Fully Solderable Large-Area Screen-Printed Al-BSF p-Type Mc

advertisement

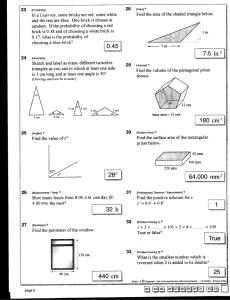

27th European Photovoltaic Solar Energy Conference and Exhibition FULLY SOLDERABLE LARGE-AREA SCREEN-PRINTED AL-BSF P-TYPE MC-SI SOLAR CELLS FROM 100 % SOLAR GRADE FEEDSTOCK YIELDING > 17 %: CHALLENGES AND POTENTIAL ON CELL AND MODULE LEVEL Fabian Fertig1*), Karin Krauß1, Ino Geisemeyer1, Juliane Broisch1, Hannes Höffler1, Jan Ove Odden2, Anne-Karin Soiland2 and Stefan Rein1 1 Fraunhofer ISE, Heidenhofstrasse 2, 79110 Freiburg, Germany 2 Elkem Solar AS, Fiskaavn 100, 4621 Kristiansand, Norway *) Phone: +49 761 4588 5482, Fax: +49 761 4588 9250, Email: fabian.fertig@ise.fraunhofer.de ABSTRACT: A promising alternative to purifying metallurgical grade silicon via the gaseous phase is purification by for example slag refinement, leaching and solidification yielding so-called solar grade silicon (SoG-Si). Despite several advantages of SoG-Si, a wider distribution in PV industry has so far been hindered by reservations towards efficiency potential, reverse bias behaviour, module reliability and material yield. We achieved peak efficiencies over 17 % on standard (15.6×15.6 cm2) industrial fully-solderable screen-printed aluminium back-surface field (SP AlBSF) solar cells on multi-crystalline silicon (mc-Si) wafers from 100 % Elkem Solar Silicon (ESSTM). To our knowledge, this is amongst the highest efficiencies reported for SP Al-BSF cells on 100 % SoG-mc-Si so far. The average efficiency over an entire brick is 16.6 % which is the same value as for a reference brick from pure polysilicon feedstock. The reverse bias behaviour of all cells appears to be well suited for standard industrial module integration concerning global current density and locally resolved power dissipation behaviour. Keywords: Multicrystalline Silicon, Compensation, Metallurgical-Grade, Diode Breakdown, Hot Spots, Shading 1 2 INTRODUCTION Although the price of poly-silicon has decreased dramatically from 500 USD/kg in 2008 [1] to 22 USD/kg in 2012 [2], it is still a significant cost driver in silicon PV accounting for approximately 16 % of solar module manufacturing cost according to recent cost analyses data published, e.g., by Centrotherm in 2012 [3,4]. Out of this share of 16 %, a cost percentage of 83 % is attributed to process-related expenses of purifying metallurgical-grade silicon. A promising alternative to the standard Siemens process of purifying metallurgical-grade silicon via the gaseous phase is purification by other techniques such as slag refinement, leaching and solidification yielding socalled solar-grade silicon (SoG-Si). No standard process for gaining SoG-Si via a metallurgical refining route has been established so far, which leads to strong variations in the material quality from different suppliers. However, even when almost all contaminants can be cleaned out of the feedstock, phosphorus is difficult to eliminate via the metallurgical route leaving dopant compensation as the dominating challenging phenomenon in SoG-Si. Despite several advantages of SoG-Si towards its Siemensprocess counterpart such as a reduced energy consumption by a factor of 4 and a reduced investment cost for production equipment by a factor of 3 [5-9], three main arguments are so far hindering a wider distribution in industry (processing yield has been shown to be no limiting factor [10,11]): Compensation is assumed (i) to limit the achievable solar cell and module efficiency, including possibly higher light-induced degradation (LID), (ii) to cause an inferior reverse bias behaviour, i.e., it is suspected to affect module reliability due to possibly critical hot-spot heating and (iii) to lead to a p/ntype change-over during crystallisation which means that only a part of a brick could be used for cell processing. The purpose of this work is to address these points on standard industrial screen-printed aluminium backsurface field (SP Al-BSF) solar cells from p-type mc-Si crystallised from Elkem Solar Silicon (ESSTM) feedstock. Elkem Solar’s purification process includes slag treatment, wet chemical leaching and directional solidification [5-7]. APPROACH Base resistivity b (cm) 2.1 Experimental design To evaluate feedstock-dependent effects on efficiency, LID and hot spot endurance, two blocks are crystallised in the same furnace at an industrial crystal grower: one from 100 % ESSTM feedstock and one from highly pure, virgin-grade poly silicon feedstock. To enable a meaningful comparison, similar resistivity levels across the bricks are targeted. From both blocks, one edge brick of similar positions within the blocks is cut into 15.6×15.6 cm2 full square wafers. A selection of wafers covering the entire commercially utilizable brick height of both bricks is used for solar cell manufacturing. Furthermore, reference virgin-grade wafers from an industrial supplier in the same base resistivity range are included into the experiments (named “ISE reference” within this paper). 