Aluminum Technology - The Wiring Harness of the Future

Next Generation Terminals for Aluminum Wire Application

2015-01-0245

Published 04/14/2015

Markus Gaertner

Delphi Deutschland GmbH

CITATION: Gaertner, M., "Aluminum Technology - The Wiring Harness of the Future Next Generation Terminals for Aluminum Wire

Application," SAE Technical Paper 2015-01-0245, 2015, doi:10.4271/2015-01-0245.

Copyright © 2015 SAE International

Abstract

The Wiring Harness of a Vehicle

Historically aluminum was recognized as a valuable material to

achieve weight reduction targets in engines, vehicle chassis and

suspension. Aluminum needs to be also considered in new areas

like vehicle electrification to support the overall weight reduction

targets. The use of aluminum helps to improve fuel economy and

brings down CO2 emissions by reducing weight. This benefit is an

attractive option for the wiring harness to replace heavier copper

conductors. In addition to large cross section wires for power

cable, where aluminum conductors are already in use, the

intermediate aluminum cable cross section of 2.5mm2 to 6.0 mm2

provides a good potential for car implementation to hit weight

saving targets.

Today reducing weight and simultaneously implementing more

functionality is the challenge for the design of wiring harnesses. A

wiring harness for a vehicle from 1960 would have a weight 3 to

5 kg. Today, a wiring harness weight can be in the range of 50 to

70 kg, dependent on the equipped functions.

The major implementation roadblocks for aluminum technology

are the surface oxides Al2O3 which are an insulator and the

potential galvanic corrosion of aluminum in combination with the

always present copper terminal. Galvanic corrosion can occur with

the presence of electrolyte fluids inside the car. Traditional

termination solutions are mostly dependent on the use of additive

materials like paints, grease or similar approaches to protect the

aluminum at the crimp area. To achieve a permanently reliable

electrical contact, the termination technology between a copper

terminal and aluminum wire with single strands, needs to be

specifically optimized.

Delphi now provides a technology named SMC (Selective Metal

Coating). SMC is an innovative technical solution for a wiring

harness equipped with aluminum cable.

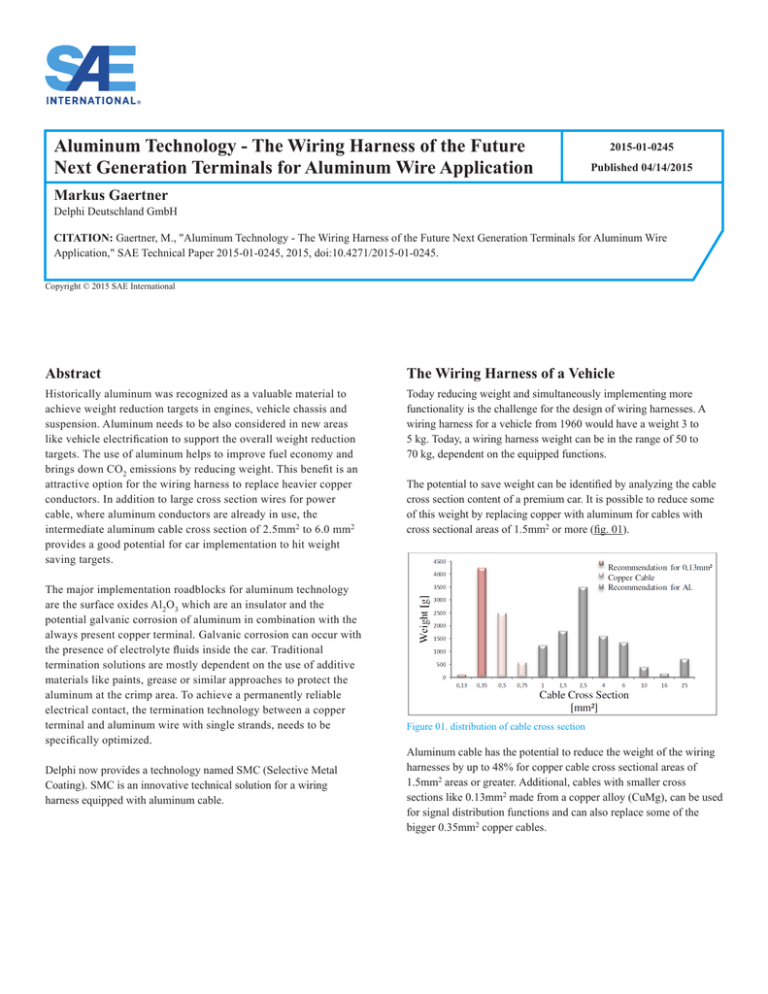

The potential to save weight can be identified by analyzing the cable

cross section content of a premium car. It is possible to reduce some

of this weight by replacing copper with aluminum for cables with

cross sectional areas of 1.5mm2 or more (fig. 01).

