as the rate of cooling slowed. The container was held on a ring stand so that most of the Styrofoam was in contact with air. Before every measurement the container was stirred or shaken for at least 10 s until the water temperature stabilized. Data Analysis and Interpretation Plot theoretical (predicted) heat flow and experimental heat flow against time to explore how well losses due to conduction account for the actual energy loss. The constants known: Conductivity of Styrofoam: k = 0.033 W/m/K Specific Heat Capacity of Water: c = 4200 J/kg/K The variables measured: Mass of water: m = 0.2232 ± 0.0001 g Thickness of Styrofoam: dtop = 0.0030 ± 0.0002 m, dbottom=0.0019±0.0002 m, dsides=0.0017±0.0002 m Radius of bottom (rbottom)= 0.025 ± 0.001 m Radius of top (rtop)= 0.040 ± 0.001 m Slant height (s) = 0.090 ± 0.001 m Surface area: A = ? Calculating surface area: For this experiment, we will take the surface area to be that of one Styrofoam cup with the top covered as this was the only part of the Styrofoam actually in contact with the water. To calculate the area of the side of the cup, use the formula for the surface area of a right circular cone. r bottom A = Area of thebottom + Area of the top+ Area of the side 2 2 = πrbottom + πrtop + π (rbottom + rtop )s = π (.025 m) 2 + π (.04 m) 2 + π (0.025 m + 0.04 m)(0.09 m) 2 2 = 0.002 m + 0.005 m + 0.0183 m = 0.0253 m 2 € Physics and Astronomy Outreach Program at the University of British Columbia slant height (s) 2 r top The heat loss due to conduction for a temperature difference can be predicted using the formula: where ΔT is the temperature difference between the water and its surroundings. In this case, its surroundings were the top, bottom and sides of the container which each had slightly different temperatures at any given time. Thus the total energy loss due to conduction can be predicted to be (at any given time): These predicted energy losses can be plotted against time to get a theoretical cooling curve. This curve can be compared to the actual measured energy losses, calculated using measured temperature differences and times using: The change in temperature at a time point was calculated by finding the difference between the temperature at the next time point and the previous time point. For example at t=2 min, ΔT=T3min – T1min, and Δt = 3 min – 1 min = 2 min. Figure 2 shows both curves. Vertical error bars are included for P(experimental). Figure 2: Plots of theoretical and experimental heat loss over time. Physics and Astronomy Outreach Program at the University of British Columbia If we have correctly modelled the sources of heat loss we expect that the two curves should overlap, which they do. It is also possible to use the data (a spread sheet of sample data is available for this activity) to determine the conductivity of the container. If the conductivity were unknown the value for k (in the theoretical energy loss calculation) could be altered to shift the theoretical plot onto the experimental plot. However, in this case, the plots align nicely with the accepted value for k = 0.033 W/m/K. Thus we have shown that the heat loss can be successfully modelled taking only conduction into account and that losses due to radiation and convection are negligible. Some procedural specifications to take note of: • Thicknesses were measured with a caliper. • Care was taken to make sure very little water escaped from the hole in the top. It if did it was dried up with a napkin immediately because if the top of the container were wet, it would have significantly different heat transfer due to the evaporation. • Measurement errors were mostly ignored, however to create the error bars in Figure 1, errors of 0.008 min and 0.5° were used. • The specific heat capacity of the marble was ignored. • It was difficult to obtain simultaneous measurements of the temperature of the sides, top and bottom of the container. They were always measured in the same order but there is some systematic error in the time‐temperature correlation. Summary Modelling the heat loss with conduction took into account most of the energy lost by the water so that the theoretical and experimental heat losses against time produced similar curves. Therefore most of the heat was lost due to conduction between water and the Styrofoam cup. Brittany Tymos and Rachel Moll 2009/08/27 Physics and Astronomy Outreach Program at the University of British Columbia