2.0 TM ESS virgin 1.8 1.6 1.4 1.2 1.0 0 20 40 60 80 100 E IS Relative brick height (%) f. Re Fig. 1: Base resistivity as a function of relative brick height for wafers from the investigated solar-grade and virgin-grade bricks as well as base resistivity of ISE reference wafers. Fig. 1 shows the base resistivity distribution as a function of relative brick height for all wafers used within the described experiment; the range is b,virgin = 1.26 - 1031 27th European Photovoltaic Solar Energy Conference and Exhibition 1.72 cm and b,ESS = 0.99 - 1.98 cm. The ESSTM brick shows the characteristic increase of base resistivity with increasing brick height for feedstock being compensated by boron and phosphorus. The virgin brick exhibits the correspondent characteristic decrease in resistivity due to boron segregation with a segregation coefficient below 1. Hence, wafers in a comparable resistivity range from both, compensated and uncompensated, feedstock are investigated. Fig. 1 also shows that there is no type change-over within the commercially usable brick height for the ESSTM crystal. Efficiency (%) area Al-BSF and Kohler/Braun [15,16] avg = 15.4 % and peak ≈ 16.2 % using a full-area Al-BSF. A direct comparison is difficult since the cited results date back a few years. However, this study shows that higher peak efficiencies than those reported are possible in a standard industrial SP Al-BSF process using 100 % SoG-mc-Si. 2.2 Cell process For solar cell processing, we applied a standard industrial cell process at Fraunhofer ISE’s pilot line PVTEC [12], whose sequence is displayed in Fig. 2. The applied process contains an adapted but not prolonged diffusion, no additional cleaning steps and printing solderable busbars on the rear side. Therefore, the resulting solar cells are completely usable for integration into solar modules. 16.5 TM ESS virgin 16.0 degraded 0 20 40 60 80 100 E IS Relative brick height (%) f Re . Fig. 3: Efficiencies as a function of relative brick height (filled symbols = as-processed, open symbols = degraded under 0.2 suns for t >48 h) for the ESSTM and the virgingrade brick as well as for industrial reference wafers. Fig. 2: Process flow applied at Fraunhofer ISE’s pilot line PV-TEC for standard industrial SP Al-BSF solar cells. The process contains an adapted but not prolonged diffusion, no additional cleaning steps and printing solderable busbars on the rear side. 3 17.0 Table 1 summarizes the results of the IV measurements; both the cells from the ESSTM and the virgin-grade brick yield equal medium efficiencies of medium ≈ 16.6 % which is on the same level as the solar cells processed from the industrial reference material used. However, the cells from the solar-grade brick exhibit a standard deviation of ESSTM,std,dev = 0.35 % compared to virgin,std,dev = 0.20 % for the virgin brick. The industrial reference wafers are in a narrower corridor of ISEref,std,dev = 0.11 % but do not represent an entire brick. This would mean a larger number of power bins during classification in industrial production for the ESSTM cells, but also better top quality bins. For the ESSTM brick, all cells between relative brick heights of 10 – 40 % exhibit efficiencies of > 16.95 % whereas the maximum efficiency of the virgin brick is max,virgin = 16.97 %. Efficiencies of both bricks strongly degrade with increasing brick height, due to a decrease in both, opencircuit voltage Voc and short-circuit current density Jsc. Fig. 4 shows the dependence of Voc and Jsc on base resistivity while indicating the direction of solidification during crystallisation (compare to Fig. 1). For both parameters, the dependence on base resistivity is in opposite directions for cells from each feedstock following the direction of solidification. Hence, the higher the relative brick height is, the lower is Voc and Jsc for both bricks independently of the development of base resistivity with brick height. First, the limitation of Voc