Figure 01. distribution of cable cross section

Aluminum cable has the potential to reduce the weight of the wiring

harnesses by up to 48% for copper cable cross sectional areas of

1.5mm2 areas or greater. Additional, cables with smaller cross

sections like 0.13mm2 made from a copper alloy (CuMg), can be used

for signal distribution functions and can also replace some of the

bigger 0.35mm2 copper cables.

Although replacing the copper with aluminum will result in a larger

harness cross section due to the physical characteristics of aluminum

compared to copper.

Figure 02. shows the relation between copper and aluminum cable in terms of

cross section for the same current carrying capacity

Aluminum Cable Intermediate Size

Aluminum cables with cross sections greater than ≥ 2,5mm2 are

designed out of nearly pure aluminum. A typical alloy used is Al

99,7. For lower cross sections, due to cable mechanical

requirements several alloys are available that have a higher tensile

strength characteristic.

Aluminum Cable, Current Load Capacity

The theoretical approach of getting the current equivalent cross

section between aluminum and copper is the equation (1) based on

the same electrical current. The cross section is reversely

proportional to the electrical conductivity. The cross section for

aluminum needs to be about 1.6 times larger than for copper for

carrying the same current.

Figure 04. conductivity Cu-ETP & Al99,7 according LV 112-1/2 [2] The

corresponding cross section between aluminum and copper are compared to

each other. The test shows that the current carrying capacity of aluminum is

mostly higher Imax,Al >= Imax,Cu. than is the current equivalent of copper.

Connection Technology, Cable to Terminal

Crimp Technology

Crimp technology is used to connect a terminal to a wire in automotive

industry today. Crimping is a process where the core crimp wings of

the terminal are bent around the core of the wire. The core crimp

provides the mechanical and electrical connection of the cable to the

terminal. The primary function and design of the core crimp is to

optimize the electrical performance of the cable to terminal attachment

for the service life of the terminal. The wire is compressed by the core

crimper and provides a good electrical and mechanical connection. The

insolation of the wire is in contact with the insolation crimp of the

terminal. It provides a strain relief support function for the core crimp.

For the use of aluminum cable, the connection technology crimping

and terminal design need a few modifications.

(1)

To get the equivalent cross section based on equal current capacity in

addition to the power loss due to resistance, the cooling on the cable

surface is important to consider. On the basis of the larger aluminum

cross section and the better thermal radiation the cross section

relation decreases to 1.5 times.

(2)

Figure 05. crimp terminal

Aluminum Background and Technical Challenge

Aluminum contains surface oxides Al2O3. The oxides are an electrical

insulator. The technology of connecting a terminal to an aluminum

wire has therefore two challenges to overcome.

Figure 03. conductivity Cu-ETP & Al99,7 according LV 112-1/2. [2] The

maximal current load capacity with FLRY-B copper cable in comparison to

FLALRY aluminum cable, both with the same cross section.

1.

The terminal to strand conductivity, because of the

nonconductive aluminum surface oxides, is the main challenge.

2.

The strand to strand conductivity, because of the non-conductive

aluminum surface oxides, defines an additional challenge for the

intermediate wires sizes.

Terminal to Strand Conductivity

For the terminal to strand conductivity, the terminal has a knurl

geometry inside the core crimp that assures that the hard oxide

surface is going to break.

In addition to optimized strand to strand conductivity, the nugget

gives a more robust mechanical characteristic to the design due to the

prevention of relative strand to strand movement.

Figure 09. cross section view through an aluminum core crimp after Crimping

Figure 06. Delphi terminal knurl design

Aluminum Field Test

Delphi has conducted a field test on high-mileage daily use vehicles

that have been equipped with aluminum wire (fig.10). The objective

was to gain durability and design verification experience with

aluminum cable and termination. In order to gain real world

experience with aluminum cable and aluminum specific crimp

technologies Delphi performed data monitoring on these vehicles.

The result was real-world operating conditions for our products under

constant monitoring.

Figure 07. the geometry of the terminal knurls has been adapted by the

aluminum cable

Due to the flowing characteristic of the aluminum, the oxides are

broken and a good electrical connection can be achieved.

The Strand to Strand Conductivity

Before crimping the aluminum wire to a terminal, the single strands

of an aluminum wire welded to each other by an ultra-sonic welding

process. This provides a cable that has a welding geometry

afterwards, a so called “nugget” with an electrical strand to strand

connection. This nugget is going to be crimped to the terminal.