with increasing brick height is addressed using luminescence imaging. Three representative cells from the bottom, middle and top part of the two bricks, as well as one reference cell, are discussed. Fig. 6 (row 1) depicts PL images under opencircuit conditions at an illumination level of I = 1 sun for the cells of the ESSTM brick and Fig. 6 (row 2) the corresponding spatially-resolved images of the total dark saturation current density J0 assuming a one-diode model [17]. Fig. 6 (row 3,4) depicts the same images for cells from the virgin-grade brick and Fig. 6 (row 5,6) for a cell from an industrial reference wafer. The PL images CHARACTERISATION The discussion of the experimental results is divided into forward and reverse characteristics. Under forward bias, the focus lies on efficiency and LID, whereas the focus of the reverse bias investigation lies on breakdown characteristics and hot spot endurance. 3.1 Forward bias 3.1.1 IV parameters Fig. 3 depicts the efficiency distribution as a function of relative brick height (filled symbols = as-processed values, open symbols = degraded values under 0.2 suns illumination, see next section) for the solar cells processed from the ESSTM and the virgin-grade brick as well as the values for the industrial reference wafers. The gained efficiencies are on an equal level, with the cells from ESSTM feedstock even exhibiting slightly higher peak efficiency values of > 17 %. The best cell reached an independently confirmed efficiency of max = 17.13 %. This value is amongst the highest efficiencies reported for standard SP Al-BSF cells on 100 % SoG-mc-Si. To our knowledge, the highest efficiency on SoG-mc-Si using an industrial high efficiency concept with dielectrically-passivated and locally-contacted rear, seed and plate front contacts etc. was reported by Engelhardt with = 18.5 % [13]. Concerning industrial SP Al-BSF Si solar cells, Petter [11] showed avg = 16.0 % and peak ≈ 16.5 % for one block with a “slightly more sophisticated process”, Peter [14] achieved avg = 16.0 % and peak ≈ 16.3 % for one block using an optimized POCl diffusion step and a full- 1032 27th European Photovoltaic Solar Energy Conference and Exhibition Table 1: IV parameters of the processed solar cells: efficiency , open-circuit voltage Voc, short-circuit current density Jsc, fill factor FF, pseudo fill factor pFF, parallel resistance Rp, dark current density J(-12V) and breakdown voltage Vbd. For the best ESSTM and virgin-grade cells, Vbd has not been determined. All cells have the format 15.6×15.6 cm2 and the values are given as-processed. *) independently certified by Fraunhofer ISE Callab Material virgin ISE Ref. Average (59 cells) Best cell*) Average (56 cells) Best cell Average (40 cells) Best cell Open-circuit voltage Voc (mV) Short circuit-current 2 density Jsc (mA/cm ) (b) FF 2 J(-12V) 2 2 Vbd mA/cm % % kcm mA/cm V 16.63 620.2 33.88 79.1 81.8 7.5 3.6 -15.0 17.13 628.7 34.06 80.0 - - - NA 16.62 617.3 34.17 78.8 81.5 8.1 3.2 -16.7 16.97 620.9 34.51 79.2 81.9 8.1 1.8 NA 16.59 620.6 33.84 79.0 81.7 7.7 3.1 -16.4 16.76 622.4 34.01 79.2 81.8 8.9 1.9 -16.5 TM ESS virgin 620 615 610 crystallisation direction 605 TM (a) ESS 34.5 virgin 1.0 0.8 TM crystallisation direction 33.5 1.50 1.75 2.00 Base resistivity b (cm) Fig. 4: (a) Open-circuit voltage Voc and (b) short-circuit current density Jsc as a function of wafer base resistivity. The arrows indicate the direction of solidification during crystallisation. ESS bottom TM ESS middle TM ESS top virgin bottom virgin middle virgin top ISE ref. 0.6 0.4 0.2 0.0 300 450 600 750 900 10501200 (a) 34.0 1.25 Rp mV 625 1.00 pFF % 630 (a) Jsc Internal quantum efficiency Internal quantum efficiency IQE (%/100) IQE (%/100) ESSTM Voc Wavelength (m) 1.0 0.9 0.8 0.7 (b) 900 950 1000 Wavelength (m) Fig 5: (a) Internal quantum efficiencies of selected cells from the bottom, middle and top part of both ingots and one ISE reference cell and (b) zoom into the diffusionlength-sensitive wavelength range. illustrate, that the dislocation density increases with increasing brick height (which is true for every casted mc-Si crystal). These dislocations lead to increased recombination activity, i.e., a reduced minority carrier lifetime as illustrated in the J0 images which causes a decrease in Voc. Besides the carrier lifetime, the base saturation current density amongst other parameters also depends on base doping [18]. That is, the effect of increasing base resistivity (which correlates to a decreasing net doping) with brick height for the ESSTM cells amplifies the drop in Voc whereas for the virgin grade cells an increasing base doping attenuates the drop in Voc with increasing brick height. The increasing dislocation density with increasing brick height also leads to degradation of Jsc over brick height. This degradation can also be explained by increased recombination in the base under short-circuit conditions as can be seen in the long wavelength regime of the internal quantum efficiencies, see Fig. 5 (a)-(b). Table 2: Short-circuit current densities Jsc determined via IV measurements and effective diffusion length Lb,eff extracted from the quantum efficiencies of the cells shown in Fig. 5. Material Brick height Jsc Lb,eff 2 ESSTM ESSTM ESSTM Virgin Virgin Virgin ISE Ref. 1033 Bottom Middle Top Bottom Middle Top - [mA/cm ] 34.11 33.93 33.59 34.42 34.27 33.94 33.88 [m] 417 353 291 531 439 396 388 27th European Photovoltaic Solar Energy Conference and Exhibition Fig. 6: PL images under Voc-conditions and spatially-resolved dark saturation current density J0 determined via the “coupled determination of dark saturation current and series resistance (C-DCR)” technique [17] for ESSTM and virgin-grade cells from the bottom, middle and top part of the two bricks and for one ISE reference cell. 1034 27th European Photovoltaic Solar Energy Conference and Exhibition The higher the relative brick position is, the lower is the respective internal quantum efficiency for both bricks. From QE measurements, an effective bulk diffusion length Lb,eff can be extracted using Fischer’s model [19]. Table 2 shows the Jsc values of the investigated cells and the corresponding Lb,eff values extracted from the QE measurements which show a close correlation. In summary, the efficiency degradation of both bricks with increasing brick height is due to increasing dislocations density which leads to larger recombinationactive regions that cause a drop in both Voc and Jsc. complex concentration linearly depends on the net doping in compensated silicon [23,24], which decreases with increasing brick height, and quadratically depends on the oxygen concentration [25], which also decreases with increasing brick height due an effective segregation coefficient of oxygen > 1 [26], the BO complex concentration is expected to decrease with increasing brick height. As this differs from the experimental results, we doubt that the observed light-induced degradation can be assigned to the formation of BO complexes but is caused by another metastable defect, which is further investigated. Furthermore, the amplitude of the degradation is in the same order for the ESSTM and virgin-grade cells not indicated a higher light-induced degradation for cells from compensated feedstock. 3.1.2 Light-induced degradation To investigate light-induced degradation of the cells due to the boron-oxygen (BO) complex, e.g. Ref. [20,21], we exposed all cells to illumination with an intensity of I ≈ 0.2 suns for a time of t > 48 h. The open symbols in Fig. 3 show the results. No degradation can be observed within the measurement inaccuracy of the industrial cell tester in Fraunhofer ISE’s PV-TEC. To assure that the solar cells had not been degraded already at the point of the initial measurement, we annealed selected samples covering the entire brick height for t = 20 min at a sample temperature of T = 250°C in the dark (those conditions should anneal the BO complex [20,21]) and degraded them again at I ≈ 0.2 suns for t > 48 h. The deviations between both measurements were below < 0.1 % not showing a significant degradation effect. However, in other publications significant lightinduced degradation in mc-Si has been reported, e.g. Ref. [22]. The studies vary in applied illumination levels and degradation times. To investigate the effect of varying illumination level during degradation, we exposed the same cells to an illumination level of I ≈°1 sun for t > 48 h. In Fig. 7 (a), the resulting efficiency values are given. All efficiencies degrade after the degradation at I ≈ 1 sun compared to the previous degradation at I ≈ 0.2 suns. For some cells, the 1 sun degradation step leads to an increase in series resistance which reduces efficiency, see e.g. cells 1 and 9 in Fig. 7 (b). We attribute this effect to thermal degradation of the contacts due to the thermal treatment. To exclude a potential effect of the sequential order of the performed degradation steps, the cells are subsequently