Figure 10. test set up of the aluminum wire installed inside the engine

compartment with constant data collection of contact resistance

Different technologies were evaluated through the field test. The table

(fig. 11) shows the test result after a duration of 300,000 hours of

vehicle operation and with a total over 1,300,000 miles.

Figure 08. Delphi ultra-sonic welding nugget design

Figure 11. [%] percentage of passed terminals

Technology 01 as an example is designed without any additional

corrosion protection. It passed the test even though being located at

the exterior of the engine compartment.

Selective Metal Coating (SMC)

The connection of an aluminum cable to a copper terminal requires

protection against galvanic corrosion in some vehicle compartments.

Figure15 shows that copper is freely accessible at the punched edges

of the terminal at the core crimp and spatially located right next to the

aluminum wire. At electrical connection location, galvanic corrosion

is particularly likely occur under the influence of an electrolyte.

Figure 12. the picture shows the terminal after one year. It has low resistance

and no visible corrosion.

Aluminum Technologies

Corrosion protection should be used depending on the vehicle

installation location. As the field test indicates, corrosion protection is

not always needed everywhere. Delphi offers the OEM a modular

approach where corrosion protection for the terminal is available as

an additional option that can be used in the compartment areas where

it is recommended.

Figure 15. schematic view of a core crimp

The terminal is formed mainly out of a copper based lead frame

material. The Delphi SMC-protective layer is applied on the hot-dip

tin of the copper base material (Fig.16) as well as on the bare copper

of the punched edges of the terminal. The selectively applied SMC

layer consists of an electroplated layer of brass (CuZn) and an

overlying deposited layer of tin.

Figure 13. recommendation for aluminum terminals

The experience of testing and evaluation in field vehicles results in an

allocation of three different zones for the vehicle as shown in fig. 13.

Zone 1 is without any need for further corrosion protection for “high

and dry” locations, for example the instrument panel. Corrosion

protection is recommended for zone 2 and zone 3. Zone 2 is for

interior compartments that can accidentally be exposed to a corrosive

atmosphere. Here corrosion protection is realized by a selective metal

coating treatment of the terminal. Zone 3 is for exterior, wet

application areas and corrosion protection realized by a connector

housing with a single seal design.

Figure 16. Delphi SMC protection layer

During the corrosion test, a sodium chloride solution is used as an

electrolyte. Chloride is the reactive element which promotes the

corrosion. Therefore, its influence is considered in more detail.

Chlorides are compounds of the chemical element chlorine. Metal

chlorides such as sodium and cobalt chloride are salts.

Sodium chloride dissociates in water into Na + and Cl-ions. The

resulting solution is conductive, a prerequisite for galvanic corrosion.

Chloride is able to react with copper, tin, zinc and aluminum and to

dissolve these metals. It preferentially reacts with zinc and aluminum,

and only then with the nobler metals, tin and copper.

Figure 14. Delphi aluminum technologies

The outer tin layer of the terminal is connected to the aluminum

cable. This connection has an electrochemical potential between tin

and aluminum. This electrochemical potential is available to initiate

galvanic corrosion. ΔE (mV), is the electromotive force (EMF) of the

galvanic corrosion.

Copper has a tendency to form intermetallic phases with tin (Cu3Sn

and Cu6Sn5), and in doing so diffuse into an adjacent layer of tin.

Chloride penetrates from outside into the tin and dissolves it.

Galvanic Corrosion Potential

The basis of galvanic corrosion is the corrosion potential. If metals

with a sufficiently high potential difference are in electrical

connection to each other, a conductive solution (e.g. sodium chloride

in water), dissolves the metal with the more negative potential under

the formation of hydrogen.

Figure 19. REM picture, chloride is in copper by SEM/EDX barely detectable

Figure 17. potentiostat measurement with three electrode set up

The current-density-potential curves of the corrosion potential have

shown (fig.17) that the used aluminum has its potential at −901 mV.

Before the measurement has been done, the oxides of aluminum have

been removed with 25% sodium hydroxide solution by pickling and

rinsing. Measurements with the slightly nobler aluminum oxide layer

result in a potential of −733 mV. At the contacts between the

aluminum wire and the terminal the aluminum oxide layer is the

actual galvanic partner. The measurement for copper has its potential

at −298 mV. Thus, the ΔE between copper and aluminum is 435 mV.

The SMC protective layer has a reduced corrosion potential of

306 mV. In comparison to bare copper the ΔE can be reduced by

30%.In order to avoid galvanic corrosion direct contact between

aluminum, copper and chloride should be prevented (fig.15).

If copper and aluminum are placed in a sodium chloride solution while

in electrical contact with each other, the less noble metal aluminum

behaves as the anode and the more noble metal as a cathode. This

battery effect speeds up the dissolution of the aluminum.