annealed again at T = 250°C for t = 20 min in the dark and then again degraded at I ≈ 0.2 suns, this time for t > 90 h. Fig 7 (b) shows the effects of the additional thermal treatment steps on series resistance. With this approach, we can conclude, that if a later measurement in time yields higher efficiency values than a previous measurement, it is not caused by series resistance effects. Hence, to validate the effect of higher light-induced degradation for an illumination level of I ≈ 1 sun compared to I ≈ 0.2 suns, we consider the differences in efficiencies between the annealed state (point in time 3) and the degraded state after illumination at I ≈ 1 sun for t > 48 h (point in time 2) and the difference between the annealed state and the degraded state after illumination at I ≈ 0.2 suns for t > 90 h (point in time 4). Fig. 7 (c) shows the efficiency differences for the annealed state compared to the different degraded states. It can be seen, that the difference is highest for the degraded state after illumination at I ≈ 1 sun compared to the other degraded states. No dependence of the increased degradation at I ≈ 1 sun illumination over brick height is observed, which would be typical for the BO complex. As the BO TM ESS virgin ISE Ref. degraded 1 (0.2 suns, > 48 h) degraded 2 (1.0 suns, > 48 h) annealed (250°C, 20 min) degraded 3 (0.2 suns, > 90 h) 3 4 annealed - degraded (%) Fill factor difference pFF-FF (%) Efficiency (%) 17.2 17.0 16.8 28 16.6 9 16.4 1 16.2 16.0 15.8 (a) 15.6 4.0 3.8 9 3.6 3.4 3.2 8 3.0 1 2.8 2.6 3 2.4 2 (b) 2.2 0.3 0.2 1 12 5 10 11 6 6 10 11 4 12 5 13 7 23 6 4 10 89 0.1 13 7 11 5 7 13 12 0.0 -0.1 -0.2 (c) -0.3 0 20 40 60 80 100 E IS Relative brick height (%) f. Re Fig. 7: (a) Efficiencies, (b) series-resistance-enhanced fill factor losses and (c) efficiency difference between annealed and degraded states for different degradation states of selected cells from the ESSTM and virgin-grade brick as well as for ISE reference wafers. The measurement accuracy of the IV-Test used for repeated measurements is ≤ 0.1 %abs. 3.2 Reverse bias When cells are partially shaded during module operation, they can be reverse-biased by the other, unshaded cells in the module and dissipate power rather than generating it [27]. If the dissipated power is 1035 27th European Photovoltaic Solar Energy Conference and Exhibition concentrated in a small area on the partially shaded cells, those “hot spots” can lead to a significant increase of the cell temperature and in the worst case to the failure of the solar module. One prejudice hindering a wider use of solar cells made from solar-grade feedstock is that they exhibited a higher hot spot risk than cells from virgingrade feedstock. That is why we investigate the global and locally distributed reverse behaviour of the cells within this experiment. 7 1 , Current I (A) 5 4 Vrev,max (24 cells/string) 3 Vrev,max(20 cells/string) 2 I=1.5 A Vbd 1 3.2.1 Global characteristics Fig. 8 (a) depicts the dark reverse characteristics of one cell from the ESSTM and one cell from the virgingrade brick, both from a relative brick height of approximately 25 %. Both cells exhibit an almost identical global reverse characteristic down to a reverse bias of Vrev ≈ -12.5 V. For lower reverse voltages, the ESSTM cell breaks down significantly earlier than the virgin-grade cell causing an increase in global current. When interpreting the reverse characteristic of solar cells and the possible hot spot risk arising from partial shading of those cells, the applied module architecture has to be taken into account since it determines the possible operating conditions of the incorporated cells. The standard architecture used in industrial modules from mc-Si solar cells consists of 60 solar cells connected in series using one bypass diode connected in parallel to 20 cells, each. That is, the voltage being applied to a single shaded solar cells is limited to , TM ESS virgin 6 Current density 2 J(Vrev= -12 V) (mA/cm ) (a) (b) 0 -18 -15 -12 -9 -6 -3 0 Voltage V (V) TM ESS virgin 8 I=1.5 A 6 4 2 0 0 20 40 60 80 100 SE Re f. I Relative brick height (%) Fig. 8: (a) Global reverse characteristics of one cell from the ESSTM and one from the virgin brick from a relative brick height of approximately 25 %. (b) Current density of all cells at an applied voltage of Vrev = -12 V in the dark. 1 As indicated in Fig 8 (a), the reverse behaviour of the cells from the ESSTM and the virgin-grade brick differ for voltages significantly smaller than Vrev = -12 V. This difference is due to local junction pre-breakdown as will be shown in the next section. To discuss the effect of prebreakdown on the global reverse characteristic, we use the value Vbd(Idark = 10 A); that is a voltage for which the cells are completely broken down. Fig 9 (a) shows the dependence of Vbd on relative brick height for the investigated cells. For both bricks, the well-known [28,29] anti-correlation between base resistivity and breakdown voltage is observed (compare to Fig. 1). However, when plotting Vbd versus base resistivity, see Fig. 9 (b), the cells from ESSTM feedstock exhibit a significantly earlier breakdown voltage than their virgingrade counterparts for equal base resistivities. We attribute this to the effect that a higher net doping in compensated silicon is necessary for equal base resistivities because of decreased carrier mobility [28]. The solar cells from industrial reference wafers behave similarly to the virgin-grade cells. The slight difference can be caused by multiple reasons, including different crystallization processes and therefore different dislocation densities, other metal precipitate concentrations and so on. for every operating point of the module, with VBPD being the voltage of the bypass diode in operation. In real modules, a term considering the resistive losses in the feed lines of the bypass diodes and cell interconnectors in-between the cells of the module has to be taken into account, which generally slightly reduces the maximum voltage being applied to the cell in reverse (the BPD feed lines increase the voltage, the module interconnectors decrease it). This will be discussed in more detail elsewhere. However, Eq. (1) is well-suited to estimate the worst case operating conditions for a solar cell under full shading conditions. If we assume an average open-circuit voltage of Voc,mean = 620 mV (compare Table 1) and a bypass-diode voltage of VBPD = 0.3 V, a worst case reverse voltage of Vrev,worst case = -19×620 mV-0.3 V = -12.08 V in a standard 60 cell module can be estimated at a temperature of T = 25°C. Fig 8 (b) shows the current density of all cells at a voltage of Vrev = -12 V as a function of relative brick height. A current value in the regime of Vrev = -10 to -12 V is generally used for binning during cell testing within industrial solar cell lines. The critical value is generally in the regime of Ilimit = 1 to 3 A. Almost all cells of both bricks and the reference wafers exhibit values of I(Vrev = -12 V) < 1.5 A and therefore fulfill common reverse specifications. The mean values across brick height are in a comparable range, as shown in Table 1 (3.5 mA/cm2 ≙ 0.85 A). Also, no significant dependence on brick height can be observed. That is, cells covering the entire commercially usable brick height meet common reverse bias specifications for both investigated bricks. 1036 Breakdown voltage Vbd (Idark = 10 A) (V) 27th European Photovoltaic Solar Energy Conference and Exhibition 24 cells/string and 60-72 cells/string (that is, no bypass diodes are incorporated which causes complete junction breakdown when shading one cell). TM ESS virgin -14 -15 3.2.2 Spatially-resolved characteristics Fig. 10 (a)-(c) show dark lock-in thermography (DLIT) images of an ESSTM cell from a relative brick position of approximately 25 % - for the reverse characteristic see Fig. 8 (a) – for the three operating points discussed above. Under full shading conditions, Fig 10 (a) represents the case of 20 cells/string (Vrev,20 cells/string = -12.0 V, Idark(Vrev = -12.0 V) = 0.6 A), Fig. 10 (b) the case of 24 cells/string (Vrev,24 cells/string = -14.2 V, Idark(Vrev = -14.2 V) = 5.2 A) and Fig. 10 (c) the case if no bypass diodes were incorporated (Vrev(Idark = Isc,mean = 8.5 A) = -14.7 V). The value for this cell given in fig. 9 is Vrev(Idark = 10 A) = -14.8 V but since the Isc value of the cells is lower than 10 A, this value cannot be reached for module operation condition at ≤ 1sun. The depicted DLIT signal (phase shift of -90°) is proportional to the local power dissipation [30] and can be calibrated accordingly. This power-calibrated image can be used as the input for the simulation of the temperature development under partial shading conditions in a solar module using standard commercially available glass, EVA and back sheet [31]. For this simulation, we assumed a surrounding temperature of the module of T = 50°C (which represents the circumstances during