The aluminum dissolves with the formation of hydrogen gas (H2). Thus,

the pH value in the sodium chloride solution increases which in turn

accelerates the aluminum dissolution. If conductive contact between

copper and aluminum can be avoided corrosion is slowed down.

Tin Layer as a Corrosion Protection

Corrosion tests have indicated that a re-tinning of terminals e.g. at the

copper punched edges, slows down the galvanic corrosion effect and

offer a significant protection.

Due to the difference in electronegativity between the potential of

CuSn and copper of the base material, the intermetallic CuSn-phase

protects the copper base material. Using a tin plated copper base

material without a CuZn intermediate layer, the contact between the

aluminum, copper and chloride, cannot be prevented sufficiently over

the entire time of the required corrosion tests. CuSn-phases are

formed. But these are not enough to prevent contact corrosion.

CuZn as an Additional Corrosion Protection

Copper and brass (CuZn) have a different diffusion behavior with

tin layers.

If equally 5 μm thick tin layers are deposited directly on brass and on

a copper interlayer (fig.20), after a storage temperature of 170 ° C,

the layer on the copper interlayer is dissolved after 25 days, directly

on the brass, however, it is dissolved in only about 60 days. [1]

This study shows clearly that copper out of the brass layer is

significantly slower diffusing into the tin in comparison to pure

copper. The concentrated copper has a high priority to alloy with tin.

Zinc and tin do not form intermetallic phases. The endeavor of the

copper from the brass layer to mix with tin is significantly lower.

The brass phase dissolves very slowly. The diffusion of copper in the

overlying tin is significantly slowed down by the CuZn-interlayer.

Inspecting the SMC-layer system at the end of the corrosion test, the

chloride is distributed in the outer Sn layer (fig. 21) and diffuses into

the CuZn-intermediate layer, but not beyond that.

Chloride reacts with the zinc in the CuZn-intermediate layer and

dissolves it slowly.

Summary/Conclusions

The SMC Terminal integrates solutions to break the aluminum oxides

through knurls and nugget, and metal plating in the crimp area to

reduce the galvanic corrosion to stay inside customer requirements.

For the SMC layer system, the following protective effects can

be determined.

Figure 20. diffusion of copper into a tin layer

1.

Reduction of electrochemical potential between the terminal and

the aluminum wire.

2.

The chloride is distributed homogeneously in the outer tin layer,

thereby it will be slowed down in the diffusion behavior towards

the copper.

3.

The chloride remains in the brass phase (CuZn) and is prevented

from penetrating directly into the copper of the base material.

Preferably chloride reacts with the zinc, it engages the zinc in

the CuZn layer and dissolves it. As long as zinc is available for

the reaction, the chloride does not penetrate into the copper or

bronze layer.

4.

As the investigation [1] shows, copper from the brass

intermediate layer has a slow diffusion behavior into the

overlying Sn layer. Thus copper as a galvanic element, is lately

available. The diffusion of copper from the base material to the

upper layer of tin, through the brass phase, can be neglected.

5.

By the slowed down aluminum corrosion, the pH value

increases slowly in the electrolyte, sodium chloride. Thus, the

dissolution of the aluminum is delayed.

SMC technology is based on a material optimization for the crimp

design of the terminal. The corrosion protection is inside the terminal

integrated. SMC technology does not need any additional materials like

conformal coating, grease, powder, etc. Delphi aluminum terminals do

not entail any fundamental change for cable harness manufacturers.

References

1.

Source: Manfred Jordan, Die galvanische Abscheidung von

Zinn und Zinnlegierungen, Saulgau 1993, page 206. (Scott, B.

C.: Inst. Metal Finish, Ausgabe 65 (1987), page 90).

2.

LV 112-1/2, Delivery Specification for automotive cable of German

OEMs, LV112-1 for copper cable, LV112-2 for aluminum cable.

Contact Information

Markus.Gaertner@delphi.com

Figure 21. REM picture, SMC protection layer after corrosion test

Acknowledgments

The preparation of this paper was supported by the Delphi aluminum

team: George Drew, Kurt Seifert, Thomas Reinders, Petra Bauer,

Thomas Plinta

The Engineering Meetings Board has approved this paper for publication. It has successfully completed SAE’s peer review process under the supervision of the session organizer. The process

requires a minimum of three (3) reviews by industry experts.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the prior written permission of SAE International.

Positions and opinions advanced in this paper are those of the author(s) and not necessarily those of SAE International. The author is solely responsible for the content of the paper.

ISSN 0148-7191

http://papers.sae.org/2015-01-0245