certification) while keeping the cell parameters at T = 25°C. That is, a worst case scenario is addressed. -16 -17 (a) 0 20 40 60 80 100 SE Re f. Breakdown voltage Vbd (Idark = 10 A) (V) I Relative brick height (%) -14 TM ESS virgin ISE Ref. -15 -16 -17 (b) 1.00 1.25 1.50 1.75 2.00 Base resistivity b (cm) Fig. 9: Breakdown voltage Vbd(Idark = 10 A) as a function (a) of relative brick height and (b) of wafer base resistivity. We have discussed, that for modules with 20 cells per string, none of the cells breaks down and therefore the ESSTM, virgin-grade and ISE reference cells exhibit a comparable global reverse behaviour. However, the breakdown behaviour significantly differs between the cells from compensated ESSTM and the cells from virgingrade feedstock. Some module manufacturers have recently started to incorporate 72 cells (with Acell = 15.6×15.6 cm2) into solar modules without increasing the number of bypass diodes. That is, a string then contains 24 instead of 20 cells. For the worst case conditions derived in Eq. (1), a worst case voltage of results Vrev,worst case = -23×620 mV-0.3 V = -14.56 V assuming Voc,mean = 620 mV, VBPD = 0.3V and T = 25°C. For the ESSTM cells, this value is in the order of Vbd(I = 10 A) whereas for the cells from virgin-grade feestock there is still a corridor in-between. Fig. 8 (a) illustrates the different scenarios; the ESSTM cell and virgin-grade cell exhibit a comparable behaviour for 20 cells/string but a different behaviour for lower reverse voltages. In solar modules under realistic operating conditions, the discussed worst case situation can overestimate the actually applied voltage. Besides the reasons addressed before, another point is, that the higher the current of the shaded, reverse-biased cell is, the further the other, non-shaded cells in the string veer away from open-circuit conditions and therefore exhibit a smaller voltage than Voc. That is, the actually applied voltage to the shaded cell in reverse is reduced [27]. Also, for temperatures higher than T = 25°C, the voltages of the forward biased cells decrease with increasing temperature which leads to another attenuating effect on the reverse bias of the shaded cell. Those effects can be considered in the determination of the adequate operating point of shaded cells and will be discussed elsewhere. Within this work, we address the operating points under full shading conditions for a module with 20 cells/string, Fig. 10: (a)-(c) Dark lock-in thermography images of the ESSTM cell from Fig. 8 (a) at the worst case operating conditions under full shading conditions in a module with (a) 20 cells/string, (b) 24 cells/string and (c) no incorporated bypass diodes. (d)-(f) Corresponding simulation results of the backsheet temperature fields assuming commercially available module encapsulation materials. Fig. 10 (d)-(f) depict the simulation results of the temperature fields on the backsheet of the corresponding 1037 27th European Photovoltaic Solar Energy Conference and Exhibition [3] modules. Detrimental module encapsulation failure can generally occur at module backsheet temperatures of T ≥ 150°C [27]. For 20 cells/string, the simulation gives a maximum temperature of Tmax,20cells/string ≈ 60°C which is far from being critical for the module encapsulation materials. The resulting temperature for 24 cells/string is Tmax,24cells/string ≈ 122°C which should still be tolerable. When completely omitting bypass diodes however, a maximum temperature of Tmax,no BPDs ≈ 167°C is simulated which is in the critical range. In summary, the simulation results indicate, that fully shading a typical solar cell from the ESSTM brick should be uncritical for standard modules exhibiting 20 cells/string. Although localized junction prebreakdown occurs for the assumed voltages representing a module architectures with 24 cells/string, the simulated temperatures under full shading conditions are uncritical. Only when completely omitting bypass diodes, the temperature of the fully shaded cell is expected to reach critical values. 4 [4] [5] [6] [7] [8] [9] [10] [11] [12] CONCLUSION AND OUTLOOK [13] The results of this study are that both wafers from the ESSTM and the virgin-Si brick yielded average efficiencies of avg = 16.6 % over the entire brick. The peak efficiency of the ESSTM brick was peak,ESS = 17.13 % which is even higher than peak,virgin = 16.97 % for the virgin brick and amongst the highest efficiencies reported for standard industrial SP Al-BSF solar cells on 100 % SoG-mc-Si. No lightinduced degradation could be measured for long-term illumination under I = 0.2 suns but for illumination under I = 1sun. This effect points towards another origin than the typically assumed BO defect. However, the degradation effect was in the same order for cells from ESSTM and virgin-grade feedstock. The solar cells from ESSTM break down earlier than their virgin reference at comparable base resistivities. This well-known effect [28] is caused by a higher net base doping due to compensation which is confirmed by this study. However, within standard (60 cells) industrial modules, reverse voltages are usually limited to Vrev ≈ -12 V by incorporating bypass diodes [27]. The average current density at Vrev = -12 V is J = 3 mA/cm2 (~0.73 A) for all ESSTM, virgin and reference cells which therefore fulfill common specifications, that are usually in the range of Ilimit = 1 – 3 A. Measuring the spatially resolved breakdown behaviour via DLIT and simulating the worstcase hot-spot temperature under full shading conditions in a solar module has not led to critical temperatures in modules with 20 and 24 cells/string. Only when omitting bypass diodes completely, critical temperatures are assumed to be reached. In a next step, we will transfer the investigations on module level. If the very promising results on efficiency level can be transferred while ensuring module reliability, as is expected by our simulation results, this work could contribute to a wider acceptance of SoG-Si in photovoltaic industry and possibly a wider distribution in the market. 5 [1] [2] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] [27] [28] [29] [30] [31] 6 REFERENCES Rutschmann, I., “Zell- und Modulhersteller, die umg-Silizium verarbeitet haben”, Photon 07/2012, p.80. Spot market prizes, 12.07.2012 Article “Looking under the hood”, Photon International, 05/2012, pp. 90-98. Herbst, W., “How to achieve c-Si module production cost below 0.50 €/Wp”, Photon’s 7th PV Production Equipment Conference (c-Si), 2012. Odden, J.O. et al., in Proceedings of Silicon for the Chemical and Solar Industry IX. 2008. Oslo, Norway. Glockner, R. et al., in Proceedings of Silicon for the Chemical and Solar Industry IX. 2008. Oslo, Norway. De Wild, M. et al., submitted for 27th EUPVSEC. 2012. Frankfurt, Germany. Rutschmann, I., „Interview mit Eicke Weber, Leiter des Fraunhofer ISE, über umg-Si“, Photon 07/2012, p. 79. Jester, T., PHOTON’s 10th Solar Silicon Conference, March 26, 2012, Berlin, Germany Hoffmann, V. et al., Proceedings of the 23rd EUPVSEC. 2008. Valencia, Spain. Petter, K. et al., in Proceedings of the 25th EUPVSEC. 2010. Valencia, Spain. Biro, D. et al., in Proceedings of the 21st EUPVSEC. 2006. Dresden, Germany. Engelhart, P. et al., in Proceedings of the 37th IEEE PV Specialists’ Conference. 2011. Seattle, USA. Peter, K. et al., in Proceedings of the 25th EUPVSEC. 2010. Valencia, Spain. Kohler, D. et al., in Proceedings of the 24th EUPVSEC. 2009. Hamburg, Germany. Braun, S. et al., in Proceedings of the 24th EUPVSEC. 2009. Hamburg, Germany. Glatthaar, M. et al., Physica Status Solidi RRL 4 (2010), 13. Goetzberger, A. et al., Sonnenengergie: Photovoltaik. (Teubner, Stuttgart, 1997) Fischer, B. et. al., in Proceedings of the 29th IEEE PV Specialists’ Conference. 2002. New Orleans, USA. Rein, S. et al. in Proceedings of the 17th EUPVSEC. 2001. Munich, Germany, 2001. Glunz, S. W. et al., in Proceedings of the 2nd World Conference on Photovoltaic Energy Conversion, 1998. Vienna, Austria. Tayyib, M. et al., Energy Procedia, 2012. 27: p. 21-26. Macdonald, D. et al., Journal of Applied Physics 105, 2009, p.: 093704. Rein, S. et al., in Proceedings of the 24th EUPVSEC. 2009. Hamburg, Germany. Rein, S. et al., in Proceedings of the 3rd World Conference on Photovoltaic Energy Conversion. 2003. Osaka, Japan. R. Hull, Properties of crystalline silicon. (INSPEC, The Institution of Electrical Engineers,London, UK, 1999). Fertig, F. et al., in Proceedings of the 26th EUPVSEC. 2011. Hamburg, Germany. Kwapil, W. et al., Journal of Applied Physics, 2010. 108: p. 023708 Wagner, M. et al., in Proceedings of the 24th EUPVSEC. 2009. Hamburg, Germany. O. Breitenstein et al., Lock-in Thermography. (Springer, Berlin, 2010). Geisemeyer, I. et al., accepted for 27th EUPVSEC. 2012. Frankfurt, Germany. ACKNOWLEDGEMENTS The authors would like to acknowledge the help of all colleagues with cell processing and characterisation in Fraunhofer ISE’s PV-TEC. 1038